How to calculate the expense?

Calculation of the amount of reinforcing wire helps to understand how much material needs to be purchased to perform the work and how much it will cost. For bulk purchases, the cost of the material is usually indicated on the basis of one ton, although the maximum weight of a coil with wire rod is 1500 kg.

The norm of knitting wire, which will be required to carry out a certain set of works, is calculated based on the thickness of the frame reinforcement and the number of nodal joints of the structure. Usually, when joining two rods, you will need to use a piece of knitting material, the length of which is at least 25 cm, and if you need to connect 2 rods, then the consumption rate will be 50 cm per 1 docking node.

To simplify the counting task, you can refine the number of docking points and multiply the resulting number by 0.5. It is recommended to increase the finished result by about twice (sometimes it is enough and one and a half times) in order to have a margin in case of unforeseen situations. The consumption of knitting material is different, it can be determined empirically, focusing on the method of performing knitting technology. To more accurately calculate the wire consumption per 1 cu. m of reinforcement, you will need to have a diagram of the location of the docking nodes. This calculation method is rather complicated, but judging by the standards developed by the masters in practice, it is believed that at least 20 kg of wire is needed for 1 ton of rods.

As an illustrative example, consider the following situation: it is required to build a tape type of foundation with dimensions of 6x7 m, which will have 2 reinforced belts containing 3 rods in each. All joints in the horizontal and vertical direction must be made in 30 cm increments.

First of all, we calculate the perimeter of the future frame of the foundation, for this we multiply its sides: 6x7 m, as a result we get 42 m. 3 and get 140 intersection points as a result. On each of the jumpers, 3 rods will be docked, which means that these are 6 docking nodes.

Now we multiply 140 by 6, as a result we get 840 joints of the rods. The next step is to calculate how much knitting material is required to join these 840 points. To do this, we multiply 840 by 0.5, as a result we get 420 m.To avoid a lack of material, the finished result must be increased by 1.5 times. We multiply 420 by 1.5 and we get 630 meters - this will be an indicator of the consumption of knitting wire necessary for performing frame work and making a foundation measuring 6x7 m.

The next video shows you how to prepare a knitting wire.

1 Knitting wire - where and why is it used?

Reinforcing wire is used in the field of individual and industrial construction for the manufacture of frames used to reinforce reinforced concrete structures. By means of a knitting wire, adjacent reinforcement bars are connected at the point where they overlap.

The material can be used when assembling the following types of frames:

- foundation (tape, monolithic, columnar);

- floors (basement and interfloor);

- floor screeds.

The most common wire for reinforcement in monolithic construction. In the industrial production of reinforced concrete products - piles, floor slabs, reinforced concrete blocks, their frames, in order to save time, are joined by means of spot welding.

Wire reinforcement

The connection of reinforced cages by means of knitting wire has two important advantages in comparison with welding technology. Firstly, this is the absence of weak points in the frame with increased susceptibility to corrosion, which are welded seams. During operation, the seams come into contact with moisture penetrating through the micropores of the concrete structure, the reinforcement rusts and the frame loses its original strength.

Also, many engineers point out that the wire frame is elastic, which increases the overall strength and resistance of the concrete structure to deformation. Whereas a rigid welded frame is not capable of handling severe bending loads that can cause cracks in concrete.

1.1 How to calculate material consumption?

According to the provisions of SNiP, the consumption rate of knitting wire when assembling the reinforcement cage is 30 cm per joint or 4 kg per ton of reinforcement. To find out how much material you need to use, you need to determine the number of reinforcement coupling points in the frame and calculate the total consumption.

As an example, we give the calculation of the wire consumption for the reinforcement of the tape-type foundation. We use the conditional size of the foundation 5 * 6 m, it will have 2 belts of longitudinal reinforcement - upper and lower, 3 rods in each, connected by vertical and transverse jumpers with a step of 40 cm.

Knitting with an automatic pistol

Flow rate determination algorithm:

- We calculate the frame perimeter: 5 * 6 = 30 meters.

- Determine the number of jumpers based on a step of 40 cm: 30 / 0.4 = 75 pcs.

- Each jumper will have 6 joining points (3 rods on each belt), we determine the number of connections: 75 * 6 = 450 pcs.

- We calculate the consumption of knitting wire: 450 * 0.3 = 135 m.

In total, to connect the frame rods, we need to use 135 meters of material. In a similar way, having determined the number of connections and multiplying them by the standard consumption, it is possible to calculate the total consumption of wire for assembling the reinforcement cage of any configuration.

General characteristics

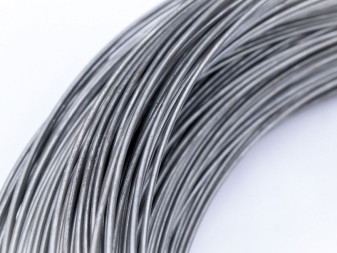

Obeying the requirements of GOST, the knitting wire is made of annealed steel with a low percentage of carbon content, due to which it has ductility and soft bending. The wire can be white, with a steel sheen, which gives it a zinc coating, and black, without additional coating. GOST also regulates the cross-section of the wire, which is selected for frame reinforcement in a certain way.

For example, the diameter of the reinforcement is 14 mm, which means that a wire with a diameter of 1.4 mm is needed to fasten these rods, and for a reinforcement with a diameter of 16 mm, a wire diameter of 1.6 mm is suitable. The batch of wire produced by the manufacturer must have a quality certificate, which contains the physicochemical characteristics of the material, the diameter of the product, the batch number and its weight in kg, the coating, and the date of manufacture. Knowing these parameters, you can calculate the weight of 1 meter of knitting wire.

When choosing a material for knitting reinforcement, you should know that diameters from 0.3 to 0.8 mm are not used for these purposes - such wire is used for weaving a netting or used for other purposes. Diameter sizes from 1 to 1.2 mm are often used when working in the low-rise housing sector. And for the construction of powerful reinforced frames, they take wire with a diameter of 1.8 to 2 mm. When tying the frame, wire is most often used after heat treatment, unlike the usual one, it is more resistant to corrosion and less susceptible to stretching, which means that it makes it possible to build a truly reliable and durable frame.

The diameters of galvanized knitting wire differ from their uncoated counterparts. Galvanized wire is produced in sizes from 0.2 to 6 mm. Wire without a galvanized layer can be from 0.16 to 10 mm. In the manufacture of wire, discrepancies with the indicated diameter by 0.2 mm are allowed.As for galvanized products, their cross-section may become oval after processing, but the deviation from the diameter specified by the standard cannot exceed 0.1 mm.

At the factory, the wire is packed in coils, their winding is from 20 to 250-300 kg. Sometimes the wire is wound on special spools, and then it goes on wholesale from 500 kg to 1.5 tons. It is characteristic that in winding the wire according to GOST goes as a solid thread, while it is allowed to wind up to 3 segments on a spool.

1 meter of BP wire contains different weights:

- diameter 6 mm - 230 g.;

- diameter 4 mm - 100 g.;

- diameter 3 mm - 60 g.;

- diameter 2 mm - 25 g.;

- diameter 1 mm - 12 gr.

Brand BP is not available with a diameter of 5 mm.

2 Classification and varieties

Reinforcement wire is classified into varieties according to such parameters as:

- the presence or absence of a protective coating;

- heat treatment;

- strength class.

Depending on the presence of a protective coating, the material is divided into two types: made of ordinary low-carbon steel and galvanized. The coating is applied by hot-dip galvanizing, which involves holding the coils of wire in a bath of molten zinc.

The material with a protective coating is divided into two classes - 1C and 2C. The differences between them are in the thickness of the galvanized layer, in the material of class 2C the protective layer is much thicker: for comparison - 155 against 85 g / m2 in a wire with a diameter of 6 mm. An alternative to galvanized materials is MNZHKT wire made of a copper-nickel alloy, but its use in construction is unjustified due to its high cost.

Galvanized wire VR-1

By the type of hardening, the reinforcing wire is classified into untreated and annealed (it has the letter O in the marking). The essence of heat treatment is to heat the material to a predetermined temperature in a blast furnace and then cool it down. As a result of annealing, the crystal structure of the metal changes and the internal stress of the steel is destroyed, which provides increased elasticity and mechanical strength of the wire.

Depending on the strength class, the products are classified into two groups B-1 (normal) and B-2 (high strength). The difference between them lies in the grade of the alloys used, for the manufacture of B-1 wire, low-carbon steel is used, for B-2 - steel with an increased amount of alloying components. The V-2 material is used to connect frames made of prestressing reinforcement, while class B-1 is intended for the installation of non-stressed structures.

2.1 Sizes and weights

The diameter of the material depends on the presence of a protective coating - galvanized wire is produced in diameters of 0.2-6 mm, without coating - 0.16-10 mm. From the factory, products are delivered in coils (weight from 15 to 250 kg) or spools (500-1500 kg). The coil should consist of one piece of wire, the coil should be no more than 3 pieces.

We give a table knitting wire weight of 1 meter, BP brand, the most demanded on the market:

- VR-1 (diameter 1 mm) - weight 0.012 kg;

- VR-2 (diameter 2 mm) - weight 0.025 kg;

- VR-3 (diameter 3 mm) - weight 0.06 kg;

- VR-4 (diameter 4 mm) - weight 0.1 kg;

- VR-6 (diameter 6 mm) - weight 0.23 kg.

A characteristic feature of the BP brand is the presence of corrugated walls, due to which the adhesion (adhesion) of the material to the reinforcement bars increases, which has a positive effect on the overall strength of reinforced concrete structures.

Wire "Kazachka

Recently, wire for tying reinforcement with rings, also called "Kazachka", has become widespread on the market. It is available in 8, 10, 12 and 14 cm lengths, at the ends of which there are rings for a crochet hook. The connection of the fittings "Kazachkoy" is performed much faster than the standard analogue, since there is no need for cutting and independent formation of rings. The material is supplied in the form of bobbins, consisting of 1-5 thousand pieces.

2.3 How to knit?

To assemble the frame from 10-14 mm reinforcement bars, use a wire with a diameter of 1.2-1.4 mm. If the material has poor elasticity, the bay must be kept in a fire for 20-30 minutes, and then allowed to cool at natural temperature. It is possible to use products of a smaller diameter, however, in this case, when performing the connection, you will need to bend it twice.

You will need a special tool - a crochet hook, which can be manual or mechanical. A hand hook can be bought for 100-300 rubles, or you can make it from a trowel or a paint roller, bending and sharpening their end.

Crochet reinforcement instructions

Reinforcing wire is knitted quite simply - a 30 cm length is folded in half, at a distance of 1/3 of the loop, the wire bends around the finger and slips under the overlap of the reinforcement. A hook is inserted into the loop, after which the free end of the material is bent through the reinforcement and inserted into the hook bed.

Further, by rotating the tool, the connection is tightened. The number of turns of the hook is determined by eye so that the connection is strong enough, but not overtightened.

In the process of manufacturing the frame of reinforced concrete structures, it is necessary to observe a protective layer of concrete 3-5 cm thick.Here, instead of special supports, you can use cut rings of plastic plumbing pipes with a diameter of 4-5 cm.

Rebar portal »Mesh» Wire »Nuances of using knitting wire

What is it and where is it used?

Knitting wire belongs to a wide group of building materials made of low-carbon steel, where carbon in combination with steel contains no more than 0.25%. Steel billets in molten form are subjected to the drawing method, pulling them through a thin hole, applying high pressure for this - this is how the final product, called wire rod, is obtained. To make the wire strong and give it its basic properties, the metal is heated to a certain temperature level and subjected to high pressure treatment, after which the material undergoes a slow cooling process. This technique is called annealing - the crystal lattice of the metal changes under pressure, and then it slowly recovers, thereby reducing the stress process within the material structure.

The use of knitting steel material is most in demand in the construction industry. With the help of this material, you can knit steel reinforcing rods, creating frames from them, perform floor screed, interfloor floors. Knitting wire is a strong, but at the same time elastic element for fastening. Unlike welding fasteners, the wire does not impair the properties of the metal at the place of heating, and it does not need heating itself. This material resists various multiple deformation loads and bending.