Manufacturers

All furniture factories work with veneer, but we will consider the most popular of them, whose furniture really deserves attention.

- "Shatura-Furniture". A domestic company has been pleasing us with its products for half a century. She has a network of branded stores throughout the country. The quality of the furniture has been repeatedly noted with awards at various exhibitions.

- Rival. One of the ten best factories in Russia. The furniture is presented with good design and excellent fittings.

- Pinskdrev. The largest Belarusian holding company with 130 years of experience. He became famous for the release of environmentally friendly furniture using high-quality veneer.

- IKEA. A famous Swedish manufacturer that produces affordable and diverse products based on wood, composite panels and veneers.

Veneer and its varieties

It is impossible to understand what veneered doors are without knowledge of the material itself. So, what is veneer, and what types is it divided into?

- Fine-line veneer. This type of material is made from natural wood, and this characteristic helps to give it any structure. For the production of fine-line veneer, wood varieties are used that are characterized by a high growth rate. The structure of the material is well developed, so you will not find repetitions of the pattern in it. Veneer is characterized by high porosity, so a lot of glue is required to fix it.

- Natural veneer. This type of material is made from solid wood by removing a thin layer from it. The structure of the wood is preserved, and the cost of natural veneer is in the middle price range, which makes it possible for people with a low income level to purchase it. Veneer is much cheaper than natural wood, but more expensive than chipboard panels. Environmental friendliness is considered an additional advantage of the material. The pattern on the surface is characterized by uniqueness and sophistication.

- Multi-veneer. This type of material is made from natural wood and has good decorative characteristics. The multi-veneer is made with different shades and patterns, so it can be matched to different types of interior.

- Eco-veneer is a new material characterized by multi-layer, manufacturability and naturalness, the structure of eco-veneer repeats the texture of real wood. From a distance, the material is very similar to real veneer, but close up the plastic texture is still visible. At the same time, with the help of eco-veneer, you can create an imitation of wood of any kind and of various colors. The advantage of eco-veneer lies in its resistance to temperature extremes and humidity, as well as durability. Doors made of eco-veneer are characterized by durability, retaining their texture and shade for many years of operation. Such structures are resistant to ultraviolet radiation, not prone to deformation under the influence of mechanical factors. Such a decorative coating is resistant to acids, detergents and chemical solutions.

Today, veneer is considered a demanded and popular type of decorative material that allows you to create an imitation of natural wood.

Interior veneered doors basically contain a frame made of solid pine and covered with MDF on top. The cladding for such a door is made of veneer sheets, a special material that is natural wood of a very small thickness (from 0.2 mm to 5 mm).

Door structure

Wood veneer is often found in construction, and doors with its use are more and more in demand, since they look chic and expensive in the interior. Natural veneer is made from different types of wood. All of them are characterized by a high level of strength. These are mainly ash, mahogany, walnut, oak. It is recommended to fix the veneer on a base, also made of wood, and it is best to cover the material with varnish. Outwardly, such doors are no different from real wood.

How is veneered MDF made?

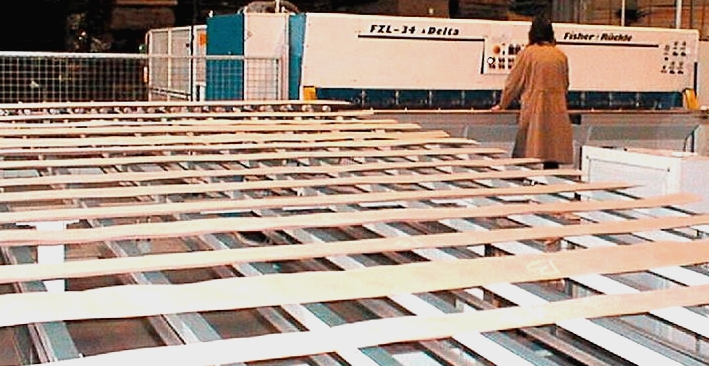

The manufacture of such material is a rather laborious process, however, with the help of high-tech equipment and the skill of workers, excellent results are achieved. The factories use fully automatic mechanisms and high quality raw materials.

Natural veneer comes to factories in rolls or packs, packaging is carried out taking into account the required dimensions and properties that will differ in the final product. Experienced craftsmen put prepared veneer sheets on the prepared and treated MDF surface with a special adhesive. When using roll raw materials, gluing is carried out in one step. When gluing veneer, which is brought in in packs, a special technology is used. It consists in longitudinal and transverse gluing, which resembles a fish bone. There are other gluing methods. But all processes are necessarily strictly controlled by employees and using a computer that carries out measurements and settings. The veneer is glued to MDF boards with an adhesive. The next step is press drying, after which the surface still needs to be sanded and varnished. Today, many industries use a high temperature drying press. It makes it possible to glue veneer on many MDF boards in a short time, therefore, much less time and money is spent on warehouses for drying the final product. Provided that the surface of MDF is uneven, for example, on curly door plates, the technique of vacuum gluing is used. However, this process is more costly and time-consuming.

After all these procedures, the resulting veneer plate must be sanded first across, and then along. Only after that a perfectly smooth surface is obtained. In addition, in order for the varnish to lay down more evenly, the veneered surface must be ironed with a hot roller. This must be done because there is a possibility that the wood grain on the veneer will rise during the application of paints and varnishes. As a result of this painted surface, bumps or depressions can form, which greatly spoil the appearance and quality of the final product. For this reason, ironing technology is used, during which excess fibers are soldered to the surface, and it becomes completely smooth.

The slab is painted with transparent or opaque varnish, colored paint, as well as special wax.

Despite the fact that there are huge reserves of forest in the world, wood is still a valuable and expensive material. Therefore, veneering MDF profiles or panels is the most profitable solution than solid wood.

Veneered MDF panels

Let's see what veneer and MDF are. Veneer is a thin cut of wood. It is obtained by sawing or peeling timber, most often of elite varieties, for example, oak, elm, maple, walnut and others. In appearance, veneered MDF is very similar to the wood of valuable varieties of trees. However, the cost of such furniture is much lower than that of solid wood furniture. The primer and varnish, which the veneer is covered with, reliably protects the material from mechanical damage, and also makes the furniture more noble in appearance.

Designers are very fond of veneer for the wide opportunities for the implementation of creative ideas, as well as for the natural origin of furniture and interior items in general.

There are several types of coatings for veneer products, such as spray-applied polyurethane varnishes or roller-applied acrylic varnishes. Such paints and varnishes make the product not only more aesthetic, but also form an ideal surface. Also, veneer can be dyed during the varnishing process, which is not applicable for already made synthetic finishing materials. After varnishing, the furniture becomes matte or glossy.Complex geometric patterns can be applied to the veneer surface. If damage has formed on the furniture, then it can be quickly removed. However, the main positive difference between veneer and other finishing materials is its high level of environmental friendliness.

Of the minuses, a rather high cost can be distinguished, but it fully reflects the high quality of the material.

The MDF board itself is made from fine wood chips, which are pressed at elevated temperatures and under high pressure. No additional materials are used to glue the particles. At high temperatures, lignin is released from wood - this compound is completely organic and does not pose a danger to human health.

What can be made of such material, besides furniture? Various veneer products are perfect as finishing materials. In building supermarkets, a variety of profiles, panels, skirting boards are sold, which will be a great addition or even the main accent of the interior of your apartment.

With the help of such panels, you can finish all walls and ceilings, you can do it partially.

Often, of all the profiles of such a plan, cornices, baguettes, as well as MDF veneered skirting boards for the floor or ceiling are used. They are perfectly combined with other finishing materials, for example, decorative plaster, stucco, wallpaper or laminate.

The veneered walls will be the highlight of any interior. Today this type of finish is very popular. Veneer is appreciated primarily for its versatility. The use of veneer is very wide. It is used for wall decoration, flooring, furniture and doors. In addition, such material is often used on yachts, terraces, offices and even expensive car interiors.

The second advantage is environmental friendliness. Natural finishing materials do not pose any danger to human health, they do not cause allergies. Wood motives always look expensive and elegant.

There are a huge number of shades and textures of veneer panels. Unique panels, mosaics, and inlay are made from veneers of different types of timber.

Also, the advantages of veneer include:

- easy care. You just need to wipe the veneered elements with a napkin without using detergents and cleaning agents

- light weight. Such materials are much lighter than those of a solid board.

- rational use of natural materials. For the manufacture of veneered furniture, much less wood is consumed. Therefore, buying such furniture, you save the forest.

Which doors are better veneered or foil eco-veneer, PVC

Veneer or eco-veneer, now often the choice sounds like this. We have already talked about the advantages of ecopon, how durable it is, well conveys the appearance of natural wood and the price is not high. And against this background, sellers, vparivaya their doors, often begin to offend products made from natural veneer, such as expensive, fragile, they are afraid of moisture, scratch, everything will unstick, etc. We disagree with this.

Yes, eco-veneer is cheaper and maybe better withstand shock and scratching, but that's all. The main advantage of natural veneer is that doors from it really look better, they are natural, you can see it right away, many cannot be distinguished from the most expensive doors made of solid oak or ash. No matter how high-quality the film material is, in any case it is clear that this is a fake wood, and not the wood itself.

Door with gray eco-veneer for flooring

Dale on the list. Are veneered doors afraid of moisture? In the previous paragraph, we did not specifically talk about what the veneer is covered with on finished products. It is tinted to the desired shades and covered with protective compounds, varnishes of various types, which, by the way, are not worse than films in terms of strength.

The veneer is dyed, and the paint is also an excellent moisture barrier.All this is done with the doors already assembled, i.e. cover them entirely, without seams or gaps. Therefore, the surface of the door leaf is protected no worse than that of an eco-veneer.

Veneered bathroom door

If we imagine that the doors are installed in a small bathroom, where condensation periodically flows down all surfaces, then the situation is the same for veneer and eco-veneer. The first to take the blow will be all the unprocessed areas of the door block: the upper and lower end of the door leaf, cuts and back sides of platbands, boxes and add-ons.

And in this case, it is there that problems can begin: MDF will begin to absorb moisture, swell, and, accordingly, the coating in this place will begin to peel off (any coating, it does not matter veneer or eco-veneer). To protect yourself from this, you need to thoroughly, before installation, coat all these places with varnish

Also, it is better to grease the insertion points of the fittings (handles, locks, wraps, hinges) before installation.

To protect yourself from this, you need to thoroughly, before installation, coat all these places with varnish. Also, it is better to grease the fittings inserts (handles, locks, wraps, hinges) before installation.

Eco-veneered bathroom door

Now about the strength and gluing. As we already said, when veneer is applied, it is so firmly connected to the base that it literally becomes one with the frame, if, of course, everything is done with high quality. Therefore, even with very severe mechanical damage, this sandwich behaves as a whole.

Even if a whole piece of material is torn out of the surface by something heavy and sharp, the veneer will not peel off further (as happens with a film coating), but rather behave like natural wood. Therefore, such damage on veneered doors can be restored, for example, with mastic in the color of the coating, which cannot be said about foil doors.

Sliding door with large mirror in wenge veneer

Another plus of veneered doors is a heavier and more durable construction. Because veneered doors in themselves are more expensive than eco-veneered doors, then manufacturers make the door leaf and moldings of higher quality, stronger, without voids and honeycomb filler. This point must also be taken into account when comparing, and not only the beauty of the coating.

But veneer has one unexpected drawback, it fades in the sun, this is a payment for naturalness.

DIY furniture and other wood products: drawings of benches, tables, swings, birdhouses and other household items (85+ Photos & Videos)

Veneered doors what are they?

Veneer door - a structure made of frame, filler and veneer. It plays the same role as furniture upholstery. Under such cladding there can be a door leaf made of wood or, more economically, of MDF.

Such products are popular in the construction market. They have good quality characteristics: decorative data, durability, easy maintenance and versatility. Their appearance organically fits into the classic interior, which cannot be said about plastic products. And the price of interroom doors made of natural veneer is lower than that of solid wood counterparts.

Production technology

Veneer doors consist of a frame, a filler and a cladding layer. Two types of construction are popular: from MDF panels (economical option) and solid wood (more expensive option).

Manufacturing technology of veneered doors from MDF:

- A frame is assembled from an inexpensive tree, for example, from pine.

- Fill with filler - corrugated cardboard;

- Fasten MDF panels to the door frame;

- A layer of veneer is applied.

- A layer of varnish is applied to protect against moisture.

The process of creating products from solid wood differs in that instead of a frame, a wooden canvas is used - often assembled from small pieces. This reduces the cost.

Veneering - the technology of fixing veneer on the base - is of two types:

Hot pressing.The veneer sheet is glued with a chemical composition with formaldehyde at temperatures above 100 ° C. This method is widely used due to its low cost.

Cold pressing. More environmentally friendly, but also expensive. Use glue without formaldehyde, which cures at a temperature of 30–35 ° C.

These methods are used for all types of veneer in the manufacture of interior doors: this is how both natural and multi-veneer are fixed.

Advantages and disadvantages

Veneered doors have their own advantages and disadvantages. They need to be studied before buying in order to make the right choice.

Dignity

The veneer covering the interior doors has many advantages:

- Attractive appearance and variety of shades. Without detailed consideration, the door appears to be made of natural wood. The veneer retains its color, the original grain and knot pattern. Unlike laminated flooring, the pattern is unique and natural.

- Affordable cost: by purchasing doors with veneer, you can save money and decorate your house with valuable species without hitting your budget.

- Health safety, especially for cold-pressed doors.

- Durability: the service life reaches at least 10 years, and with careful use it increases to 15–20 years. Additional coating with paints and varnishes protects the door from moisture and mechanical damage.

- Environmental friendliness. Buying a veneer door, a person indirectly participates in nature conservation. The production of a product requires much less wood material than a solid wood door. There is practically no visual difference.

All this makes veneered interior doors deservedly in demand.

disadvantages

Before buying, you need to remember about the shortcomings of the material:

- When gluing to the door leaf by hot pressing, formaldehyde is used. In a large amount of evaporation, substances can be toxic to humans. Therefore, you need to choose a reliable manufacturer with a good reputation, who monitors the safety of their products.

- Veneer is susceptible to sunlight: its color fades under excessive light.

- The material does not tolerate contact with moisture and temperature extremes. It is used only in indoor heated rooms.

If the house has suitable climatic conditions, then the veneered door will show its best side.

The main disadvantages of veneer

There is no material that does not have at least one drawback. Veneer is no exception.

There are not many of them, but you cannot forget about the cons:

- If the veneer is fixed on the canvas using hot pressing, then formaldehyde is present in the binders. In significant quantities, it is toxic to humans. In order not to harm your health, you need to choose veneer doors only from trusted manufacturers with certificates confirming the safety of the goods.

- Veneer tends to fade when exposed to direct sunlight, because of this, it will eventually lose its decorative effect.

- Veneered doors can only be used as interior doors, always in rooms that are heated. This is due to the fact that the coating does not tolerate sudden temperature fluctuations. High humidity and condensation are contraindicated for veneer.

- Sometimes they try to sell synthetic veneer under the guise of natural. Externally, the materials for the average consumer are not much different.

In order not to spoil the veneer, it must be properly looked after. Do not use abrasive cleaners. The cloth should be wrung out thoroughly before wiping the door. The veneer can be polished with wax polishes to give it a shine and prevent dust from attracting.

Veneer doors are an excellent combination of value and quality. Due to the variety of colors and textures, such products will decorate a room with any interior.In order for veneered doors to last longer, you need to properly care for them, avoid exposure to high humidity and direct sunlight.

Why you should order furniture from Karelian birch from the company "Derevyagino"

Do not miss the opportunity to buy furniture made of Karelian birch in Moscow by contacting Derevyagino specialists. By contacting our managers, you will receive the following benefits:

- Not only residents of Moscow, but also of regional cities can buy first-class furniture from Karelian birch from us.

- We manufacture products of any complexity and size, providing customers with a huge selection of standard projects.

- We have a team of talented designers on staff who are always ready to develop a new project. They will include in it all the client's ideas and suggest their own interesting developments, adapting them to the existing or planned interior style solution.

- Our masters are professionals in their field, as we and our customers have already been able to make sure of it many times. They have extensive experience in working with natural solid wood and create amazing things from it.

- We carry out careful quality control of both the materials used and the finished products.

- We are manufacturers, and buying a product directly from the manufacturer means getting the best price and one hundred percent quality guarantees.

- We love our clients. It is beneficial for us that they come back again and recommend us to their friends. We do everything for this - we listen carefully, take into account wishes, carefully measure, work out the details, check every little thing, quickly and efficiently manufacture, install, give guarantees, while keeping prices at a minimum level.

Thus, furniture made of Karelian birch is a magnificent decoration for a beloved lady or a work office, which will delight with its beauty and retain its original appearance for a long time. Have you decided to buy it? Just give us a call and we will do our best to make you satisfied.

Veneer: description of the main types

On a production scale, wood veneer began to be produced in the 19th century, when Mark Isambard Brunel (Great Britain) received a patent in 1806 for the construction of a planer. Further, a peeling and sawing machine was invented, constantly improving the thickness, uniformity and speed of production of a strip from wood.

To date, the range of veneers has grown tremendously. As materials most often used beams of the highest quality such species as oak, beech, ash, maple, alder, pine, sycamore, walnut, wenge, cherry and many others. Manufacturers offer customers the following types of veneer:

Natural veneer.

1) Natural peeled veneer. Perhaps the most popular type of natural veneer due to its low cost and availability. The thickness varies between 0.1-10 millimeters. For the production of natural peeled veneer, churaki - short rounded logs (most often pine, birch, alder, oak) are cut in a spiral into shavings. Rotary cut veneer is used for the production of plywood, laminated wood, wood-laminated plastics.

2) Sawn natural veneer. High quality expensive veneer used for facing works (parquet, doors, wall panels, stairs). The thickness of the sawn veneer ranges from 1-12 millimeters. Sawed veneer is the oldest type of veneer, which was often used for inlays and making musical instruments. This natural veneer is produced on horizontal sawmills or veneer saws. Sawed veneer is made of coniferous wood - spruce, cedar, fir.

3) Sliced natural veneer. This type of natural veneer is most often used in furniture decoration, as it perfectly conveys the unique texture of wood.Sliced veneer is made by planing (cutting) a bar in different directions, which allows you to get all kinds of wood patterns. Sliced veneer is made mainly of fine wood with a beautiful structure: acacia, walnut, beech, oak, Karelian birch, mahogany, etc.

Artificial veneer

This is a plastic film that in appearance imitates the structure and color of natural wood. Artificial veneer is widely used in decorating JSM surfaces.

Multi-veneer

It is a veneer made from natural wood, but reconstructed in such a way that the grain of the wood is not visible (usually). Designers often use geometric shapes as drawings. The multi-veneer can be of all sorts of shades and looks very stylish. Thanks to this "chip" - wood that does not look like wood - multi-veneer is often used in the creation of modern interiors.

Fine-line veneer

This type of veneer, like the previous one, is made from natural wood and reconstructed, but in such a way that the veneer texture resembles natural wood. Fine-line veneer is made from fast-growing tree species, the beams of which are first peeled, dried, dyed, glued, pressed, and then planed again, thus obtaining a veneer with the required color, structure and texture. This is the main advantage of fine-line veneer: the ability to choose a shade, size, color, etc. True, such a veneer turns out to be quite fragile and porous.

Veneer is quite easy to use - even at home. You will learn how to properly veneer (veneer) from the next article.

Tatiana Kuzmenko, member of the editorial board Sobkor of the Internet edition “AtmWood. Wood Industrial Bulletin "

How useful was the information for you?

Features of interior doors

The main criteria for choosing interior doors are color heterogeneity, low price, practicality and originality of design. It is the fulfillment of all these points that will help make the room light and harmonious and save the contents of the owners' wallets.

For a competent arrangement of living space, it is necessary to choose the right interior doors. Veneer, in comparison with other types of cladding, will most successfully cope with the task. Its indisputable advantages are a unique pattern, natural shades, high wear resistance, the possibility of reconstruction without replacement. After surface treatment with a special varnish, veneered doors tolerate a humid climate well and are easy to clean.

Peculiarities

The seamless texture of the veneer allows it to be used for finishing door panels, furniture, decorative wall panels. Oak veneer externally is a thin plate up to 3 mm thick. To understand what it is, imagine the peel of an apple being carefully cut off with a sharp knife. Finished wood cut plates are glued to a base made of denser materials - this is how veneered chipboard or MDF sheets are obtained. The raw material for obtaining a thin cut can be various types of oak, as well as its main parts of the trunk or outgrowths. But there is also a veneer of oak root, which is pre-treated before use.

High quality veneered materials are visually indistinguishable from natural solid wood. With careful handling and proper care, the veneered surface retains its noble appearance for many years. The material is resistant to high humidity, not prone to delamination or cracking.