Weight calculation

How much does the block weigh?

To carry out calculations, you must initially know the dimensions of the material and density.

Calculations are carried out according to the formula m = V * p. The designations are as follows: m - block weight (kg), V - volume (m3), p - density (kg / m3).

Help To find out the volume, you need to multiply all the values.

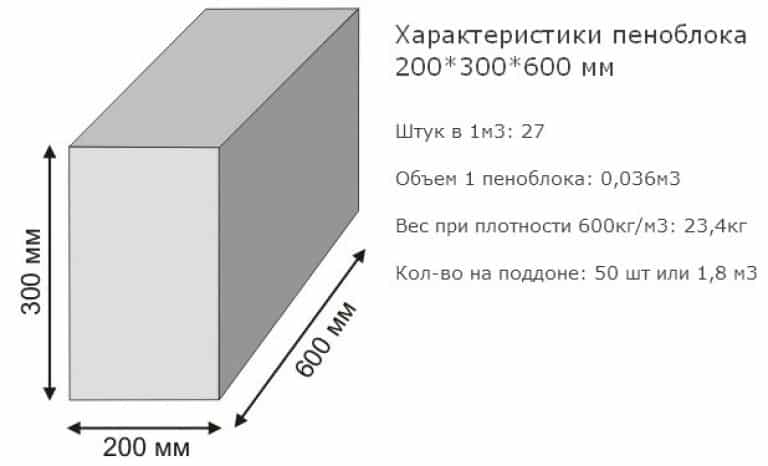

Calculation Given:

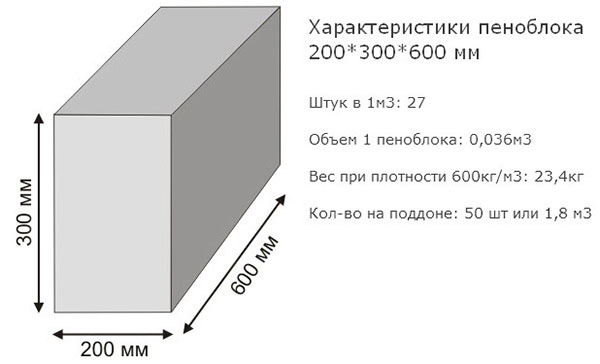

- Size: 200x300x600 mm

- Density: 500 kg / m3.

Solution:

- Knowing the dimensions, you can calculate the volume. For the specified product, it will be:

V = 200 mm * 300 mm * 600 mm = 36000000 mm3 = 0.036 m3 - Further, starting from the mark on which the density is indicated, the weight of the block is determined:

m = 0.036 m3 * 500 kg / m3 = 18 kg

Answer: The weight of the aerated concrete block 200x300x600, excluding humidity, is 18 kg.

Calculation Given:

- Size: 250x400x600 mm

- Density: 400 kg / m3.

Solution:

- V = 250 mm * 400 mm * 600 mm = 60,000,000 mm3 = 0.06 m3

- m = 0.06 m3 * 400 kg / m3 = 24 kg

Answer: Weight 250x400x600 excluding humidity is 24 kg.

If the calculation is made in order to determine the load of the walls of the house on the foundation, then humidity does not play a big role in determining the mass in this case. Since the parameter of humidity in the walls in use does not rise above 5% in any weather conditions.

At the initial stage of construction, the foundation will be loaded with walls, the load from which is greater than the calculated one due to the release moisture. But by the time of installation of windows, construction of a roof, interior and exterior decoration, installation of equipment and furniture, the wall material will release a significant part of the moisture into the environment and take the estimated mass. That is why moisture should not be taken into account when calculating loads.

Some self-builders build aerated concrete walls alone. And not by hearsay, they check on themselves the mass of the block only when masonry of the first row... In this case, they should understand that fresh factory blocks, due to the moisture they contain, will be heavier than the values calculated above by about 25%. If the wall thickness of the project is 500 mm, then one person will not be able to lift such heavy products. He will either have to take an assistant, or buy a lighter material with a thickness of 200 mm and 300 mm (and lay out a double wall out of it).

Note to the builder

Note to the builder

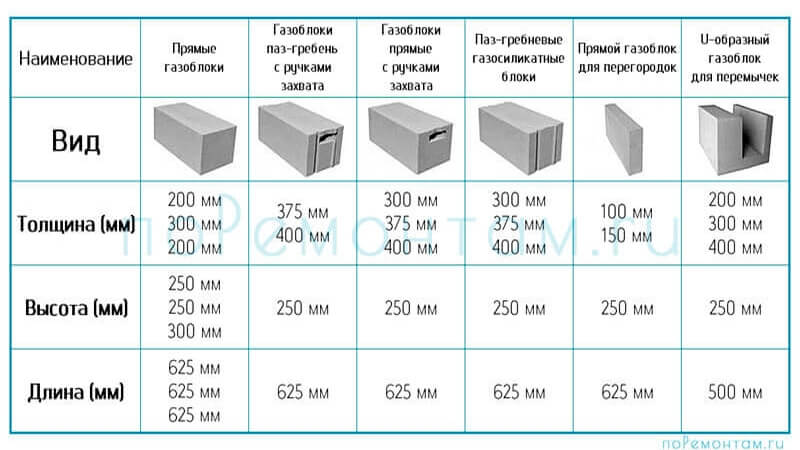

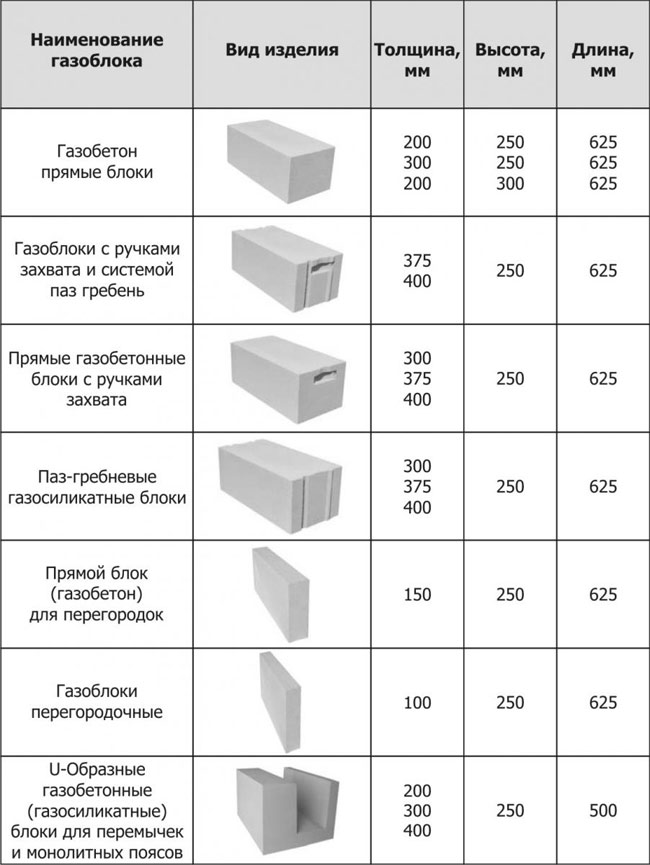

In addition to standard blocks with straight edges, some modern factories produce blocks with hand grips on both sides.

It is convenient to lift and carry such material.

In this case, the consumption of glue does not increase, since according to the installation technology, the voids do not need to be filled.

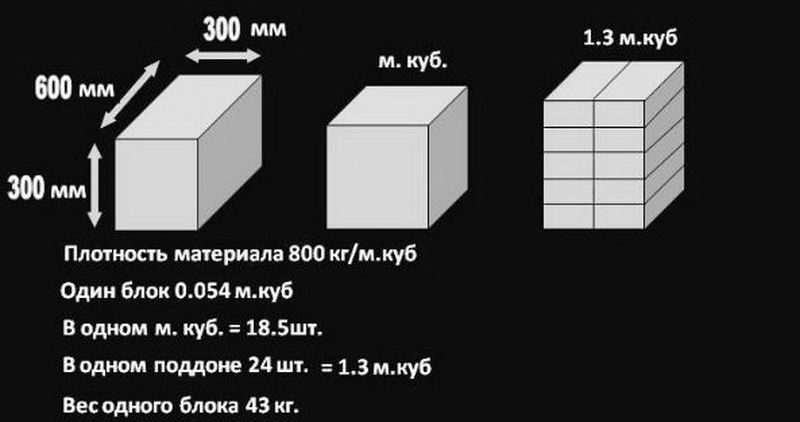

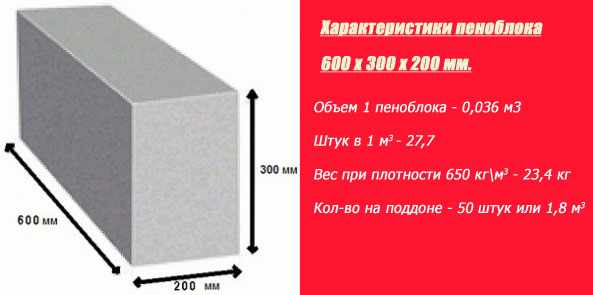

So, in our first example, a fresh factory block, just off the assembly line, will be 30% heavier than the calculated values. Its weight for our first example will be:

m = 18 kg * 1.30 = 23.4 kg

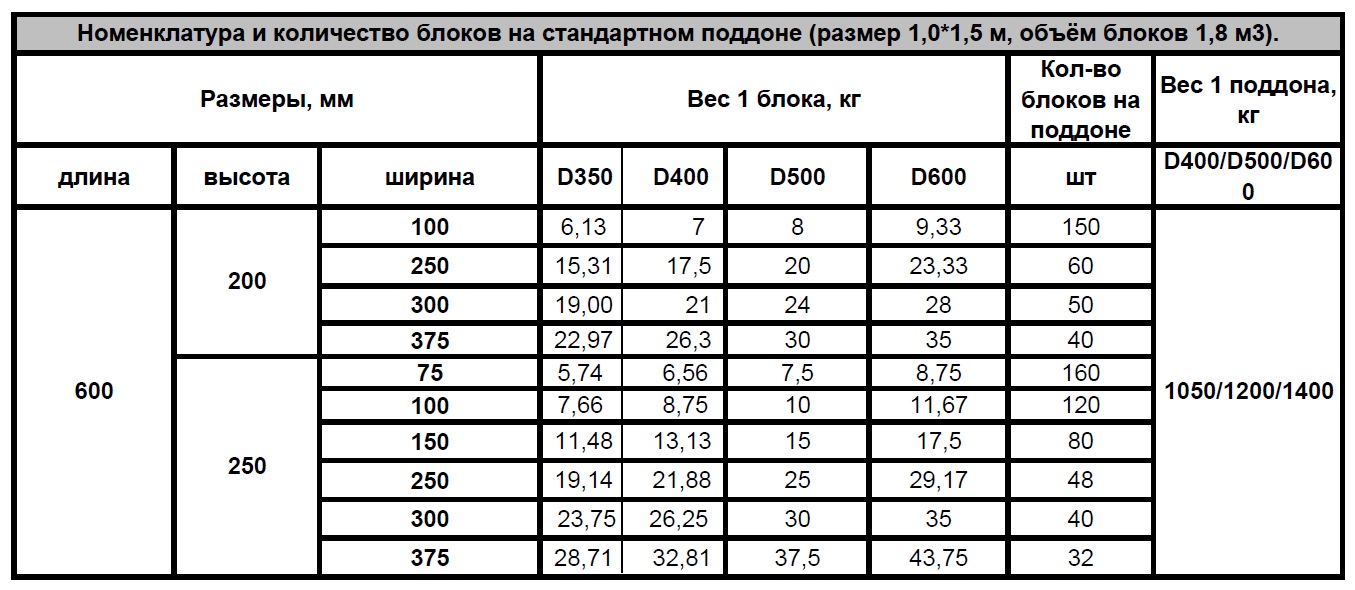

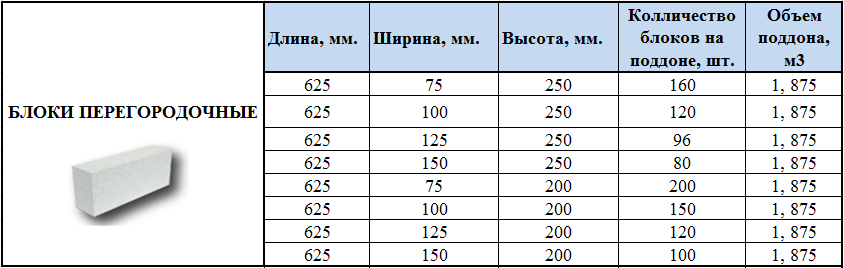

Pallet weight with blocks

This characteristic is useful when planning the delivery of material to the site. Each truck has limit values for carrying capacity and the volume of goods transported.

Let's say visually it seems to you that 10 pallets will enter the truck. But the driver, having learned the weight of the pallet, will say that he can take only 8 pallets. And he will be right, as the carrying capacity of the vehicle must not be exceeded.

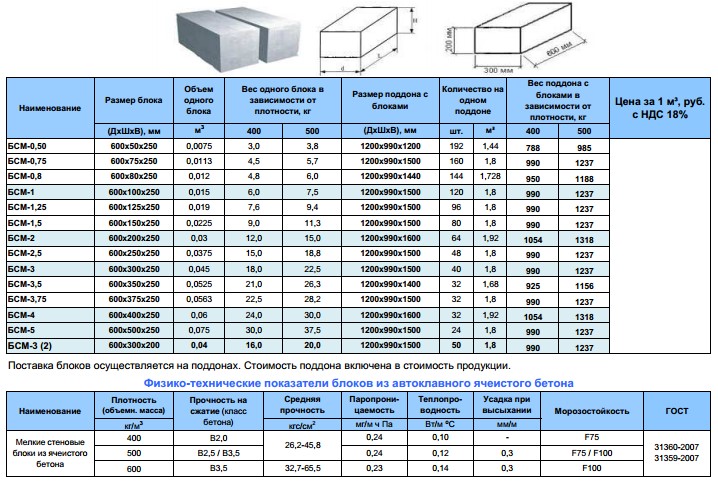

Determining the weight of a pallet with aerated concrete is easy. Knowing the number of units of material in the pallet and the weight of one gas block, multiply these values.

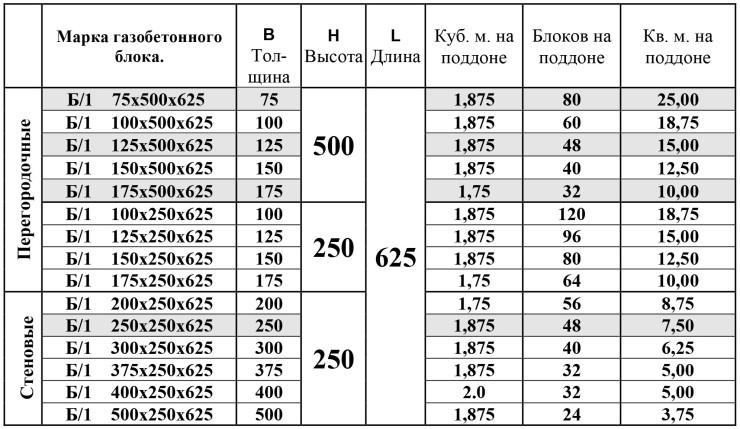

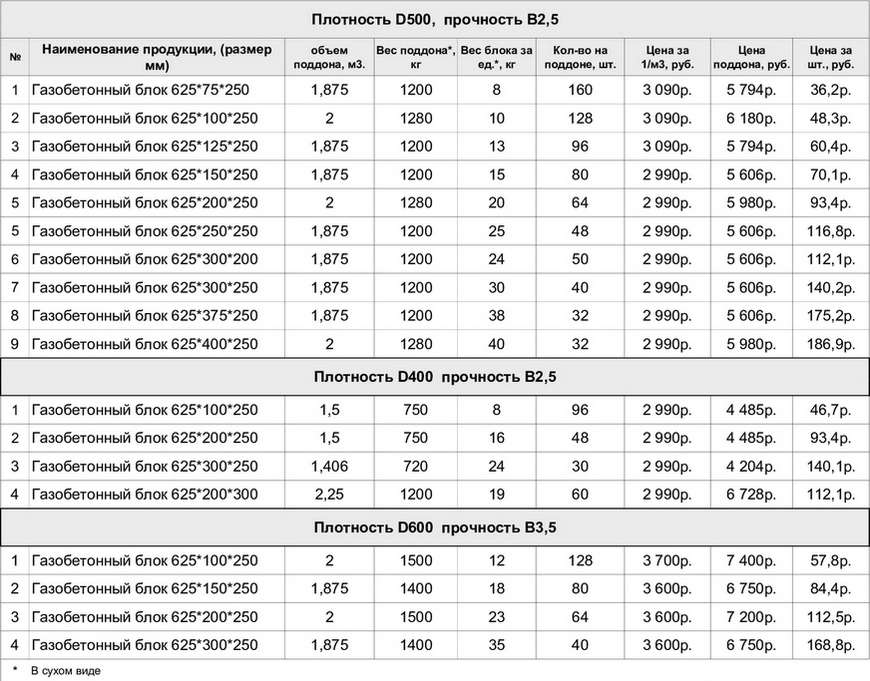

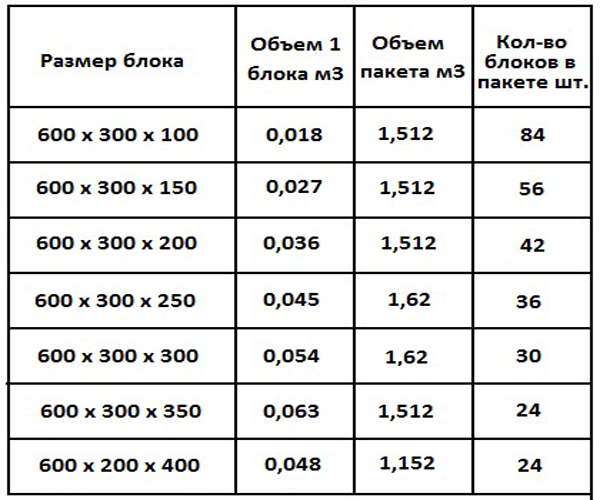

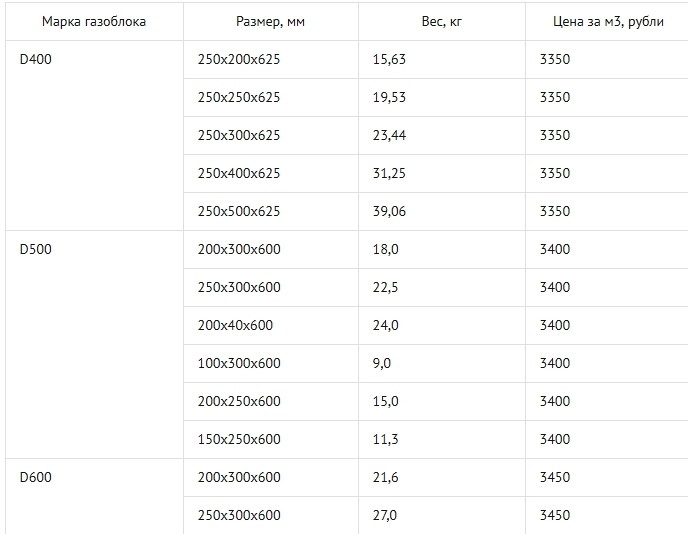

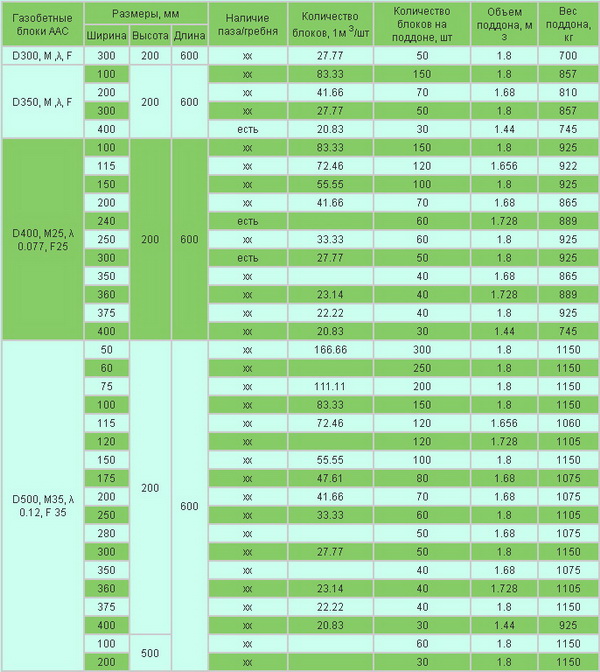

By the way, many sellers release the material from the warehouse in whole pallets. And in the price list indicate the density and volume of the pallet.

We already know that the density of blocks corresponds to the mass of one cubic meter. Accordingly, multiplying the density by the volume, we get the desired weight of the pallet.

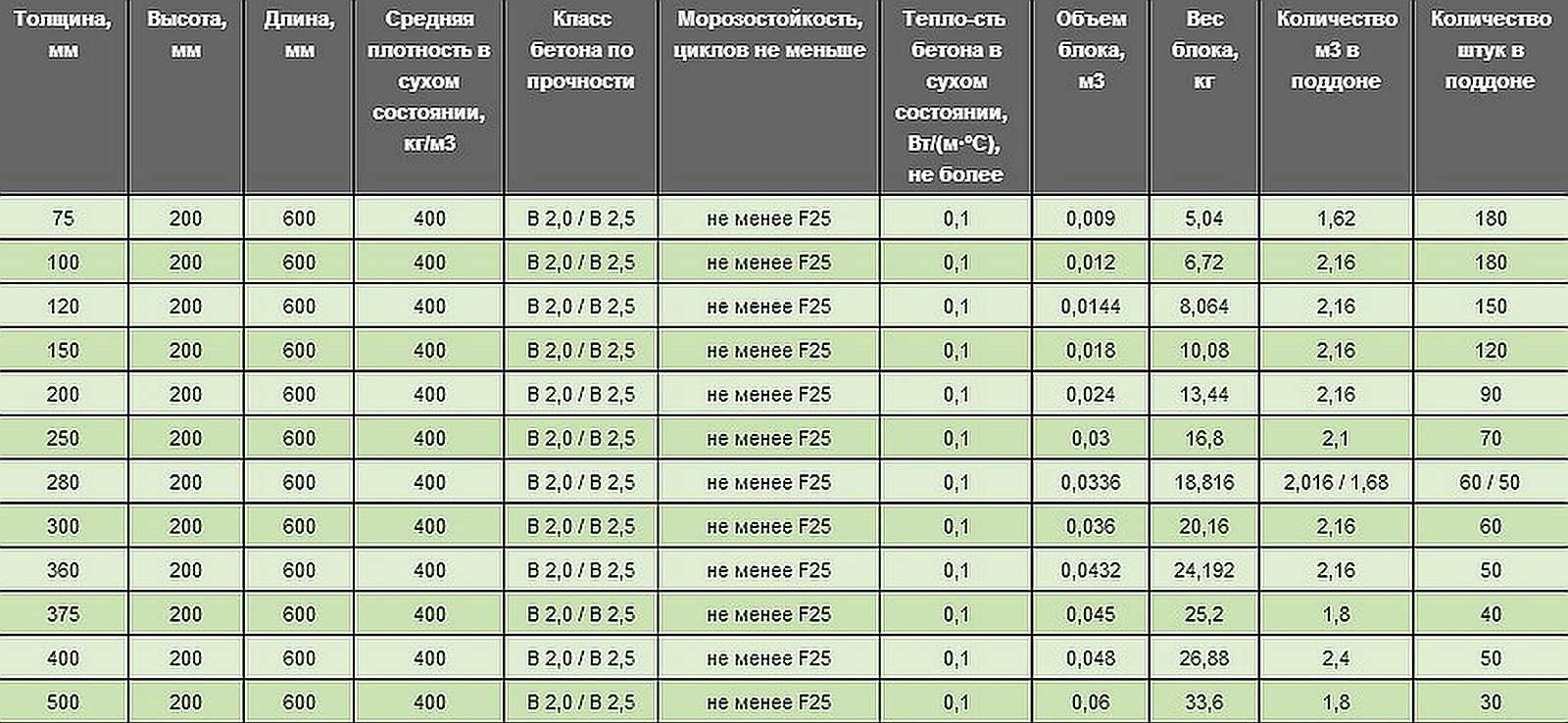

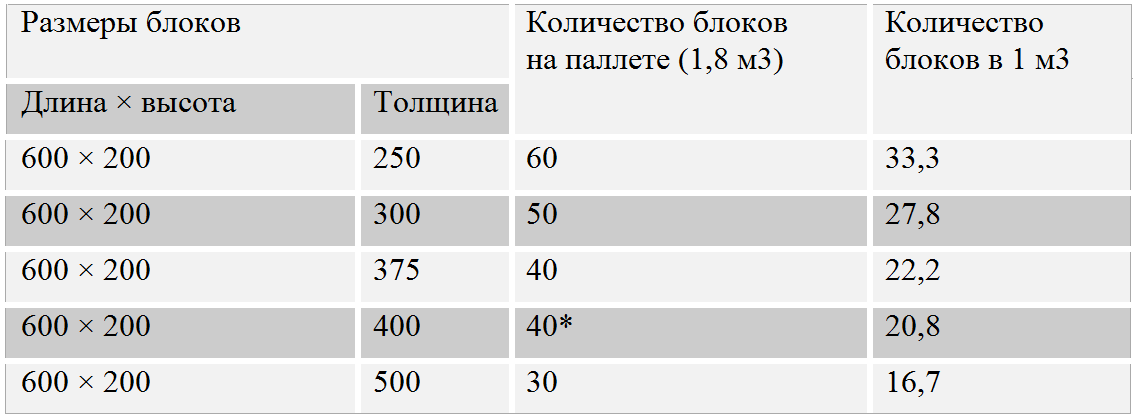

For example, as can be seen from the proposed price list, the volume of a pallet with blocks of 600x200x300 mm is 1.8 m3. Let's calculate the mass of the pallet for the density D400.

m = V * p = 1.8 m3 * 400 kg / m3 = 720 kg

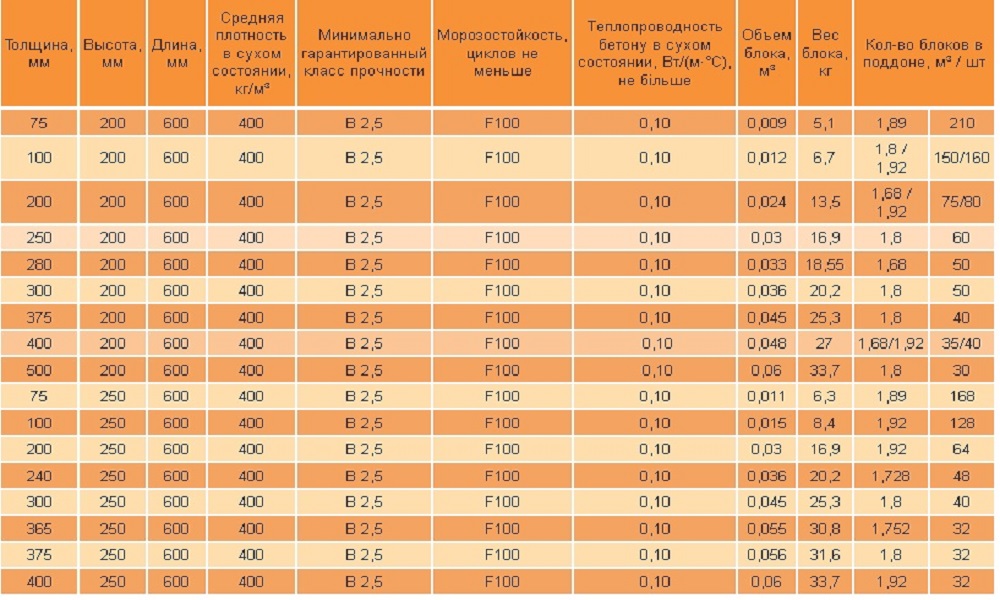

How much does a cube of aerated concrete weigh and determine the real density

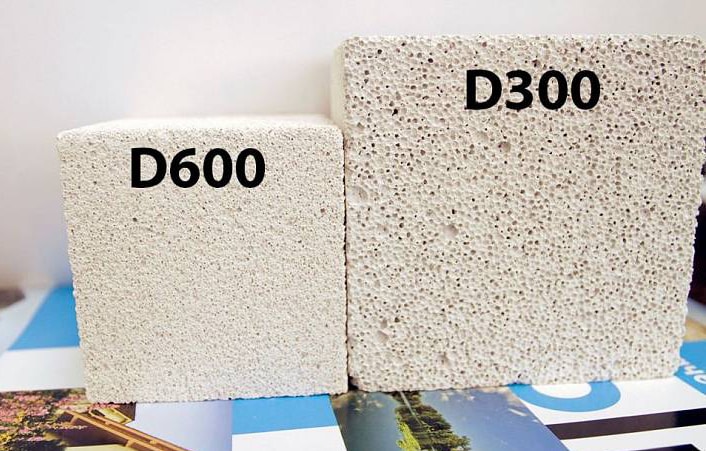

At the beginning of the article, the very first table shows these values without any calculation. The weight of a cubic meter of gas silicate material corresponds to the density indicated in the marking (D400, D500, etc.).

However, situations are different. You may want to check the compliance of the factory gas silicate with the declared characteristics. Or you don't have enough pallet of blocks, and your neighbor has surplus. At the same time, your neighbor does not remember the characteristics of his aerated concrete.

Attention! Having learned the real mass, we can calculate the real density.

In this case, we need to weigh 1 block and calculate using the inverse formula p = m / V. Where:

- m - weight (kg) - you need to find a scale and weigh 1 block;

- V - volume (m3) - we considered it above;

- p - density (kg / m3).

Don't forget to take moisture corrections.

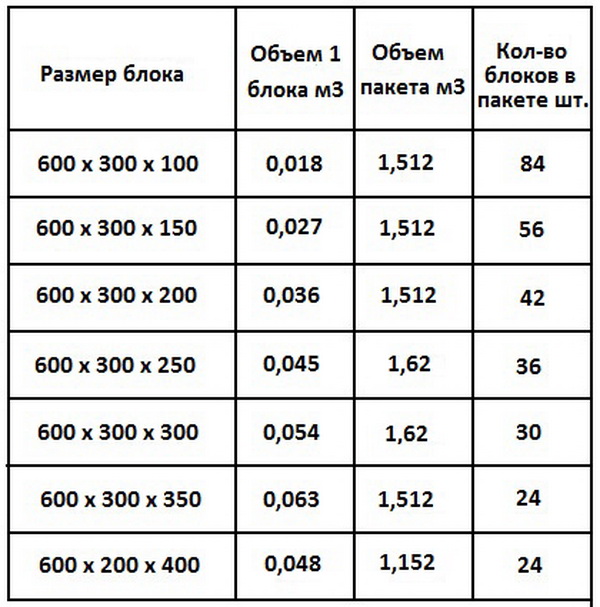

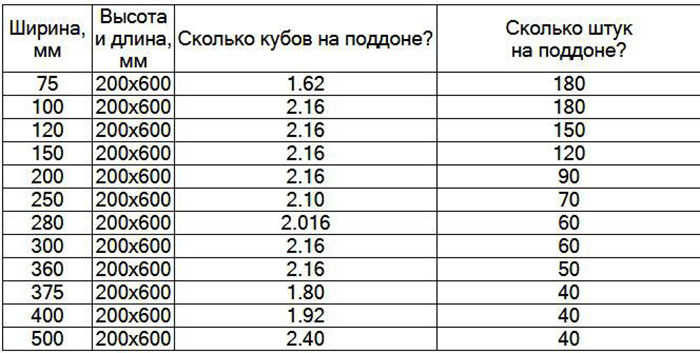

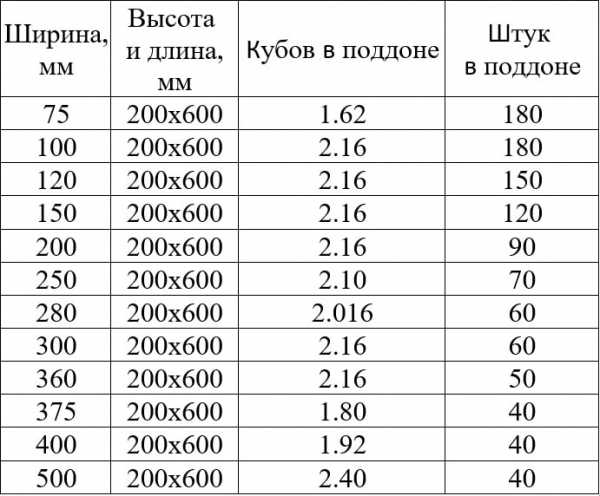

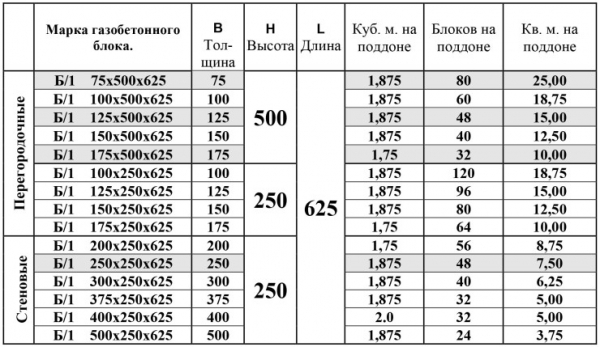

How many in 1 m3 of aerated concrete blocks in a pallet

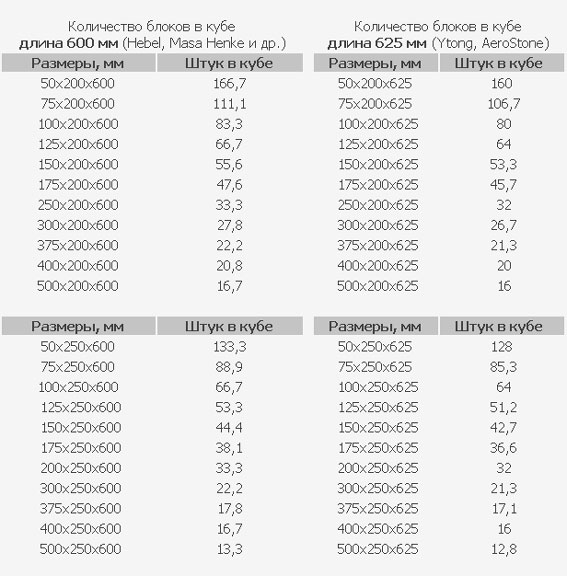

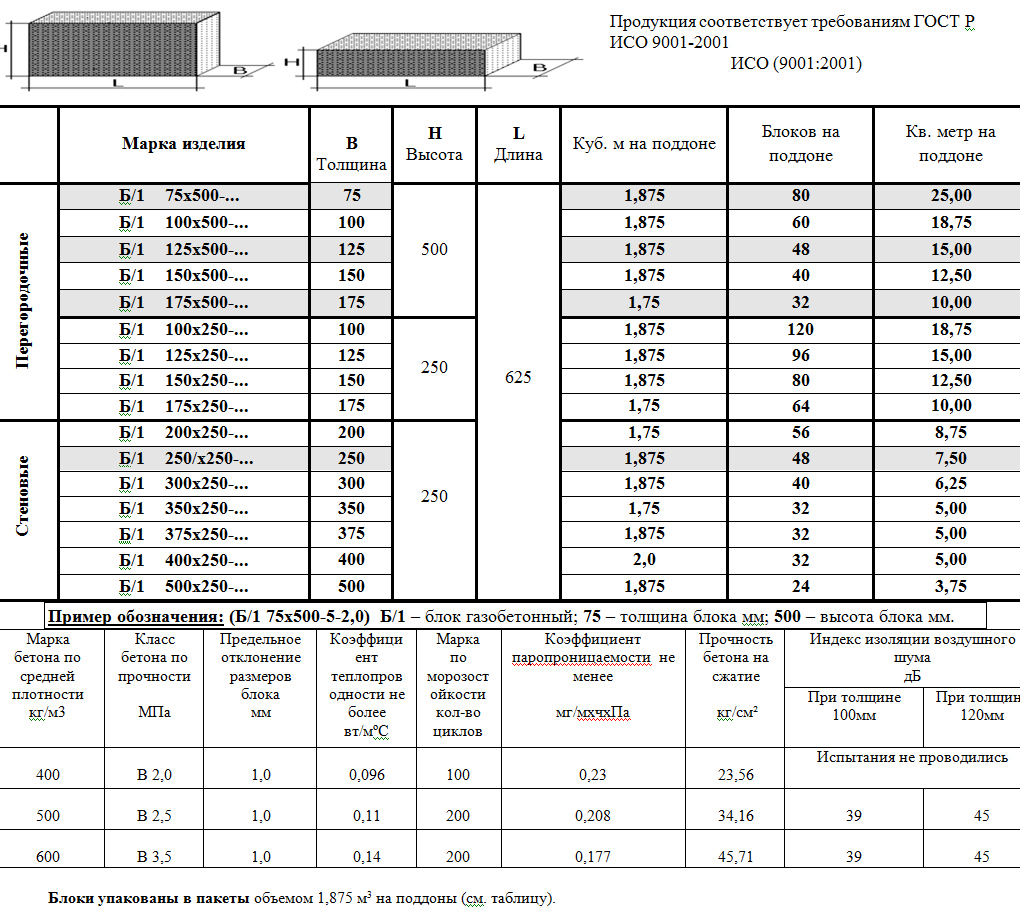

Manufacturers ship building elements in packs, in which 50 pieces of aerated concrete with dimensions of 600x300x200 mm are stacked. They occupy a volume of 1.8 m³. On pallets with a size of 0.9 m³, 25 pieces are stacked.

If the width is 10 cm, then 64 pieces can be placed on the pallet. with a volume of 1,152 m³. The principle of calculating the number of gas blocks in a pallet of non-standard size differs from the calculation of blocks of basic parameters. When buying a large batch of building material, it is not recommended to round off the calculated values.

How many pieces of foam block in the pallet are determined by arithmetic. On a pallet with dimensions of 80x120x14.4 cm, building materials are stacked in 4 rows of 8 pcs. When buying, losses that arise during the construction process are taken into account.

How to calculate

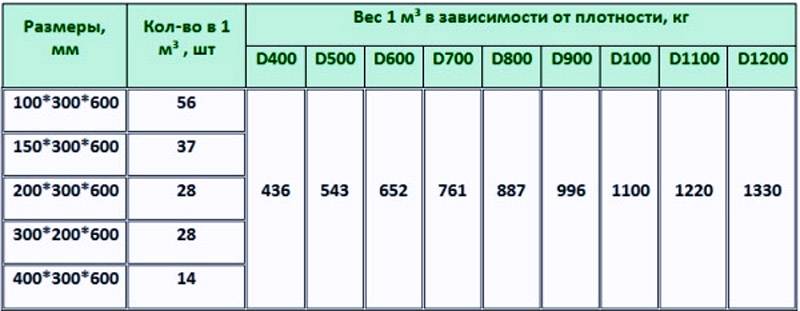

If it is necessary to calculate the weight of 1 m3 of the foam block, you need to take into account its dimensions and density. There are standard mass values adopted for blocks of a certain density and size.

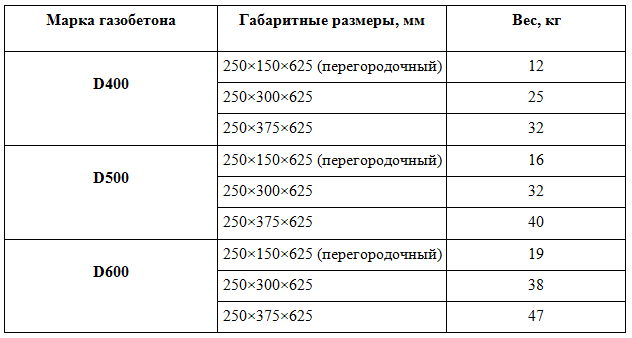

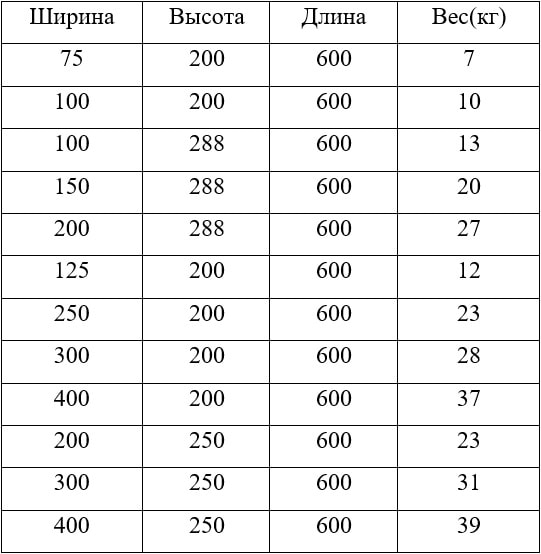

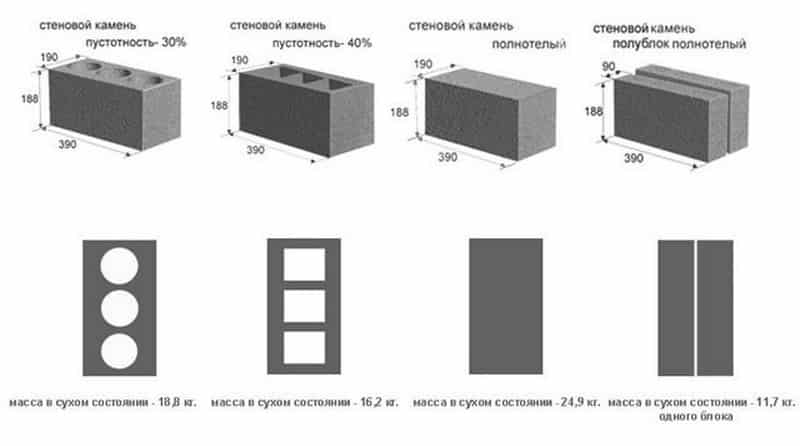

The standard weight of foam blocks measuring 600x300x200 millimeters of popular brands:

- D500 - with a porosity of 0%, the weight is 23.4 kilograms, if the porosity is 20%, then 18.75 kilograms, 50% - 11.7 kilograms.

- D600 - at 0% porosity, the weight is 27.72 kilograms, at 20% 22.18, if the porosity is 50%, then the weight is 13.86 kilograms.

The specific gravity according to the standards is determined by the brand: a cubic meter of D400 material weighs about 436 kilograms, D600 - from 450 to 900 kilograms, D1000 on average per cubic meter should weigh about 1100 kilograms. These figures are relevant provided that all established standards are strictly adhered to. Weight is determined by its composition and proportions of sand, cement, water, foaming agent.

The volumetric weight of a cubic meter of foam concrete in kilograms can be calculated by density: multiply the volume by the density

But in this case, the moisture indicator is not taken into account, which is very important. Indeed, as a certain volume of water is absorbed, the block increases its weight, sometimes by a significant indicator

The block volume is calculated by multiplying height and width by length.

So, for example, if you need to know the weight of a D600 density block with a size of 600x200x300 millimeters, then the total volume of the structure is 0.036 cubic meters (the value in meters is multiplied 0.6x0.2x0.3). The marking says that a cubic meter of a foam block weighs 600 kilograms. Thus, the weight of one block will be: 0.036 x 600 = 21.6 kilograms.

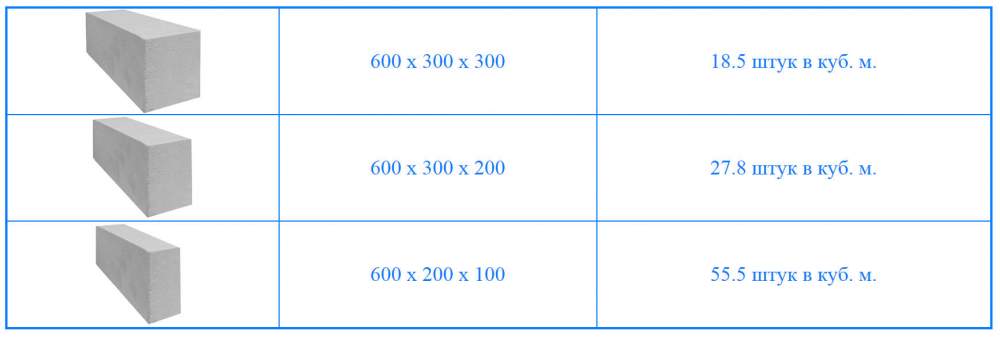

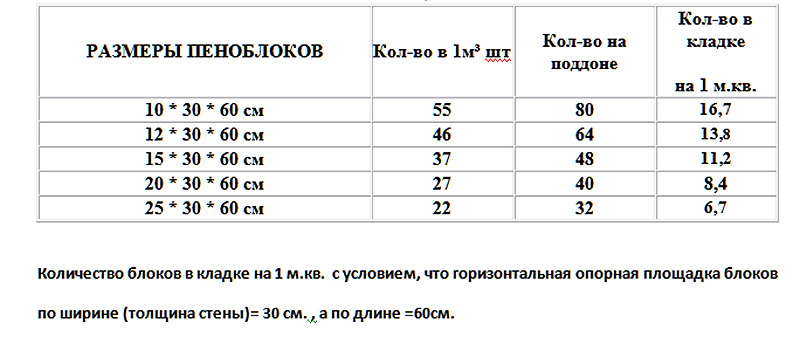

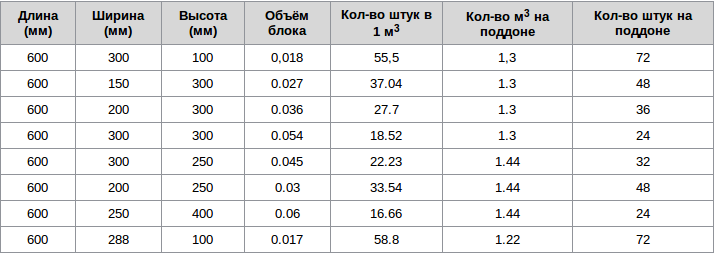

There are 27.8 pieces per cubic meter of volume. foam block measuring 600x200x300 millimeters. If we use blocks 100x300x600, the same volume will hold a little more than 55 pieces. Given the weight of 1 piece of product, you can calculate the total weight of one pallet / pallet.

But in all these calculations, the sorption moisture content of the material is not taken into account. So, according to GOST 25485-89, the level of sorption moisture content of foam concrete can be equal to 8-15% when it is produced on the basis of sand and, in addition, it can absorb up to 22% when using ash as a filler.

If we take it for a fact that the sorption humidity is at a minimum (8%), then another 1.728 kilograms should be added to the weight of the product with dimensions of 600x200x300. Thus, the total mass of the foam block will be at least 23.328 kilograms. If the sorption humidity is maximum, then the mass of the block will be 26.352 kilograms.

To avoid the need to independently perform all calculations, when buying a block, you need to clarify all the characteristics with the manufacturer, which must be confirmed by the appropriate certificates and other documents.

Due to the fact that foam blocks have a lower density and mass in comparison with traditional materials, as well as due to a decrease in the volume of mortar for masonry, the total weight of pressure on the base of the building is significantly reduced

This is important for both the partition wall and the wall unit. Significantly affects the characteristics of the scope of application of foam blocks: structural grades D600-900 have a weight of 23-36 kilograms, insulating D300-500 - 12-19 kilograms

The densest and heaviest blocks measuring 600x300x200 millimeters can weigh 40-47 kilograms. The average weight of the partition block is 21 kilograms. GOST prohibits the production of blocks with a length of more than 600 centimeters. Wall blocks for thermal insulation weigh 11.6-19.5 kilograms, partition wall blocks with dimensions of 100x300x600 millimeters weigh the least (5.8-9.7 kilograms).

Once again, it is worth mentioning the need for water correction when calculating

It is especially important to consider the value for grades D1000-1200: the dry weight of the blocks is 47 kilograms, but when saturated with moisture, the elements can weigh up to 50 kilograms. For one block, this is not much, but taking into account a large number of elements in transportation and calculating the load on the foundation, the values are significant

Be able to calculate and know how much does the foam block weigh, it is very important both at the stage of implementation of calculations in the project, and in the process of building a building. Only taking into account all indicators and adherence to technology will allow you to get a reliable, strong and durable structure

How many gas blocks are there in one cubic meter?

To get the best understanding of how to count materials for a project, let's go straight to an example. So, let's say we have a box of 6 by 4 m, 3 m high. We plan to install 3 window openings in it 1.5 by 1.5 m and a doorway 2 by 1 m. What are our actions:

- First, we calculate the volume of the wall made of gas blocks. (6 + 4) * 3 = 60 cubic meters. m. At this stage, windows and doors are not counted.

- Now we calculate the volume of the openings. 1.5 * 1.5 * 3 + 2 = 8.75.

- The total volume is 60-8.75 = 51.25 cubic meters. m.

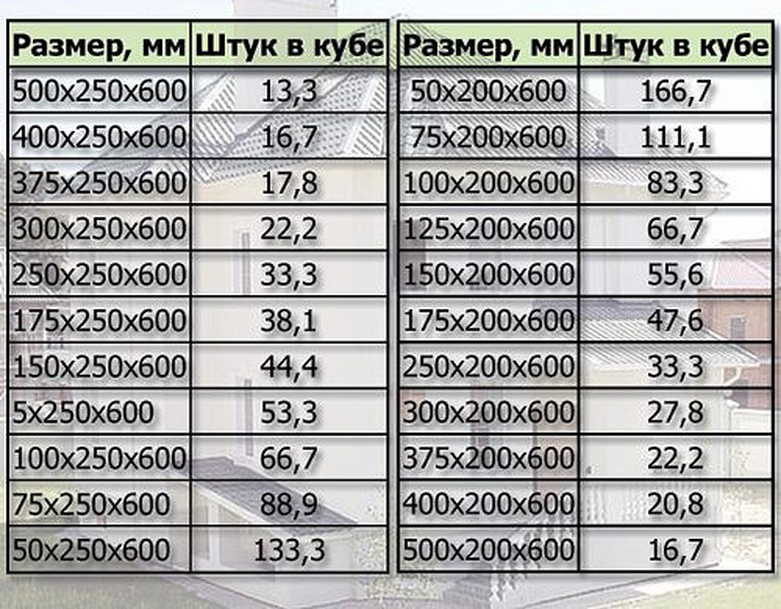

Now it is clear how the number of gas blocks is calculated. It is necessary to find out how many blocks are in 1 m3. To do this, we convert 1 m3 to cm.It turns out 1,000,000 cm3 (100x100x100). If we take the value of the most popular block size 600x300x200 mm, we get a volume equal to 36000 cm3. Now, in order to find out the number of gas blocks in 1m3, we need 1,000,000 / 36,000 = 28 pieces.

To find out the number of blocks that will be needed for the entire structure, you need to multiply 28 by 51. Get 1428 (1430) blocks.

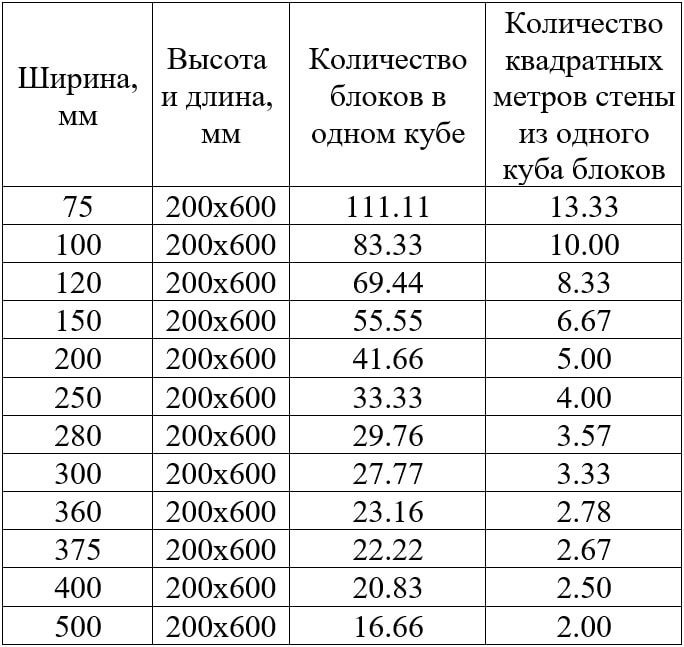

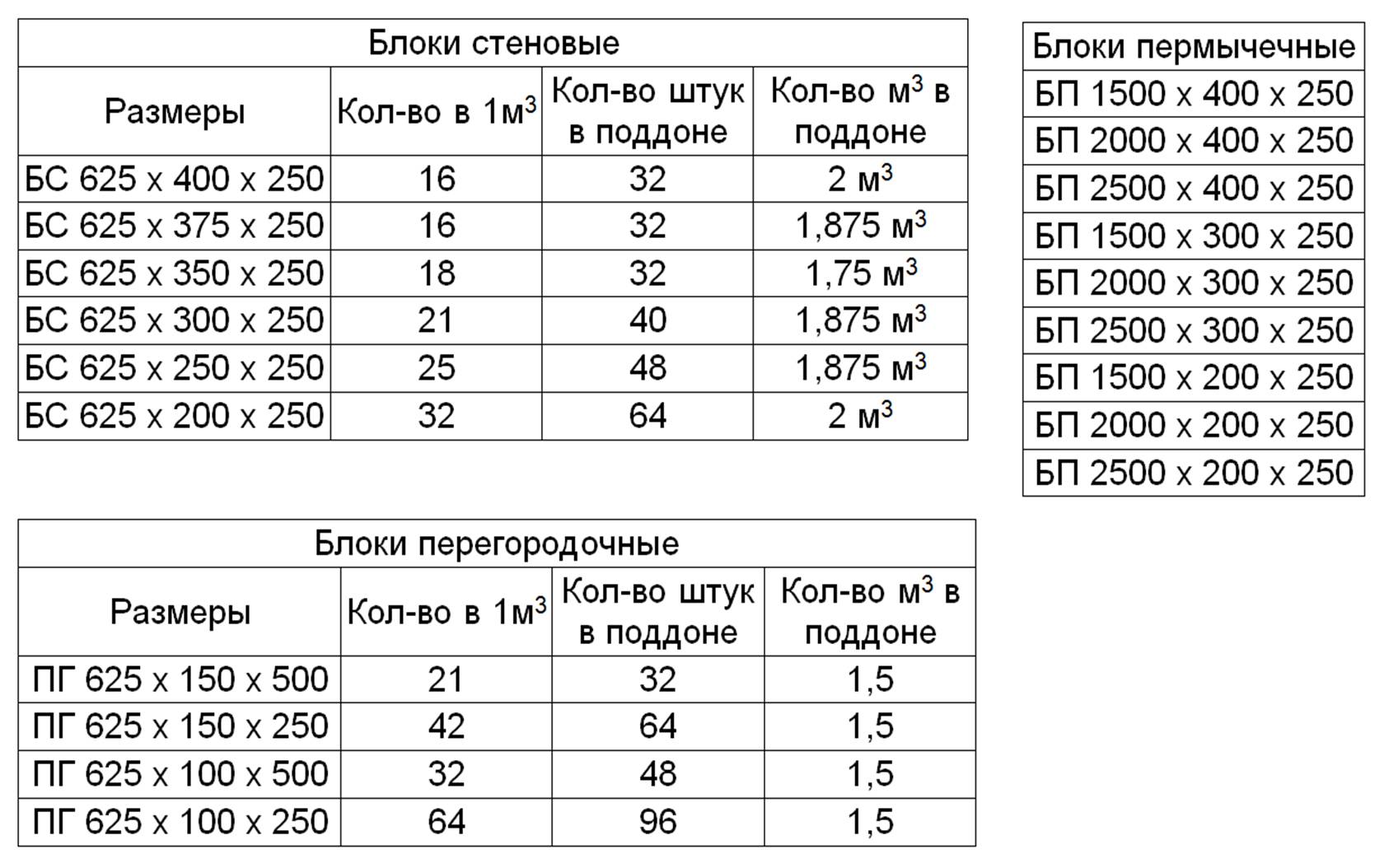

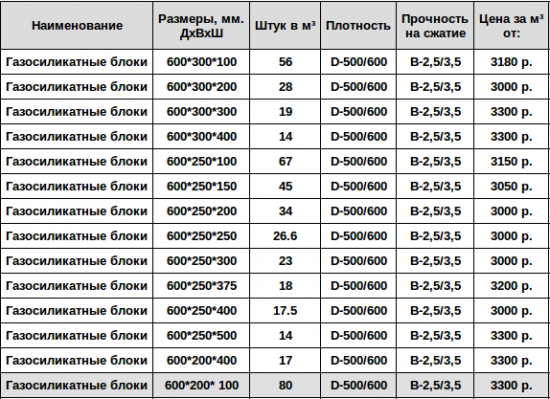

The table below shows values for blocks of different sizes and densities.

| Dimensions of aerated concrete block (DVSh), mm | Density, kg / m³ | Weight of one block, kg | Volume of one block, m³ | Number of blocks in a pallet, pcs. | The volume of blocks in a pallet, m³ | Mass of blocks in a pallet, kg |

| 600×300×200 | 500 | 18 | 0,036 | 32 | 1,152 | 576 |

| 600×300×200 | 600 | 22 | 692 | |||

| 600×300×200 | 700 | 25 | 807 | |||

| 600×300×250 | 500 | 22,5 | 0,045 | 24 | 1,08 | 540 |

| 600×300×250 | 600 | 27 | 648 | |||

| 600×300×250 | 700 | 32 | 762 |

Calculation of aerated concrete blocks and glue

| ROOM PARAMETERS: | |

| Wall height (m): | |

| External walls: | |

| Density class: | D350D450D500D600D700 |

| Wall length (perimeter) (m): | |

| Wall (block) thickness *: | 100 mm. 150 mm. 200 mm. 250 mm. 300 mm. 375 mm. 400 mm. 500 mm. |

| Area of door and window openings (m2): | |

| PARTITIONS: | |

| Density class: | D600D700 |

| Partition wall length (perimeter): | |

| Partition wall thickness: | 50 mm. 75 mm. 100 mm. 150 mm. 200 mm. |

| Area of door and window openings (m2): | |

| Total for the premises: | |

| APPROXIMATE VOLUME OF BLOCKS: m3 |

|

| VOLUME OF PARTITIONS: m3 |

|

| QTY BAGS OF GLUE **: PCS. |

|

|

* - wall thickness according to the project ** - glue consumption: 25kg per 1m3 of aerated concrete blocks with an adhesive layer thickness of no more than 3mm and a block size of 600x375x250. |

How to calculate the number of gas blocks per house 6 × 8 meters

To calculate the amount of aerated concrete for the construction of a private house, consider a specific example. Let's say we have a one-story house with walls measuring 6 and 8 meters and 2.8 meters high.The building has an attic space made in the form of a triangle, 2.5 meters high. The walls are laid using a gas block of a standard size 60 × 30 × 20 centimeters flat, so that the thickness of the wall is 30 centimeters. The house has 8 windows and two doors, the total area of the openings is 18 m 2.

Based on the basic dimensions, we determine the area of useful walls (6 + 8) × 2 × 2.8 = 78.4 m 2, excluding openings 78.4-18 = 60.4 m 2. Further, to determine the number of blocks on the laying of the walls of the first floor, it is necessary to calculate its volume, provided that the wall thickness is 30 centimeters - 60.4 × 0.3 = 18.12 m 3. According to building standards, there are 28 pieces of gas blocks in a cubic meter, so 18.12 × 28 = 507 pieces will be needed to erect the walls of the first floor. It should be noted that the amount of material will be slightly less due to the arrangement of mortar joints and the alignment of the masonry at the corners of the building.

Now let's move on to calculating the number of blocks for the attic floor device. We know that the walls are in the shape of a triangle with a width of 8 meters and a height of 2.5 meters. As you know, the area of an isosceles triangle for our case is 8 × 2.5 / 2 = 10 m 2, for two sides 20 m 2. Now we calculate the volume of building material 20 × 0.3 = 6 m 3, and the number of blocks in the attic is 6 × 28 = 168 pieces. In this regard, the total number of aerated concrete blocks for laying the main walls will be 507 + 168 = 675 pieces.

We calculated only the number of products for the construction of load-bearing walls, but in any house there are partitions and their volume must also be taken into account. Suppose the total length of all partitions in the building is 15 m, which means that the area of the walls will have the following value 15 × 2.8 = 42 m 2 (we assume that the area of window openings is subtracted from this indicator).

For the construction of internal partitions, gas blocks of the same size are used, but the products are laid on the edge so that the wall thickness corresponds to 20 centimeters. In this case, the volume of material will be the following 42 × 0.2 = 8.4 m 3, which is 8.4 × 28 = 235 pieces of blocks. In this regard, the total number of products for the whole house is 675 + 235 = 910 pieces.

Like any large-scale construction, the construction of an aerated concrete house should begin with a project. It indicates the dimensions of all walls - both internal and external, including the thickness of the "brick" - and, therefore, all the necessary data for our calculations.

Containment:

Many sites have a calculator for building a house from aerated concrete. Let's open it and start calculating. Let's start with calculating the gas blocks required for the construction of external walls. To do this, we need to know the following dimensions:

- The perimeter of all walls;

- the height of the house;

- wall thickness.

The amount of wall material depends entirely on several important indicators, which are entered into the formula of the calculator for calculating aerated concrete at home.

Must be taken into account:

- number of storeys, on which the height of the building depends, both outside and inside. Nuances can arise if there is an attic floor, which most often has a non-standard roof structure: gable, broken, triangular, pyramidal, symmetrical and asymmetrical, as well as a special configuration of windows. The average wall height (H), indicated in meters, is entered into the calculation form;

- the length of the outer walls (L) along the perimeter and inner partitions (the data are summed up);

- wall thickness. This indicator is not constant, since certain requirements are imposed on the thickness of the walls for different climatic conditions. The strength and thermal insulation of the structure also depends on the width of the stone in accordance with the rules and regulations. For example, in regions with a temperate climate, blocks must be at least 400 mm thick, provided that the stone is laid in one row. Only experts can give advice and recommendations on this indicator;

- door and window openings (the area is taken in total and denoted by S in square meters);

- the size of the stone itself

The final cost of the entire construction largely depends on how the calculation of aerated concrete for the house will be performed.

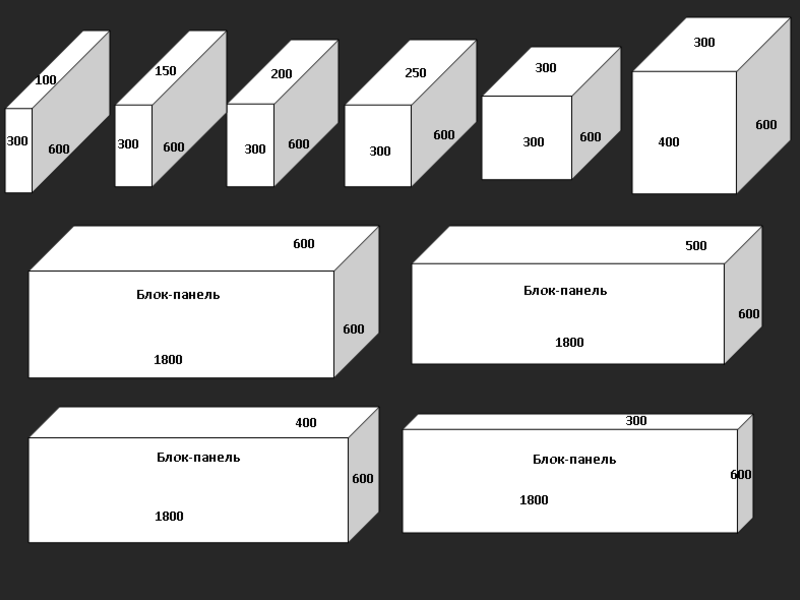

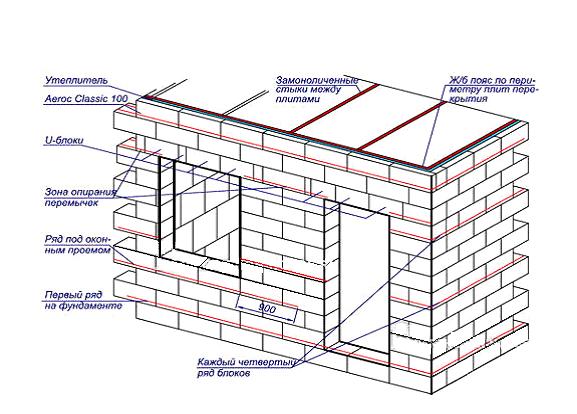

The uniqueness of aerated concrete blocks lies in the fact that the wall material has different sizes, wide stones are used for external load-bearing walls that are capable of withstanding significant loads, in particular, reinforced concrete floor slabs.

And for internal partitions, blocks with a smaller width are produced, due to which the usable area in the premises does not decrease.

Properties of aerated concrete

Today, one of the most reliable materials from which you can build a country house is aerated concrete, which is of two types:

- Solidification is atmospheric (natural).

- Autoclave hardening (artificial).

Layout of aerated concrete walls.

It is completely environmentally friendly, as it is made mainly of silicate sand and does not contain any unstable (vapors) compounds and harmful substances in its composition, which, of course, is better for human health. Rodents bypass aerated concrete. Its vapor permeability is very high, and this allows buildings to "breathe". The material provides a better supply of fresh air and leads to the outside of the exhaust carbon dioxide.

The low thermal conductivity of aerated concrete blocks (in comparison with concrete) makes it possible to better maintain a stable temperature level in the room. In a house with walls made of such building material as aerated concrete, it is warm in frosty winters and cool in hot summers. The premises do not overheat, and the walls with low air permeability feel "warm" to the touch and will remain so for a long time.

Since the aerated concrete production technology is autoclaved, the blocks are homogeneous with an almost uniform distribution of air pores, which, of course, is better for the strength of the material for construction. The geometry of aerated concrete depends on the simple form in which it is prepared, and therefore the blocks are almost perfect (with an error of +/- 1 mm). This allows simple glue to be used as a connector. At the same time, the costs and assembly time are significantly reduced.

Aerated concrete blocks for construction can be processed with any tool. Even with a knife, you can cut as many centimeters as needed. If you have a special cutting tool, the work is much easier. Aerated concrete blocks are produced with a density of 400-700 kg / m3. The calculation shows that under such circumstances, aerated concrete is much lighter than concrete and less pressure on the foundation supports. And therefore, it becomes possible to reduce the size of the foundation (in comparison with a concrete frame), which has a positive effect on saving money for construction. Aerated concrete has a long shelf life.

Now let's calculate how many blocks are needed to build a house

For your home, you will need to substitute your numbers to get the result.

OPTION 1 (very detailed based on the house plan)

- define the perimeter of all (and also internal) walls of the house (even in the case of a complex configuration, this is easy to do): fold the lengths of all sides based on the plan;

- determine the area of all walls: the perimeter (item 1) x the height of the walls;

- determine the total area of all openings - doors and windows;

- from the area of the walls (clause 2), subtract the area of the openings (clause 3). As a result of calculations, you will receive wall masonry area;

- masonry area of the walls (item 4) x block thickness = volume in cubic meters meters of blocks (number of blocks in cubic meters) required for masonry walls;

- count blocks per cubic meter (item 5) / number of blocks in a cube = number of blocks in pieces ,necessary for masonry walls.

Now let's consider the calculation of the number of blocks using the example of a specific house, using the plan of our house:

we find the dimensions of the house on the plan and for the calculation we take the length and width of the house: 10,800 m (the width of the house) x 2 + 24,000 m (the length of the house) x 2 = 69.6 m. is the design length of the outer walls of the house. Why in our case only the length of the outer walls is taken into account - this will be discussed a little later;

we find on the plan the design height of the house. We have it equal to 2.70 m., And the height of the basement of 0.4 m is not taken into account in the total height of the house 2.7 m

Pay attention to this when calculating for your home !;

- When laying the outer walls, the blocks will be laid in such a way that the width of the wall is 300 mm (0.3 m), i.e.the height of the block in the masonry will be 200 mm (0.2 m). As a reminder, the dimensions of our gas silicate block are 200 x 300 x 600 mm.

- when laying the walls, we used the thickness of which during laying is about 1.5 cm or 0.015 m per one row of masonry;

- in other words, taking into account the solution, the height of the block in the masonry can be taken equal to 0, 215 m;

- we consider how many rows of blocks we will have to lay: 2.70 m (design height of walls made of blocks) / 0.215 m (block height) = 12.56 rows. Of course. no one will lay half a block, so you need to decide how many rows you want to lay? We have chosen for our house the option with 13 rows of blocks when laying walls;

- those. without taking into account the solution, the height of the wall would be 13 x 0.2 m = 2.6 m

- we consider the total area of the outer walls: 69.6 mx 2.6 m (house height) = 180.96 square meters;

- it is necessary to find out the area of the walls minus the window and door openings, therefore, we also calculate the area of all openings on the basis of the plan;

- the plan shows that our house has two entrance doors (this is understandable: the house is designed for two families), two doors to the veranda and one door to the utility room. For simplicity of calculations, we will take the dimensions of the doorways the same: 1.2m x 2.10m.Total we get: 1.2 x 2.1 x 5 = 12.6 sq.m .;

- windows in the house will be:

- 2 large (2 x 1.2) x 2 = 4.8 sq.

- 6 medium: (1.5 x 1.2) x 6 = 10.8 sq. M.;

- 3 small for utility rooms: (0.7 x 1m) x 3 = 2.1m

- the area of window and door openings will be: 4.8 + 10.8 +2.1 + 12.6 = 30.3 square meters;

- the area of walls made of blocks, excluding window and door openings, will be: 181 - 30 = 151 sq. m;

- we consider how many blocks are needed for 1 sq.m. masonry walls: 0.2 m (block height) x 0.6 m (block length) = 0.12 square meters; 1 sq.m / 0.12 = 8.33 blocks;

- we consider how many blocks are needed for laying the outer walls, taking into account the openings: 151 sq.m. (wall area) x 8.33 pcs. = 1258 pcs.

- We planned to lay the inner walls as follows: the width of the block during laying is 0.2 m, the height is 0.3 m. Similarly, we calculate how many blocks are required for the inner walls: the area of the inner wall is 48 sq. m .;

- we consider how many blocks are needed for 1 sq.m. inner wall masonry: 0.3 m (block height) x 0.6 m (block length) = 0.18 sq. m; 1 sq.m / 0.18 = 5.56 blocks;

- 48 sqm * 5.56 = 267 pcs. blocks needed for the inner wall;

- final settlement: 1258 + 267 = 1525 pc ... blocks needed;

- 1525 / 27.7 = 55.05 or 55 cubic meters blocks are needed to build our house.

OPTION 2

Now gas blocks and other aerated concrete products can be considered one of the most promising wall materials, so many private developers turn their attention to them. If aerated concrete is chosen for the construction of a private house, then before the construction of the building it is necessary to create its project, which indicates the main dimensions of the walls, both external and internal, as well as the number and dimensions of windows and doors

At the design stage, the density of the blocks and their main dimensions are determined. It should be noted that the walls of the aerated block can be finished with ceramic bricks, which makes it possible to somewhat increase their thickness and thermal insulation properties.

Calculation of aerated concrete blocks

Storage of aerated concrete blocks

Storage of aerated concrete blocks

When calculating the economic part of construction, as well as for solving logistic issues, it is necessary to know the exact amount of the purchased material.

A simple instruction will help to deal with the basic calculations for gas blocks:

- How many m3 does the aerated concrete block occupy with its volume? It entirely depends on its parameters. Consider the most popular sizes 60 * 20 * 40 cm. The volume of one product is calculated quite simply - all sides are multiplied and the value is converted into meters. For example: 0.6 * 0.2 * 0.4 = 0.048m3.

- The number of blocks in one cubic meter can be calculated by knowing the previous figure, namely: 1m3 / 0.048m3 = 20.83 pcs. But, not a single seller will sell us too much, so we think approximately that there are 20 pieces in one cube. However, when calculating for large volumes, we take the true figure.

Blocks of various parameters

Blocks of various parameters

To purchase products for interior walls, you need to know how much aerated concrete is in a square meter. The principle of calculation is the same as in the first case

Only when multiplying the parameters, the thickness of the blocks is not taken, since it is important to cover the required area, and not to create the volume of the walls. Accordingly, the calculations will look like this: 0.6 * 0.2 = 0.12m2

By this action, we have calculated the quadrature of one block. In order to know exactly how much aerated concrete is needed per square, we perform the following action: 1m2 / 0.12m2 = 8.33 pcs.

How many aerated concrete blocks are on the pallet. There are no standards for laying a certain volume of aerated concrete blocks. It all depends on the standards adopted at the enterprise. But, as a rule, they try to fit 1 square meter of small-piece wall products on a pallet.

Automatic stacking of blocks on pallets

Automatic stacking of blocks on pallets

Knowing the unit volumes of the blocks, it becomes possible to accurately calculate their total number for building a house. For this, the total square of the bearing walls is calculated by multiplying their height by the total perimeter minus all door and window openings.

If the load-bearing walls according to the project need to be erected in two blocks, then, accordingly, this value is doubled.

The video in this article will tell you in more detail how to calculate volumes taking into account all the geometric subtleties of the project.

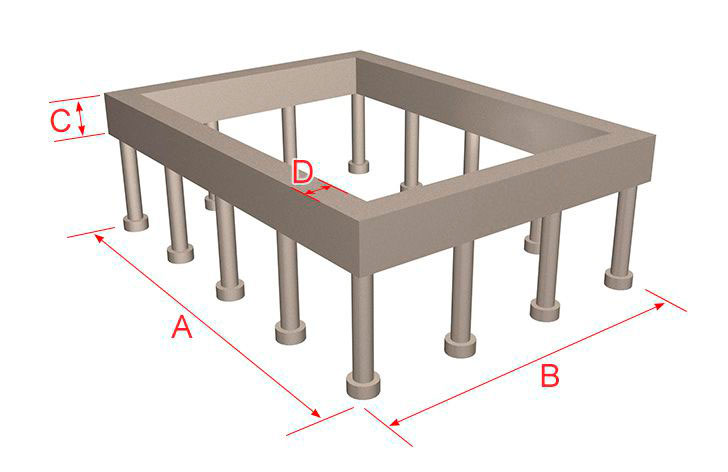

Calculation of the pile foundation

Select the type of grillage:

Grillage parameters:

Grillage width A (mm)

Grillage length B (mm)

Grillage height C (mm)

Grillage thickness D (mm)

Concrete grade

M100 (B7.5) M150 (B10) M200 (B15) M250 (B20) M300 (B22.5) M350 (B25) M400 (B30) M450 (B35) M500 (B40) M550 (B45) M600 (B50) M700 ( B55) M800 (B60)

Poles and piles parameters:

Number of poles and piles (pcs)

Column diameter D1 (mm)

Post height H1 (mm)

Post base diameter D2 (mm)

Post base height H2 (mm)

Reinforcement calculation:

Rebar length (m)

Calculation of the grillage formwork:

Board width (mm)

Board length (mm)

Board thickness (mm)

Calculate

Transportation and storage of aerated concrete

The photo shows how much aerated concrete can fit in a pallet

The photo shows how much aerated concrete can fit in a pallet

Knowing how many aerated concrete blocks are in a pallet, you can easily calculate the total volume and number of flights required to transport the entire amount of products. For such calculations, it is also necessary to take into account the carrying capacity and area of the transport used.

What else you need to know when working with gas blocks:

It is highly discouraged to transport products unpacked or in loose masonry, especially over long distances and along a country road. If the blocks fall, there is a risk of breakage.

Aerated block marriage

Aerated block marriage

- When buying aerated concrete, you need to provide them with a high-quality storage area. After all, such a material is susceptible to moisture and after a while can begin to deteriorate.

- It is recommended to place pallets on a flat asphalt area away from puddles and slush.

- If the manufacturer did not provide for the packaging of the pallet of blocks completely in polyethylene, then it is advisable to place aerated concrete under a canopy, especially if long-term seasonal storage is expected.