Packaging and storage

Adhesives are available in a variety of containers. In everyday life, tubes of 125 g are most popular, as well as jars of 250 g. Small packages are equipped with caps, so it is more convenient to work with them (you can tighten the product at any time). Typically, this glue is used to create crafts, carry out minor repairs to furniture, interior items, for gluing the corners of wallpaper.

Also on sale there are cans of 750 g. They are used for repair work, they are often added to wallpaper glue to enhance adhesion (to hold heavy cloths). Professionals usually choose 3 kg buckets, and furniture factories usually choose 30 kg buckets. Packages of 3 kg have a sealed lid, as well as larger containers, although the glue does not have to be stored for a long time under production conditions. Additional packages of 100 and 200 g are available for the "Instant Grip" glue, as it is often used for small jobs that require fast and reliable gluing.

The product should be stored at + 5 ... + 30 degrees in the original packaging, tightly twisted and closed. It must be protected from high humidity, direct sunlight. Despite the moderate frost resistance, it is better not to freeze the glue unless absolutely necessary. Otherwise, the frozen product must be brought to a room with room temperature, let it melt in a natural way. When used correctly, Moment adhesives from the Joiner series will become reliable assistants at construction sites and in repairs.

Application

For maximum reliability of the fastening, a number of conditions must be met. Therefore, before gluing, read the recommendations and instructions of the manufacturer. Below are the general rules for handling Moment joinery glue.

Instructions and rules for working with wood glue:

- The tip of the nozzle is trimmed according to the required seam width. The thinner it is, the smaller the cut is made.

- Before processing, the surfaces are cleaned of dust and debris.

- To remove excess fat, a solvent is used. The measure is necessary to improve the adhesion of the adhesive to the surface.

- One surface is processed with glue using a spatula, roller or brush.

- The surfaces to be joined must be kept fixed for about 10-15 minutes for the glue to work better. "Moment Express Carpenter" seizes much faster, therefore it is used for processing small parts.

- Time for complete hardening is at least a day.

- The higher the moisture content of the wood, the longer the glue will set.

- You can use clamps or heavy objects for fastening.

- The glue temperature should not be lower than +10 degrees.

Glue "Moment joiner" is a worthy option for woodworking and not only. With its help, new furniture is assembled and old ones are repaired. This product is an alternative to nails and screws, which only spoil the look.

When repairing or assembling furniture, wooden models, laminate and other materials of such a structure, it is necessary to use glue - "Moment Joiner" is suitable for these purposes. In addition to the aforementioned materials, it is used when working with veneer, rough fabrics, cardboard, fittings and plastic. He earned the trust, so he became a common glue for wood.

Specifications

Moment universal glue is supplied in cans of 750 ml, in cans of 10 liters; smaller packaging - 30, 50 and 125 ml (in tubes). There is also a universal "Moment-1" 125 ml. The carpentry variety of the material is sold in a package of 3 kg, since working with furniture and wooden structures requires a significant expense.

A tube with a capacity of 400 g is most often "Moment Montage Superstrong MV-70". This mixture allows you to glue wall panels, window sills, skirting boards and decorative structures of various kinds.

If there is a need to buy especially strong glue, it is better to choose "Moment 88".It easily tolerates the effects of cold and moisture, it can even connect cardboard to glass, cork to concrete or plastic to rubber. But styrofoam and individual polymeric materials cannot be glued with such a composition.

According to the reviews, the transparent universal Moment glue perfectly holds a variety of materials, including gypsum. It is actively used by the creators of all kinds of crafts and home craftsmen: thanks to inconspicuous seams, the created objects seem to be solid, sometimes it is difficult to guess that glue was used at all.

Instructions for use

Each adhesive must be applied in a specific way. It is advisable to consider the use of the mixture "Moment Montage" - one of the most popular in construction.

- At the time of application, it is required to strongly press the surfaces to be joined to each other, it is this force, and not the duration of the pressure, that is especially important. If there is no special roller, bottles and other elongated objects can be used for pressing to ensure uniform pressure.

- Leaving the glue for storage, you need to make sure that it is hermetically sealed, and the temperature is not lower than -20 and not higher than +30 degrees. Glue that has been frozen in permissible cold will need to be mixed before use.

- Before using the mixture, it is necessary to remove fatty deposits and deposits on the treated surfaces (using gasoline or acetone) and after placing a thin layer of the substance, leave it alone for 15-20 minutes (then press).

- If an excess of glue is found, you need to wait for it to partially dry and manually collect it into a small ball, which is then thrown into the trash can. The adhesive mixture is removed from the surface of the clothes by simple washing with a standard program.

For more information about the Moment-1 universal glue, see the video below.

Performance properties and performance characteristics

The tool is used for gluing a huge amount of materials, has a minimum of restrictions. Application of a thin layer on only one side of the part and joining of the elements ensures the highest strength of the glue seam. This is achieved through an excellent level of adhesion. "Moment Crystal" is transparent, which only expands the scope of its operation, because after gluing the joint will be completely invisible.

The main technical characteristics of the tool:

- the recommended temperature while working with glue is from +15 to +30 degrees (it is possible at a different temperature, although the polymerization time will change);

- the operating temperature of the products after the glue seam has dried is from -35 to +75 degrees;

- high cold resistance - the seam can withstand several cycles of defrosting and freezing, the glue itself in the tube also quickly restores its original properties after defrosting;

- consumption - 200-400 g / sq. m (depending on the type of surface, purpose);

- moisture resistance, no changes in technical parameters even with direct exposure to water;

- resistance to ultraviolet radiation, the influence of dilute acids, weak alkalis;

- the optimal density of the glue is 0.88 g / cu. cm.

The glue has several restrictions on its use. It is forbidden to use it to repair things made of teflon, polypropylene, polyethylene. Also, glue should not be used to glue dishes, other kitchen items and utensils that may come into contact with food.

Secondary adhesives

Such means are intended for fastening any materials in a short time, therefore their second name is "second". Typically used for small surfaces. It is undesirable to apply to leather products: over time, they often dry out.

In addition to the usual gluing, craftsmen often use the technique of mixing superglue and soda. The result is a white, tough acrylic-like substance that can reliably repair any defect.

The most famous series of adhesives:

- "Super Moment Ideal" - transparent gel, forms a seam in 20 seconds;

- "Moment 88 Extra strong" - gives a joint of special strength, reliability;

- "Super Moment Profi Plus" - sold in a convenient reusable package, which is accompanied by a brush;

- "Super Moment Maxi" - has an increased volume;

- "Super Moment Glass" - specially designed for glass.

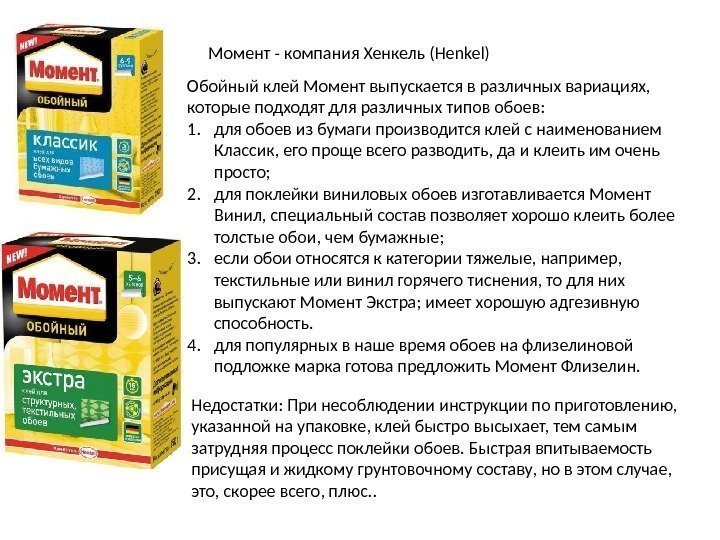

Wallpaper mix

Adhesives of this series are also available in several modifications. Before use, they need to be diluted correctly, but it's easy to do it at home. You just need to pour dry powder into a measured amount of water, mix the solution thoroughly.

Here are the main series adhesives:

- "Moment Wallpaper Classic". Instant formulation based on modified starch. Smooth in structure, without lumps, economically consumed, ready-made it can be stored for up to 10 days. It is used for paper wallpaper, including corrugated and embossed, duplex, structural.

- "Moment Non-woven". Applied to the wall, it makes it possible to adjust the position of the canvases. Has a high adhesion, allows you to glue joints directly on the wall. Suitable for all types of non-woven wallpaper.

- "Moment Indicator". High quality product with application indicator, used for vinyl wallpaper, silk screen printing and foamed vinyl. After drying, it becomes completely transparent.

- "Moment Vinyl". Ideal for all types of vinyl wallpaper. Has a new and improved formula, due to which it becomes ready to work in 3 minutes.

- "Moment Extra". Fast-dissolving adhesive with the addition of methylcellulose, which has increased adhesion to the substrate. It is highly durable and contains antifungal additives. Allows to stick heavy wallpaper: embossed, textile, structural.

Also in the "wallpaper" line is realized glue for gluing wallpaper and fixing joints - a ready-made composition in a tube of 120 g, which has a convenient spout and helps to glue hard-to-reach places.

"Liquid Nails"

The most famous product of the series is "Moment Montage Super Strong". It is produced in two versions: matte and transparent. Such a tool can replace fastening materials (self-tapping screws, screws), it is used for indoor and outdoor work. One-component adhesive allows you to fix even heavy structures without additional installation. The main properties of the glue are as follows:

- hardens with moisture;

- leaves time to adjust the position of parts (a few minutes);

- suitable for smooth, dense and porous materials;

- after drying, it can be sanded, painted;

- makes it possible to seal joints, cracks;

- reduces noise level;

- glues natural stone, wood, metal, glass, plastic, mirrors.

Other types of assembly adhesives are:

- "Installation Superstrong MVP-70" - moisture-resistant, frost-resistant composition;

- "Express MV-50" - quick-drying agent;

- "Express Decor MV-45" - made on an acrylic base, used for fixing decor, etc.

The same category includes Moment sealants, which perfectly fill voids and help to form a complete coating, as well as Moment Ceramic tile adhesives, applied directly to the tile and having a high degree of adhesion.

Peculiarities

First of all, it is worth emphasizing that there is by no means one Moment glue, it is a whole galaxy of connecting materials, each designed for a specific task.

Regardless of the specific application, they differ:

- long period of work;

- immunity to water ingress;

- excellent resistance to overheating;

- mechanical strength;

- stability of the glue line formed.

When the adhesive hardens, it does not widen or shrink (and these are the main reasons for premature joint failure). Even when a solvent or machine oil gets on the joint, the performance is fully maintained. Adhesion between surfaces occurs very quickly, there is no need to break away from usual daily activities for a long time.

But the high qualities and the popularity associated with them made Moment a constant target of counterfeiters. Nobody can guarantee the quality of their products.

Specifications

In our country, the production of Moment brand glue is carried out in accordance with GOST. It is waterproof and durable, and due to its technical characteristics it instantly adheres to the surface of the materials to be bonded. Bonded parts and structures are durable.

Let's consider the main characteristics.

- Drying time. It is very easy and pleasant to work with Moment glue. The joint dries quickly, the glued product can be fully used after 24 hours after processing. Achievement of such drying times is due to the properties of the special components that make up it.

- Has the property of not spreading. It gives convenience in work and a high-quality look to the repaired things.

- It is waterproof due to this property, it can be used to glue various objects that may constantly be in contact with water. The properties of moisture resistance allows you to use things after gluing for their intended purpose, without fear of water getting on objects.

- Transparency. The glue has a valuable quality - it is transparent. This property allows you to restore products without visible violations of the connection.

- Availability. You can buy it at any store within walking distance. Adhesives are sold there exclusively for household needs. If you need a large amount of glue for the implementation of large-scale construction work, then this product can be purchased only in specialized hardware stores.

- For ease of use, the adhesive is sold in different quantities. Packaging "Moment 1 Classic" has different volumes of tubes of 30, 50, 125, 750 ml. Small packages are suitable for gluing small parts.

Large packages are purchased for serious construction work. It is easier to work with a large volume of adhesive, it will last for a long time, and it does not dry out for a long time, since the packaging containers are made with a special purpose for long-term use.

Negative sides

With all its positive features in use, this brand has its negative sides.

- The great popularity among buyers has led to the fact that a lot of fakes have appeared on the market that cannot meet the required declared qualities of branded products. Counterfeits contain toxic and harmful substances.

- It has a strong specific smell, but all household chemicals of this kind have odors due to the components included in their composition.

- Some adhesives are difficult to wash off after contact with skin. This problem, most likely, can be attributed not to the quality of the product, but to its inaccurate use.

Peculiarities

The Stolyar contains a polyvinyl acetate dispersion with the inclusion of special plasticizers and additives that improve the adhesive properties of the material and increase the reliability of the connection. In the process of manufacturing Moment glue, toxic and poisonous substances are not used, which makes the material environmentally friendly and allows it to be used in the repair of household items. The chemical safety of the product is confirmed by a quality passport and certificates of conformity that meet strict European standards.

Thanks to special additives, the adhesive does not disturb the structure of the wood fibers. After drying, it is invisible. The scope of the product is quite wide. The glue is successfully used when working with all types of natural wood, plywood, chipboard and fiberboard, cardboard, veneer and laminate.

It is allowed to work with the composition at temperatures above 10 degrees and a relative humidity of no more than 80%.When working at low temperatures, the glue may lose its high adhesive properties, and the gluing will turn out to be of poor quality. Average material consumption is about 150 grams per square meter of surface. The dried composition is compatible with all types of paints and varnishes, therefore, if necessary, the glued thing can be painted or varnished.

It is interesting: Clay "Moment" - types and characteristics

How to prepare the mixture

To prepare the working material, take ready-made grain, dry powders, tiles, granules. They are thoroughly crushed, diluted with warm water according to the instructions. Swelling of active components is awaited. Then use. Store in a hermetically sealed container. All formulations, except for casein, retain their sticky properties for several days.

The method of preparation is prescribed in the instructions on the package. ... The composition of the mixture may differ from manufacturer to manufacturer. Consistency matters. The description of a specific glue indicates the required amount of water. It is designed to produce a mixture of a specific viscosity. If a more liquid material is needed for work, the liquid is added in small portions, each time the paste is thoroughly mixed.

Before gluing the surfaces to each other, they are cleaned and degreased. Then the solution is applied with a thin layer on one of the parts, the planes are pressed. To increase the effect, a load is placed on top, it does not allow the workpieces to disperse. Bonding takes place in 2-3 hours, drying - in 2-3 days. The exact terms and conditions are spelled out in the technical characteristics of each composition.

Instructions for use

Precautions should only be taken if you have an allergic reaction to a specific group of repellents. The fact is that the plasticizer, dibutyl phthalate, in its pure form is used to repel mosquitoes, and its concentration in the PVA glue is super, rather high

To prevent possible reddening of the skin of the hands, we recommend using latex gloves. Otherwise, this glue is safe.

To understand how to glue with PVA glue with high quality, you must firmly master the following rules:

The surfaces to be glued must not be dusty.

Degreasing is the key to a quality seam.

Reliable fixation during the day is an important condition for polymerization.

Compliance with the temperature regime is the foundation of successful work.

After mastering the above rules, the instructions are pretty simple. The optimum temperature for gluing is 18-25 ° C. Please note that the parts themselves must be at this temperature, and not just the air in the room. The surfaces to be glued must be cleaned of all excess. This is best done with fine sandpaper. Moreover, the use of sandpaper will increase the surface roughness, which leads to an increase in the contact area and thereby improve cohesion.

The cleaned and sanded surface must be wiped with a highly volatile solvent. In addition to degreasing, this procedure will remove dust. The presence of dust dramatically reduces the adhesion of the glue to the part.

PVA dispersion is applied in a thin layer on both surfaces and left for 6-8 minutes. During this time, on each part, the glue penetrates into the thickness of the material by several microns and already begins the polymerization process. Then the surfaces to be glued are pressed against each other and securely fixed

Please note that, unlike solvent-based adhesives, when working with PVA, the fixing time is of decisive importance. The minimum time for reliable setting is 24 hours at a temperature of 20-25 ° C

Only after this time, the glue line acquires the declared characteristics.

Of course, if you glue the cardboard, then you don't have to wait that long. But when working with furniture, adherence to the aging period is highly desirable.When gluing wood, careful adherence to the instructions leads to a paradoxical effect - the glue seam of PVA super glue becomes stronger than the product itself. In other words, if the load is exceeded, the piece of wood itself will break, not the glue seam!

It is best to remove excess glue immediately after application. This can be done with a damp cloth. After drying and complete curing, only scraping with a knife or sandpaper is possible. The action of household solvents causes the polymer film to swell and does not lead to dissolution.

- Composition

- Mezdrovy

- Isinglass

- Bone

- Casein

- Moisture resistant

- How to prepare the mixture

- Titebond

- Moment

- Titanium

- Selection rules

Joiner's glue is intended for joining parts made of paper, cardboard, wooden boards, bars, hardboard. The material is inexpensive, safe, and has a natural composition.

Interesting: Cold welding "Almaz-press" - overview and scope of use

Storage conditions and tips for use

For all funds, approximately the same rules apply: they need to be stored at a temperature of -20 ... + 30 degrees, away from heating devices and sources of fire. It is advisable to avoid exposure to the sun's rays, being in conditions of high humidity. Store the formulations only in the original packaging.

Any old material, especially loose material, should also be removed. Smooth surfaces should be pre-sanded, cut to improve the quality of adhesion. Next, you need to apply glue to one or both surfaces (as indicated in the instructions), fix them, wait until they dry completely.

For applying wallpaper adhesives, rollers or brushes should be used, which should be prepared in advance.

Varieties

In the modern market of household chemicals, the model range of joinery adhesives is represented by five series, differing from each other in composition, conditions of use, time of initial setting and complete hardening.

"Moment Stolyar Glue-Express" is a universal moisture-resistant agent produced on a water-dispersion basis and intended for gluing wood of different species, as well as wood-fiber and chipboard, veneer and plywood. Full curing time is from 10 to 15 minutes and depends on the ambient temperature and the moisture content of the wood.

The adhesive has high moisture resistant properties, does not contain solvent and toluene. The product is suitable for working with paper, cardboard and straw, which allows it to be used instead of stationery glue for making crafts and appliqués. After applying the composition, the working surfaces must be pressed tightly against each other. This can be done with a vice. Also, products can be crushed by a book or other heavy object.

The product is available in tubes weighing 125 g, in cans of 250 and 750 g, as well as in large buckets of 3 and 30 kg. You need to store the glue in tightly closed containers in a temperature range of 5 to 30 degrees.

"Moment Stolyar Super PVA" is the optimal solution for gluing wood of various species, laminate, chipboard and fiberboard. The glue is available in red cans, has a transparent structure and is practically invisible after drying. The moisture resistance of the material corresponds to class D2, which allows it to be used in dry and moderately damp rooms. The joinery is suitable for working with laminated plastics, straw, cardboard and paper, which allows you to carry out crafts together with children without fear of harmful effects. Complete setting of the solution occurs after 15-20 minutes.

Moment Joiner Super PVA D3 waterproof is a universal assembly compound capable of withstanding repeated freezing and thawing, intended for gluing wood products and laminated surfaces.The water resistance limit is determined by the DIN-EN-204 / D3 index, which indicates the high moisture-repellent properties of the material and allows the use of products repaired with it in conditions of high humidity. The product has proven itself well in renovation work in kitchens, bathrooms, lavatories, and also as an assembly tool for gluing parquet and laminate flooring.

"Moment Universal PVA Joiner" is a water-based glue suitable for gluing elements made of any wood species, MDF, fiberboard and plywood. The product has a short full-setting time, a transparent structure and does not leave colored or cloudy stains on the wood. The initial initial setting force is 30 kg / cm2, which characterizes the excellent adhesive properties of the product. The main condition is that the surfaces to be glued must be firmly fixed within 20 minutes. Adhesives on a water-dispersion basis have in their composition a strictly defined amount of water, therefore, it will not be possible to additionally dilute the agent to increase the volume, otherwise the proportions will be violated, and the mixture will lose its operational properties.

"Moment Joiner Instant grip" is a universal moisture-resistant agent made on an acrylic water-dispersion basis, intended for any wood. The initial setting time is only 10 seconds, which refers to the composition as a second adhesives and requires careful use. The solution is easy to apply and leaves no residue. The product is excellent for gluing wood to metal, PVC to plastic, withstands up to five short-term freezing cycles.

Types and features

Universal glue "Moment 88" is made from a solution of ethyl acetate, phenol-formaldehyde resin and rubber. It easily bonds wood, cardboard, leather, rubber and metal surfaces, as well as ceramics, glass and textiles. At the same time, it is not recommended for bonding polypropylene, styrofoam, plasticized PVC and polyethylene, as well as for dishes and containers in contact with food and drinking water.

Moment 88 glue has several varieties.

- 88-CA is designed for bonding porous and fibrous objects. It securely bonds metal to rubber. It does not lose strength and elasticity at a temperature of -50 C, it is also called rubber. Suitable for small home renovations. The glue is moisture resistant, does not cause metal oxidation. Available in containers from 1 to 200 liters.

- 88-NP is designed for bonding wood with rubber, concrete, leather and plastic. It is very water resistant, salt and fresh water is not chemically affected. It is superior in strength to 88-CA glue. The adhesive is used in shipbuilding and assembly work. Does not lose its properties at temperatures from -50 to +70 C. It does not cause corrosion of metal, it is used for cold and hot gluing. It is sold in tubes of 50-125 ml.

- 88-M extra strong 15 kgf / sq. cm, created to connect any materials. It is mainly used in the repair of motor vehicles. Does not lose its properties at temperatures from -40 to +70 C.

- 88-NT is designed for bonding wood, concrete, metal and ceramics. Does not lose its properties from -40 to +50 C. Waterproof. The technical characteristics of the glue are suitable for hot and cold bonding methods. Waiting time after bonding before operation 6 hours.

- "Lux" is designed for bonding metal, textiles, paper, plastic, glass and foam. It is used in everyday life, construction work, radio engineering and furniture assembly.

Application technology

PVA Moment glue is a high-quality and reliable composition, but it must be used correctly. It will not be difficult for experienced craftsmen to quickly achieve the desired result using this product, but neophytes often suffer from their mistakes when the products to be joined diverge or lie unevenly.

To avoid adverse consequences, it is recommended to precisely follow the phased work with the adhesive mass:

- Remove dirt and dust from work surfaces, dry.

- Make sure that the air temperature in the working room reaches + 18-25 degrees.

- Spread the mixture over one surface in a thin and even layer.

- Place surfaces on top of each other, press down and leave for 20 minutes.

The glue will set pretty quickly, but this does not mean that the connected parts are already ready for further use. After the indicated 20 minutes, you can only release the products and not provide pressure with them on each other, but they can be processed only a day after gluing.

Tips & Tricks

Glue Moment is not only a means for gluing wood. It is also allowed to be used when working with paper, cardboard or straw. So, with the help of such a mass, you can make a craft with your child or make a gift for a friend on your own. This is the versatility of the composition - it is good in everything - from heavy repairs to DIY works.

When connecting parts, they must be pressed down. This can be done with your hands or with devices specially designed for this - clamps or vices. As a last resort, in the absence of such tools at hand, books or any other heavy object will do.

Packaging, storage and shelf life

PVA Moment is sold in different packages. They contain a different volume and, accordingly, they are purchased for specific purposes:

- tube - 125 g (for children's crafts);

- bottle - 250 or 750 g (for frequent making crafts);

- bucket - 3 or 30 kg (for repair and construction work).

Regardless of the container, it is recommended to store the composition at a temperature of + 5-30 degrees Celsius. In addition, it is imperative to keep the glue in a tightly closed container so that it does not dry out.

The maximum shelf life is 18 months from the date of production. But you should not store in an opened package for more than 15 months, and even more so, use it after the specified time.

Views

Nowadays, there are more than 100 brands of adhesives of this brand. They are produced by contact, second, wallpaper, stationery, epoxy. They are conveniently shaped for ease of operation. They are sold in the form of adhesive tape, as sealants, in the form of alkaline batteries. It is almost impossible to list all the options.

The declared universality of the "Universal Moment" glue provides for the combination of several types of adhesives into one group. The versatility of the process of gluing materials together is not limited to the operations performed when processing specific materials. Each brand of glue contains various components that enhance its specific functions when exposed to materials with different adhesion characteristics.

Let's list the popular universal brands available on the shelves of our stores.

"Moment Gel Crystal"

A special feature is that it contains a large number of different types of thickeners that provide a gel-like consistency. Such an adhesive composition has an excellent property of not spreading. It is very easy to use and does not drip.

"Moment Montage"

Specially designed for fixing all kinds of finishing materials on various large vertical and horizontal surfaces (floors, ceilings, walls). It is sold in special convenient packages for installation in a construction gun. When the trigger is pulled, it is squeezed onto the surface to be treated. The adhesive composition has a gel-like structure that does not allow spreading.

"Super Moment"

It contains a large number of hardening accelerators, which impart particularly strong adhesion properties. When working with it, it is necessary to very quickly apply and dock the workpieces to each other.

"Moment 1 Classic"

Most popular for home use. Serves for gluing together various structures, parts in all kinds of combinations.

"Joiner PVA"

Indispensable when carrying out woodworking works. They are happy to work on large construction sites, and in their apartments, home craftsmen.

Wallpaper glue "Moment"

It has many varieties. Their variety depends on the characteristics of different types of wallpaper. The manufacturer adds components that stop the development and growth of molds to the composition of the adhesive materials for wallpaper.