When it becomes necessary to use putty

Before starting restoration work with parquet, it is necessary to find out what materials should be used to seal defects and flaws that have appeared during operation. If everything is clear with the topcoat, then the question about the putty remains incomprehensible for many owners. According to the recommendations of experts, it is appropriate to use it in the following cases:

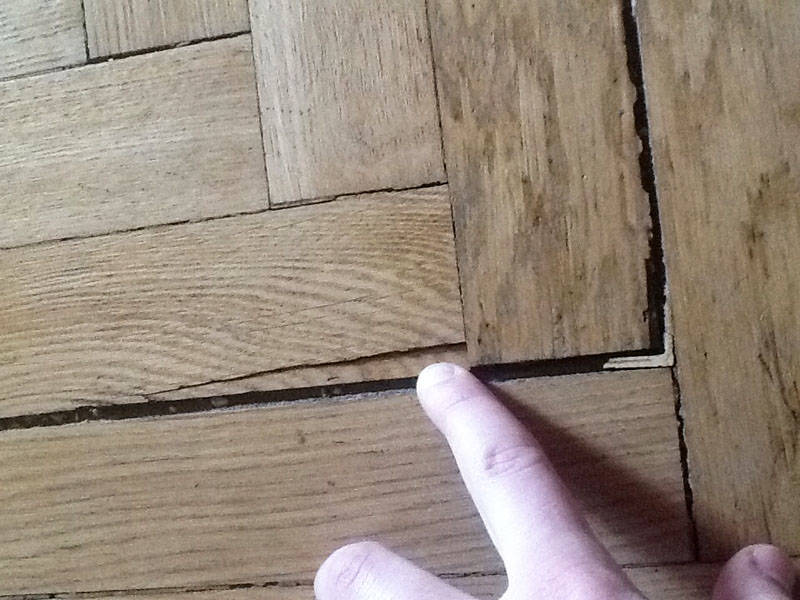

• after laying a new parquet covering to seal the gaps between the dies;

• after prolonged use of the parquet, when potholes, chips, cracks become visible on the surface with the naked eye.

You can do without putty when laying the floor with a parquet board. Usually it is not rigidly fixed, which provides free movement over the surface at different amplitudes. If you treat the cracks with the highest quality putty, then when the boards move while walking on them, the seal will fall out. Also, without the puttying procedure, the installation of a massive board with a chamfer is dispensed with due to a change in the structure of the wood during the drying process.

Types, composition and characteristics of putties

Depending on the method of application and purpose, the following types of putties are distinguished:

- Basic (starting). Used to repair serious floor defects.

- Finish. Allows you to complete the processing of parquet and save it from minor flaws.

- Universal. This type of putty is suitable for any kind of parquet grouting.

In addition, all putties differ in composition. Different components give materials different properties and characteristics.

Solvent-based

The main advantages of a putty containing solvents are its fast drying and high strength. The use of such materials reduces the time for repairing the floor covering. Natural sawdust acts as fillers in the putty, due to which the composition quickly fills all pores and gaps. Solvent-based alkyd putties are also produced, additionally including alkyd resins and linseed, soybean or other vegetable oil. The only drawback of solvent-based products is a strong unpleasant odor. When working, you will have to strictly observe personal protective measures and constantly ventilate the room.

Acrylic

Acrylic based grout is the most popular for parquet flooring. They reliably fill pores, cracks, chips, small grooves, and are suitable not only for parquet, but also for other similar coatings. The composition with acrylic is safe, environmentally friendly, does not harm the body and is odorless.

Among the advantages of such putties, it is worth mentioning elasticity, resistance to mechanical stress, suitability for grinding. Unfortunately, acrylic has a moderate adhesion to substrates and can flake off edges over time, especially with frequent exposure to moisture. The coating with the applied acrylic putty will have to be periodically restored.

Oil

Oil putties contain only natural raw materials - vegetable oils, chalk, water, they are harmless and environmentally friendly. The oil solution fills gaps and cracks well, and is suitable for working with all types of wood, including maple, pine, oak. The putty serves for several years without the need for repairs. The only disadvantage of such products is the long drying time, so the speed of mashing the parquet will be low.

Polymer

Polymer and latex based putties are used for all types of parquet, except for cork flooring.They are laid in a rather thin layer (up to 3 mm), so they practically do not crack. Polymer materials have high adhesion to substrates, even to very smooth ones, they serve for a long time, do not sag, are elastic and very durable. They are not afraid of moisture, water vapor, and can be used in rooms with any level of humidity. The disadvantage of such funds is their high price.

Homemade putties

If necessary, you can make a high-quality parquet putty with your own hands. To do this, you need to prepare a small set of available components and a mixing container. The most popular recipe is as follows:

- drying oil - 0.5 l;

- animal glue - 100 g;

- liquid desiccant - 25 g;

- turpentine - 125 g;

- liquid soap;

- chalk powder.

The glue is heated in a water bath, since it is realized in solid form. Other components are added to it, except for soap and chalk, and mixed well. The two remaining ingredients are added in a small amount so that the mixture acquires the consistency of thick sour cream. The finished mass is immediately used for its intended purpose, periodically heating it, otherwise it will quickly thicken. In terms of quality, such a mixture will be inferior to professional ones, but it will fulfill the main tasks.

There are other recipes that are suitable for making putties. Here are the most popular ones:

- Take PVA wood glue, add equal parts of chalk and small sawdust. Stir the ingredients until a mass resembling sour cream is obtained. Fill the cracks in the parquet with the mixture and leave to dry for a day.

- Mix sawdust and crushed chalk (equal amount) and dilute the mixture with a transparent water-based varnish. Such a mixture dries faster and gives minimal shrinkage, moreover, it is highly elastic. It can be tinted without any problems with a stain or pigment for water-dispersion paint of the desired tone.

- Take a base of sawdust and chalk, dilute it with nitro varnish to a thick sour cream, add color. Apply immediately to the coating, as the nitro varnish dries quickly. You need to work only with good ventilation of the room - the varnish has an unpleasant odor.

Is it necessary to putty the cracks on the parquet at all?

Despite the likelihood of the putty sagging, I believe that it is imperative to putty the cracks on the parquet floor. Why? The fact is that, ultimately, the putty allows you to save the varnish applied to the parquet. So, if the gaps are not repaired, then during varnishing the varnish will flow into the cracks, which will lead to a significant increase in varnish consumption. In fact, the cracks will be sealed, but not with putty, but with varnish itself. Usually, putty is cheaper than varnish, so this option can hit your pocket.

In addition, open gaps can lead to a number of other problems: 1) Pouring into the gaps, water-based varnishes can lead to warping of the wood. 2) When varnishing, dirt will rise to the floor surface from open cracks. 3) The varnish, pouring into the cracks, can come into a chemical bond with various parquet chemistry of the Soviet era, which were usually produced from aggressive substances, which can lead to damage to the varnish film. 4) Unpackaged cracks do not look aesthetically pleasing.

Thus, I always recommend filling up the gaps before varnishing the parquet floor - with minimal additional spending, this will solve many problems. Of course, it should be remembered that the puttying is always carried out in conjunction with the general scraping of the parquet.

If your parquet floor does not hold well and openly dangles, or the gaps on your parquet are very wide (3-5 mm), then really puttying with a standard parquet putty will lead to its very soon crawling out. Therefore, for such cases, we have come up with a special option for filling gaps, which will not only allow the putty to hold on for a long time, but also strengthen your parquet floor. You can ask us about this "secret" method and about any question that interests you by calling us.

Types of putty for wood floor

Today, a large number of different putties for wooden floors are offered on the construction market, which, in terms of composition, can be divided into several main types:

- solvent-based putty mixtures;

- acrylic blends;

- oil putties;

- polymer mixtures;

- hand-made mixtures.

- Solvent-based mixtures contain fine wood chips as the main component, which is considered a reliable coating for all types of wood flooring. The main positive characteristics of such a composition are the ease of use and quick drying of the mixture, which significantly speeds up the process of laying or repairing the floor.

Solvent based blend.

- Acrylic parquet putty also has several positive qualities and is indispensable in the work on the elimination of minor wood defects. It is often used for grouting joints between wooden strips of the coating, since it is environmentally friendly and does not emit toxins when exposed to high temperatures. The main quality is elasticity and resistance to various mechanical loads. Also, acrylic significantly increases the water-repellent qualities of wood and significantly increases its service life.

Acrylic mixture for parquet floor putty.

- Oil formulations contain components such as oil, water and ordinary chalk, which makes it possible to use it on any type of wood. The putty has a very long service life, however, due to the presence of oil in the composition, it dries for a very long time, which significantly reduces the speed of work. Do-it-yourself parquet putty using oil mixtures requires strict adherence to the instructions for use, which is indicated on the packaging from the manufacturer's factory.

Oil mixture for parquet flooring.

-

Polymer solutions are environmentally friendly, usually used in rooms with increased requirements for sanitary conditions. It is used on any kind of wood, except for cork coatings. The main advantages of polymer putty mixtures are the following features:

- filling small voids and cracks;

- smoothing irregularities and other natural defects;

- protection of the end edges of the tree;

- does not settle after drying;

- does not create static electricity, which prevents dust from sticking.

Polymer mixture for wood floor putty.

- Very often, it is practiced to putty parquet from self-prepared solutions, which allows you to significantly save money and make exactly the composition that is necessary for a particular case.

Homemade putty mixture

First option

In order to prepare this mixture at home, you need the following ingredients:

- 500 grams of drying oil;

- 100 grams of animal glue with 10% concentration;

- 125 grams of varnish kerosene or turpentine;

- liquid desiccant 25 grams;

- liquid soap;

- regular chalk in a powder consistency.

Hot animal glue.

Animal glue is heated in a metal container over a fire, stirring constantly. In a heated state, the remaining components are added to the glue and mixed until a mixture is formed, which in consistency will resemble thick sour cream. Such a solution is mainly used as a putty for parquet: oak, aspen or pine.

It is important to remember that the mixture must be used only in a warm state, maintaining its constant temperature during operation.

Option two

The second option is a simpler, but no less effective way of cooking.

To do this, you need to take regular PVA glue and add wood dust to it, which remains after processing your parquet. The dust is mixed with glue to a thick mass (photo) and applied to the surface with a spatula. This type of putty will provide a natural color when sealing joints, but it has its drawbacks.When dry, the glue settles and hardens.

Self-prepared putty from PVA glue and wood dust.

Putty process

Before puttingty the parquet, it must be thoroughly vacuumed and, if possible, wiped with a damp cloth. Puttying is used in all types of work, both when installing a new parquet, and when repairing or maintaining an old one.

The putty is applied to the parquet with a conventional metal trowel in circular or semicircular movements in order to fill all the seams and small cracks as much as possible. After the mixture has hardened, the floor is ready for polishing.

Parquet puttying.

Putty composition and its varieties

Preparing floor putty

Preparing floor putty

Depending on the purpose, the parquet putty can be:

- parquet starting or basic, which is used for "rough" elimination of noticeable holes and irregularities;

- finishing putty mixture is used at the final stage for the final leveling of the floor surface;

- a universal composition of putty for all types of wood is used simultaneously at the initial and final stages of repair. In this case, they perform both "rough" work and the final leveling of the floor.

Depending on the composition, putties are divided into types:

gypsum mix has earned popularity due to its universal purpose. Plus, this composition provides reliable adhesion to the floor surface and has a low cost. They are used both for "rough" work and for the final leveling of the parquet.

Gypsum filler for parquet

Gypsum filler for parquet

- you can use oil putty for different types of wood. A significant disadvantage of this kind of composition is the drying time due to the presence in the oil.

- acrylic parquet putty is used for work related to the removal of minor defects in the flooring. This mixture is environmentally friendly, elastic and resistant to mechanical stress. A significant disadvantage of the putty is the low adhesion of the mixture to the edges of the parquet planks. During operation, the gaps increase, accompanied by the loss of the putty material from the cracks.

Acrylic putty

Acrylic putty

- alkyd putty is made on the basis of flax oil, soybean oil and others. It is viscous, elastic and sandable. Used for finishing work.

- the latex mixture for parquet is recommended for the final decoration works. In this case, it can be used for irregularities up to two millimeters. Otherwise, the surface layer of the parquet may crack. This mixture adheres perfectly to a surface that is smooth and even. In addition, it is worth noting the vapor-proof characteristics of the latex floor putty. The cost of such products exceeds the price of standard gypsum building materials.

- mixture or dispersion requires further development of the composition. In this case, there is no need to purchase a special dye. You can take the rest of the dust from the top parquet layer and mix with the mixture. As a result, you will have excellent material for leveling parquet planks with a recess of up to 6 mm. This is one of the cheapest ways to restore the look of your flooring.

Dispersion for parquet

Dispersion for parquet

Depending on the composition of the base putty there are:

water-based putty is distinguished by its drying speed and environmental safety from the point of view of the complete absence of toxic fumes;

Basic mistakes when working

It happens that the performed repairs soon begin to deteriorate, the putty areas are destroyed. The main reason is the violation of the technology of work when sealing chips, cracks, cracks, as well as when laying parquet. Often, the putty does not last long if the individual lamellas are poorly fixed. They loosen and the mixture cannot hold in the crevice.

Another possible reason for the poor quality of the repair can be the incorrect manufacture of the putty, the violation of the mixing proportions of the components. Also, problems can arise when applying too thin a layer or with a small number of layers, or if the drying time of the material is not observed.

We clean up the floor in every possible way

Keep in mind that wood, as a natural material, can both shrink and expand due to violation of the rules of operation, as well as the ingress of moisture, cracks can form between the boards. The appearance of a cracked or stained floor will definitely make you think about restoration. So, dirty spots and darkened places can be cleaned, well, cracks can be putty.

You can also tidy up the floors made of grooved boards.

It is also important to consider the humidity and temperature of your room here. After all, high humidity in the room can lead to a crumpled surface.

And if the house has central heating, then it is assumed that the boards can contain a maximum of 10% moisture. A chisel and a hammer will help to repair such a floor - we insert a chisel between the boards, hit it with a hammer, and insert a hacksaw blade into the resulting crack and saw along the board itself. In this case, bad boards are cut along the grain.

You can also fight cracks with thin strips and wood sawdust. If they are mixed with varnish or paint, then the cracks in the floor can be repaired. To prepare a special composition, you need to take 4 parts of sawdust and mix with 1 part of varnish or paint of the desired color. If the floor has not been painted before, and you are going to fill up the cracks, then you can use sawdust putty. In this case, the putty for parquet is prepared as follows: a five-liter bucket is taken, filled to the top with sawdust and poured with boiling water. The homogeneous mass should cool down, after which wallpaper glue is added to it and continues to mix. After that, the floor is cleaned with a spatula, and the cracks are covered.

Auxiliary materials for the restoration of parquet

If in some cases it is possible to repair the parquet without scraping, then it will not be possible to carry out restoration work without the use of special compounds. Therefore, as an example, the table contains the materials necessary to put the parquet in order. Moreover, they are used not only for repairs, but also when laying a new coating.

| Repair compositions | Brief description of their affiliation and application |

|---|---|

|

Gel remover for varnish and paint made in Italy by Borma Professional Solutions s.r.l. sold in a 750 ml pack. The basis in this tool is dichloropropane, it has a strong effect, therefore it quickly removes any paint and varnish compositions from wooden surfaces. The gel is non-aggressive towards wood and does not change its color. The wash should be applied in a ventilated area. The gel should be applied generously to the parquet surface with a brush and left for 12-15 minutes to act on the varnish or paint layer. Then the varnish is removed from the coating with a spatula, scraper or scraper. The remains of the varnish are removed with a solvent, which needs to be moistened with a napkin. This way you can clean the old varnish from the parquet without using a scraper. Other formulations can be found commercially for the same purpose. When choosing this material, you need to carefully study its characteristics. |

|

"Borma Holzmasse" is a fast-drying one-component composition of the putty from the same manufacturer, made on the basis of cellulose nitrate with the addition of sawdust crushed into dust. The tool is excellent for filling joints between parquet floors, as well as removing various defects on a wooden surface. Once dry, this putty can be treated with any tool designed for woodworking. Drying time - 7-10 minutes, depending on the depth of the joint gap of the volume of the applied composition.According to the color scheme, the putty should be chosen one tone darker than the wood color. On top of the hardened and sanded putty, any decorative coating made on the basis of solvents or on the basis of water can be applied. The volume of material in this package is 250 ml. In addition to this option, a wide range of different wood putties from different manufacturers is presented in hardware stores. |

|

BORMA Easy Parkettlack matt polyurethane parquet lacquer is ideal for varnishing parquet flooring. After drying, the polyurethane layer gains strength and resistance to moisture, abrasion and UV exposure. The varnish can be used in rooms with high traffic, as well as buildings that are not heated in winter. The coating of this varnish can be damp cleaned with detergents. The composition is colorless, which allows you to preserve the texture of the wood. In addition to polyurethane compounds, you can find epoxy, alkyd and acrylic based varnishes on sale. |

|

Parquet glue is required if you have to dismantle and re-install a part of the parquet. In this case, a two-component polyurethane adhesive sealant is presented, intended for all types of parquet, without shrinkage. The adhesive has excellent adhesive properties, so it can be used to glue parquet to concrete, ceramic or wood substrates. In addition, this adhesive is suitable for the installation of decorative coverings on the "warm floor" system. |

Views

Such a mixture for flooring can be prepared with your own hands or purchased at a hardware store ready-made.

According to the method of application, the putty is divided into several types:

- Basic or starting grout. This option is used to eliminate significant disadvantages of parquet.

- The second group is the finishing one. She completes the treatment of the floor.

- The third type includes universal compounds that can be used on wooden surfaces. They combine the characteristics of the previous two groups.

Also, the putty is divided into subspecies depending on the composition.

Below are some of these subspecies options:

- Gypsum-based mixture. It is very popular because of its versatility, it adheres well to the flooring and has a low cost. Both base and finishing grout are used.

- The oil-based putty is suitable for parquets made from different types of wood. Its disadvantage is the long drying time. This is due to its oily composition.

- An acrylic-based product is used to eliminate and mask small floor defects. The mixture is environmentally friendly, as its basis is water. It is elastic and tolerates mechanical damage well. Its disadvantages include poor adhesion to the edges of cracks after drying. After some time, the crack enlarges, and because of this, the putty can fall off from it.

- The next type is alkyd, made from resins of soybean and linseed oils. The mixture is very viscous, elastic, excellent for grinding.

- Latex-based putty is similar to the previous look, it is also a finish. It is used depending on the unevenness of the parquet flooring to avoid cracks. It adheres perfectly to a smooth surface and has the property of vapor permeability. Its cost is several times higher than the gypsum type.

- Dispersion is a selection of all the necessary components for the preparation of the putty with your own hands.

First you need to choose the desired tone so that it matches the color of the flooring. The composition is easy enough to prepare. It is necessary to mix the dust particles left after sanding with the purchased base. This will give the color the same color as the wooden planks of the parquet flooring. You can putty in an even layer, applying the substance to cracks and irregularities up to six millimeters in size.

The most budgetary primer recipe has PVA glue as a base. Due to its low cost, this method is widely used.

There is a division according to the type of the main substance of the mixture:

- Parquet grout, which has water as the main substance, dries quickly. Also, it does not produce toxic fumes if the temperature is high, therefore it is an environmentally friendly material and completely harmless. But it is not recommended to use it for grouting hard wood species: chestnut, oak, cedar and other surfaces.

- Another type is parquet mix. For example, Kiilto Gap. This option is based on a solvent. It is versatile and suitable for any type of flooring. This putty is more durable than a water-based mixture.

Mixture selection by manufacturer

Swedish BONA can be proud of its water-dispersive acrylic composition "Bona Mix & Fill". This mixture belongs to putties, which acquire the color of the treated parquet when added to it dust after grinding... When it comes to treating clean wood flooring, the best solution is PARKETTGRUND solvent putty as the base.

German Loba has a high-quality water-based putty that adheres well to the surface, dries quickly and with low consumption during operation. But a material based on the LOBADUR Fugenkittlosung solvent is appreciated, since it perfectly adheres to wood flooring and has high elasticity.

Also in Germany, the Uzin company can be distinguished, which is engaged in the production of quick-drying putties for any parquet. Moreover, it is permissible to use them on heated floors.

Italian Chimiver produce a universal putty with universal performance characteristics and ease of sanding after the layer dries. Available in both water-based and solvent-based varieties.

The varieties of mixtures used do not end there. Mixes of Belarusian production will cost the owners cheaper and without loss of quality. Qualified managers of home improvement stores will help you choose the most suitable mixture for a specific coating and room.

How the material is applied to parquet

To make the floor smooth and even without gaps between the planks as a result of using the putty, it is important to apply it correctly to the mounted surface. For this, the base is prepared in three stages:

- cycle;

- dry cleaned from dust;

- wipe with a damp cloth.

The finished solution is applied with uniform movements in a circle using a spatula. After drying, the material is sanded. The use of a putty for the initial treatment of the floor implies the treatment of the entire surface. Repair and restoration work is bypassed by partial filling of areas requiring correction.

This is interesting: Is it possible to disassemble the laminate - we read the main thing

Parquet putty: how to choose a ready-made composition

Many people prefer to create parquet putty on their own, but why, if you can buy a ready-made composition in a special store? They can be of various types and colors. This will give you the opportunity to choose exactly the type that suits your flooring.

Parquet putty is available in various types and colors.

There are 3 main types of ready-made compositions:

- Acrylic. This putty is indispensable if you want to make your floor water-repellent. It is flexible, withstands most mechanical stress and is environmentally friendly. In addition, it can increase the service life of the coating.

- Solvent based. Here, the main component is shavings of various types of trees. It is easy to apply, dries quite quickly, but has an unpleasant odor. Therefore, it is necessary to use such a putty in a room with good ventilation and airing.

- Hot-melt putties. They are a hard type of wax that is used to repair defects. To apply such a putty, you will need a special tool that is used only by specialists. Therefore, it is used on its own very rarely.

All ready-made formulations are produced by the manufacturer, taking into account all the needs of customers. Therefore, it will not be difficult to purchase a finished product.

Plastering and board replacement processes

You can also use a process such as grinding. In order to make a floor without stains, you must first replace the nails with screws in those boards that are loose. Next, use a saw to replace the broken sections of the board with new ones. If the new one is thinner than the old one, then you can place a piece of plywood or cardboard under it. And then fill with leveling mastic.

When starting to putty, you should know the following. In order for the floor to be even and without flaws, lighthouses are filled horizontally. A mixture based on PVA and sawdust is poured between the slats.

Useful tips from knowledgeable people:

- Before mixing sawdust with glue, you need to moisten the sawdust and then squeeze them out a little. After carrying out such a manipulation, the glue will not be absorbed quickly.

- The mixture should be applied in a thick layer (2-3 times). Each layer is about 1–2 cm.

- Only after the mixture has dried can the leveling material be laid.

- For a time-consuming process such as leveling the floor, it is best to use a sander.

- Before scraping, you must first sink (hammer) the nails that are in your floorboards. For this you need a hammer.

- The looping should be started from one corner of the room. In this case, the movement should resemble a "snake".

- The top, most contaminated layer should be removed first, and only then proceed to thoroughly filling the cracks and holes with putty.

- The putty should be selected according to its color.

- You can continue to cycle only after the putty has completely dried.

- The secret to restoring a damaged board is to remove, turn it over and put it in the same place. The board will not differ much in texture and color.

- If you don't have a sander, you can use a hand-held scraper. It is convenient for working in hard-to-reach places (corners).

- After completing the work, we must vacuum the room.

- Before applying varnish, the floor must be wiped clean with a special cloth. It is better to soak it in a solvent.

The main stage

The putty of the wooden floor is carried out in stages. The first layer is the starting (rough) layer. Its purpose is to eliminate large cracks, seams. To do this, use a serpyanka tape. It will help to avoid waste of material, prevent cracks. A gap or seam is coated with putty, let it dry a little, apply a tape on top. Deep cracks can be closed with twine. To do this, pick up a rope of the required thickness, impregnate it with carpentry glue and lay a gap. With the help of a chisel, the twine is compacted. After the glue has dried (a day must pass), you can start applying the solution.

When doing the finishing putty with your own hands, the solution can be made more liquid. This will allow you to apply it in an even, thin layer (approximately 1.5 mm). The finished coating is cleaned with dry sandpaper. If a nitro putty was used, then the skin must be moistened with turpentine (when using ordinary paper) or in water (if the paper is waterproof).