How to calculate the cost if you decide to build a house from cinder blocks yourself

There is nothing special about budgeting for the construction of a cinder block house. We talked about calculating the amount of wall material, so it will not be difficult to calculate the cost of building materials for this part of the construction site. But remember that, in addition to the walls, you will need to invest in the foundation, roof, interior and exterior decoration, and the necessary communications.

You will not find a calculator that will give you a complete calculation. The budget will be formed depending on the prices of materials in the region, the cost of builders' services, or, if you are going to do this work yourself, the purchase of the necessary tool.

If you do not have a plot of land for a house, add the cost of buying it to the total budget.

In short, if you want to estimate future costs, look among your friends and acquaintances for those who have recently mastered a similar construction project. Ask local construction companies for turnkey prices. You can safely reduce their amount by a third - about how much it will cost you to build such a house with your own hands.

Types of material

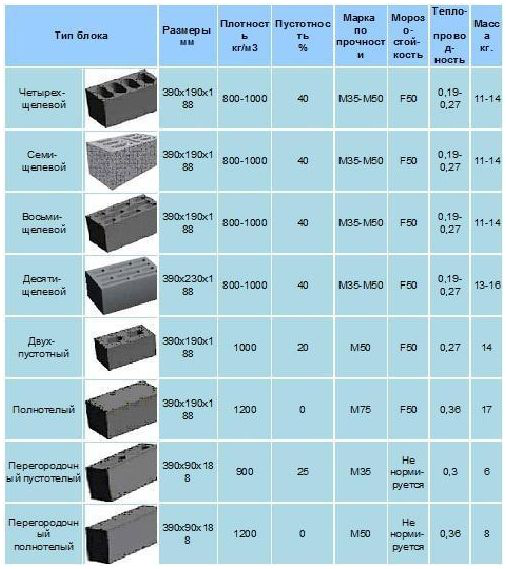

As mentioned earlier, a material such as a cinder block has several varieties, each of which has its own characteristics and rules of application. Let's take a closer look at such products.

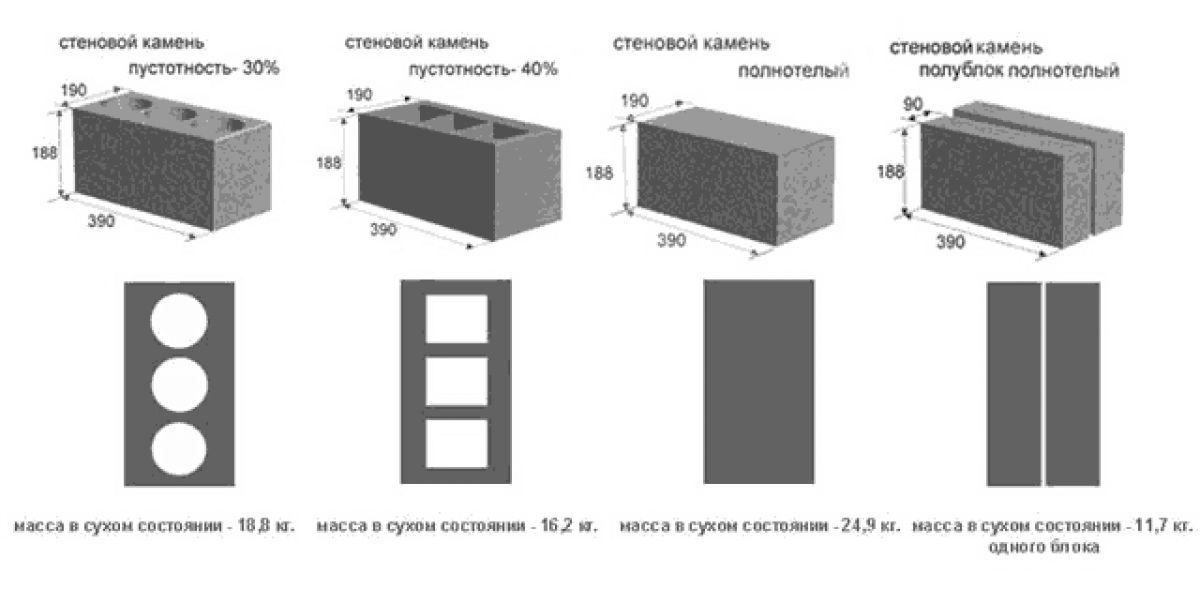

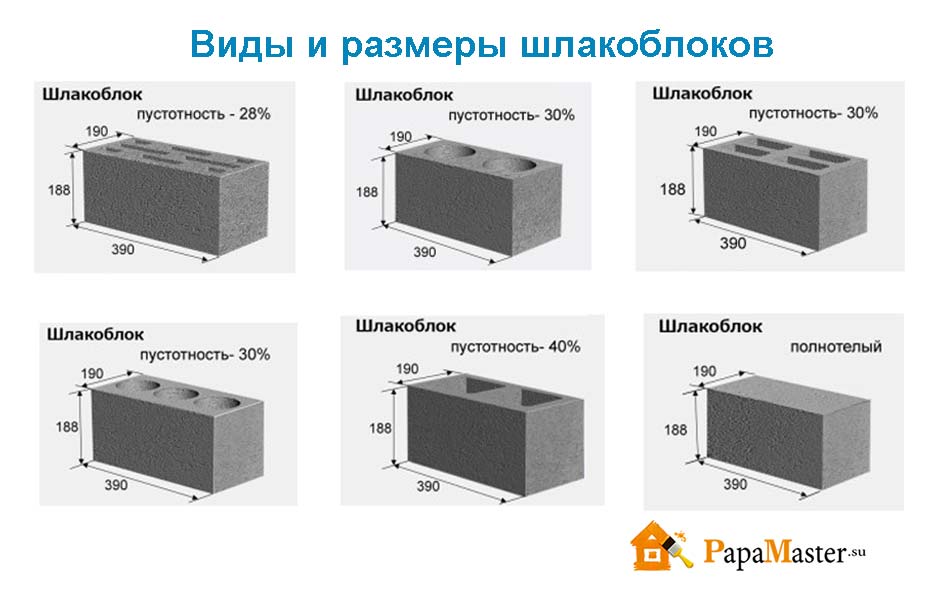

Hollow and full-bodied

Both of these block options are in great demand. For example, common full-bodied varieties are most often used in the construction of foundation structures, columns of various modifications and load-bearing foundations. Moreover, hollow blocks are great for the formation of basements.

As for hollow blocks, they are usually purchased for the construction of partitions and walls. They have a modest weight, so they do not weigh down the overall base of the dwelling at all.

Decorative

Such cladding materials have occupied their niche in the market quite recently. They are complemented by a special decorative coating, which can be located both on one and on both sides of the block. This additional layer can repeat all sorts of textures (for example, stone or plaster). In addition, in this way it will be possible to protect the blocks themselves from such negative factors as moisture and dampness. If you have chosen decorative materials for construction, then you can refuse the exterior decoration of the building.

Partition

If you have moved on to the construction of partition structures in a block house, then you need to use the indicated types of materials. Such specimens differ in that they can be used to build even and neat walls, while saving on mortar. It should also be noted that partition cinder blocks are lightweight, and their installation is quick and easy.

Fundamental

Foundation blocks are also called building stone. These materials have high strength and durability. Over time, such blocks do not give serious shrinkage, and also do not collapse, which indicates their increased reliability. If you are laying cinder blocks on a sufficiently strong and stable base, then you should remember the need to use reinforced concrete tape. Its layer should be at least 1.5 cm.

Experts advise to pay attention to the fact that the walls of cinder block foundation structures must be insulated with heat and vapor with special materials.

Chipped and torn

Not so long ago, the building materials market was replenished with original slag blocks with a decorative surface with an imitation of torn / chipped bricks. These options are most often used when decorating various buildings and fences.

Color

There is also a colored version of cinder concrete on the market. Fences, pediments or pillars are most often constructed from such material. The required shade of this material is achieved at the stage of its manufacture.

Slag blocks differ from each other and their main components.

Slag based

The properties and characteristics of such blocks primarily depend on the properties of the feedstock. This mainly refers to the environmental safety of materials (meaning the presence of toxic substances in their composition). The specified parameter should be taken into account when choosing slag blocks.

These materials are distinguished by high thermal insulation qualities. As for the service life, it is the same as that of a brick. But here you need to start from what kind of filler is present in the material. Slag-based blocks will last a very long time and will not cause problems if they are correctly laid and finished.

Arbolitovye

Blocks based on wood concrete are in great demand today. Such materials are in great demand, as they have excellent thermal insulation characteristics. However, such products have one serious drawback - they cannot boast of a sufficiently long service life. Of course, in the manufacturing process, wood concrete blocks can be made more durable, but this usually affects their environmental friendliness. Such negative changes are due to the fact that special substances are added to the usual composition that cannot boast of a natural origin.

Expanded clay

Blocks based on expanded clay are rightfully recognized as the safest and most environmentally friendly. Such products are famous for their excellent thermal insulation properties and durability.

It should be borne in mind that the popularity of such blocks is explained not only by their environmentally friendly base. These varieties are lightweight and have multiple voids in their structure. Most experts recommend using just such types of cinder blocks for building a house. Currently, more than 50% of homes in Europe are made from similar elements.

Application in construction

The use of cinder block in construction

The use of cinder block in construction is very diverse and depends on the type of material chosen. For the walls and foundations of the house, it is better to use a solid cinder block, and for the construction of partitions in a house, a bath, a garage, a barn and other utility rooms, hollow blocks are quite suitable. He also proved himself well, as a heater in frame-type structures. This will be the optimal material for such buildings.

The use of foam blocks in the construction of buildings of various storeys is considered optimal, taking into account the economic benefits. Which grade of this material is best for the construction of certain buildings depends on their type.

Blocks are subdivided into:

- heat-insulating type, from which you can build interior partitions,

- structural and thermal insulation, suitable for low-rise construction and for the construction of partitions,

- as well as the structural type of blocks from which the load-bearing walls of multi-storey buildings can be built.

The question of what is better for the construction of the necessary object, a foam block or a cinder block, must be solved at the design stage of the structure.

What is best suited for a given building should be chosen from the purpose and characteristics of the building and the planned budget.

- Aerated concrete in construction

- Cinder blocks in construction

- Foam blocks in construction

- What's the best material?

Today the construction of houses, garages, fences and other structures is not difficult.The market offers a variety of construction materials that even a lay builder can apply. Houses are built mainly from bricks, wood and equally popular materials, which include cinder blocks, aerated concrete and foam blocks. If everything is clear with brick and wood, then the remaining three materials still cause distrust. Only a specialist who understands the composition of the above materials and their technical characteristics can answer the question of which is better - a brick or a cinder block, a foam block or aerated concrete.

If the question of choosing a suitable material arises before construction, all the materials offered should be thoroughly studied. Let's try to determine: what are the differences between aerated concrete, cinder block and foam block. After all, these materials, similar in appearance, contain a lot of distinctive features.

# 1. Cinder block: production features

Slag concrete belongs to the category of lightweight concrete blocks. For the first time, such material became known at the beginning of the 20th century, when Nicholas II was building a garage in the Winter Palace. The cinder block then, however, was made on the basis of waste from burning coal - slag, hence the name. Since then, the production technology has changed somewhat, and the durability of the first cinder block buildings provided the material with sufficient popularity.

Today the cinder block is made on the basis of cement and sand, clay, lime or gypsum can be added, as well as various plasticizing additives. The filler is no longer slag, but crushed stone, granite screenings, expanded clay, broken bricks, perlite, cullet and sawdust. In terms of environmental friendliness and harmlessness to health, the best fillers are expanded clay, sawdust, crushed stone and shell rock. The production is carried out on vibroforming equipment.

If in the 70s, when the cinder block began to be actively used in construction, garages, sheds and other utility and utility rooms were erected from it, today the advantages of an inexpensive material make it possible to use it for the construction of houses and even industrial buildings.

Features of masonry work

Despite the fact that the materials have similarities, the masonry of each of them has its own characteristics. Let's figure it out. What is the process of erecting a building from a slag and aerated block?

Tips for building cinder block buildings

When building using this material, you should adhere to some rules that will help to avoid unpleasant consequences.

They boil down to the following:

- Masonry work should be carried out in the warm season in the absence of precipitation;

- The first row should be on an elevated foundation, more than 0.7 meters high;

- Do not pull with the decoration of the walls, they should soon be protected from moisture;

- The roofing device should also be done immediately after the completion of the work for the same purpose.

Stages of wall construction:

- Laying begins with setting the corners, which is done using rows. A thread is pulled between them, which serves as a guide.

- The most important row is the first, you need to approach it with all responsibility. The adhesive mixture is applied in a thin layer, using a trowel. After laying the three blocks, they must be checked for evenness and, if necessary, corrected. It is recommended to do this as often as possible in order to avoid errors.

- Subsequent layers are laid by analogy with the displacement of the seam. All gaps must be filled with mortar.

Stages of erecting walls from aerated concrete

The process of laying aerated concrete blocks is very similar to laying a cinder block.

Let's consider briefly:

- The first blocks are laid in the corners, a thread is pulled between them.

- The first layer is laid on a mortar in order to better adhere to the base and strengthen the structure. It is recommended to lay subsequent rows on glue, adhering to a thin layer, in order to reduce cold bridges.

- The base must be even!

- After installing the blocks in the corners, start laying the entire row. If there is a gap, the block is trimmed to the desired size.

- Adjustments are made with a level and a rubber mallet.

- When laying the first and every 4th row, reinforcement is performed.

- The second and subsequent rows are laid with a seam offset.

- After the wall has been erected, it is necessary to perform an armored belt device.

Characteristics of aerated concrete

Table of technical characteristics of aerated concrete.

Aerated concrete is also an artificial building stone. It is composed of quartz sand, lime and aluminum powder. It may also include gypsum and industrial waste such as ash and slag. However, thanks to a special manufacturing technology, it is environmentally friendly and safe for humans. This is a new generation material that has a number of significant advantages.

- First, as already noted, aerated concrete does not contain impurities harmful to humans and does not emit gases and dust into the environment. That is, it meets all environmental requirements. According to this parameter, gas blocks are ahead only of exclusively natural material - wood. In addition, the blocks themselves do not accumulate fungi, mold or bacteria inside themselves. This means that you do not have to additionally treat the walls with antiseptics.

- Secondly, aerated concrete is very durable, frost-resistant and non-flammable. The resource of its use is calculated for more than 100 years, and over time it does not deteriorate, but becomes harder and harder. Gas blocks will withstand more than 200 freeze and thaw cycles, and since they consist only of mineral components, they do not support combustion.

- Thirdly, it is one of the "warmest" materials. Due to their low level of thermal conductivity, aerated concrete blocks with a thickness of about 40 cm can compete with 0.5 m brickwork. As a result, the cost of heating your house can be reduced by 3 times! In this case, additional thermal insulation is not required.

- Fourthly, despite its strength, aerated concrete is better than other materials, amenable to processing with a tool, sawn, drilled, it is easy to finish and install. It does not rot and does not rust, it allows you to very quickly build not only low-rise residential buildings, but also high-rise public buildings and even industrial facilities.

Well, and fifthly, the price of such a convenient building material allows any builder to become a fan of aerated concrete. This explains its massive popularity: today gas blocks are produced in more than 50 countries of the world, and they are used in an even wider territory.

But this material also has its drawbacks. For example, he is afraid of moisture and cracks.

Therefore, it is recommended to pay additional attention to waterproofing: revet the walls with foam, do not use aerated concrete in the construction of basements, avoid excessive contact with the soil

Cons of a cinder block foundation

- The cinder block foundation is heavy. This disadvantage is attributed to the cinder block strip foundation. This type of foundation can hardly be attributed to light, since the cinder block itself is the same concrete, but in a combined form with slag, crushed stone, bit and other stone impurities. If we are talking about the installation of a strip foundation from a cinder block, then by the number of blocks, you should carefully calculate what the weight of the foundation itself will be and what load it will exert on the ground.

-

Hygroscopicity. Since the cinder block has a porous structure, it absorbs moisture well, which will directly come from the soil and atmosphere. Moisture in the foundation has a quick destructive effect on the foundation from the inside. This disadvantage is eliminated by necessarily good waterproofing of the foundation. It is also not worth planning a cinder block foundation on soils with a high groundwater table and in areas with high humidity.

- Cold foundation.For the most part, this drawback is noticeable if a basement is laid out from a cinder block. But the longevity of the foundation and any building stone is determined by the number of freeze and thaw cycles - frost resistance. Cinder block is a cold material and its frost resistance is not great from 25 cycles. Therefore, the cinder block foundation should be additionally insulated.

- Not stable on shifting ground. The severity of the cinder block strip foundation and strength, allows it to be erected only on stable and stable soils. For a cinder block foundation, caked clay soils, mixed rocky-sandy soils and similar soils are well suited. On loam-type soils, the cinder block foundation can shift under its own weight. And this will lead to cracks and destruction of both the foundation and the entire building. It is not recommended to place buildings with a base made of this material in an area with high humidity and close to the groundwater table.

-

Cannot withstand high loads. It is recommended to erect a building not heavier than 100 tons on a foundation of cinder blocks. But this is often enough to build a full-fledged residential building. If for construction a lightweight bearing material such as wood, foam blocks and building panels is used, then the foundation of cinder blocks will perform well its function.

- The difficulty of mounting alone. The technology of laying the foundation itself is simple, but the difficulty can be caused by the large weight of the cinder block, which is from 18 to 28 kg. When laying the foundation, it is recommended to use a solid heavy cinder block, the weight of which reaches 28 kg. During installation, the cinder blocks must be laid evenly on the mortar along the cord, which will be problematic to do alone. Therefore, laying alone will be tedious and may require the help of helpers if you are doing the laying yourself.

Helpful hints

It is recommended to check the compliance with the horizontal level more often. This will avoid curving the walls. If the subsequent finishing of the walls will not be carried out, it is necessary to take care of the aesthetics of the joints between the blocks. They can be decorated with a simple rounded stick, which allows for a slight depression of the seams. This must be done until the solution has completely hardened.

Use colored crayons when marking out cinder blocks. They are more visible on blocks than pencils.

The cinder block is quite vulnerable to moisture, so after laying it is highly recommended to make plaster. At the same time, use a reinforcing mesh so that in the future the plaster does not crumble from the walls.

How to build a house from a cinder block with your own hands: highlights

The construction of cinder block buildings is a simple process. It is much faster and easier to build such structures than from ordinary bricks. The main thing is to correctly calculate and follow the general building rules.

How to calculate the number of cinder blocks for building a house

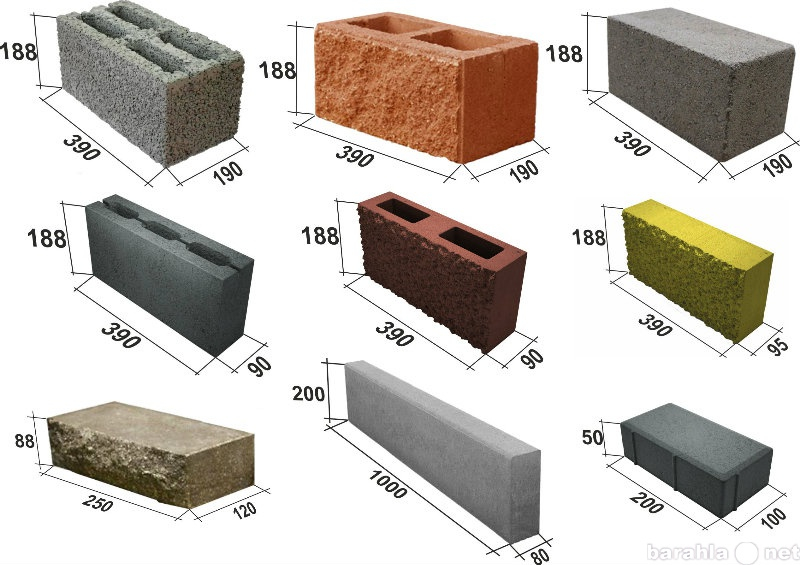

Savings in construction are achieved not only by using cheap building materials, but also by correctly calculating their amount. It is better to buy more blocks, if they are not enough, than to puzzle over where to attach the extra ones. What are the indicators of the calculation? The first is the thickness of the cinder block wall. It depends on the region of residence. For the south and central part of Russia, it is permissible to put external walls with a thickness of 20 to 40 centimeters. For the northern regions, at least 60 centimeters is required.

The second important indicator is the dimensions of the building (width, length and height of the building)

How to calculate the number of cinder blocks in 1 m²: for laying one row, 12.5 pieces of blocks of a standard size are required. If the wall thickness is 40 centimeters, two rows are required, which means we multiply number of elements in one row per two - we get 25 pieces. If you need a wall of 60 cm, multiply by three.

Even a second grader can calculate the total wall area: you need to multiply the length by the height. For example, if the wall of a house has dimensions of 10 × 4, then we have 40 m² of masonry. Laying in two rows: 40 × 25 = 1000 blocks. Do I need to subtract the area of door and window openings? If you have ordinary, medium-sized windows planned, do not subtract them from the total area.

Cinder blocks are fragile and break often, so consider this a bonus to combat

How to lay the foundation for a cinder block house

For a cinder block house, a high moisture-insulated foundation is required. It is required to protect the wall material from contact with groundwater. For one-story and two-story buildings without reinforced concrete floors, there is no need to make a reinforced base.

The cinder blocks themselves are not heavy and do not exert an increased load on the foundation, but the base must be reinforced in any case

The foundation must stand at least a month before the walls are erected. Only during this period will the solution completely rise, and the base will gain the required strength.

How to properly lay the cinder block on the foundation

Blocks are first placed on the moisture-proof layer of the foundation in the corners. The correctness of their location is carefully checked by the building level. Only after setting the corners between them is the cord stretched, and the masonry of the walls will be built along its line. In practice, it looks like this.

How to build the walls of a house yourself - features of laying cinder blocks

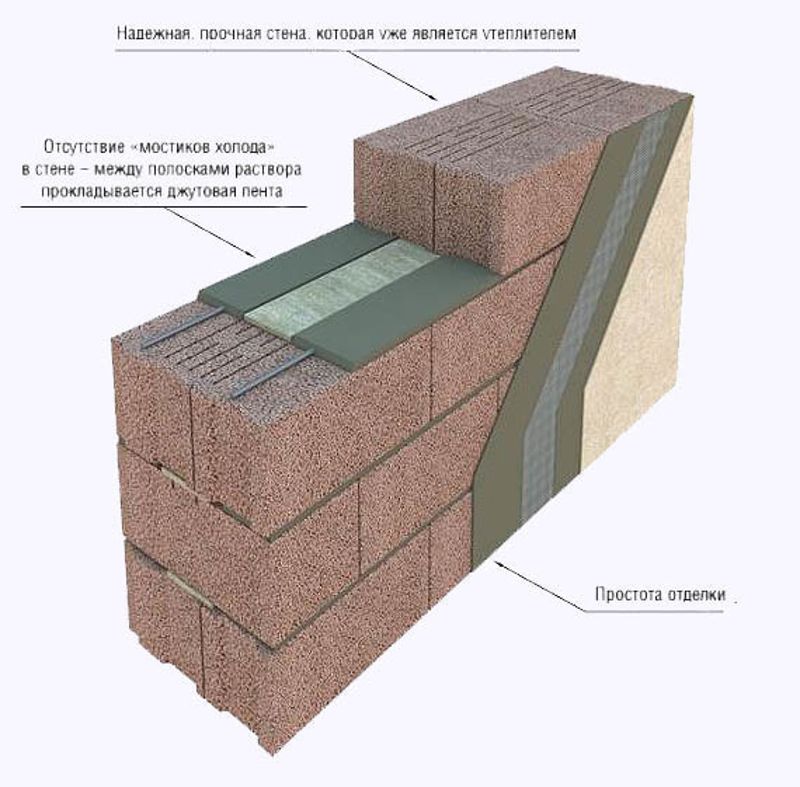

The peculiarity of construction work with a cinder block is that they can only be carried out in good weather at a temperature of at least + 15 ° C. To preserve the thermal insulation properties of the material, it is necessary to make seams no thicker than one and a half centimeters and in no case fill the voids in the blocks with a solution. The elements are stacked with an offset of half a stone.

The verticality of the masonry should be constantly checked by the building level.

In every fourth row, you need to make reinforcement. To do this, recesses are made with an electrofusion cutter, pieces of reinforcement are inserted, and cement mortar is poured. This technique allows you to make the walls much stronger.

Roofing and interior decoration

In the construction of a cinder block building, an important point is the installation of a roof. This should be done as quickly as possible so that rain or snow does not hit the walls. If for some reason you do not have time to cover the roof before the rain starts, use at least temporary moisture protection: polyethylene or any other covering material.

It is better to insulate cinder block walls from the outside.

In any case, the facade of the building will need decorative finishing. If internal insulation is required, a vapor barrier is first mounted, and on top - mineral wool or expanded polystyrene plates. The walls in such a house can be plastered, sheathed with plasterboard and OSB boards.

How is it different from other materials?

Currently, block building materials are among the most popular and demanded. Structures made from them are found at an enviable frequency. Today there are many types of blocks, and many users are wondering how cinder blocks differ from other options. We will try to answer this question.

From sand blocks and expanded clay blocks

Sand blocks and expanded clay blocks are made in the same way as cinder blocks. As for their ecological characteristics, here the latter are inferior to sandy and expanded clay options, because the raw materials for their production are sand and expanded clay, which can boast of a pure composition without any chemical and aggressive substances. Cinder blocks are usually made from various industrial waste.

From aerated concrete and aerated concrete

It is also necessary to understand how the cinder block differs from aerated concrete and gas block. In fact, the latest materials are identical. In their manufacture, an important point is the appropriate chemical reaction that provides a porous structure.Cinder blocks are made mechanically - by pressing.

Based on the parameters of these products, one can come to the following conclusions:

- cinder blocks are denser, harder and stronger than gas blocks, but inferior to them in thermal qualities;

- cinder blocks are less frost-resistant than aerated concrete.

From foam blocks

Foam blocks today are in demand materials, from which not only houses are built, but also all kinds of outbuildings. These materials are similar in many respects to cinder blocks.

The standard dimensional parameters of cinder blocks when laying are 4-5 bricks, while standard foam blocks can replace as many as 7-8 bricks. However, one must take into account the fact that the foam block is inferior in cost to cinder blocks. The same cannot be said for its thermal insulation performance and weight.

From brick

The lion's share of consumers is interested in how the cinder block differs from the good old brick. It's no secret that the latter is extremely popular and has been used in construction for many years. In terms of its operational characteristics and parameters, the cinder block is in many ways similar to a brick, and in some issues even surpasses it (this concerns strength properties).

In rare cases, masonry bricks have a strength grade greater than M-100. Cinder blocks are also produced with higher markings - M125 or M-150. In addition, one cannot fail to mention that it is very difficult to make a brick with your own hands (as a rule, it is almost impossible without the appropriate knowledge and equipment), and it is quite possible to make cinder blocks yourself.

Advantages and disadvantages of cinder block baths

Like any other material, the cinder block has its pros and cons, which will inevitably affect the operational characteristics of the building. Let us consider in more detail the positive aspects of the advantages and disadvantages of a cinder block bath.

Pros of a cinder block bath

The most significant benefits include the following factors:

minimum budget. The cinder block is one of the cheapest materials, so the estimate for construction work will be small. With a limited budget, a cinder block is the best option for building a bath;

significant time savings. Thanks to the impressive dimensions and the correct geometric shape, the construction of the box does not take much time. Suffice it to say that one cinder block is 4.5 bricks in area;

the possibility of self-production of cinder blocks. Construction costs can be significantly reduced if you produce the cinder block yourself. The manufacturing technology is extremely simple, and everyone can cope with such a task. Another advantage of self-made blocks is that a counterfeit will not be acquired;

the possibility of self-construction. The laying of cinder blocks does not require any special skills. With due patience, accuracy and care, you can build a bath from cinder blocks on your own. This will allow you not to pay money to hired workers;

long period of operation. In the presence of high-quality materials and adherence to construction technology, the building can stand up to 100 years;

cinder blocks do not ignite

The material is able to withstand temperatures up to + 80C without collapsing, which is very important for such a building as a bath. The cinder block not only does not burn, but also does not support combustion;

environmental Safety

Blocks are made of natural materials and do not emit toxic substances even at high temperatures;

biological resistance. The cinder block does not contribute to the spread of fungus and mold, in addition, it is not of interest to mice, rats and other rodents;

a large number of exterior finishes. A ventilated facade can be attached to the walls, decorative plaster is applied, they can be lined with tiles or facing bricks.

High thermal insulation properties. The voids inside significantly reduce the thermal conductivity of the cinder block. This property of the material is especially important for the steam room, since the heated air and steam remain inside.

Cons of a cinder block bath

Along with the advantages listed above, there are also disadvantages:

- the need for a reinforced foundation. The weight of one solid block can reach 28 kg. To withstand such a load, the foundation must be very strong, you cannot save on this. If the strengthening of the foundation is not sufficient, shrinkage cracks may appear;

- low moisture resistance. The hygroscopicity of the cinder block makes it necessary to take additional measures to ensure hydro and vapor barrier. If you do not take appropriate measures, the room will be damp, and condensation may appear on the walls;

- difficulties with laying communications... The high strength of the blocks makes it difficult to form grooves and drill holes. To carry out these works, a special expensive tool will be required, which will entail additional costs;

- unpresentable appearance. A bathhouse built of cinder blocks, without external decoration, resembles not a temple of purity, but a camp barrack. In addition, the exterior cladding protects the walls from excessive moisture absorption. Siding, facing bricks, various types of decorative plaster can be used as an exterior finish;

- great weight. The significant mass of cinder blocks (some species can weigh up to 28 kg) greatly complicates the masonry process. In some cases, two people have to stack one block.

Having analyzed the above advantages and disadvantages of a cinder block bath, we can say with confidence that with a minimum budget, the construction of a bath from this material is fully justified. High thermal insulation properties, strength, environmental friendliness and long service life, combined with an affordable cost, make the cinder block the best option for the budget construction of a bath.