Varieties of products

Sheetrock products are manufactured in America and five European countries. The manufacturer has earned a reputation for quality over a hundred years. Modern manufacturing technologies and a unique composition make the products a versatile material for interior and exterior decoration.

Today on the construction market there are three main types of fillers from the Ready-Mixed category (which means ready-to-use products):

Sheetrock Fill Finish light. Used for leveling minor defects, sometimes for surface lamination. The latex component makes the material resistant to moisture and completely eliminates the possibility of cracking during its operation.

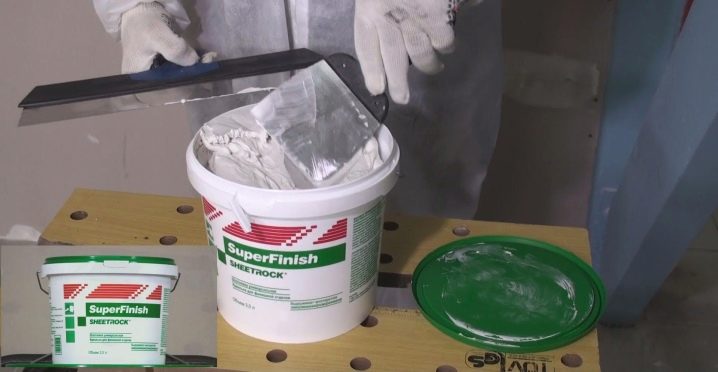

Sheetrock Superfinish. This is Shitrok finishing putty. Can be applied as a final finishing coat. The material has high adhesion, but at the same time insufficient for screed deep cracks and processing corners.

Sheetrock All Purpose. This putty is considered universal, therefore it is suitable for any type of finish. The product is often used for texturing, sometimes used to fill spaces in masonry.

Peculiarities

Sheetrock putty is a ready-made building compound used for interior wall decoration. Also on sale there is a semi-finished filler material in the form of a dry mix. In the future, such a mixture will need to be diluted with water in certain proportions. The ready-mixed Sheetrock is easy to use, because you just need to open the container and start finishing work. The constituent ingredients of the mixture (vinyl) make it versatile: it does not require special skills to use. In turn, polymer lightweight putty has its own varieties.

This type of putty has the consistency of a cream, thanks to which it adheres perfectly to the surface. Sheetrock is suitable not only for application on walls, but also for filling cracks, processing corners - all this is due to the components that make up the product.

The mixture has a high density, which allows it to be applied to the surface in an even layer. The drying time of the material is only 3-5 hours, after which you can start sanding the surface. Drying time depends on temperature conditions and layer thickness. Due to its high adhesion, Sheetrock can be used in high humidity environments. This is a big plus compared to other types of putties.

Special mixture Sheetrock withstands up to 10 cycles of defrosting and freezing, which has been proven experimentally. The defrosting process should only take place at room temperature. It is forbidden to influence additional heat loads. Therefore, do not worry if you purchased frozen putty.

Also, this type of finishing material is suitable for any type of wallpaper and paintwork, does not cause chemical reactions. Thanks to the content of environmentally friendly materials, repairs with a putty solution can be carried out in children's rooms and hospitals. The only drawback of Sheetrock putty is the high cost of production.

The areas of application are as follows:

- filling cracks in plaster and brick finishes;

- puttying plasterboard sheets;

- covering up the inner and outer corners;

- decoration;

- texturing.

Finishing stage of finishing

After applying the finishing layer, you must wait until all the applied putty layers are dry. Then you need to smooth out the "bumps" with a spatula so that the surface becomes even.The rest of the mortar is applied to the seams and fasteners. At this stage, a slight addition of water to the mixture is allowed. The applied layers must be well leveled. This will shorten the surface treatment time with a sanding float. It is also worth "walking" with putty on all noticeable defects.

Ready putty mixtures are an ideal option for preparing gypsum plasterboards for further painting. When applying glossy paints, all irregularities and depressions can be visible on the wall. The use of Sheetrock finishing filler eliminates the possibility of such situations.

Consumption

Sometimes it is difficult to determine the right amount of required material. Basically, such difficulties are faced by people who are not professionally decorating, but amateurs who decide to make home repairs on their own.

As for the consumption of Sheetrock putty mixture, it is quite economical and amounts to approximately 1 kg of material per 1 square meter of the room, if finishing on drywall, and 0.51 kg / p. m. per 1 m² when applied to the joint of gypsum board sheets. It is worth considering the degree of readiness of the surface for applying the putty mixture. If the wall is uneven and has many flaws, then a little more material may be needed. If, for example, this is an ideal drywall sheet, then the material consumption may be less than indicated.

Consumption rates of finished putties

Ready putty is a mixture of thick consistency, ready for putty. She is usually used to align ceilings with respect to smooth walls or restore carpentry. It is sold in plastic buckets. Such mixtures are an order of magnitude better in quality than dry ones, since they contain substances that give the putty special properties (increase adhesion, reduce cracking). Although such mixtures are much more expensive, their price is justified by the quality.

Today the Shitrok mixture is in great demand. Experts like it for its economy. Its costs with a thickness of 1 mm will be equal to 0.5 kg / m2. Craftsmen appreciate its simplicity in work, quick drying, absence of asbestos and cracks upon drying.

In addition to this mixture, today Knauf, Pufas and Ceresit are readily used when carrying out repair work. Their consumption can range from 1.5 to 1.7 kg / m2. Consumption of Vetonit putty with a layer thickness of 1 mm is 1.2 kg / m2.

How many bricks are in the pallet: calculations

How many tons of rubble in a cube

Table of consumption rates for some types of putties

| Type of putty | Consumption for 1 m2 |

| Facade putty | 1.18-1.6 kg |

| Vetonite | 1.18 kg |

| Oil and glue | 3 Kg |

| Glue | 0.47 kg |

| Gypsum | 0.85 kg |

| Finish | 0.44 kg |

| Shitrok | 1 kg |

When preparing for finishing work, remember that their quality depends on the correct choice of material, including putty. When choosing it, consider the quality and nature of the surface. Be aware that at different stages of work you need a different amount of mixture. If the wall is flat, then the starting putty will need about 1 kg / m2 with a thickness of 1 mm, and the finishing 0.5 kg / m2 with a thickness of 0.5 mm. With an increase in the layer, the consumption will also increase. One layer of putty is rarely enough. The second layer will be thinner. Do not forget that ready-made mixtures are of higher quality and more economical. Remember that you need to add a little more to the calculated volume of the mixture, because the minimum amount will remain on the spatula and bucket.

Recommended to read

Cement consumption for 1 cubic meter of concrete

Consumption of water-based paint per 1m2

How many bricks are in one cube (1m3): calculations

Subtleties of application

Tools for applying Sheetrock putty:

- spatulas (width - 12.20-25 cm);

- Sheetrock Joint Tape

- sponge;

- sandpaper.

It is necessary to apply the topcoat on the prepared surface, which has been pretreated with a filler for leveling, plastered or sanded. The surface must be free from unevenness and cracks.It is necessary to apply the first layer of putty on completely dried plaster, otherwise, mold will form over time. A small amount of putty is collected on a wide spatula, then stretched in a uniform layer over the entire area of the wall or ceiling.

Next, you need to let the first layer dry. The next layer is applied only to the completely dried previous layer. To obtain an ideal surface condition, experts recommend sanding each layer of putty using an abrasive mesh with a grain size of 180-240 units. The maximum number of layers is 3-4. After all work, the treated area is cleaned of dirt and dust.

If necessary, you can dilute the composition with water, but you need to add it in portions of 50 ml, followed by stirring. A large amount of water will only worsen the adhesion of the solution to the surface, but the result obtained will not give the desired effect. It is forbidden to mix the putty mixture with other materials. Stir the frozen putty mixture to a homogeneous consistency without lumps and air bubbles.

To prevent the applied finishing material on the walls from freezing, it is recommended to cover it with a heat-insulating coating (foam). At the end of the finishing, the putty remaining in the container must be tightly closed with a lid. Store at room temperature.

Sealing with Sheetrock:

- close up the seams (trowel width - 12 cm);

- install the tape in the center, which must be pressed into the wall;

- the excess putty mixture must be removed, applied in a thin layer on the tape;

- screw head putty;

- after one hundred percent solidification of the first layer, you can proceed to the second. For this, a spatula 20 centimeters wide is used;

- give time to dry the second layer of putty;

- Apply a thin layer of finishing filler (trowel 25 cm wide). The same layer is applied to the screws;

- if necessary, smooth the seams with a sponge soaked in water.

Interior corner finishes:

- cover all sides of the tape material with putty;

- the tape is folded along the middle, pressed against the corner;

- get rid of excess mixture and apply a thin layer to the tape;

- give time to harden;

- applying a second layer to one side;

- drying;

- applying 3 layers to the second side;

- give time to dry.

Outside corner finishes:

- fixing a metal corner profile;

- application of three layers of putty with preliminary drying. The width of the second layer should be 10-15 cm larger than the previous one (the width of the spatula is 25 cm), the third layer should slightly go beyond the previous one.

Texturing:

- apply Sheetrck filler to the required area with a paint brush;

- texturing technology using special tools (paint roller, sponge and paper);

- drying time is about 24 hours at air humidity 50% and temperature + 18 degrees.

Grinding putty:

- To carry out sanding work, you will need a sponge and sandpaper.

- A sponge moistened with water is wrapped in paper. This is necessary in order to generate less dust.

- Grinding is carried out with light movements along the resulting irregularities.

Sheetrock, Knauf "Rotband paste" or Vetonit LR - which is better

The listed materials are the most popular among finishers. But there are features that must be taken into account when choosing. So, Shitrok creates the smoothest surface even without sanding. After sanding it must be primed, but you can skip this step without sanding. Shitrok is ideal for painting, the most durable.

A primer must be applied on top of Vetonit, this material is best suited for subsequent wallpapering. The disadvantage of Vetonit in comparison with Shitrok is its lower plasticity, but the color is perfectly white. Another disadvantage of Vetonit is the need for breeding, while Shitrok is a ready-made mass.

Scope of putty

Shitrok finishing putty is used as a finishing layer before applying paint or wallpapering. It gives walls an even and smooth surface, and also performs the following tasks:

- Elimination of minor cracks and chips on a plastered concrete base.

- Sealing joints when fixing gypsum plasterboards.

- Derivation of angles and straight lines in difficult areas.

- Giving a textured shape to a surface.

Due to the versatility of the use of the composition, the putty is intended for interior finishing work, and also has a number of features:

- Versatility lies in the application of the mixture both as a finish and when filling the surface.

- Sheetrock is ready to use. There is no need to knead it, but you can start working right away.

- Shitrok material has an oil composition, due to which it is easily and evenly applied to the surface.

- Due to the density and characteristics of the components, the layer is even and beautiful, does not require significant sanding or grouting.

- Finishing putty Shitrok is packaged in buckets of 17 and 3.5 liters. Based on the consumption per square meter, you can determine the required amount of kilograms of material for work.

- The applied composition dries quickly. As a finishing finish 3-5 hours (1 layer).

- Both a professional and a beginner can work with the material.

What determines the consumption of putty

The consumption rate of the putty depends not only on the surface area, but also on its quality. Therefore, before starting work, you should calculate how much material is required for work. The manufacturer indicates on the packaging how much putty is needed for 1m2. The norm of the starting putty is indicated for 1 cm, and for the finishing one for 1 mm. First you need to build on this information. But these are approximate figures, since the consumption of the mixture depends on many factors:

- From the state of the surface. Are there any cracks and how deep are they? How flat is the work surface? Are there many rough edges on the wall or ceiling? The better the surface, the less putty will be required.

- From the surface material. Different materials require different amounts of putty.

- Stage of work on leveling the surface. The initial stage consumes a greater mass of the composition than the final one.

- Employee qualifications. The non-professional will need more material for the job.

How many liters of water are in a cubic meter?

Primer consumption per 1m2: what is needed and consumption rates

Peculiarities

For fast and high-quality work with drywall, it is recommended to use only first-class finishing materials, use auxiliary tools from trusted companies and additional accessories. Combining all of these factors increases productivity and improves the bottom line. One such product is Sheetrock putty.

The advantages of such solutions are obvious:

- improved technical characteristics;

- increased operational life;

- homogeneity and uniformity controlled in each batch;

- prolonged use (compared to self-prepared fillers).

The product is available in packs of 28 and 17 liters. You can rest assured of the quality of the composition, since it goes through 10 freezing / thawing phases during experimental tests and does not lose its properties at all.

If Sheetrock is exposed to frost, try to thaw gradually. Never use hot water and heaters for heating. Let the mixture stand indoors at room temperature. Then stir the product until a homogeneous mass is obtained, simultaneously getting rid of air bubbles.

Preparation for work

Stir the contents of the container, you do not need to add water. Apply solution to corner protectors, fastener heads. For sealing joints with construction tape, it is allowed to add a small amount of water (it varies from 50 to 60 ml).

Drywall seams

The heads of the fasteners (self-tapping screws, screws) should be sunk into the surface of the drywall so that they do not protrude. To do this, you need a screwdriver or screwdriver. Then apply a continuous layer of Sheetrock with a stainless trowel, filling the joint between the drywall sheets. Slightly sink the paper tape into the filler layer. While tilting the spatula, slide it over the tape. Press down firmly on the tool to release the excess solution.

A filler layer of about 1 mm should remain under the construction tape. Then another layer of the mixture should be applied to prepare the substrate for the next finishing step and to protect the tape from edge curling. Wait until the joint is completely dry.

After the entire surface has got rid of moisture, you can proceed to the next stage of puttying. Take a wide spatula (about 20 centimeters) and start the second step of application.

Using protective corners made of metal on a paper base

Paper-backed corners have the same function as regular metal or PVC corners. But they are used when the connecting tapes are glued, and not when the drywall is being installed to the base. Their plus is that the paper base in any case has better adhesion characteristics than the usual metal one. Such a corner creates a stronger and more homogeneous structure, increases the resistance to cracking, which can occur as a result of natural shrinkage of residential buildings and industrial premises.

The difference between these corners and conventional metal and vinyl corners is that the Sheetrock corners are glued with putty, and the normal corners are simply put on. Paper-backed corners ensure that subsequent layers of putty, decorative plaster and other materials have good layer-by-layer adhesion. The corner is pressed into the putty layer, after drying it is putty.

How to choose?

When asked which putty is better, acrylic or latex, it is worth knowing that latex would be the best option. This is due to the fact that acrylic does not have a sufficient thickness that would create a high strength of the material. Ready-made polymer putty Sheetrock is a professional solution to any problem of interior decoration of walls and ceilings. It has been verified by experimental experiments. There is a product quality certificate. Its presence allows not to be mistaken in the choice of this material.

The choice of the type of filler material depends on the existing problem:

- SuperFinish solves the problem of surface finishing;

- Fill & Finish Light is used for finishing gypsum boards;

- the purpose of ProSpray is mechanized processing.

Methods for applying the composition

The initial action before applying the putty is to prepare the surface. Usually the material is applied in several layers. The plane must be leveled so that there are no sharp drops, remove the old fraction. Then prime the base with special compounds. Then the bucket is opened and, according to the instructions, the contents are thoroughly mixed with a spatula. Next, you can start working on applying Shitrok putty on the plane. When processing the seams, the mixture is applied by means of a connecting tape, onto which the material is pressed. There are 2 ways:

- Manual - using a spatula and improvised tools to work with the composition.

- Mechanical - carried out using a spray gun with a spray of material over the surface.

After the work is over, do not throw the remaining putty down the drain, as this can lead to a blockage. And the tools involved in the process, it is enough to rinse with running water, without soaking and scraping. The surface should be left to dry for three days. The material will shrink slightly. After that, you can glue the wallpaper or apply paint.

Shitrok universal building compound allows you to level surfaces made of different materials. The composition fills cracks and joints, making the substrate uniform and smooth. The material provides excellent adhesion to the plane, and its ductility makes it possible to get the job done quickly and efficiently.

Views

Sheetrock is available in three versions, each with its own range of applications.

Their description:

Sheetrock Fill Finish Light. This type of mixture is characterized by maximum strength

This is especially important when a thin layer needs to be applied. It is mainly used for restoration

It is also beautiful in tandem with drywall.

Sheetrock Superfinish (Danogips). From the name itself, the purpose of the putty is clear - finishing. It is characterized by minimal shrinkage and is not used for sealing joints.

The technology for creating Sheetrock wall decoration cosmetics is constantly being improved, meeting the most stringent requirements and needs of the client.

Precautionary measures

It is necessary to remember about the safety rules that must be observed during construction work with Sheetrock material:

- If the putty solution gets into your eyes, you must immediately rinse them with clean water;

- when performing dry sanding of the material, it is recommended to use protective equipment for the respiratory tract and eyes. Finish with gloves;

- it is strictly forbidden to take the putty mixture inside;

- keep away from small children.

If the use of putty occurs for the first time, then it is better to give preference to branded manufacturers with positive reviews. Sheetrock putty has only proven itself on the good side. According to the description of the technical characteristics and the technique of applying the material, it can be seen that the finishing work is not particularly difficult.

For an overview of Sheetrock Finishing Putty, see below.

Additional Information:

Ready shitrok 17L is a highly effective putty building material, completely ready for use. High performance and technical characteristics of products are due to the use of special technology and a range of special ingredients in the manufacture. The finished sheet of 17 l, due to the presence of vinyl fibers in the product, is capable of retaining the plasticity of the resulting finish for a long time.

An important advantage of the product is the economical consumption of the putty composition and fast drying. Practical shitrok 28 putty is a completely ready-made composition for the implementation of high-quality finishing work indoors. Therefore, shitrok 17 putty eliminates errors that occur during preparation from analog building materials of working compositions. You should not also worry if shitrok 17l putty accidentally opens or remains after finishing. It will not dry out.

What are the advantages of Shitrok 17l putty

It is worth noting that 28kg shitrok putty is recommended for use only indoors. When carrying out exterior decoration and repair work in wet rooms, 28kg sheet putty is not used by specialists, since it is not intended for such work

Universal mix sheetrock 17L ready-to-use for almost all surfaces, from masonry to plastered surfaces. It should be borne in mind that after the sheetrock 28kg has been finished has been applied to the surface to be treated, formulations with chemicals cannot be used in subsequent treatments.

Ready-made sheetrock 17L is extremely easy to use

In order to achieve an ideal processing result, the ready-made shitrok 17 l putty mixture is applied only to the cleaned substrate. In the case when the surface to be treated is porous, it is recommended to prime the working area before applying the shitrok 28 putty.

In the event that plastering processes are previously carried out, it is important to select compatible building materials, preferably from one manufacturer. For example, a guaranteed high result of repair work is achieved if plaster and filler sheet 17 are taken

If shitrok 17l putty is used on plasterboard structures, they must be assembled according to the technology. It is also important to take into account that 17L shitrok putty is used in finishing works when the temperature is maintained above +13 degrees.

Economical in consumption shitrok 28kg putty is the most convenient to use. For 1 sq. meter of the processed area requires about 400 grams of product. This putty building material is relevant in the course of sealing joints between walls, drywall sheets and other building materials.

What is the effectiveness of the putty product

Terms of Use

There are a few basic rules for using Sheetrock Superfinish Putty.

- The tool is intended for internal use only.

- A new application of the putty is carried out only on a completely dried previous layer.

- The putty is sanded with 240 grit sandpaper.

- To successfully paint and apply decorative finishes, you must strictly follow the manufacturer's instructions. In order for the paint to lay down well, the coating must be dry, dust-free, matte, and should not stick to your hands.

- The application of a thin leveling layer of putty to the drywall sheet helps to level the water absorption of the material. In the future, this will help to avoid stains on the treated surface.

- Don't overdo it when dry sanding. Do not process the top of drywall and putty tape. Together with Sheetrock putty, paper tapes, metallized liner tapes and protective corners are used.

Features of paper tape:

- makes the structure uniform, strong;

- has a fold in the middle for easy handling;

- does not need the use of adhesives;

- has good strength indicators;

Purpose of metallized paper tape:

- strengthening of corners;

- reinforcement of structures when installing drywall.

Features of Paper Backed Metal Corner Guard (Corrosion Resistant Steel Busbars Paper Backed):

- gives strength to the corners;

- does not need additional fasteners;

- the adhesion of the finished composition to the paper base is higher, which ensures an ideal surface smoothness.

Aligning surfaces

The air temperature in the room and the base must be above 13⁰C. The surface to be putty must be dry, free from dust, dirt and delamination. Significant differences (2-6mm) are recommended to be pre-leveled with Dano JET fillers. To equalize the absorbency of mineral substrates, it is recommended to treat it with DANO primer. When used on gypsum plasterboard, preliminary priming is not required.

Continuous filling of the surface:

- Apply a layer of putty to the substrate and smooth with a trowel.

- Each subsequent layer of putty is applied after the previous layer has completely dried.

- It is recommended to sand the filler by hand using sandpaper no larger than P320.

- It is recommended to treat the resulting surface with DANO primer.

- After the primer layer has completely dried, you can proceed to the subsequent stages of finishing, such as painting, wallpapering, etc.

GKL seam finishing

- Put putty on the joint with a narrow spatula.

- We apply the tape and lightly, without pressure, fix the tape with a spatula. For best results, we recommend using SHEETROCK paper strips.

- We accelerate the putty under the tape from the middle to the edges. Thus, we glue the tape, remove the excess adhesive layer from under it and level the surface.

- We are waiting for the complete drying of the putty.

- Next, take a wider spatula and apply a layer over the tapes. This layer should be 5-10 cm wider than the previous one on each side.

- After the layer has completely dried, we can proceed to the continuous leveling of the surface into a plane.

* UK - thinned edge

You can find detailed instructions in the Articles section

External and internal corners processing:

- Prepare in advance a piece of a corner or tape of the required size. For a perfect result, we recommend using SHEETROCK professional corners.

- Apply an adhesive layer of putty to the base on both sides of the corner with a narrow spatula.

- We fix the corner or tape on the surface.

- We accelerate the putty under the tape from the middle to the edges. Thus, we glue the tape, remove the excess adhesive layer from under it and level the surface.

- We are waiting for the complete drying of the putty.

- Apply a layer over the corner or tape using a 25-30 cm wide spatula.

- After the layer has dried, we proceed to the continuous filling of the surface.

You can find detailed instructions in the Articles section

Specifications

Undoubtedly, Sheetrock polymer lightweight putty is one of the leaders in the finishing materials market.

Ready putty mixture of this brand is distinguished by the following technical characteristics:

- Convenience of packing. The volume of the container in which the ready-made mixture is produced varies from 3.5 to 28 liters, which allows you to select the required amount individually for each finishing object. There are purchase options for 7, 17, 18, 20 liters.

- Material color. The color of the putty in the container will be white. After drying on the surface, it takes on a pleasant ivory shade.

- Drying time of the material. Sheetrock putty dries quickly - from three to five hours. This drying is influenced by the factors mentioned above.

- The density of the putty is 1.65 kg / l.

- Vinyl, which is part of the mixture, allows it to be processed on any surface (it also contains powder with talcum powder, limestone and attapulgite).

- You can store the mixture for up to one year, while using it more than once.

What is the finishing putty Shitrok APJC

Almost all types of finishing putties are made on a polymer basis with the addition of fine fillers, gypsum, resins and stabilizers, which makes most types of thin-layer finishing materials somewhat similar in characteristics and capabilities. But even in such conditions, the use of Shitrok putty makes it possible to bypass the closest competitors, for example, Vetonit and Multifinish, in terms of the quality of the resulting surface.

The main difference from competitors is that Shitrok, like a putty, is a highly specialized material that is good only in specific conditions of use:

- The thickness of the layer to be laid does not exceed 0.1-0.5 mm, although the manufacturer allows the maximum thickness of the working layer to be up to 2 mm;

- After applying the putty, the surface is not sanded or sanded;

- The finishing putty is not used to level the walls; the surface is covered with the thinnest possible layer, filling in the marks remaining from the preliminary finishing, micro-caverns and point defects.

Finishing mass Shitrok in 99 cases out of 100 is used for finishing for painting walls. After drying, the finishing putty gives the effect of frosted glass - an even and uniform layer, translucent in thickness. After painting, it is almost impossible to understand how many layers have been laid on drywall or concrete surface. It is possible to apply two or three coats with polishing, but the total thickness of the finishing putty should not exceed 2 mm.

The secret of the composition of the Shitrok branded finishing material

Most craftsmen who professionally prepare walls with putties recognize the high plasticity of the Shitrok finishing mass, excellent adhesion and relatively small shrinkage of the material. The manufacturer's specialists give the following approximate composition of Shitrock APJC:

- Finely ground limestone or dolomite of fraction 20-40 microns, most often these are magnesium-calcium carbonates of natural origin;

- Ethylene vinyl or vinyl acetate copolymers;

- Atapulgite and pyrophyllite, which provides a dry sliding effect, when the finishing putty, even with too much pressure of the trowel on the surface, easily glides on a dry substrate.

But this does not explain all the nuances of high ductility and strength. In fact, the composition of the putty should be much more complex and voluminous than American technologists tell us. As a minimum, the Shitrok finishing mass should include mixture stratification stabilizers, preservatives and thickeners.

Cellulose microfiber, which is quite expensive and difficult to manufacture, is used as an additive that can make the finishing putty more airy and viscous, like whipped butter cream. The fiber provides excellent ductility and strength to the Sheetrock layer even on glass surfaces. So that microcellulose does not cause the development of mold or mildew, liquid preservatives based on polyhydric alcohols are always added to the Shitrok putty production formulation.

Conclusion

Experts believe that Sheetrock is free from any significant drawbacks. It resists frost perfectly. It is amazingly convenient to store and apply the putty. The surfaces are of amazing quality. The product is packed in buckets, which can then be used for a long time for mixing mortar, glue, etc.

Of course, you will have to pay a decent amount for Shitrok. However, it is not worth saving. The result obtained is undoubtedly worth the money spent

See photos, buy APJC, hire a team of professionals or do it yourself if you feel confident in your abilities, and a good result is guaranteed to you.