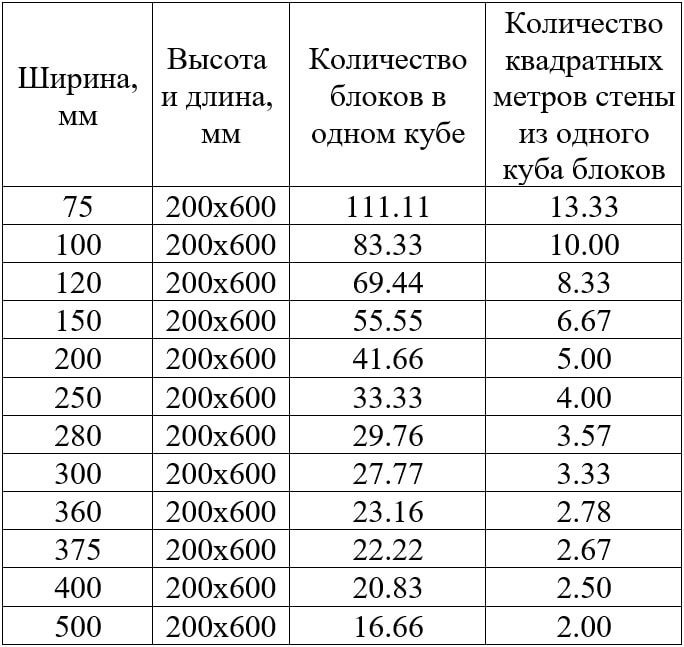

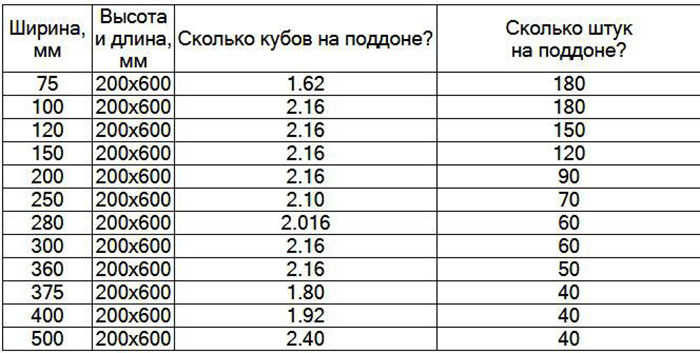

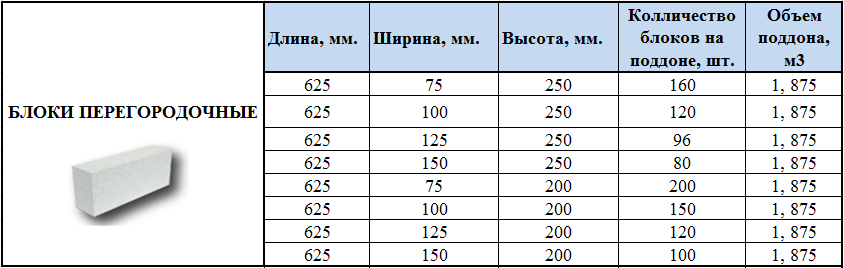

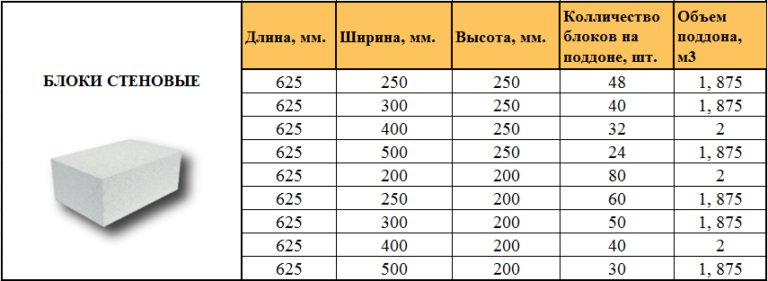

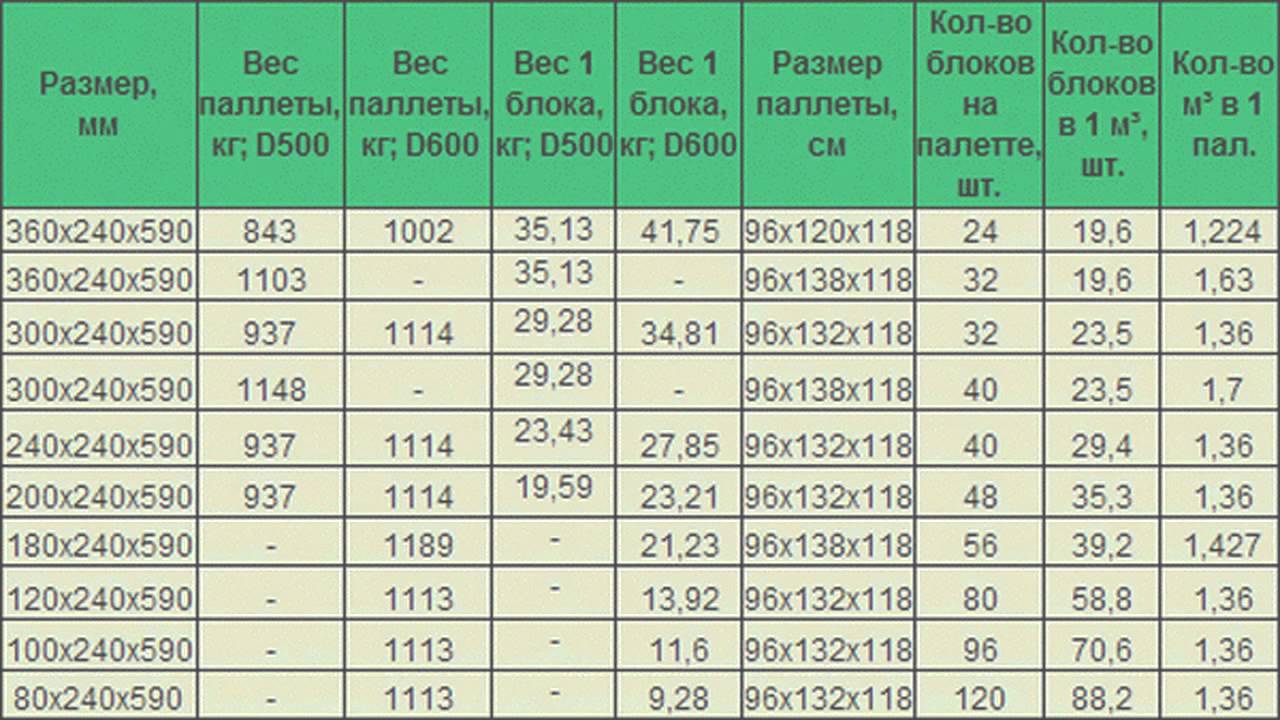

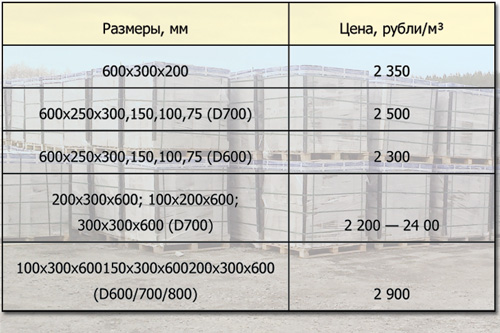

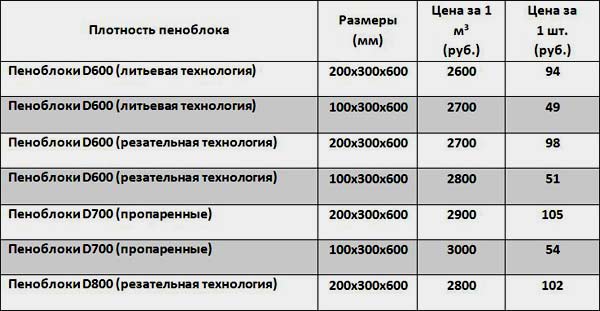

Quantity per pallet

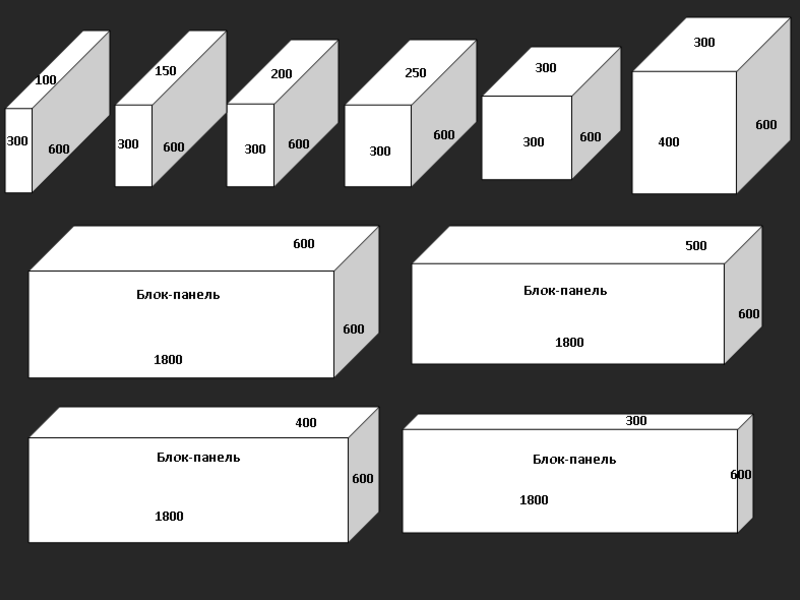

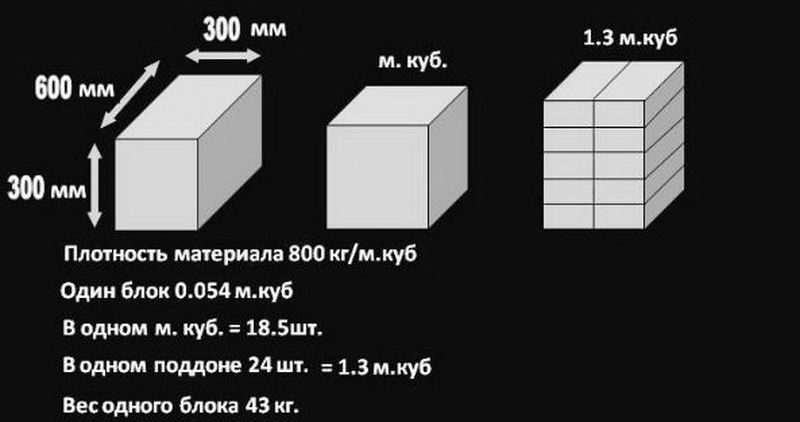

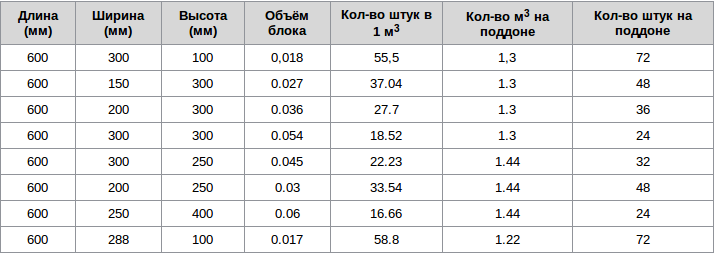

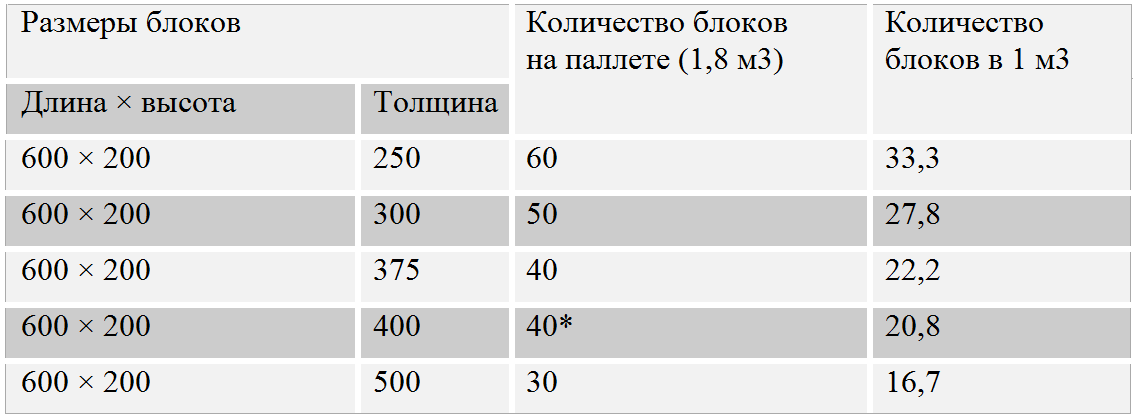

To calculate the number of foam concrete blocks in 1 pallet, it is necessary to take into account only the dimensions of the material itself and the size of the pallet. Before buying, it is imperative to check the quality certificates and product compliance with the state standard. Let there be a set of blocks 200x300x600 mm in size, which you want to put in pallets 1200x990 mm. This pallet volume is indicated for a reason - it is it that is most often used by modern manufacturers. For ease of counting, any manufacturer always puts the same number of products on pallets.

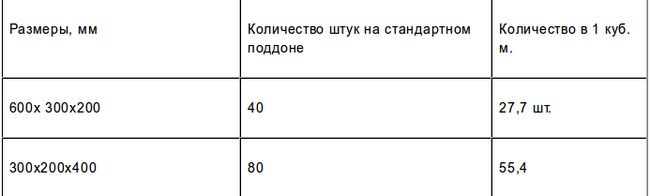

Blocks 600x300x200 mm in one pallet with a capacity of 1.8 m3 can accommodate exactly 50 pieces. If you need to calculate the pallet capacity only in square meters, the standard solution is to multiply the length by the width. For the same most popular type of foam concrete structures, the result will be 0.18 m2. That is, for 1 sq. m of pallet area 5 foam concrete elements are placed.

Returning to volumetric calculation, it is necessary to point out such massive varieties of pallets as:

- 0.9;

- 1.44;

- 1.8 cc m.

When laying out the most common group of foam concrete products, 25, 40 and 50 pieces can fit on them, respectively. The mass of the product, the density of which is 600 kg per cubic meter. m, can reach 23.4 kg. But real construction often involves the use of blocks of non-standard size.

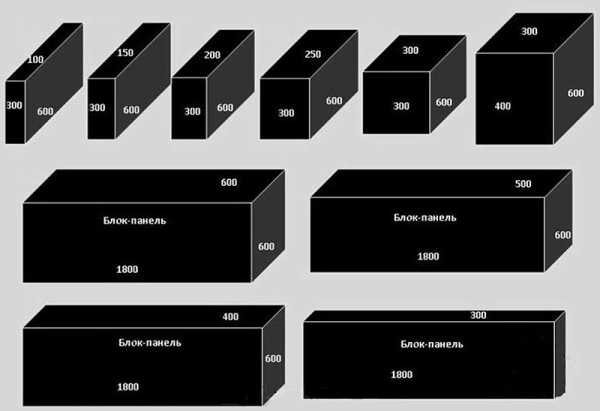

The layout for all three main dimensions (0.9, 1.44 and 1.8 m3) of pallets is:

- for blocks 100x300x600 - 50, 80 and 100 pieces;

- for blocks 240x300x625 - 20, 32, 40 units;

- for blocks 200x300x625 - 24, 38, 48 copies.

Difficulty is the calculation of non-standard blocks that need to be laid out on atypical pallets. Suppose, when measuring, it was found that the width of the pack is 1 m, and its length will be 0.8 m (with a height of 120 cm). The simplest calculation according to school formulas will show the volume - 0.96 m3.

Measurement of individual products shows that they have sides:

- 12 cm;

- 30 cm;

- 60 cm.

Pros and cons of the material

The appearance of cinder blocks is directly related to the natural human desire for waste-free production. In the postwar years, production in the USSR developed at a rapid pace. Metallurgical plants are literally overgrown with mountains of slag. Then the decision came to use this waste to create building materials.

Slag served as a filler for a cement-sand mixture. The resulting mass was molded into large "bricks". The finished blocks were too heavy - they weighed 25-28 kg. To reduce weight, voids were made in them. Hollow specimens were slightly lighter - from 18 to 23 kg with standard dimensions.

The name cinder blocks is still used today, although not only slag, but also other components are used as fillers. In modern blocks, one can find granite screenings or crushed stone, river gravel, broken glass or expanded clay, volcanic mass. Small business is most often engaged in the release of cinder blocks. Small private enterprises produce building blocks on vibrating machines, filling several forms with a cement mixture at once. After molding and tamping, the "bricks" gain strength for at least a month.

Cinder blocks are endowed with certain advantages and disadvantages.

- The advantage of block building material, first of all, is its low cost. That is why the material is in great demand.

- This building material also has other positive characteristics. For example, blocks do not change their size after laying out. The structure will not shrink, which means that the design calculation will not be adjusted during the construction process.

- The strength and hardness of the "big brick" determine its service life. This is no less than 100 years! Durability is not calculated, but time-tested. There are many buildings of the middle of the last century that "stand firmly on their feet." The houses did not lurch or crumble, only the facades require cosmetic repairs.

- Blocks react poorly to ultraviolet light and temperature extremes. The material is not edible for rodents and insects.

- Due to the increased size, construction is proceeding at a rapid pace. Much less masonry mix is used for laying blocks than, for example, for a brick wall of similar dimensions.

- Street noises are not audible behind the cinder block wall, because it is capable of absorbing sounds.

- Finally, if you have simple equipment and desire, the blocks can be made at home, which will further reduce the cost of construction.

The disadvantages of a building material are no less than advantages.

These include the following characteristics.

- Nondescript appearance.

- Problematic of fastening to walls due to voids in the body of the block.

- The need for cladding to make the structure attractive and protect the building material from the effects of external moisture.

- Fragility. If dropped during work, during transportation or loading, the unit may break.

- High thermal conductivity. Without additional insulation, the structure retains heat poorly.

- Wide tolerance limits. Dimensions may differ significantly from the nominal value.

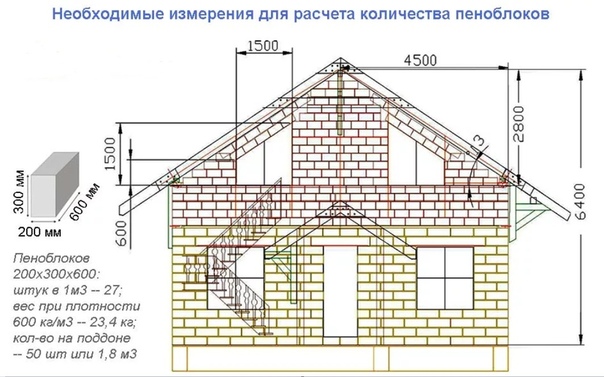

How to determine the amount of block material

What size of foam block is best for building a house, we found out. The standard size of its dimensions gives another advantage - according to the known parameters, the total number of stones that will be required for construction work can be easily calculated.

So, how many cubes of a foam block do you need to build a house of 8 by 8 meters? To carry out all calculations, you must perform the following steps:

- fold all sides to define the overall perimeter of the object. At the same time, it is recommended to record the results in centimeters;

- clarify the height of future walls;

- since the standard block is 60 cm long, the entire perimeter is divided by this value. We will get the number of blocks in one masonry row;

- it remains to divide the value of the height of the walls by 20 (30, 40) cm (indicator of the height or width of one stone) to get the number of rows;

- to obtain the total amount of material, the number of blocks in a row will be multiplied by the number of rows.

Naturally, any object presupposes the presence of window and door openings. This means that the total amount of material is reduced by dividing the total opening area by the same masonry value. Then, five to ten percent must be added to the resulting number to create a stock of material for trimming and chips.

For partitions, you should use a material with dimensions 10 x 30 x 60 cm. To determine the number of blocks, you will have to divide the length of the wall by 60, and the value of the height by 30. We multiply the obtained values, add no more than 5 - 10% for unforeseen circumstances.

Now let's calculate how many blocks are needed to build a house

For your home, you will need to substitute your numbers to get the result.

OPTION 1 (very detailed based on the house plan)

- define the perimeter of all (and also internal) walls of the house (even in the case of a complex configuration, this is easy to do): fold the lengths of all sides based on the plan;

- determine the area of all walls: the perimeter (item 1) x the height of the walls;

- determine the total area of all openings - doors and windows;

- from the area of the walls (clause 2), subtract the area of the openings (clause 3). As a result of calculations, you will receive wall masonry area;

- masonry area of the walls (item 4) x block thickness = volume in cubic meters meters of blocks (number of blocks in cubic meters) required for masonry walls;

- count blocks per cubic meter (item 5) / number of blocks in a cube = number of blocks in pieces ,necessary for masonry walls.

Now let's consider the calculation of the number of blocks using the example of a specific house, using the plan of our house:

we find the dimensions of the house on the plan and for the calculation we take the length and width of the house: 10,800 m (the width of the house) x 2 + 24,000 m (the length of the house) x 2 = 69.6 m. is the design length of the outer walls of the house. Why in our case only the length of the outer walls is taken into account - this will be discussed a little later;

we find on the plan the design height of the house. We have it equal to 2.70 m., And the height of the basement of 0.4 m is not taken into account in the total height of the house 2.7 m

Pay attention to this when calculating for your home !;

- When laying the outer walls, the blocks will be laid in such a way that the width of the wall is 300 mm (0.3 m), i.e. the height of the block in the masonry will be 200 mm (0.2 m). As a reminder, the dimensions of our gas silicate block are 200 x 300 x 600 mm.

- when laying the walls, we used the thickness of which during laying is about 1.5 cm or 0.015 m per one row of masonry;

- in other words, taking into account the solution, the height of the block in the masonry can be taken equal to 0, 215 m;

- we consider how many rows of blocks we will have to lay: 2.70 m (design height of walls made of blocks) / 0.215 m (block height) = 12.56 rows. Of course. no one will lay half a block, so you need to decide how many rows you want to lay? We have chosen for our house the option with 13 rows of blocks when laying walls;

- those. without taking into account the solution, the height of the wall would be 13 x 0.2 m = 2.6 m

- we consider the total area of the outer walls: 69.6 mx 2.6 m (house height) = 180.96 square meters;

- it is necessary to find out the area of the walls minus the window and door openings, therefore, we also calculate the area of all openings on the basis of the plan;

- the plan shows that our house has two entrance doors (this is understandable: the house is designed for two families), two doors to the veranda and one door to the utility room. For simplicity of calculations, we will take the dimensions of the doorways the same: 1.2m x 2.10m.Total we get: 1.2 x 2.1 x 5 = 12.6 sq.m .;

- windows in the house will be:

- 2 large (2 x 1.2) x 2 = 4.8 sq.

- 6 medium: (1.5 x 1.2) x 6 = 10.8 sq. M.;

- 3 small for utility rooms: (0.7 x 1m) x 3 = 2.1m

- the area of window and door openings will be: 4.8 + 10.8 +2.1 + 12.6 = 30.3 square meters;

- the area of walls made of blocks, excluding window and door openings, will be: 181 - 30 = 151 sq. m;

- we consider how many blocks are needed for 1 sq.m. masonry walls: 0.2 m (block height) x 0.6 m (block length) = 0.12 square meters; 1 sq.m / 0.12 = 8.33 blocks;

- we consider how many blocks are needed for laying the outer walls, taking into account the openings: 151 sq.m. (wall area) x 8.33 pcs. = 1258 pcs.

- We planned to lay the inner walls as follows: the width of the block during laying is 0.2 m, the height is 0.3 m. Similarly, we calculate how many blocks are required for the inner walls: the area of the inner wall is 48 sq. m .;

- we consider how many blocks are needed for 1 sq.m. inner wall masonry: 0.3 m (block height) x 0.6 m (block length) = 0.18 sq. m; 1 sq.m / 0.18 = 5.56 blocks;

- 48 sqm * 5.56 = 267 pcs. blocks needed for the inner wall;

- final settlement: 1258 + 267 = 1525 pc ... blocks needed;

- 1525 / 27.7 = 55.05 or 55 cubic meters blocks are needed to build our house.

OPTION 2

Now gas blocks and other aerated concrete products can be considered one of the most promising wall materials, so many private developers turn their attention to them. If aerated concrete is chosen for the construction of a private house, then before the construction of the building it is necessary to create its project, which indicates the main dimensions of the walls, both external and internal, as well as the number and dimensions of windows and doors

At the design stage, the density of the blocks and their main dimensions are determined. It should be noted that the walls of the aerated block can be finished with ceramic bricks, which makes it possible to somewhat increase their thickness and thermal insulation properties.

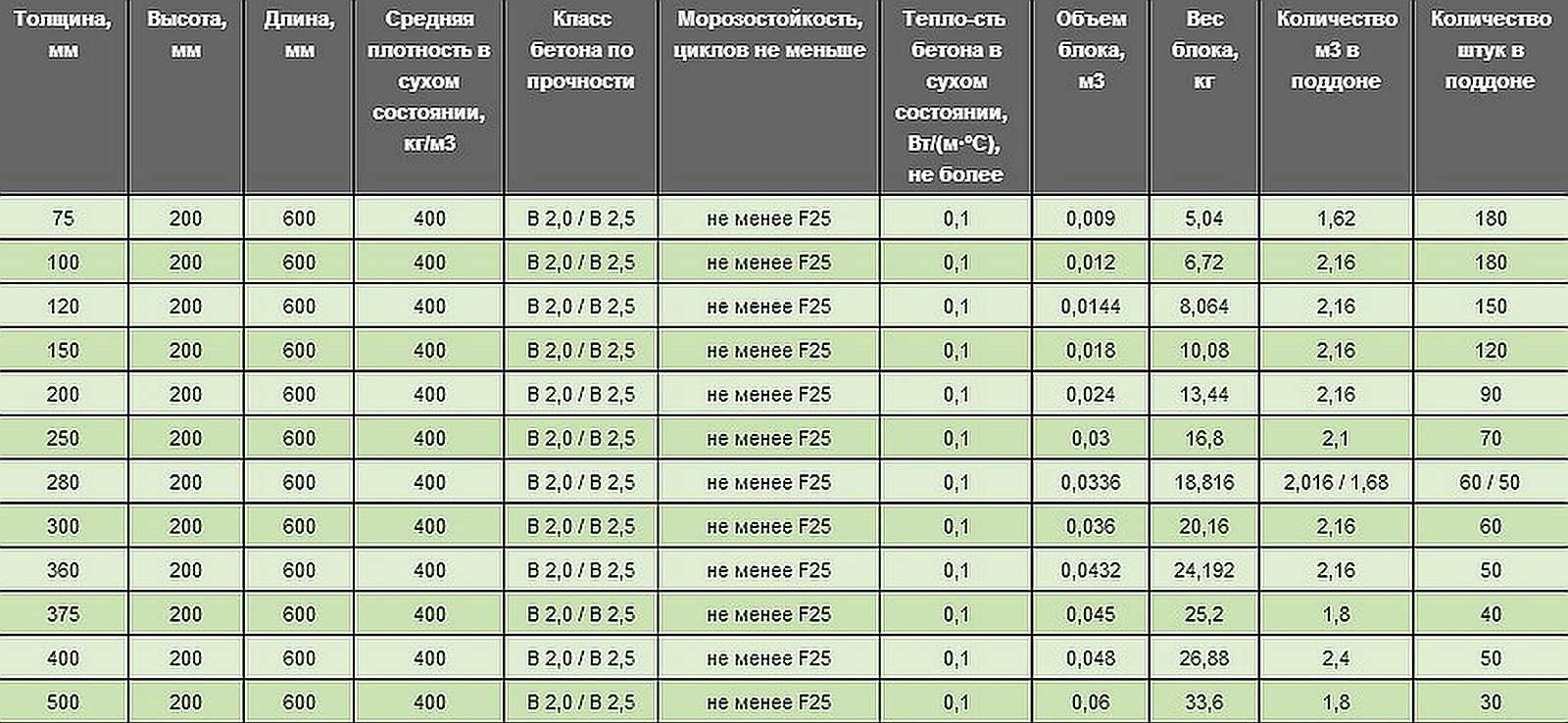

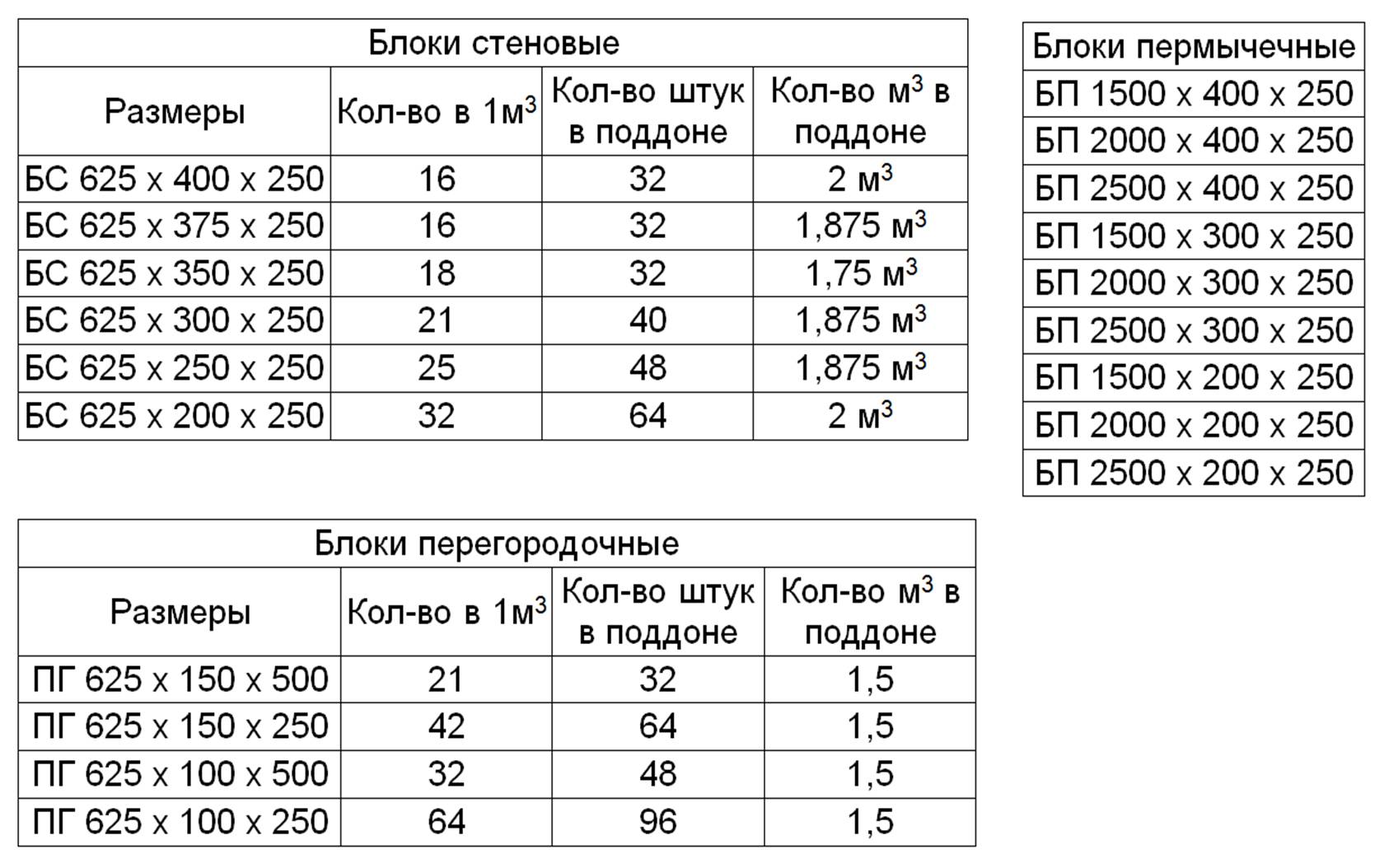

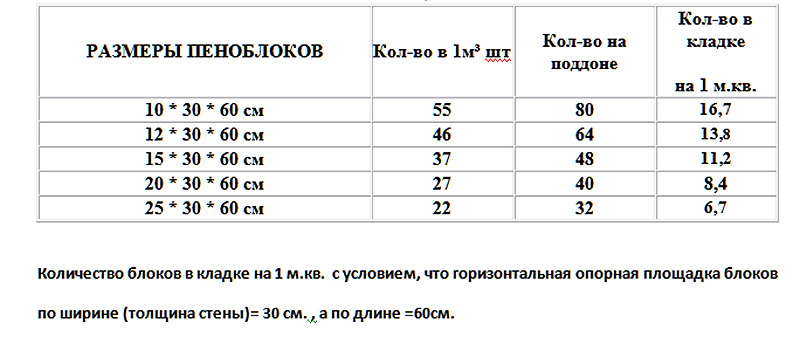

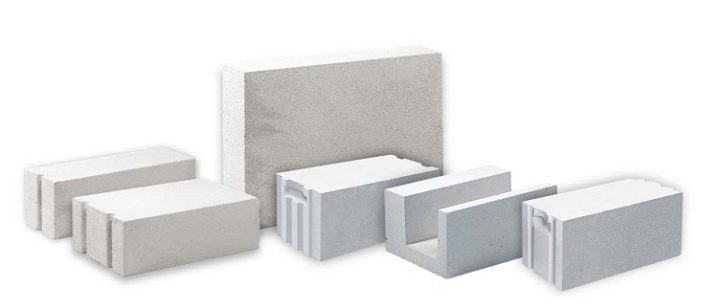

How many foam blocks are there in a cube?

The first thing to take care of when buying foam blocks is counting the number of blocks that are needed for the construction of an object. This question is quite relevant both among professional builders and among beginners in this business.

In order for the calculation of a certain number of foam blocks to be as accurate as possible, you must rely on the following parameters of the facility under construction:

- Length.

- Width.

- Height.

- Volume.

- Square.

It is very easy and simple to calculate the number of blocks for the construction of one wall, for this there are several options, for example, counting the square meters of the wall and building them into cubic ones.

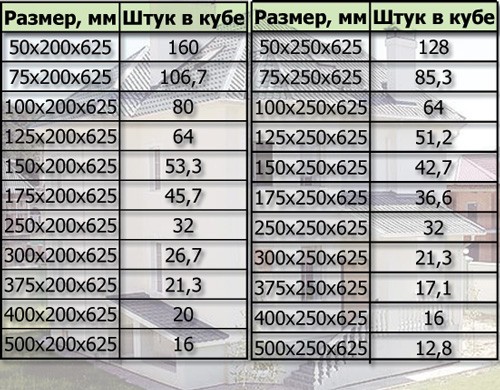

It is worth knowing that the sale of foam blocks takes place in cubic meters, which means that in order to order a certain number of blocks, you need to know their number in a cubic meter.

The popularity of building houses from this type of material is due to its excellent performance. Foam blocks have proven themselves as a building material that can withstand harsh weather conditions. He is not afraid of either cold or moisture, moreover, blocks of this type, despite their composition, are quite resistant to fire.

These factors determine the presence of special micro-substances that are contained in the foam block. In addition, despite their lightness, blocks are good materials for the construction of load-bearing walls in buildings, because they are able to withstand enormous pressure per unit of their area.

This resistance to stress is due to the presence of plasticizers in the foam block. Due to these substances, blocks of this type are strong enough and allow them to withstand high pressure without changing their shape and size.

Depending on what composition the foam block has, experts divide them into the following categories:

- Foam blocks for heat insulation work outside the premises.

- Structural blocks for the construction of frame works of buildings.

- Soundproof foam blocks.

As you can see, foam blocks are good in all areas of application, from sound insulation and thermal insulation to the construction of load-bearing walls in massive high-rise buildings.

Each of the specifics of the use of the foam block is explained by its production and manufacture. For example, foam blocks for sound insulation are made using a special technology that foams the polystyrene foam material from the inside. Thus, porosity and sound insulation effect is created, which is what is needed for this type of foam block.

Building blocks are renowned for their strength and durability.

The fact is that the composition of such a foam block includes cement of the m-500 brand with the corresponding mineral and artificial additives, which give the block hardness and density. It is worth noting that a block of this type is three times heavier than usual. In addition, its price characteristics are also significantly higher than the rest.

Blocks for strengthening the thermal insulation of the house are the cheapest

Such a building element is relatively light in weight, since in the production of such a foam block, more attention is paid to the porous base inside the block. Due to the fact that there are small pores inside the block, the effect of freezing of gases inside is formed, therefore, the heat transfer from such a block is at the very minimum value

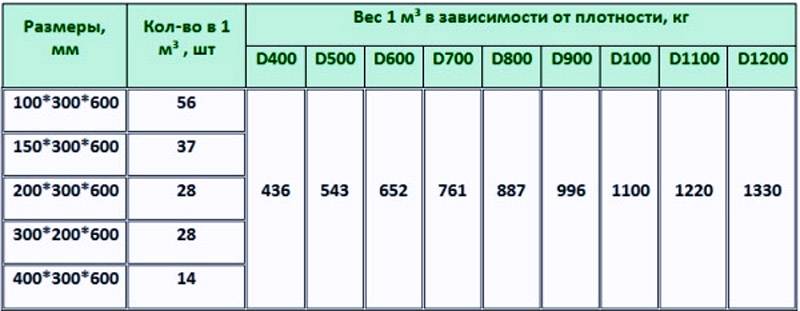

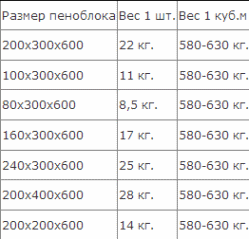

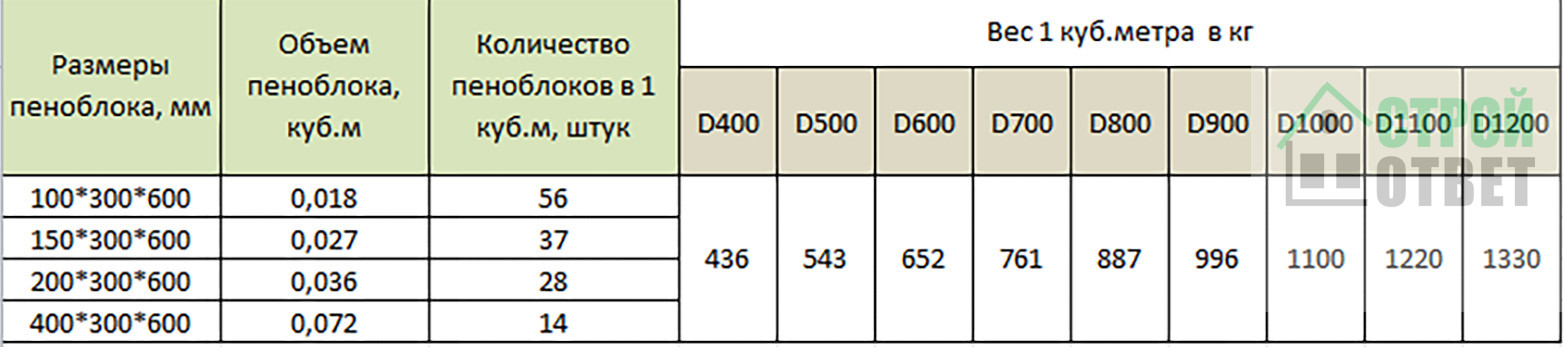

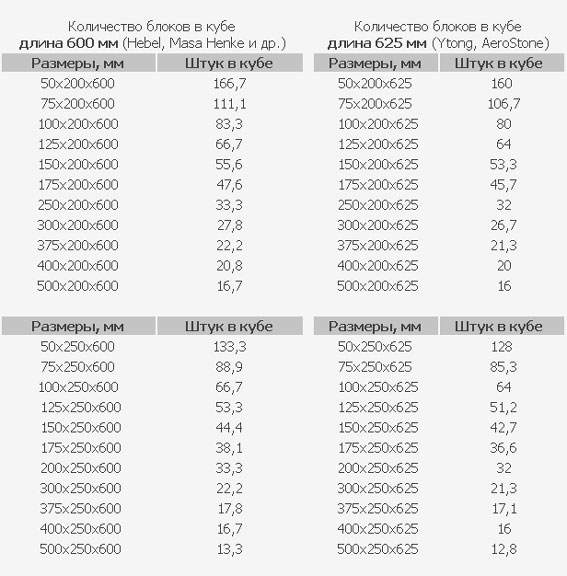

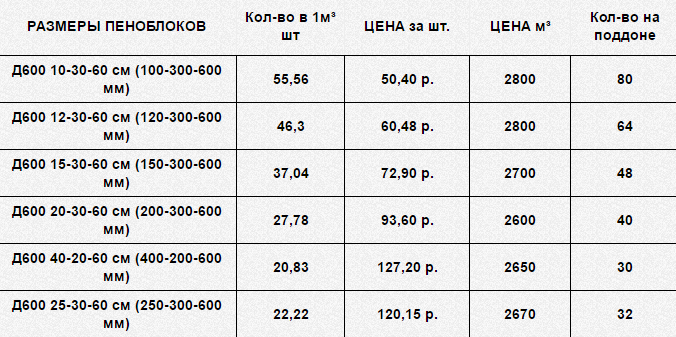

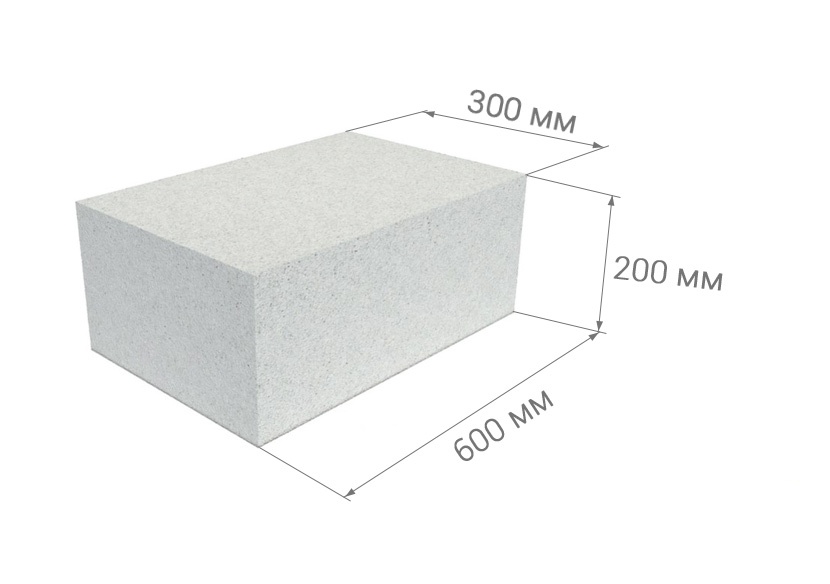

How to calculate the number of blocks in a cube?

You can also calculate the number of blocks in a cubic meter of delivery without much effort, you just need to know the dimensions of the block itself, and this is:

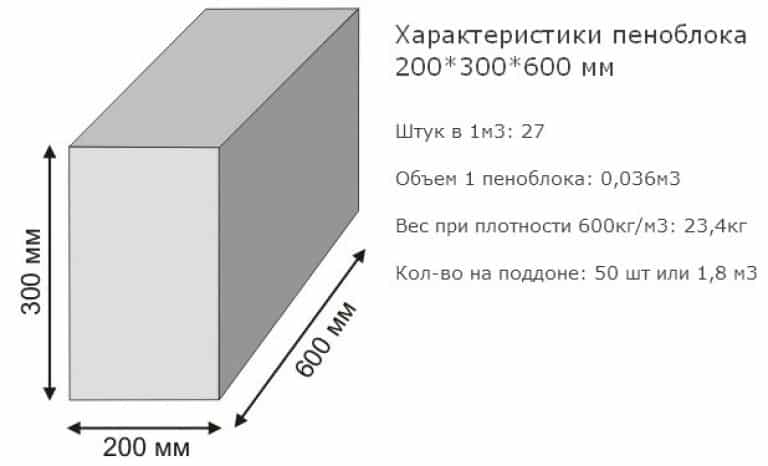

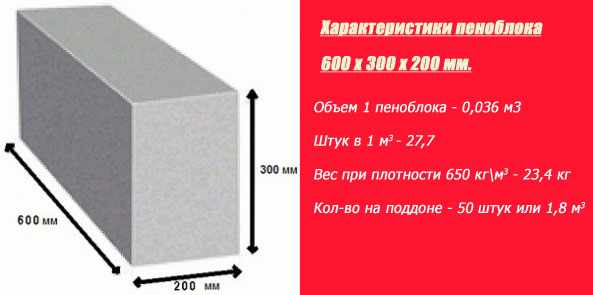

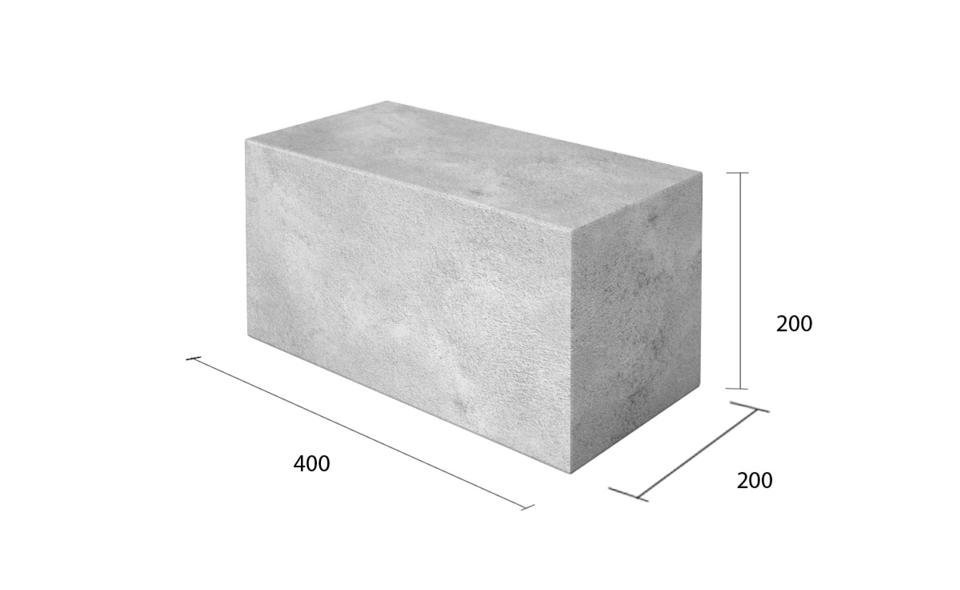

1) Length - 0.6 m 2) Width - 0.3 m 3) Height - 0.2 m

With an easy mathematical calculation, we find out how much the volume of one foam block will be:

0.6 * 0.3 * 0.2 = 0.036 cubic meters.

The only thing left to do is to divide one cubic meter by the volume of one block, as a result of which we get that one cubic meter contains 27.78 foam blocks.

By rounding off, we find that one cubic meter includes 27 blocks.

Exactly the same calculation actions must be performed with other block values.

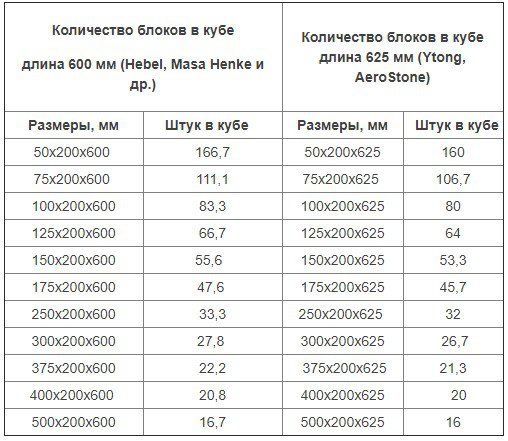

How many foam blocks are there in a pallet?

It must be said that the delivery of foam blocks takes place in packed pallets, therefore their quantity in a pallet does not depend at all on one cubic meter.

There are several types of pallets:

- 0.9 cubic meters, which holds 25 foam blocks.

- 1.44 cubic meters, which holds 40 foam blocks.

- 1.8 cubic meters, which holds 50 foam blocks.

Thus, knowing the calculated values of the foam blocks and the type of delivery pallet, you can easily calculate how many pallets to order for the construction of the facility.To do this, it is necessary to divide the total volume of all coatings of the object by the volume of the pallet, and only then multiply the resulting number by the number of blocks in the pallet.

Foam concrete and its characteristics

Foam concrete is an artificial stone, a kind of concrete, but made, unlike it, using a foaming agent. As a foaming agent, SDO acts - saponified wood resin. It gives the material plasticity, frost resistance, elasticity, and has antiseptic properties. Otherwise, foam concrete does not differ in composition from concrete: cement + sand + water.

Foam concrete is often confused with aerated concrete. In fact, these are completely different materials. Aerated concrete is made using hydrogen - a gas that is released during a certain chemical reaction. As a result, through pores are formed in it. The pores in foam concrete are closed, which makes the waterproofing characteristics of the material much higher. If you place the foam block in water, it will immediately float up, and the same experiment with aerated concrete will lead to the gas block being saturated with water within a couple of hours and sinking.

The foam block optimally combines the properties attractive for the developer:

- environmental friendliness, sound insulation, thermal insulation;

- low weight of material, speed of construction;

- fire safety, ease of processing, affordable price.

The composition, rules of use and various instructions for the production of foam concrete are regulated by regulatory documents - GOSTs, which the manufacturer must comply with. These include:

- GOST 25485-89 “Cellular concrete. Technical conditions ";

- SN 277-80 "Instructions for the manufacture of products from aerated concrete";

- GOST 5742-76 "Heat-insulating cellular concrete products";

- GOST 12852.0-77 “Cellular concrete. General requirements for test methods ".

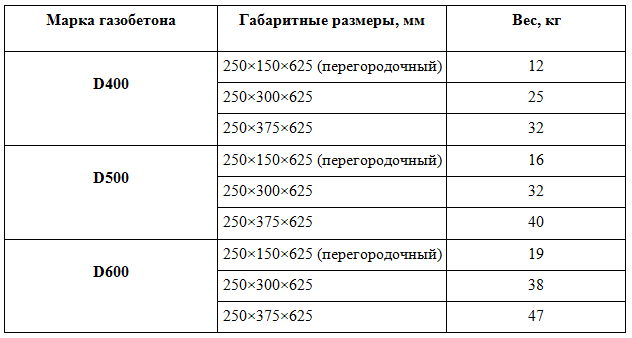

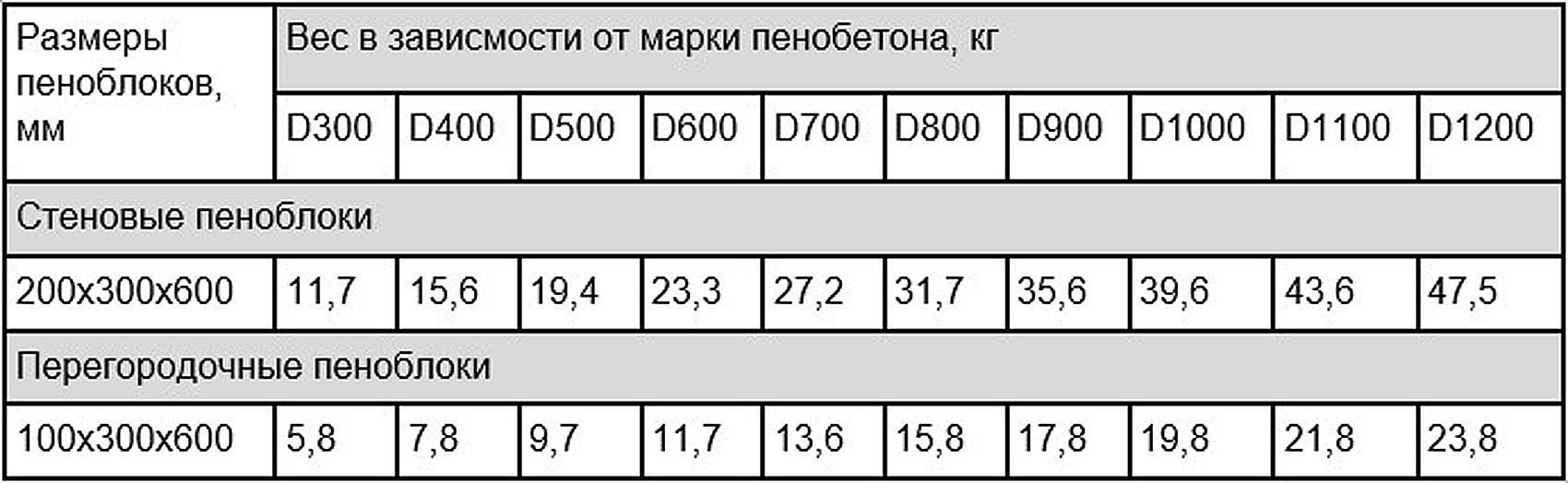

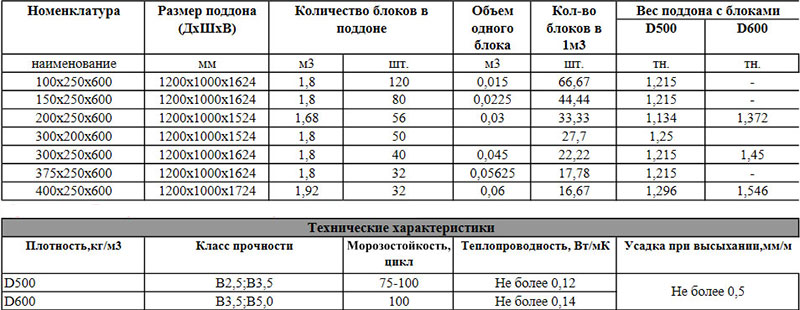

Density

This indicator is proportional to the grade of concrete. Each type of building element is used to lay structures with different loads. In order not to be mistaken when choosing a brand, you should familiarize yourself with their purpose. Aerated concrete D600 is characterized by high strength.

Monoliths are erected from D500 blocks, D 400 - for arranging insulation during the installation of openings. Products made of D350 aerated concrete, which has a high porosity and loose structure, are mainly used for heat insulation.

The material absorbs moisture, so a moisture-insulating soil ball is applied to the walls. The technology for manufacturing blocks provides for mixing the ingredients, which, when interacting, form a porous structure. High density building elements carry more weight.

How much aerated concrete in a cube can be determined by the density of the block. This indicator is designated D, and the numbers after the letter marking indicate the density value. A low index value corresponds to the presence of a large number of air pores, which increase heat conductivity.

The strength index of the D400 gas block is 45% higher than that of the D300, but the thermal conductivity is 30% lower. The price of D400, 200, 300, 600 cm building products in Moscow and other regions is lower than for similar products of higher density.

Now Reading: Recommended pouring temperatures for concrete

Calculation of the number of cinder blocks per house

We take as the basis for the calculations:

- The standard dimensions of the unit are 390x190x188 mm.

- The mass of the block with two voids is 17 kg.

- The dimensions of a one-story house are 8x8x3 m (Length x Width x Height).

Counting by rows of masonry - how many units of wall stone fit in one row. To do this, you need to know the size of the block and the size of the house. Then we calculate how many cinder blocks are per 1 sq. m. will be needed to build a carrier box.

- To do this, we calculate the perimeter of the house: Phouse = 8 * 4 = 32 m.

- To find out the number of units of products in one row, you need to divide the perimeter of the house by the length of the block: N pieces in 1 row = 32 / 0.39 = 82.05 pieces.

- Next, we calculate the total number of rows. The height of the walls is divided by the height of the building block: N rows = 3 / 0.190 = 15.78 rows.

- We find out the total number of blocks per house by multiplying: Ntotal = Npieces in 1 row * N rows = 82 * 16 = 1312 pieces.

Based on the results, you can calculate the weight of the building, which will put pressure on the foundation: weight of 1 piece. - 17 kg is multiplied by the total number of units, we get 22304 kg. Since the preliminary calculation was carried out without taking into account window and door openings, they should be subtracted in the process of a more accurate calculation, as well as their weight should be subtracted from the total weight of the load on the foundation.

To calculate the amount of mortar or glue for laying the cinder block, you should proceed from the thickness of the seam. For glue, the joint thickness is 2-3 mm, for mortar - 5-10 mm.

Since the cinder block is usually stored on pallets, it is recommended to calculate the required number of pallets before purchasing it. One pallet holds 60 items. Therefore, based on the example above, an 8x8x3m house will require approximately 20 pallets.

For the foundation, the most optimal material will be blast-furnace slag; for the walls, you can use any filler - ash slag, brick or stone quarry, crushed stone or gravel. To get a full-bodied product, 0.011 m3 of working solution will be needed to make one unit of building stone. That is, from a bag of cement, 36 units of a standard size will be obtained with a bag weight of 50 kg.

The more precisely the equipment is configured, the less mortar will be consumed for stacking blocks in rows, and the more products will be obtained from one bag of cement.

Verified suppliers

- PalletTrade - production since 1996

- BusinessPallet

- Detinets - production and sale of pallets

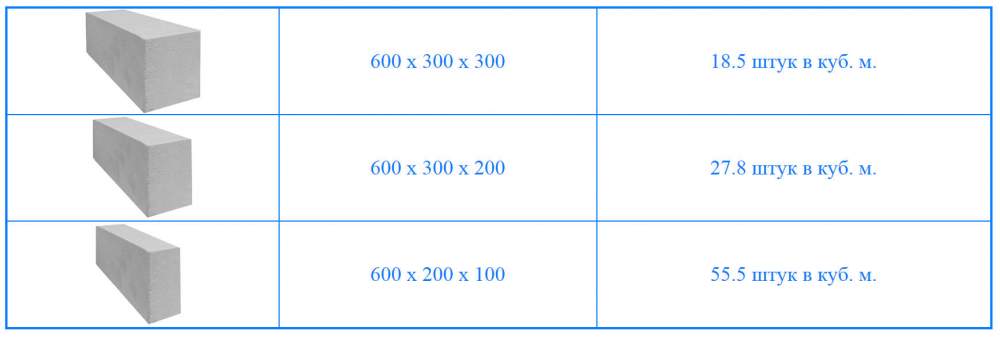

Usually, the number of foam blocks is counted in cubic meters and is supplied in pallets, tied with tape and wrapped in cellophane to protect against moisture.

But there are often cases when it is necessary to calculate the amount of material not in cubic meters, but in pieces.

So, how many pieces of foam blocks are there in a pallet? In order to correctly calculate the quantity, you need to know the size of the pallet and the size of the supplied unit.

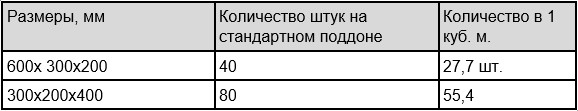

Mainly due to generally accepted shipping standards, foam block manufacturers use standard pallets.

Standard pallets are made of plastic or wood and vary in size:

- 800 × 1200 mm - Euro pallet;

- 1000 × 1200 mm - standard pallet;

In addition to standard pallet sizes, they have generally accepted recommendations for laying foam blocks on them for shipment. For Euro pallets, it is recommended to stack standard blocks of two blocks long and four wide, five rows per pallet.

For a standard pallet, the stacking recommendation is two blocks long and five wide, with five rows per pallet.

The most common standard foam block has a size of 200x300x600 mm;

The volume of one standard block is 0.036 cubic meters. meters. Based on this information, you can easily count the number of blocks on a pallet. To do this, you need to multiply the number of blocks in one row by the number of stacked lines on the pallet.

You can find out how to choose the best pallet for a warehouse by comparing the technical characteristics of several types in this informative article.

In our case, these are:

- 2 * 4 * 5 = 40 pieces on a Euro pallet (1.44 cubic meters);

- 2 * 5 * 5 = 50 pieces on a standard pallet (1.8 cubic meters);

How many foam blocks do you need at home?

Any builder by vocation or a builder by need is constantly trying to calculate as accurately as possible the amount of this or that material that will be required to erect an object. With the device for counting building material in specialized organizations, everything is clear, because there these deliveries are monitored by trained people who perform complex mathematical calculations and analyze.

But what about those who decided to build a house on their own land plot or in the country? To do this, it is necessary to make some calculations, which are needed both to save money and to save time and space for building material. It will be easier with the calculation of sack containers, but when calculating the number of bricks or blocks, it is not so simple.

If the choice fell on building a house when using blocks, then to calculate them, it is imperative to know the size of one block and the size of the area of the walls that need to be erected.

The blocks are stacked in a specific order and this gives some relief in counting. Therefore, with the correct calculation of the required amount of building material, you can save a lot on your own money.

For example, if the house has dimensions:

- Length 6 meters.

- Width 6 meters.

- Height 3 meters.

The first step is to calculate the perimeter of the building, in our case it is equal to 24 meters. The area of the walls of the house will be 72 square meters. But not everything is so simple, because on the walls there are a number of openings (door and window), the size of which is not at all useful for construction. Therefore, their parameters must be subtracted from the total area of the walls.

So, let the total area of the walls, taking into account all the openings, be 58 square meters, then the next step will be to count the number of blocks. A standard foam block has dimensions of 200 * 300 * 600 millimeters, and the thickness of the walls in this block will be equal to 30 centimeters.

Now it is easy to calculate how many blocks will need to be purchased for the construction of walls in the house:

It is necessary to multiply the area of the walls by the thickness of the wall, and this will be equal to 58 * 0.3 = 17.4 cubic meters. Knowing that there are 27 foam blocks in one cubic meter, you can easily calculate how many blocks will be in 17.4 cubic meters.

And it will be equal to:

27 * 17.4 = 481 pieces.

The location of foam blocks flat

If the construction of a house occurs in such a way that the block lies flat on the surface, then for such a construction of a house it is also necessary to find out the most accurate number of foam blocks that will be needed to erect the frame of the house. For this, the perimeter of the house - 24 meters must be multiplied by 0.3 and by a height of 3 meters.

As a result, we will have 21.6 cubic meters. Knowing that there are 27 blocks in one cubic meter, it is easy to calculate that 583.2 blocks will be needed. But do not forget that some blocks are deformed or completely defective. Therefore, it will be necessary to purchase several dozen more foam blocks.

The arrangement of foam blocks vertically

If the construction of the walls takes place in such a way that the foam block rests on the surface with its smaller side, then to resolve the issue of the number of blocks it is necessary:

the perimeter of the house is 24 meters, multiplied by 0.2 meters and by a height of 3 meters. As a result of the calculation, we will have 14.4 cubic meters of foam block, which is equal to 388.8 blocks.

How many foam blocks do you need at home

Every self-sufficient man has the idea of building a house according to his own project. The time when people were in seventh heaven with happiness, getting an apartment in "Khrushchev".

Fortunately, times have changed, and with them the needs, desires and capabilities of modern man have undergone changes. More and more people are showing interest in living away from the noise of the city. City air has a negative effect on the health and general well-being of residents.

Having decided to start the construction of a country house, you should weigh all the nuances associated with the choice of a project, material for building a house, and decide on financial possibilities.

As an affordable solution to the problem, you can consider building a house or cottage using foam concrete. Starting preparation for construction, it is necessary to determine how many foam blocks are needed per house.

Having a house project, it is not difficult to calculate the required number of blocks. You will need to calculate the area of all walls of the house, excluding the area of window and door openings. Knowing the dimensions of the block, and they are standard, it is easy to calculate the required amount of building material.

Aerated concrete blocks are a building material made on the basis of concrete using a special technology. As a result, bubbles form in the concrete, the material becomes porous and acquires good thermal insulation qualities.

The blocks have a low specific weight, which makes it easier to work when laying, and good strength characteristics.

Having concluded a contract for the construction of a house, the customer does not have to rack his brains with the question: how many foam blocks are needed per house, since construction specialists will calculate the required amount of material, according to the project.

Large block sizes allow to increase the speed and reduce the cost of construction installation. Houses made of foam concrete are not subject to decay (like wood) and retain their strength in case of fire (compared to brick houses).

Perhaps, foam concrete has, nevertheless, one drawback: it is not very presentable. When building a house, you will have to take into account the need for external finishing (plaster, siding).

Before thinking about building a house from foam blocks, you need to calculate and the number of foam blocks that you will need to bring your project to life and, accordingly, get a superficial idea of what costs you will have to purchase this building material. So, for example, let's calculate the number of foam blocks per house, the width of which is 5 meters, the length is 6 meters, and the height is 2.8 meters. The first step will be to make calculations regarding the number of foam blocks (calculation of the consumption of foam blocks) required for the construction of the first row. For this, of course, it is necessary to calculate the perimeter of the planned building. So, we got a value of 22 meters or 22000 mm. Then this value must be divided by the length of the foam block (600 mm). We get that 37 foam blocks are needed to build the first row.

Now you need to find out how many foam blocks are needed to build walls of 2.8 meters. Depending on how it is planned to lay the foam blocks, what is the planned thickness of the walls made of foam blocks, it will be necessary to divide the height of the wall by the height of one foam block. As a result, we managed to establish that in total, from floor to ceiling, we need a row of 10 foam blocks in height. Next, you need to multiply the foam blocks that fit in the perimeter and the foam blocks required for the construction of the pillar, 2.8 meters high. That's all. As a result, we get the actual number of foam blocks for the construction of a building with our specified parameters. Naturally, it is also necessary to take into account door and window openings, so as not to purchase a lot more than we need.

To do this, we calculate the perimeter of the building 6000 mm * 2 + 5000 * 2 = 22000 mm, Divide by the length of the foam block 600 mm

We get 36.6 foam blocks in 1 row

2. We calculate the number of rows of foam blocks in height

To do this, we divide the value of the building height (2800 mm) by (depending on the masonry method and wall thickness):

Option 1: height (300 mm) of the foam block

Option 2: width (200 mm) of the foam block

We get

in the first case 2800 mm / 300 mm = 9.33 rows of foam blocks

in the second case 2800 mm / 200 mm = 14 rows of foam blocks

3. Multiply the total values of items 1. and 2. with each other

We get

1 case: 36.6 * 9.33 = 342 foam blocks (minus windows and doors)

2 case: 36.6 * 14 = 513 foam blocks (minus windows and doors)

Windows and doors are calculated at the rate of 1 sq.m. = 5.56

Similarly to option 1, the number of foam blocks for wall partitions is calculated as 100 * 300 * 600, or the wall area is calculated and calculated at the rate of 1 square meter = 5.56 foam blocks.

How to calculate the number of gas blocks per house 6 × 8 meters

To calculate the amount of aerated concrete for the construction of a private house, consider a specific example. Let's say we have a one-story house with walls measuring 6 and 8 meters and 2.8 meters high. The building has an attic space made in the form of a triangle, 2.5 meters high. The walls are laid using a gas block of a standard size 60 × 30 × 20 centimeters flat, so that the thickness of the wall is 30 centimeters. The house has 8 windows and two doors, the total area of the openings is 18 m 2.

Based on the basic dimensions, we determine the area of useful walls (6 + 8) × 2 × 2.8 = 78.4 m 2, excluding openings 78.4-18 = 60.4 m 2. Further, to determine the number of blocks on the laying of the walls of the first floor, it is necessary to calculate its volume, provided that the wall thickness is 30 centimeters - 60.4 × 0.3 = 18.12 m 3. According to building standards, there are 28 pieces of gas blocks in a cubic meter, so 18.12 × 28 = 507 pieces will be needed to erect the walls of the first floor. It should be noted that the amount of material will be slightly less due to the arrangement of mortar joints and the alignment of the masonry at the corners of the building.

Now let's move on to calculating the number of blocks for the attic floor device.We know that the walls are in the shape of a triangle with a width of 8 meters and a height of 2.5 meters. As you know, the area of an isosceles triangle for our case is 8 × 2.5 / 2 = 10 m 2, for two sides 20 m 2. Now we calculate the volume of building material 20 × 0.3 = 6 m 3, and the number of blocks in the attic is 6 × 28 = 168 pieces. In this regard, the total number of aerated concrete blocks for laying the main walls will be 507 + 168 = 675 pieces.

We calculated only the number of products for the construction of load-bearing walls, but in any house there are partitions and their volume must also be taken into account. Suppose the total length of all partitions in the building is 15 m, which means that the area of the walls will have the following value 15 × 2.8 = 42 m 2 (we assume that the area of window openings is subtracted from this indicator).

For the construction of internal partitions, gas blocks of the same size are used, but the products are laid on the edge so that the wall thickness corresponds to 20 centimeters. In this case, the volume of material will be the following 42 × 0.2 = 8.4 m 3, which is 8.4 × 28 = 235 pieces of blocks. In this regard, the total number of products for the whole house is 675 + 235 = 910 pieces.

Like any large-scale construction, the construction of an aerated concrete house should begin with a project. It indicates the dimensions of all walls - both internal and external, including the thickness of the "brick" - and, therefore, all the necessary data for our calculations.

Containment:

Many sites have a calculator for building a house from aerated concrete. Let's open it and start calculating. Let's start with calculating the gas blocks required for the construction of external walls. To do this, we need to know the following dimensions:

- The perimeter of all walls;

- the height of the house;

- wall thickness.

The amount of wall material depends entirely on several important indicators, which are entered into the formula of the calculator for calculating aerated concrete at home.

Must be taken into account:

- number of storeys, on which the height of the building depends, both outside and inside. Nuances can arise if there is an attic floor, which most often has a non-standard roof structure: gable, broken, triangular, pyramidal, symmetrical and asymmetrical, as well as a special configuration of windows. The average wall height (H), indicated in meters, is entered into the calculation form;

- the length of the outer walls (L) along the perimeter and inner partitions (the data are summed up);

- wall thickness. This indicator is not constant, since certain requirements are imposed on the thickness of the walls for different climatic conditions. The strength and thermal insulation of the structure also depends on the width of the stone in accordance with the rules and regulations. For example, in regions with a temperate climate, blocks must be at least 400 mm thick, provided that the stone is laid in one row. Only experts can give advice and recommendations on this indicator;

- door and window openings (the area is taken in total and denoted by S in square meters);

- the size of the stone itself

The final cost of the entire construction largely depends on how the calculation of aerated concrete for the house will be performed.

The uniqueness of aerated concrete blocks lies in the fact that the wall material has different sizes, wide stones are used for external load-bearing walls that are capable of withstanding significant loads, in particular, reinforced concrete floor slabs.

And for internal partitions, blocks with a smaller width are produced, due to which the usable area in the premises does not decrease.