Common components of screws and bolts

One area of application, say the construction industry. The same purpose, i.e. and both connect and join different surfaces. Equally popular samples among builders for the installation of structures. They also have a similar layout in shape. Threaded rod, identical heads for some varieties, hexagonal, for example, for roofing elements.

In general, the creation system is similar and has one range of purposes. Another similar dismantling system. One and the most important thing in common between them is that their connection system is based on the law of friction, due to which the structure retains its viability over time.

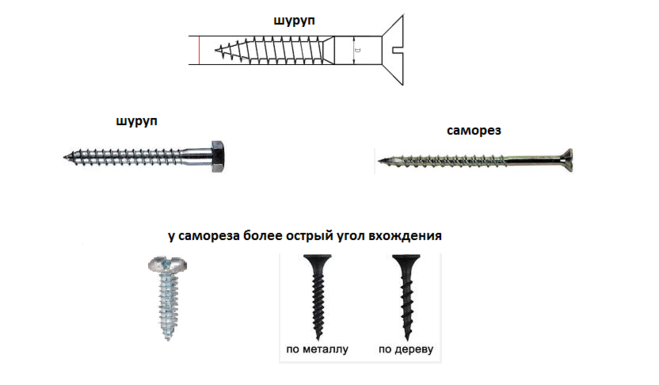

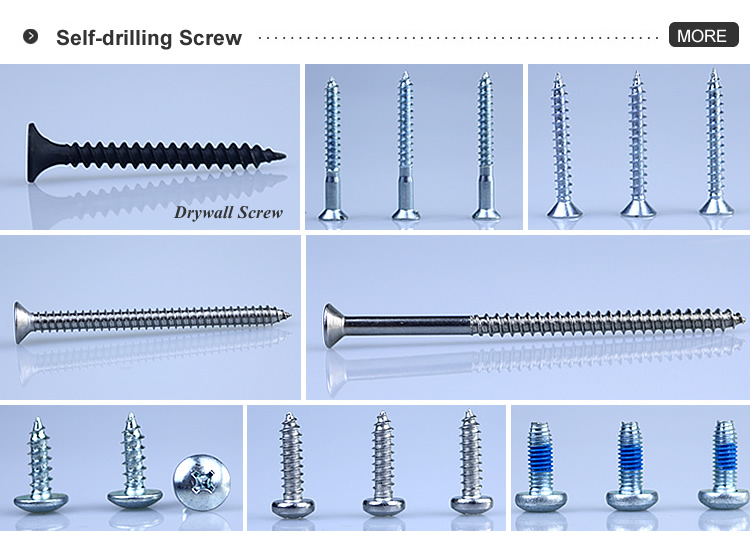

Screw and self-tapping screw

This topic is not an easy one, because even the definitions in GOSTs provoke controversy among workers. Many argue that self-tapping screws are screws, just imported. After all, then their name was translated as "self-tapping screw", which over time was simply reduced to the word "self-tapping screw".

However, there is a difference between them and it is significant, which affects the practical application. Can you tell a screw from a self-tapping screw?

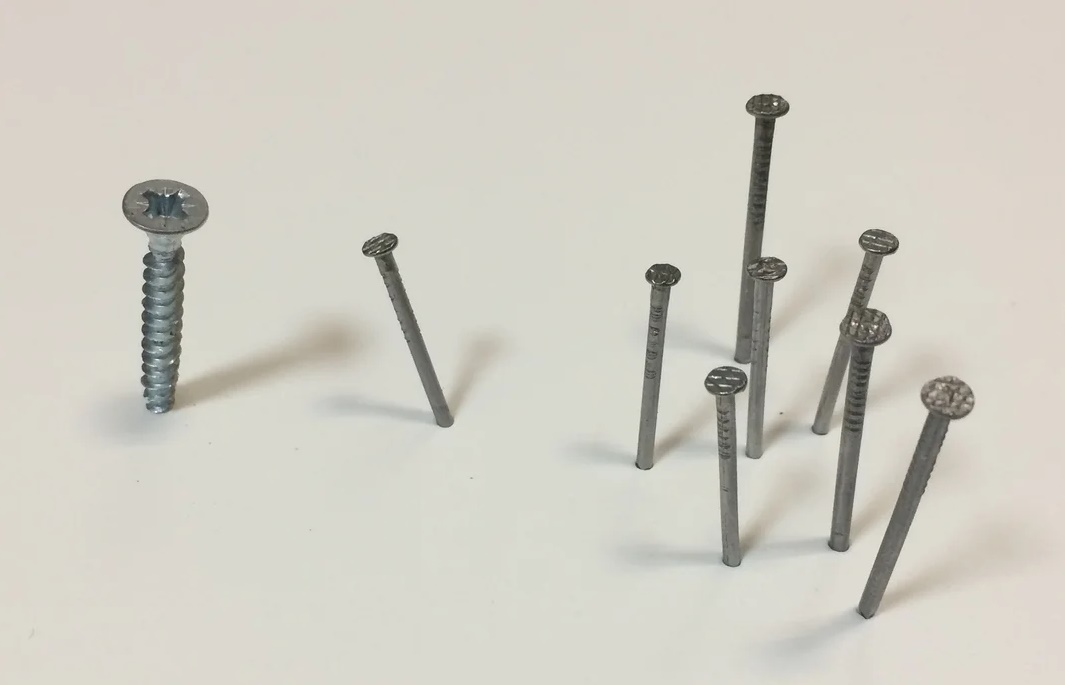

The attentive reader, of course, guessed that this is a trick question. After all, it is not the color that determines the essence of the product. The photo above shows 2 self-tapping screws, but with different galvanizing. Zinc gives a silvery color, and a yellowish tint appears due to chromium.

Do you like what you read? Like us on Facebook and be sure to share the article with your friends!

There are also phosphated or oxidized self-tapping screws, they are black. However, these screws are more fragile and not protected against corrosion. Therefore, they are intended for interior work with soft materials and lightweight structures.

What a screw looks like

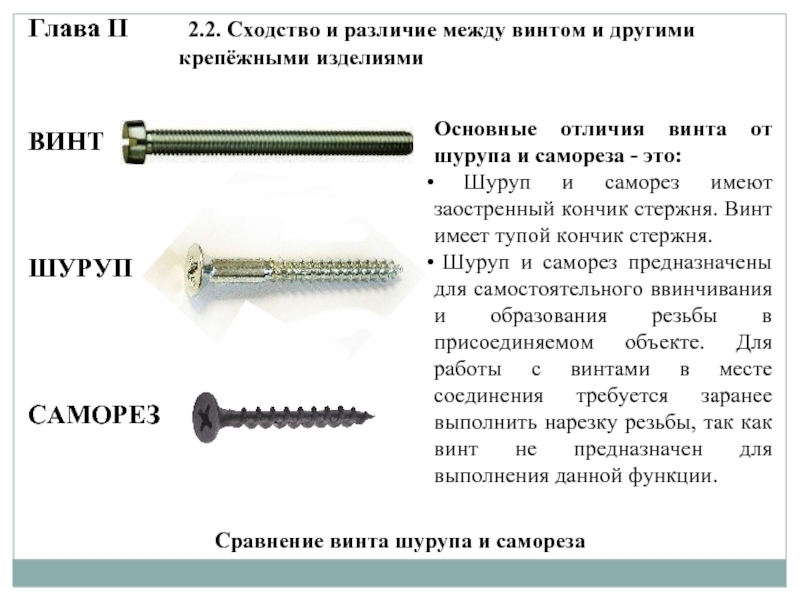

The screw shaft is wide enough, and it can be conditionally divided into two parts: with a thread at the end and without a thread near the head. This is the main visual difference that immediately catches the eye and helps to distinguish.

For the manufacture of a screw, soft grades of steel are usually used. Because of this, it is more likely not to break, but to bend. The downside of this was that you can erase the slot literally at the first tightening. Also, the screw does not have any protection against corrosion due to the lack of any special coating.

And the main practical difference between the screw is that it is necessary to drill a hole before screwing it in. In this case, you can only work with wood and plastic.

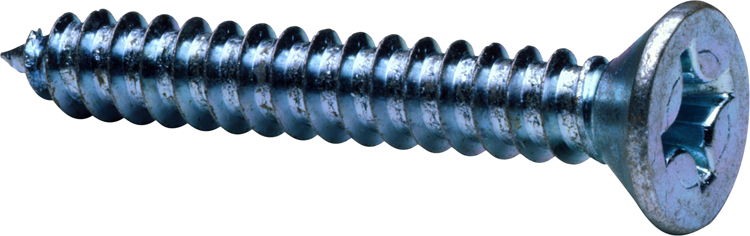

What does a self-tapping screw look like

The self-tapping screw looks like a thin screw with a fairly wide thread pitch from the head to the tip. The tip of the screw is quite sharp. Because of this structure, this fastener got its name, since it cuts itself a course.

It is made from hard steel grades that cannot be bent in any way. Also, the self-tapping screw undergoes a special heat treatment, which increases its strength, in contrast to the screw. Therefore, they can be used for working with plastic and metal.

Visually, you can see that the pitch and height of the thread of the self-tapping screw is greater than that of the screw. And its end is much sharper. Thanks to this, no pre-drilling of holes is required, but the self-tapping screw can be screwed in immediately.

As we said above, many self-tapping screws are galvanized, which makes them corrosion-resistant, unlike a screw.

It is also worth noting that there are a large number of varieties of both screws and self-tapping screws. They have different heads, splines, different threads and tips. But those main differences that we wrote about above are enough for you to always understand what kind of fasteners are in front of you.

And in the video below you can see what to do with a torn off self-tapping screw, the slot of which has erased into one large hole.

We hope that it is now clear why in recent years the market has been almost completely occupied by imported self-tapping screws, and our screws are gradually becoming a thing of the past.

Window screws

These products are used for profiles, slopes, handles and many other elements. As a rule, we are talking about galvanized self-tapping screws with a sharp end and a head, which can be of different shapes. It is most convenient to use products with a secret hat. However, such self-tapping screws often begin to scroll in plastic, so specialists often replace them with elements with a drill at the end.

In addition, there are separate self-tapping screws for window frames on sale. There are anti-vandal products for work on concrete, brick and many others. However, most often during construction and repair, exactly those options are used that were described above.

Heads

Reference article based on the author's expertise.

A screw and a self-tapping screw are fasteners, which are a rod with a head and an external thread. In some sources, it is believed that a self-tapping screw is a type of screw. The functional characteristic of this product is the creation of an internal thread in the hole of the connected object.

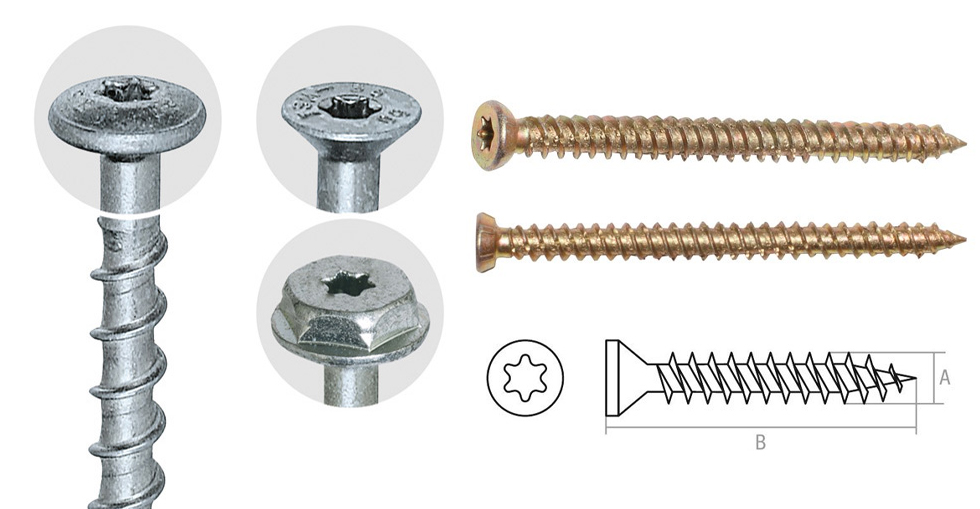

The external thread on the surface of the screw occupies half or less of the entire length of the rod, with a smooth surface near the head and a threaded surface near the tip of the rod. The external thread of a self-tapping screw either covers the entire surface of the rod, or most of it. In addition, the thread height and pitch of a self-tapping screw is greater than that of a screw. The thread height of the screw from the end to the base of the rod increases to a greater extent than that of a self-tapping screw. The rods are also distinguished by their sharpness - the self-tapping rod is sharper sharpened. The self-tapping rod itself is thinner than that of the screw.

There is a triangular thread on the cylindrical surface of the screw and self-tapping screw - for a self-tapping screw, this thread covers the entire surface of the outer part of the head, and for a screw only a part. This difference determines the higher product durability of the screw from a technical point of view. From the actual point of view, self-tapping screws are made from more durable materials, which makes them much stronger than screws. Self-tapping screws are usually made from hard steel grades such as hardened steel. The use of alloys with increased strength is due to a special technology for the manufacture of self-tapping screws, including heat treatment at high temperatures.

How to choose wood screws

It is not worth using self-tapping screws for metal or universal screws for fixing wood. Universal ones are good when you need to twist wood and metal. And when twisting two pieces of wood, they work worse. In the sense that specialized fasteners will hold the wood better. That is, we consider only wood screws. Believe me, there will be plenty to choose from.

Wood screws are better than yellow (yes, expensive) or white (a little cheaper)

As already said, wood screws have a rarer thread with a higher profile (the grooves between the turns are deeper). They are used not only for wood, but also for all types of sheet materials: gypsum fiber board, plywood, OSB (OSB), fiberboard and chipboard. Now about which ones work better.

Thread and other "bells and whistles"

First you need to choose the type of hat. Secret or with a press washer, cylindrical, hemispherical - select based on what kind of connection you need to make. It is also recommended to choose a spline of the TORX type, since it best transfers the torque from the power tool. Further in order.

- It is necessary to determine whether the thread should be applied to the entire rod or not. If you need to fasten two pieces of wood and pull them tightly together, take a self-tapping screw with an incomplete thread. This means that there must be an unthreaded area under the head. The length is equal to the thickness of the attached part or slightly more. Due to this zone, one part is "attracted" to another.

How to choose self-tapping screws for wood: a few chips for quick and high-quality work - To facilitate screwing into hard rock or sheet material, there are wood screws with a router or mill. The cutter is available only on self-tapping screws with an incomplete thread. It looks like a few screw-type notches, which are applied before the start of the thread. The notches soften the wood, after which the self-tapping screw "goes" better.

- In general, wood screws have a thinner point and thus prevent wood cracking. But there are also special "lotions" against cracking. It can be:

- grooves;

- cutting edges in the form of notches on the screw body;

- notches on several lower threads.

Are these bells and whistles necessary or is it wasted money? Incomplete threads are nothing new. One detail "sits" on top of another much more densely. And try the rest. Only from your own experience you will understand whether it works or not, and what exactly suits you best.

And practical advice on choosing wood screws

It is important that the thread runs straight from the tip itself. If the first turn is too far or the tip is blunt, do not take

There will be continuous torment, not work.

Modern fastener, its advantages and benefits

Self-tapping screws are definitely a better quality product than screws. For their manufacture, special technologies are used. The steel from which the screws are made is of better quality. Self-tapping screws also have increased strength, which is achieved by hardening at high temperatures. In order to protect against corrosion, products are phosphated, oxidized or galvanized. This gives the product protective properties and allows it to resist the corrosive process. In addition, self-tapping screws acquire a color that varies between black and shiny white. For convenience in work, especially for the tool, deep cross-shaped slots are applied to the caps of the self-tapping screws.

Sometimes you can find on sale the so-called exotic species, made of brass or stainless steel.

Self-tapping screws can be easily screwed into metal if the thickness of the metal does not exceed two millimeters. The thread in metal products is applied quite easily if the self-tapping screws have a high screw thread with a sharp thin profile. The sharp end of a self-tapping screw, like a real drill, makes a hole in products or materials, which then allows you to accurately cut the thread. In this case, the self-tapping screw is able to work like a drill. Self-tapping screws, for working with metal material, have frequent or even double-start threads.

When a material or product into which a self-tapping screw is screwed is softer, for example, wood or plastic, self-tapping screws with a wide thread pitch, a sharp end and a large thread angle are used.

Currently, fasteners with a countersunk head are in great demand on the market. It flows smoothly into the core. With the help of such self-tapping screws, the installation of plasterboard structures is done. These are the best self-tapping screws for connecting plasterboard floors.

Currently, fasteners with a countersunk head are in great demand on the market. It flows smoothly into the core. With the help of such self-tapping screws, the installation of plasterboard structures is done. These are the best self-tapping screws for connecting plasterboard floors.

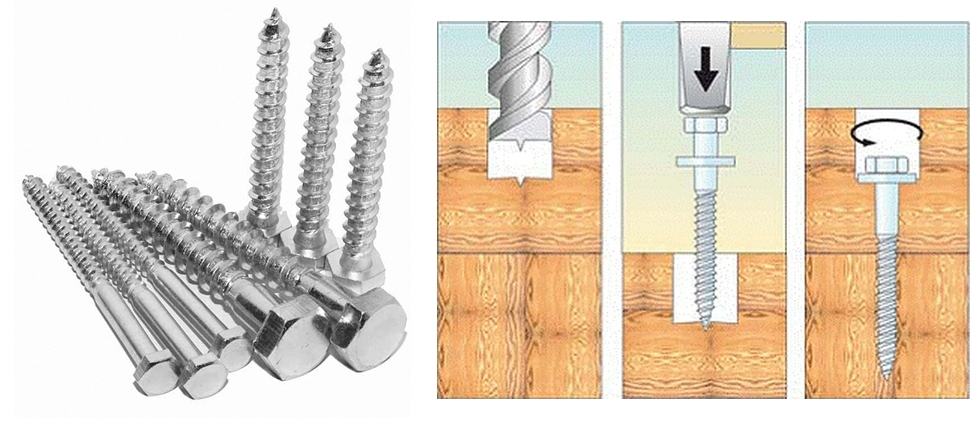

Self-tapping screws with a hexagonal head for increased strength. Such products are used in conjunction with a plastic dowel for attaching heavy objects.

Self-tapping screws, with a washer-shaped head, are used for roofing work. They are fitted with rubber gaskets for sealing and are painted in common roofing colors.

Screws, screws, self-tapping screws, bolts and nuts - all this is combined under one name "construction fasteners" or, in other words, "hardware". Their main task is to fasten various parts of industrial and domestic structures. Depending on the specifics of production and purpose, all fasteners have their own characteristics.

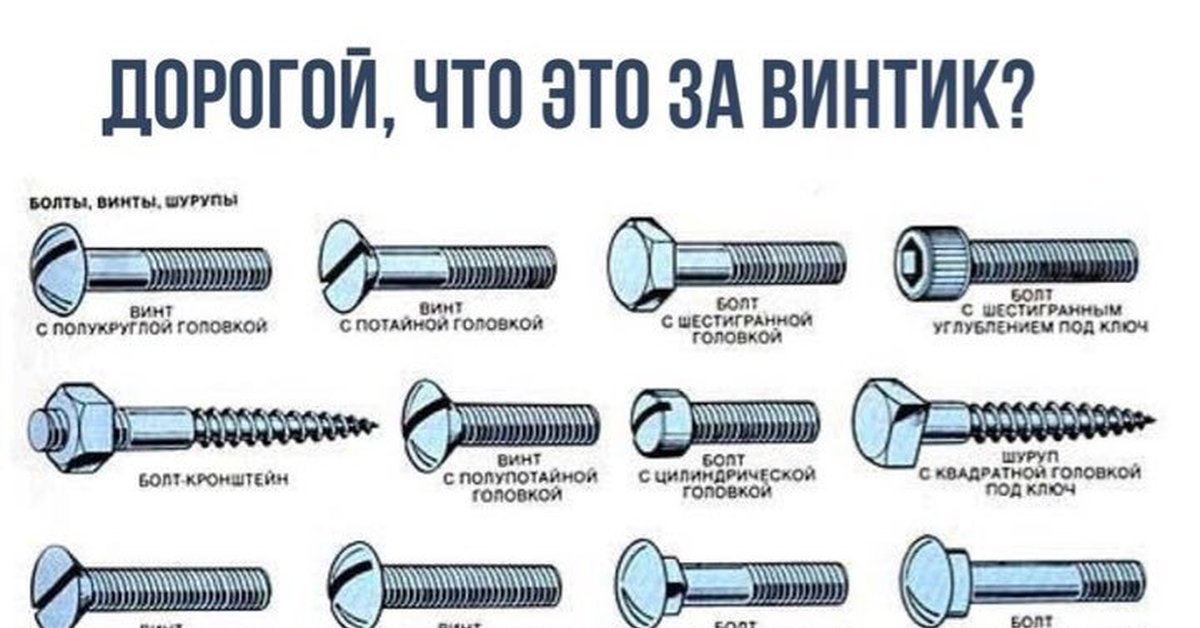

The most common part among all threaded connectors is the screw.It is with him that it is worth starting the distinctive characteristic of all threaded hardware in order to understand how a screw differs from a bolt and a screw.

What is the difference between a bolt, screw and nut?

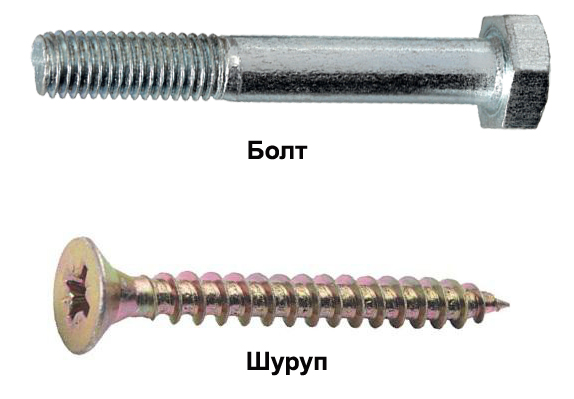

Unlike a bolt, a screw, although it looks like it, has a round head and a special recess for a screwdriver. At the bolt, the head looks like a hexagon, and there is no recess on it, since this hardware is fastened with a wrench. During the fastening process, the screw is screwed into the material and fixed in it by means of its thread. While fastening the bolt requires the use of a nut, it is this nut that is the lock of the fastening bolted connection.

Most often, screw fastening is used where there is no access from the back side of the parts to be connected to tighten the nut. For example, it can be any household or industrial mechanism, as well as a structure in the form of a lid. For conventional connections, a steel screw is used, but if work is carried out on electrical equipment, then the screws in this case are used from brass, bronze or copper.

Differences

Screws differ from self-tapping screws in the width of the rod on which the thread is cut. The first ones have a thick base, they are able to withstand a large fracture load, but to screw them in, you must first drill a hole equal in width to 70% of the screw diameter.

For self-tapping screws, the thread on the rod almost completely covers the cylindrical surface. They are less durable, but can be screwed into almost any surface without preparation. Self-tapping screws are made from carbon steel, stainless steel or brass and are used for working with drywall, wood, roofing materials, metal profiles, sheet metal and window profiles.

Self-tapping screws with a drill are designed for working with metal. There is a small drill at the tip that drills a hole in the base material. The use of such fasteners can reduce the time required to complete the job. They are mainly used in the installation of corrugated board.

Self-tapping screws that do not require drilling are used to fasten soft wood: solid boards, floorboards or picket fences. Such self-tapping screws have a wavy thread and, when screwed into the material, do not allow the wood to delaminate.

Related Posts via Categories

- Bolt strength class - how well do the hardware resist shattering?

- Anchor bolt with nut - proven fastening option

- Dowel-nail - which fasteners are of the highest quality?

- Anchor bolts - a special type of fasteners for complex structures

- Bolt designation in accordance with GOST - we are guided in the world of hardware

- How to rivet a rivet - automatic and manual methods for different materials

- Bolt manufacturing - straightforward workflow

- Spring Cotter Pin - Eared Fastener for Mechanical Engineering

- High Strength Bolts - Complete Fastener Information

- Blind rivet sizes - what should you think about when calculating?

The screw as an irreplaceable element of the connection

One of the varieties of the fastening system. The shape of the screw is an elongated rod with a sharp end and a head for Phillips and flat screwdrivers. In many ways it resembles a nail, but it copes better with its work due to the special carving on the entire surface. Range of application: finishing work in any home, when erecting fences, billboards, and so on. Screws are a popular class of fasteners.

Screw

There are roofing screws with a hex head and a washer covered with wear-resistant rubber. Such products are most often used for the installation of metal roofs, profile sheets and for cladding buildings. Most often private buildings. It is produced in the color of metal sheets and serves for a long period of time. The spectrum of staining reaches up to 18 colors. Separate products are produced for plumbing work.There are both mounting and installation screws, depending on the range of purposes.

Hex head screws

Where are they used?

Self-tapping screws with a large thread and a wide pitch are used for screwing into the surfaces of a soft and loose structure: plastic, plasterboard, wood, chipboard, MDF, fiberboard.

Fastening materials with fine and frequent threads are recommended for materials with high density and hardness: metal surfaces, dense wood and hard plastic.

Self-tapping screws with a two-start thread have a special structure: they alternate high and low threads on the base, which is convenient in case of different surface densities. They are best used for twisting drywall and metal profiles.

A special variety are self-tapping screws for roofing work, which are tightened with a key, not a screwdriver, and have a large hexagonal head. The length and width of the fastener differs depending on the roofing material, but a mandatory element is a rubber washer, which prevents water from entering the hole and holds the self-tapping screw itself more tightly.

Self-tapping screws are recommended for:

- work with aluminum profiles in the process of creating structures;

- sheathing the frame with lining, drywall, sheet metal, profiled sheet;

- assemblies of kitchens, cabinets and non-separable structures;

- installation of double-glazed windows, work with plastic panels, fastening elements in the car.

Screws are recommended for:

- installation of wooden flooring;

- installation work with MDF and OSB plates;

- creating stairs from wood;

- door frame installation;

- plumbing fixtures;

- fastening structures with movable elements.

There are also furniture screws and self-tapping screws, which are now called confirmates - they can have a sharp and blunt base, a flat head surface with a hexagonal recess. Understanding the difference in fastening materials, it is possible to most accurately determine the option that is needed for a particular case.

Application features

In the very technique of using these fasteners, there is an important difference: before using the screw, the hole for the fastener is pre-drilled with a drill to create a guide channel, while the self-tapping screw is used immediately due to the sharpness of its rod and the material of manufacture. When drilling a hole for a screw, it is recommended to clean the hole from construction dust to reduce stress when tightening the rod.

The self-tapping of the self-tapping screw into the material without preliminary drilling is explained by the sharpness of the rod and the increase in the thread height.

Extruded food products are diverse and can be found in various segments of commercial spaces such as grocery stores, supermarkets, and convenience stores, and include, but are not limited to, cereals, confectionery, textured protein products, and pet foods.

The versatility of extrusion is reflected in the use of its products in preparing military and camping food rations, diet-specific foods, and foods designed to meet nutritional needs in natural disasters.

The screws are designed for working with soft materials - wood, plastic. Self-tapping screws are used to work with solid products - concrete, metal. Therefore, the material for the manufacture of self-tapping screws is more durable and has a phosphated coating to protect against corrosion.

Screws, screws, self-tapping screws, bolts and nuts - all this is combined under one name "construction fasteners" or, in other words, "hardware". Their main task is to fasten various parts of industrial and domestic structures. Depending on the specifics of production and purpose, all fasteners have their own characteristics.

Benefits of using extrusion.When it comes to traditional conditioning or processing methods, extrusion baked goods are distinguished by the ability to develop a variety of foods in flavor and texture, including expanding properties and crunchiness, in addition to increased food digestibility and nutrient bioavailability.

Thus, the environmental problems are very limited and the efficiency of the extrusion process is improved. But mainly from the 1960s, extrusion processed products began to multiply, given the high versatility of this process. However, the performance of the related equipment has not changed since then, with the exception of the possibility of incorporating new technologies based on computer programming parameters such as times, temperatures and production formulas to be used.

The most common part among all threaded connectors is the screw. It is with him that it is worth starting the distinctive characteristic of all threaded hardware in order to understand how a screw differs from a bolt and a screw.

What material are self-tapping screws made of

The fastener consists of a base and a cover. If we talk about the main material, then self-tapping screws come from:

- Carbon steel. The material is an alloy of carbon and iron. There are no other impurities in the composition, so the finished products are the most durable.

- Of stainless steel. In this case, steel is used, which contains no more than 10.5% chromium. Thanks to this, the fasteners are resistant to corrosion and have good strength. Such self-tapping screws serve faithfully for a long time and meet all hygienic requirements. In this regard, it is them that I use when working in medical institutions.

- Brass. Copper acts as a base, to which zinc, tin, iron, manganese or lead are added. The brass version is also considered very good, since such a self-tapping screw is durable and durable. Brass perfectly withstands low temperatures, has the property of not magnetising and does not rust.

It is also worth paying attention to what the fasteners are covered with. Self-tapping screws can be:

- Phosphated. In this case, the product made of carbon steel is treated with phosphates. These fasteners are ideal for wet rooms.

- Oxidized. Also made of carbon steel, which is additionally coated with an oxide film. Fasteners of this type are applicable only for rooms with normal humidity values.

Healthy! Oxidized and phosphated self-tapping screws can be recognized by the black color of the coating.

Galvanized. They are made of the same material, only zinc is already used as a coating. This makes the products versatile, as they can be used both inside and outside the house. They can be golden, silver and black in color.

The simplest option is an uncoated self-tapping screw. Such products are used only indoors with normal humidity.

Products can also differ in thread.

What does a bolt look like and how is it different from a screw

As mentioned above, in order to clearly distinguish how a bolt differs from a screw, the definition of each of them should be made according to the fastening method. So, a nut is used as a fixing element for a bolt, and the screw is directly screwed into the depth of the fastened parts and has a counter thread in the second of them. The nuts must have the same tapped hole size as the bolts, otherwise they will not work.

These four factors are related as shown in the figures and in the table below. Example: Two pieces of aluminum are to be connected with a 6mm diameter screw. How deep should the hole be drilled? How deep should the threaded hole be? How much should the screw pierce? What is the diameter of the through hole?

Therefore: 1, 06 '6 mm = 6, 36 mm.If a threaded connection is made between different materials, calculations should be made in accordance with the material that the thread will receive. When you buy a case, it comes with a series of screws and other small parts. It is difficult even for experienced technicians to tell exactly what the use of each of these screws is. In this tutorial, we will talk about all the screws used during chip assembly and where you should use them, so by reading this tutorial you will increase your micron assembly skills.

You can always clarify what kind of design is available for hex bolts, and determine how a screw differs from a bolt, according to GOST 7805-70. It is this document that regulates the production of the named parts and their qualitative and quantitative characteristics.

Most often, universal bolts are made with full threads, but there are also options with incomplete threads - for fastening flat parts of large thickness. By the principle of fastening, you can also understand how a bolt differs from a screw. Indeed, when using a bolt, its second end always comes out of the fastened part and is fixed with a nut, while in the screw it is hidden inside the part. When considering the design features, it has already been mentioned how a bolt differs from a screw, and it is for this difference that bolts are designed to connect two flat parts, and screws are for a flat part with products of any thickness.

Figure 1: Different types of screws used in micro. Screws differ in three aspects: thread type, head shape, and length. The length and especially the shape of the head can vary greatly, but only three types of thread are used in the microrelief. Therefore, we believe that the best way to sort the screws found in micro is the type of thread they use. In Figure 2, you can see these three types of streams.

Figure 2: Types of threads used by screws that enter the body. The first type of thread, shown on the left in Figure 2, is the type of self-tapping used to secure the fans to the chassis. This is the only use of this type of screw in a trace element, which is very easy to identify as you can see. This screw is usually 10 mm long and has a flat head as shown.

Bolts, moreover, when fastened to a nut under the influence of vibrations or when connecting wooden parts, tend to self-loose. To prevent this, put a locknut on the bolt (the second after the first) or use self-locking nuts.

To prevent the bolt from damaging soft material, such as wood or plastic, and to prevent the fastener from pushing through the soft material under stress, a washer is placed under the bolt head. For more reliable connections, use two washers, placing the second under the nut.

Figure 3: Screws used to secure fans and air ducts to the cabinet. You must use a # 2 Phillips screwdriver to tighten this type of screw. To facilitate this, we will refer to this "thick" thread from now on as the third type of thread is thinner.

This means using a wire with a diameter of 3 mm with a distance of 0.5 mm between the wires. For simplicity, we will refer to this type of thread as "fine thread" from now on as it is thinner than the other two thread types used by micro screws. Screws that use both thick thread and thin thread can be found with several different head types and lengths, and this is where most people get confused. Therefore, we will talk in more detail about all the screws used in the micro.