What are they?

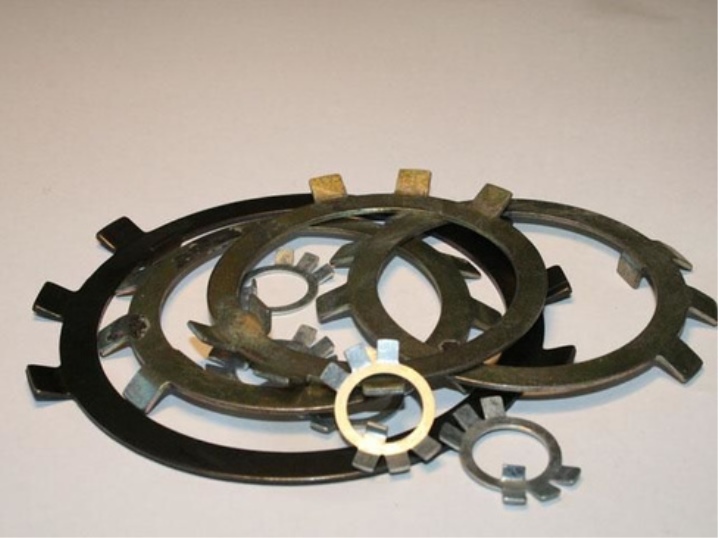

These products are initially produced in two types - light and normal, which differ only in the area of use. In addition, multi-footed washers are divided into several types, also made in accordance with the requirements of GOST:

- reduced size retaining parts;

- multi-footed devices with a toe;

- washers that have evenly grouped legs on opposite parts of the device and are distributed over the entire outer surface, not counting the obligatory inner protrusion.

Custom-made fixtures may differ in material - they are made of titanium, aluminum, copper alloys. As a protection, parts are sometimes coated with solutions of acids, phosphates, cadmium, special oils that increase their wear resistance and service life.

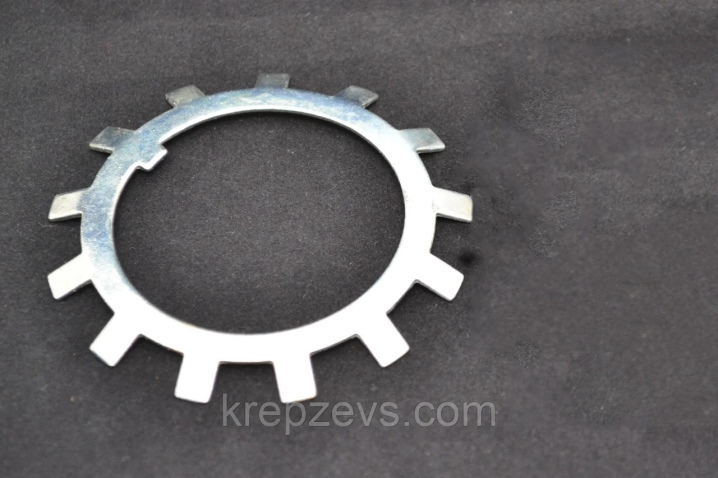

But the most popular, thanks to the guaranteed strong fastening and durability, is the lock washer GOST 11872 89, which is widely used in industry, construction and in everyday life.

What a multi-footed washer looks like, see the video below.

Description and purpose

With long-term operation of many technical devices, the main criterion for durability is the strength and reliability of the connection of different parts of the structures. Correctly selected locking multi-foot washer avoids spontaneous loosening of fasteners, and so-called feet help it in this.

When using slotted nuts on the shafts, these devices completely save the structural unit from destruction. In the grooved groove, the lock washer is fastened with a lug on the inner side, in turn, this makes axial rotation impossible, while maintaining the normal, unobstructed movement of the fastener in the direction of length. 6 special lugs, tilted at 25 degrees, exclude unscrewing, but the part is effective only in relation to slotted types of nuts.

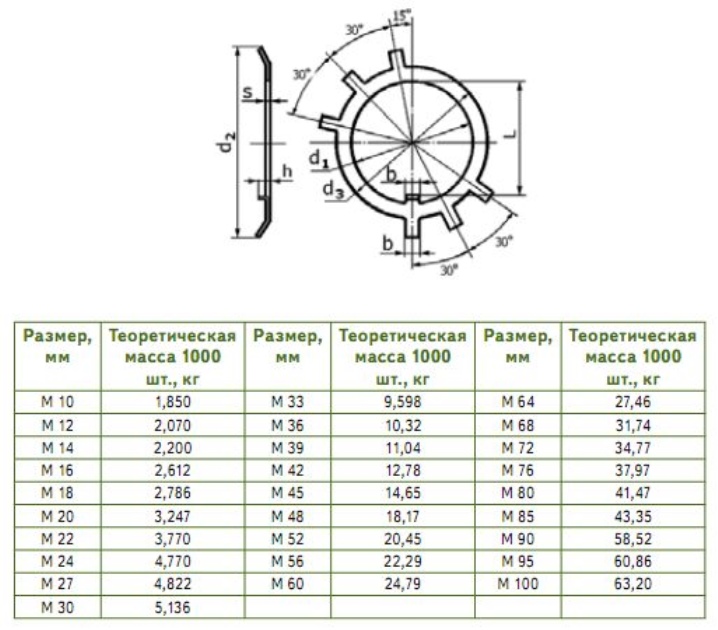

Therefore, the latching device with an inner tab has the following characteristics:

- the presence of external and internal protrusions;

- mainly the fastener is used for nuts of a certain size - with a diameter of 10-130 mm;

- the arrangement of the legs along the outer diameter can be different, sometimes they are made to order according to the presented drawings, which is due to the specifics of the design for which the fasteners are used;

- since the legs of the element can be bent many times during operation, the main material for their production is high quality plastic stainless steel;

- depending on the diameter of the thread of the spline parts, lock washers are made of thin metal sheets 0.8-2 mm thick, in addition, the surface of the washers is covered with a protective anti-corrosion layer.

The main area of application of the part is all kinds of structures and structures of industrial importance (any mechanisms that are subjected to loads on the rotation axis during operation, on the shafts of centrifugal, vane pumps, gearboxes that change the power of cars and production equipment). But in everyday life, the device also found its use - they are often replaced by ordinary flat washers with a hole inside. True, then it is required to select the desired type of nut for engaging the legs.

Control methods

During the manufacture of products, it also considers how the basic parameters are checked. Various control methods have been developed, most of which are indicated in GOST 18123-82. The features of this moment include the following:

- The angle of the feet may not be controlled.This is because it requires a high precision tool.

- It is also allowed to manufacture upon agreement with the customer without performing control and testing of the main parameters. Such washers are installed exclusively on irresponsible mechanisms.

Quite a large number of different control methods are distinguished, which exclude the likelihood of the release of a product with obvious defects. An example is the information below:

- In most cases, a visual inspection of the product is performed. At this stage, the main defects are determined, for example, cracks and dents. Visual inspection reveals most of the common defects, but basic performance cannot be determined.

- Tests are carried out to determine the basic properties. As a rule, special settings are used for this. They allow you to determine strength, reliability, hardness and other properties.

Not all parts from a batch are tested, as a rule, only selectively. The release of a product with obvious defects is prohibited, since they may not provide the required degree of fixation.

Locking washers with lugs

Locking washers with lugs are often used when creating bolted connections. The principle of operation is quite simple: there are special holes on the main surface that are designed for the direct location of the foot. This eliminates the possibility of scrolling and displacement of the fixing product. The lock washer with lugs is also characterized by the following features:

- There are not only internal but also several external protrusions.

- External protrusions are used to bend special slotted nuts into the grooves. It should be borne in mind that ordinary hexagons will not work for such a connection.

- On sale there are light and normal versions of parts. The difference lies not only in the field of application, but also in the type of material used in the manufacture.

When choosing washers, care should be taken to ensure that there are no cracks, sharp edges, burrs or rust on the surface. Even minor defects cause a significant reduction in the service life.

In addition, when the foot is repeatedly bent and bent, no crack should occur. For this, special alloys are used, characterized by increased ductility. In the manufacture of all products, the standards of GOST 11872-89 must be taken into account.

How to install and remove?

Installation is carried out in different ways. This can be done manually, mechanically or automatically. Mechanical installation takes place using a plunger and a cone plug centered on the shaft end. The automatic installation method uses special presses and pneumatic cylinders

Installation tools - this is important - must have hardened working surfaces. This minimizes potential wear and tear on equipment

The manual method of installation may be limited to the use of a screwdriver when it comes to the retaining ring.

If you need to securely fix the threaded connection, a stop washer is placed between the head of the hardware and the base where it will be screwed. Screwing it down causes it to shrink and "try" to straighten. This is how the friction force is formed, which does not allow the fastener to unwind. A flat washer (for comparison) is placed under the head for the same purpose and works in the same way.

It will be a problem in case the washer needs to be removed. For many, this becomes an unsolvable issue, but there is a way out. The choice of solution depends on the weight of the product, which the retainer supports. The heavier it is, the stronger it will hold the axis. That is, in this case, you will have to use a chisel and a hammer. If the load is small, even tweezers will do.

The main task is to move the puck from its place and catch the moment when the effort subsides at least for a short time. At this point, you need to try to unscrew the retainer.The main thing is to use a thin and flat object for this. It needs to be quickly inserted into the incision site.

If the fasteners need to be quickly put on again and the washer is already completely damaged, you can take a piece of wire and roll it up, or you can use a piece of rubber tubing. But these are half measures, with the use of a steel washer, these homemade options cannot be compared. Retaining parts are indispensable as retainers that ensure reliable operation of threaded connections under high loads.

You can learn how to properly install the piston pin circlips of brushcutters and chainsaws from the video below.

Requirements

In order for the fixing part to guarantee a long service life, it must meet the technical requirements set out in GOST 11872-89. The main requirements, according to GOST, include:

- calculating the tolerance of angles;

- the possibility of selling parts of a different thickness not specified in the tabular list;

- washers are made without bent legs, but this is agreed with the buyer;

- the steel used to create the element must have a surface hardness ranging from 41.5 to 49.5 HRB.

For manufacturing, it can be used as a material and bronze, but such a part will be 2 times more expensive. According to the requirements of the document, the fastening object cannot have visible defects. Cracks and chips will seriously reduce the strength of the fastener and other characteristics, so they are unacceptable. The technical requirements also include the dimensions indicated in the drawings.

The control method is a visual inspection of the part (for cracks and dents). It detects most of the defects, but still does not define the baseline performance. For the test control of the main properties, the part is tested on special installations to study the indicators of strength, reliability and hardness.

Lock washer star lock

This embodiment is considered a unique product that has no analogues among the safety fixing elements. Key features include the following:

- The use can significantly improve the reliability of the connection.

- At the time of installation, the destruction of the retainer should be carried out, since otherwise it will not be possible to carry out the work.

- The scope of application of the lock washer of this type is very large. An example is industry, household mechanisms and structures, medical equipment.

- In the manufacture, a metal is used, which is characterized by increased resistance to environmental influences.

Star Lock has quite a number of advantages:

- Long-term service of the connecting element is ensured when loading the surface of up to 60 tons.

- Low installation costs are also the main advantage of this fastener.

- The use of special alloys determines that hardening is not necessary.

- The production takes into account environmental and technical requirements.

The area of application consists in the fastening of axles or shafts of various shapes.

Internal tooth lock washer

The device belongs to hardware, but it is auxiliary, since by itself it does not have any use for fastening, but is used only in tandem with nuts and bolts. Such a washer outwardly does not differ from the usual smooth one, but has small protruding teeth from the inner circumference. It is placed under the fasteners. The teeth give the lock washer a spring-back effect. Thanks to these internal protrusions, the pressure area increases at the joints, that is, where the element is placed. Stainless steel products that prevent unwinding of fasteners are produced. Usually they use the A4 or A2 grade. Some manufacturers produce toothed washers made of carbon steel, but with a zinc coating. Lock washers with internal teeth, regardless of material, must be made in accordance with GOST 10462-81.Analogs of the element are two types of washers with form J (DIN 6798) and I (DIN 6797). This does not mean that they completely correspond to the declared properties of the washer with internal teeth, therefore it is imperative to check this moment directly with the manufacturer.

Locking persistent quick-release washer

In some cases, it is necessary to ensure a quick dismantling of the mechanism. For this, a quick release thrust washer is preferred. It is suitable for cylindrical products with diameters ranging from 1 to 38 mm and more. A variety of alloys can be used in the manufacture:

- Spring steel, which is characterized by increased elasticity.

- Stainless steel with a high chromium concentration.

- Bronze. This non-ferrous metal is also highly resistant to moisture and certain chemicals.

When choosing, attention is paid to a fairly large number of different parameters, most of which are indicated in the technical documentation. The main ones are:

- Diameter of a suitable shaft groove. The installation of the fixing element is often carried out in special grooves that are machined into the shaft.

- The outer diameter of the product. It is also indicated in the applicable technical documentation.

- Outside diameter of the shaft. This parameter is considered the most important. In this case, the diameter of the threaded surface can differ significantly.

- Washer thickness. The strength and reliability of the resulting joint depends on this parameter, since axial displacement can cause deformation.

- Groove width.

- Minimum overhang.

The manufacture of a persistent quick-release washer is carried out taking into account the standards that are specified in GOST or DIN... All the required parameters can be found in the tables, according to which the selection of a suitable version is carried out.

GENERAL TECHNICAL CONDITIONS

Official edition

Moscow

Standardinform

2006

General specifications

GOST

10461-81

Shake-proof washers with teeth.

General specifications Supersedes

GOST 10461-63

ISS 21.060.30 OKP 45 9800

By the decree of the USSR State Committee for Standards dated March 31, 1981 No. 1702, the date of introduction was established

01.01.82

The limitation of validity was lifted by the Resolution of the USSR State Standard of December 27, 1991 No. 2209

This International Standard applies to punch and groove lock washers with internal and external teeth for threaded fasteners.

1. DIMENSIONS

1.1. Toothed lock washers should be shaped and dimensioned to meet design and size standards for specific washer types.

1.2. A diagram of the construction of the symbol for the lock washers with teeth is given in the appendix.

2. TECHNICAL REQUIREMENTS

2.1. Lock washers with teeth must be manufactured in accordance with the requirements of this standard according to working drawings, approved in the prescribed manner.

2.2. Material and coating grades must correspond to those indicated in the table. The hardness of steel washers should be 43.5 ... 47.5 HRC3, 419 ... 477 HV, and bronze no less than 90 HRB or 190 NU.

|

Material |

Coating |

||

|

View |

Type designation according to GOST 1759-80 * |

Designation and minimum thickness according to GOST 9.306-85 |

|

|

Without cover |

— |

— |

|

|

Steel 65G in accordance with GOST 14959-79 |

Zinc chromated |

01 |

Tsb.khr |

|

Cadmium chromated |

02 |

Kdb.xr |

|

|

Zinc |

09 |

Ts6 |

|

|

Bronze Br KMts 3-1 |

Without cover |

— |

— |

|

GOST 18175-78 |

Nickel |

03 |

H6 |

* GOST 1759.0-87, GOST 1759.1-82, GOST 1759.2-82, GOST 1759.3-83, GOST 1759.4-87, GOST 1759.5-87 are in force.

Official edition ★

Reprinting prohibited

Edition with Amendment No. 1, approved in March 1986 (IUS 6-86).

Allowed:

make washers from other materials with mechanical properties not lower than the properties of the materials indicated in the table,

apply other types of coatings in accordance with GOST 9.306-85, not listed in the table.

Technical requirements for coatings - in accordance with GOST 9.301—86.

(Modified edition, Amendment No. 1).

2.3. The hydrogen brittleness of the washers that occurs during the coating process must be removed.

2.4.The surface of the washers must be clean, free from captivity, sunsets, bubbles, shells, cracks, material delamination, burrs, scale, rust.

2.5. The edges in the notch points of the teeth of the grooved washers must be sharp and directed along the radius.

2.6. The washer teeth must be set so that they resist unscrewing of the right-hand threads.

2.7. The protrusion of the teeth H on both sides of the flat part of the washer should be uniform, while the larger size of the protruding teeth on one side should not be more than 1.2 times smaller than the size of the protruding teeth on the other side.

(Modified edition, Amendment No. 1).

2.8. After testing the washers for elasticity, the height of the set of teeth H must be at least 0.8 from the height of the set before the test.

2.9. After testing the washers for torsion, the washers should be free of cracks.

4. CONTROL METHODS

4.1. The method of measuring hardness is in accordance with GOST 9013-59, GOST 9012-59, GOST 2999-75.

The hardness is measured on 3-6 reference specimens supplied for heat treatment together with

washers. Before measuring the hardness, the decarburized layer must be removed.

(Modified edition, Amendment No. 1).

4.2. Quality control and coating thickness - in accordance with GOST 9.302—88.

4.3. The test of the elasticity of the teeth is carried out by compressing and holding the washer in the device for 24 hours.

Steel washers should be tested on fixtures made of steel with a hardness of 229 ... 241 HB, and bronze washers - on fixtures made of brass with a hardness of 75HB.

A bolt (screw) of the corresponding diameter with a large thread pitch is screwed in by hand until the lock washer touches the package, and then the washer is squeezed by tightening the bolt with a wrench at an angle of 120 ° -150 °.

(Modified edition, Amendment No. 1).

4.4. Torsion test of washers: cut the rim of the lock washer and spread it axially to a distance equal to half the inner diameter of the washer.

5. MARKING AND PACKAGING

5.1. Temporary anti-corrosion protection, packing of washers and labeling of containers - in accordance with GOST 18160-72.

(Modified edition, Amendment No. 1).

APPLICATION

Mandatory

Washer

Scheme for constructing a conventional designation of lock washers

X.

1

XX.

2

X ... X.

3

XXX

GOST X ... X-XX

6

1 - execution. Execution 1 is not specified; 2 - thread diameter of the fastener; 3 - material grade; 4 - conventional designation of the type of coverage; 5 - coating thickness; 6 - designation of the standard for a specific type of washer.

An example of a designation of a lock washer of version 1 for a fastener with a thread diameter of 12 mm, made of 65G steel, with a chromated zinc coating 6 microns thick:

Washer 12.65G.016 GOST 10461-81 APPENDIX. (Modified edition, Amendment No. 1).

Washer types

The din lock washer is often used as a fastening element, which excludes the possibility of unscrewing under normal operating conditions. It should be borne in mind that there are a fairly large number of different types of such products, the classification is carried out according to the form and type of material used. An example is the fact that spring steel is often used, which is characterized by high elasticity. All lock washers are divided into several main groups:

- Grover.

- Serrated.

- Poppet.

- With special notches and grooves.

- With paws.

- Wedge.

All varieties of lock washer types have their own specific features that must be taken into account. An example is the common version with internal tines or grooving. Their features are as follows:

- The main part is represented by a ring made of metal.

- Cuts are created along the surface, located in different planes.

In most cases, the washer is manufactured using spring loaded steel. During the production process, it undergoes elastic deformation, due to which the likelihood of spontaneous unscrewing of fasteners is excluded

Almost all Grover type retainers have a square cross section.At the same time, for a significant expansion of the field of application, an anti-corrosion coating can be applied to the surface. The problem with most metal parts is that prolonged exposure to high humidity causes rust to appear, and over time it reduces performance.

There is also a split washer on the market that is flat or tapered. In this case, depending on the field of application, the teeth can be located inside and outside. This group is divided into several subgroups:

- Poppet.

- With different paws.

- With protrusions.

A lock washer with lugs is used when it is necessary to ensure high reliability of the connection. The multi-footed surface engages with special grooves, thereby eliminating the possibility of the fastener turning. The feet can be of different lengths.

Requirements

Lock washers with internal lugs, necessary for locking the slotted nuts, must comply with the requirements and standards of GOST, in particular, applicable to products of accuracy class A.

Technical requirements for these parts:

- the absence of any marriage, defects and damage - cracks, tears, burrs, sharp edges, shells;

- absence of traces of corrosion, rust;

- the domestic standard requires 6 legs at an angle of 25 degrees;

- the material of the product must be durable and at the same time plastic - when bending the legs, cracks should not form on them, therefore, different metals are taken as raw materials for the manufacture, but mainly brass, stainless steel grades A4, A2, carbon steel;

- a certain mass is provided for metal products;

- washers can be covered with a protective layer made by zinc, chromium or oxidation, but the absence of an anti-corrosion coating is also permissible;

- each part must be made in accordance with drawings and dimension tables, taking into account the type of washer and the thread diameter of the slotted nuts.

However, some corrections are allowed - corner tolerances, production of parts with different thicknesses, in addition to that indicated in the table of standards.

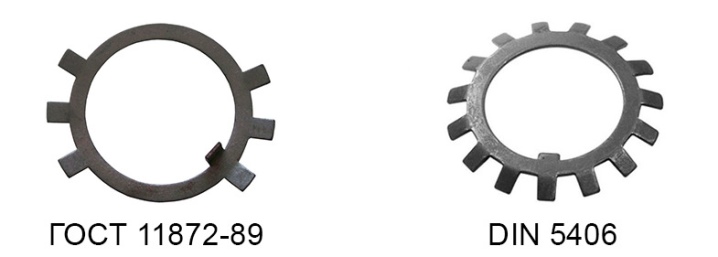

I must say that in our country multi-footed washers are used, which are oriented not only to the Russian GOST. Often, parts made in accordance with DIN 5406 are used. But these standards should not be considered completely identical, especially since DIN products often have a larger number of internal protrusions and other differences.

Locking Washers for Threaded Fasteners

Screw connections are very widespread today. This is due to their simplicity and reliability. However, there is a significant drawback - the nut can be unscrewed under the influence of an applied load or vibration. That is why a lock washer with internal teeth or their external location is used. The features of their application include the following:

- The possibility of arbitrary unwinding under the influence of vibration and applied load is excluded.

- The reliability of the connection is significantly increased.

- The cost of the washer is relatively low, but it can be installed in critical and expensive mechanisms.

There is also a lock washer with external teeth, which are widely used. The choice of a suitable part is carried out depending on the area of use of the mechanism.

Application area

Washers, acting as a stopper for the connection and fastening of various parts, equipped with internal teeth, are used as linings for fasteners in conditions where there is vibration and risks of deformation. They allow you to reduce the impact of negative factors, that is, to reduce the degree of rigidity on the parts.In other words, hardware products are used on "moving" or constantly exposed to external influences. Lock washers with teeth on the inner circumference are widely used in household connections. Most often they are used in the furniture industry and wood construction. They are used in conjunction with pins, screws, pins, bolts. The main condition for creating a connection is that the sizes of these elements match.