Do-it-yourself sealing of connections

Silicone compounds can be applied even without sufficient experience and knowledge - the process is simple, but it is carried out strictly according to the technology.

Preparation of the treated surface

Any dirt, dust, oil stains, remnants of old compounds (mastics, grout) must be removed from the bases on which the sealant will be applied. After mechanical cleaning of the surfaces, degrease them with alcohol, acetone or special solutions.

If you have to seal the gap between the bathroom and the tile with plumbing sealant, you need to pour water into it before starting work. When the tub is full and under load, the edge portions are always slightly deformed, and the sealing seam will immediately take the desired position.

Sealing

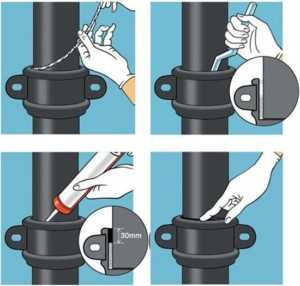

Most sealants in tubes and cartridges are excellent for installation in a nailer. The tool helps to apply funds more accurately, faster, in the strictly required amount. The procedure for working with plumbing sealant:

- Remove the cap from the tip of the tube.

- Cut off the tip of the nozzle at a 45 degree angle.

- Put the tube in the gun.

- Slowly and carefully pulling the trigger, apply the sealant.

For the quality of the joint to be good, the line of the sealant must be continuous. It is recommended to start it from any angle. After the completion of the seal, it is required to correctly form the seams, which will distribute the composition and increase the reliability of work.

Creating a seam

If the seal is small, you can use your finger to shape it to the desired shape. It is necessary to put on gloves, gently smooth out the sealant, moving the excess and directing them to where the layer came out thinner. With a large seam area, smoothing is performed with a narrow spatula, having previously moistened it with soapy water.

Finishing

To complete the sealing, it is necessary to remove the excess compound that has crawled out of the seam using a wet napkin. The initial setting period of the sealant is short, so you must act quickly, otherwise, when removing the excess, the entire seam may be damaged. After a few days, you should carefully examine the sealant layer. If defects, voids, cracks appear on it, they must be repaired.

Views

Of course, a lot of water has flowed under the bridge since the use of flax fibers as a sealant for water pipes. Including through this method of sealing. Nowadays, there are two main types of sanitary products for covering up gaps: universal and neutral.

Universal sealants are made with the addition of acetic acid (they are also sometimes called acidic) and have a corresponding odor. Such a tool is applicable to any surfaces for which contact with acid is not contraindicated. Non-ferrous metal, cement and marble are materials that should never interfere with the universal sealant.

Neutral variants are based on alcohol or ketoxime. These products are suitable for contact with any surface. Seams made with a neutral sealant do not collapse or deform under the influence of acidic or alkaline agents, do not come into contact with the surface to be treated.

Another addition to the neutral sealant is silicone rubber.

Among the advantages of such a putty, the following stand out:

- maximum adhesion to all types of surfaces;

- very moisture resistant material;

- has good resistance to direct sunlight;

- efficiency is observed in the temperature range from -60 to +300 degrees Celsius;

- practicality and durability.

Silicone adhesive sealant is a liquid transparent sealant that provides not only sealing of the room, but also glues the surfaces in the required places. It is not an electrical conductor, it is easy to apply, it serves for a long time, it is invisible due to its transparent structure, it is heat-resistant, it is completely safe from mechanical damage.

Alkaline sealant is a special-purpose agent that is used in rather rare cases, as a rule, it is in the form of a paste.

It is easy to get lost in such an abundance of building materials. Let's try to understand the main areas of application of sanitary sealant.

Advice

Practical advice on sealing the premises will help you quickly and efficiently carry out all the work. As practice shows, with modern means for waterproofing, it will not be difficult to do this even for a person who first picked up a tube with a sealant.

- At the first stage, it is necessary to prepare the scope of work. Before sealing, it is necessary to clean the surfaces from construction dust, dirt and foreign objects. To fill the joints between the bathroom and the tile, you need to draw in the first water, which will ensure its working condition. It is from this position that it will be more convenient and rational to apply the sealant.

- The next step on the road to waterproofing is sealing itself. First you need to open a tube with a pre-selected remedy. Cut off the end of the spout at an angle of 45 degrees. We insert the tube into the assembly gun. If it is not at hand, craftsmen recommend using any piston: be it a hammer handle or any other durable heavy object that will help squeeze the sealant onto the surface. Of course, this way is more labor-intensive and time-consuming, but it also takes place.

- Proceed with applying the required sealant coat. It should be remembered that the line must be continuous, of the same thickness. If something went wrong, it is better to immediately take action to remove the incorrect section. Otherwise, after drying, you will have to use additional agents such as a solvent.

- The third step involves the design of the insulating seam itself. This is done with a small spatula. This process can be carried out with your own hands, having previously protected your hands from contact with the silicone mass using gloves. So, with the selected tool we cover the seams so that they turn out to be even and neat. For greater performance and practicality, professionals advise to wet the spatula with soapy water before each contact with the sealant.

- At the fourth stage, the final cleaning of the working surface from excess silicone, dust, water and other things is carried out.

For information on how to use the sealant correctly, see the next video.

Sealing water pipes with tow

This method is the easiest way to deal with leaks in the water supply system. Even professionals use it to this day. But in order for the work to be done successfully, a number of points must be taken into account. In short, they sound like this:

- correct selection of material. The tow should be soft and thin, without inclusions of any kind;

- accuracy when performing work. The tow is impregnated with a special substance, traces of which, at times, are removed with great difficulty;

- finishing treatment. The fibers of the tow that remained in sight are carefully removed after the end of the sealing.

Below is the procedure for performing joint sealing with this water pipe sealant.

- First, divide the tow into several strands. The recommended thread thickness is 1 millimeter, but in practice the value of this parameter is determined by the characteristics of the thread.

- Apply a small amount of impregnating agent to the threads of the ends, spreading it evenly over the surface. This paste will act as a glue for tow.

- Wind the fiber clockwise around the right-hand thread. If the thread is left-handed, then naturally in the opposite direction.

- Soak the tow that has been wound to the end with the product.

- Then connect the pipes together.

It is not possible to specify the exact number of windings required. Therefore, it is recommended to make test runs of water. The appearance of leaks will tell you that there is not enough tow. But using it in excess is not the best solution. When tightened, the thread may simply break off and the pipe will become unsuitable for installation.

Scope of application

For those who decide to resort to the help of this super-means for carrying out the sealing process in the bathroom, the question of choice is not worth it. Silicone sealant is used, as a rule, to create seams between plumbing fixtures and the walls of the room, so that moisture does not get into these gaps. Transparent plumbing material is used for connections of sewer and water pipes. Sometimes a special FUM tape is also suitable for these works.

One of the types of sealant for sewage and water supply pipelines is epoxy resin. But first it is mixed with a hardener. In this case, it is imperative to follow the instructions for creating such a sealed product.

When it comes to machining cast iron pipes, a standard plumbing sealant is used.

There are actually a lot of areas for the use of silicone and polypropylene compounds in an apartment. And here we can talk not only about the processing of a water block, a bathroom, and so on. Sometimes a sealant is used to seal the joints between the window frame and the opening.

It is very convenient to resort to the help of white sealant when installing the toilet

In this type of plumbing, a large number of points are concentrated, which should be paid special attention to. So, the water hose supplying liquid to the tank has a peculiar shape, which can be sealed either by an FUM tape or a neutral silicone sealant

To seal a pipe channel in a cable duct, you can use both standard neutral or acidic sealants, and Portland cement, which is more powerful in its properties and functions.

Sealing connections with your own hands

Silicone sanitary sealant is a compound that can be applied independently, even without installation and construction skills. All work on the application of the sealing mixture is carried out in stages. Let's talk about each stage separately.

Stage 1. Preparation of the treated surface

Before starting, it is required to carry out work on the preparation of the surface, which is planned to be treated with silicone sealant. It is necessary to remove from it the remnants of old mastic or grout, dirt, dust, oil stains, etc. In any case, it is recommended to use degreasing compounds.

Stage 2. Sealing

Silicone moisture resistant sealant is sold in special tubes that may have a plastic tube for applying the composition. To make the job easier, you can use a nailer, which can be used to apply sealant mixtures faster and more accurately, ensuring the correct dosage.

If there is a pistol, then the work is carried out in the following sequence:

- First, remove the plug from the tip of the silicone sealant tube.

- Then you need to cut off the end of the nozzle at an angle of 45o.

- Next, you need to install the tube with the mixture into the gun and start processing.

- The trigger mechanism of the pistol must be pressed gently, lightly.

- The processing of joints and gaps must be started from the corner. Apply silicone sealant in a continuous, long line.

Stage 3. Creating a seam

In the third stage, seams need to be made.For ordinary household work, this is done simply with your finger. But you must first put on protective gloves. It is necessary to smooth out the applied composition carefully, removing all excess and adding the mixture to those places where it is not enough.

In the video: The technology of using silicone sealant.

Stage 4. Finishing

At the last stage, you need to remove all the resulting excess with a napkin. It should be understood that transparent or white silicone sanitary sealant has a very short drying time, therefore, upon completion of work, you should quickly wash your hands, clean the tools and equipment used.

There is a high probability that some imperfections (holes, cracks and other defects) will be found in a few days. They can be closed with the same compound that was used to seal gaps and joints.

How to apply the sealant correctly. Step-by-step instruction

Silicone based sealants are available in 310 ml plastic tubes. How to use silicone glue sealant? Before using the sealant, it must be prepared:

- The tip of the tube is cut first.

- Next, the cap that comes with the kit is put on it.

- The distributor is then cut at the desired angle.

- Then the prepared sealant is inserted into a special gun. Then it is fixed in the tool.

Starting work, insert the cap of the tube into the joint and, pressing the trigger of the gun, evenly distribute the seal on the base to be processed.

The sealant should not be saved. All cavities in the gap must be filled. Otherwise, when the sealant hardens, cracks may appear between the base and the seal.

Often, a filled joint does not turn out to be completely flat. In this case, there is no need to wait for the sealant to dry. It is necessary to remove its excess and smooth the seam with a moistened rubber spatula. You can also use a small plastic scraper for this.

Professional builders often level the filled joint with a finger soaked in a solution of laundry soap.

How to remove from the surface

The silicone seal is flexible, but nevertheless durable. It adheres firmly to the base. Tearing off the seal from its surface is not easy. The material has to be cut by inserting a sharp knife between the interlocking surfaces.

Therefore, it is necessary to work with the silicone sealant carefully.

But what if you still need to remove the hardened sealant from the base? When the silicone layer is quite thick, it is relatively easy to remove. It should be hooked with something and simply ripped off the base.

A different situation arises if you have to remove a thin layer or stains of inaccurately applied material. It is difficult to remove them, especially when it is necessary to maintain a sealed joint.

This method works well for a fresh seal that has not reached 100% strength.

Old material is removed only with the help of chemical compounds that soften it. There are many cleaners available from manufacturers to help remove old sealant. The best ones are:

Acrylic and silicone based sealants

The main component of the substance is a silicone or acrylic rubber material. Ultimately, it allows a firm fixation of the pipe joint.

According to the type of hardener, silicone pipe sealant is divided into the following types:

- Acid. Such a product is distinguished by its low cost; it is not advised to lay it on surfaces that do not react well to acid. A characteristic feature of this version of plumbing sealant is that it reacts with almost all metals. The only exception is stainless steel.

- Neutral. This is a more versatile material. It is suitable for most installations, resulting in a higher cost.

Using silicone sealants, it is possible to seal sewer pipe-rolling materials made of metal and plastic. It's not difficult to work with them.

They can be easily squeezed out with an assembly gun. When one is not available, then you can take a regular hammer. It must be inserted into the tube and pressed like a piston.

What problems does plumbing sealant solve?

It does not matter what the pipeline is made of - there is always the possibility of leakage at the connecting points of the individual elements of the line. The longer it serves, the higher this probability. Sealing issues should be taken seriously, since the next operation of the water wire may depend on it.

You need extraordinary care when different materials are joined together or you need to cut in an individual branch without using standard connectors. This section is considered to be much more difficult. An exemplary in this case will be a sealant for plumbing.

Plumbing sealant can eliminate leakage

Tasks that are solved with its help:

- prevention of leaks that appear due to the strong pressure of draining the liquid;

- protection against possible temperature extremes coming from the water in the pipe or the external environment;

- protection of the integrity of the fitting from destruction as a result of the influence of various substances in the water - ground, drain, tap.

The process ensures the external and internal reliability of the connectors. If in the case of ordinary plumbing equipment, various types of sealants can be used, then silicone is very necessary for PVC structures. With its help, the pipeline inserted into the socket is attached or the joints of the rubber cuffs are sealed. They need to be processed additionally, because the rubber gasket does not provide absolute tightness. This prolongs its life and prevents damage.

In what forms is the sealant produced, types

Depending on the material of the water supply system, different insulating pipe sealants are used:

Linen fibers - serve to seal the joints of the knees of metal parts. The tow is disassembled into fibers, while the layer can be folded of any thickness. If water seeps out at the attachment site, the flax will absorb the liquid and swell, blocking the flow. But the water will seep through the fibers and leak.

Flax is not used in pipelines with high water pressure. It can be used in combination with liquid sealants for better insulation.

Since linen contains natural fibers, it is susceptible to rotting and mold formation if it gets in contact with water. To slow down this process, the tow is impregnated with varnish.

Thread for plumbing work. It is a thin elastic tape impregnated with a solution that does not shrink and does not dry out. It is evenly wound on threaded pipe joints. The use of plumbing thread allows you to tighten the thread not completely, while the seal will remain.

The thread for plumbing is not destroyed by water, does not rot, protects the surface from corrosion. The disadvantages of the seal are the high cost and processing of holes with a diameter of no more than 5–7 cm. If the winding is uneven, there may be gaps through which water can leak.

FUM (fluoroplastic) sealant. It is a smooth elastic strip that is wrapped around threads or elbows. Fluoroplastic sealant for water supply pipes is not subject to decay, shrinkage. Withstands high pressure, temperatures up to + 280˚С, protects against corrosion.

But FUM pipe compactor may not withstand prolonged vibration. If you disassemble the joints with fluoroplastic, then with further installation it must be reapplied.

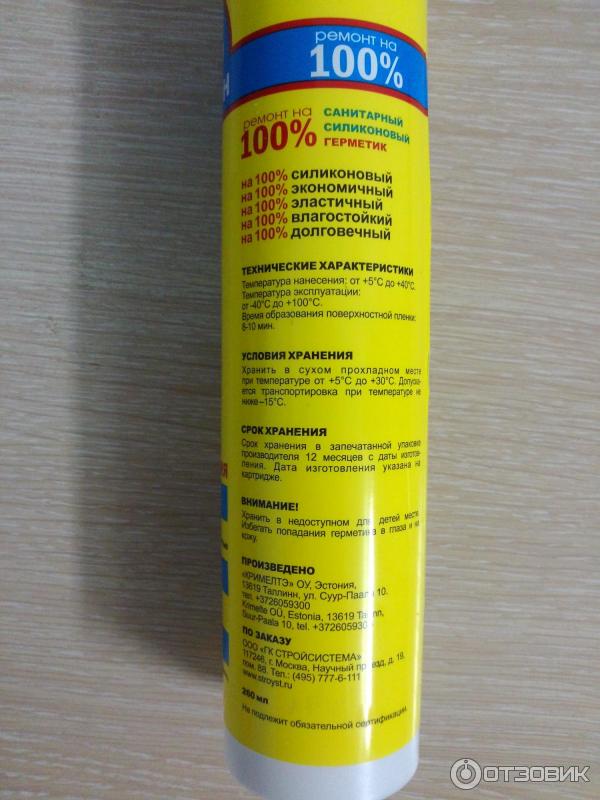

Liquid formulations are produced in cylinders or soft packs for filling into a pistol. They are used for large pipe diameters.Or in bottles for minor repairs and installation of small connections. Depending on the composition, insulating solutions are:

Acidic sealants contain an acid as a solvent. They are cheaper than neutral ones, they form an elastic waterproof seam.

Having an acidic environment, they prevent the development of mold and decay. They are not destroyed by UV rays, they can withstand pressure and temperature drops from -40 to + 120˚С.

The disadvantages of acidic sealant include the fact that they can damage the amalgam coating and non-ferrous metals. Also, acidic insulating compounds are not used in areas in contact with food.

The neutral ones are made on the basis of synthetic rubber. It is a viscous dense mass that polymerizes on contact with air. Neutral sanitary glue forms an impermeable elastic seam that retains its qualities under deformation and vibration loads.

Such compounds do not destroy plastic pipes and protect metal pipes from corrosion. They are resistant to UV rays, are not afraid of solvents, and have an operating temperature range from -40 to + 280˚С.

Sanitary silicone sealants are transparent viscous substances. They create an elastic connection that does not collapse, does not crack under vibration or high water pressure. They have high adhesion to metal, plastic and alloys.

Resistant to the action of reagents, solvents.

Anaerobic solutions polymerize in the absence of oxygen. If some of the sealant is left outside, it can be easily removed, since the sealant remains in the air in a liquid state.

Anaerobic composition allows you to connect plastic and metal parts. Not afraid of chemicals, high water pressure.

It is interesting: Brick houses and glued beams (video)

The use of sealant in plumbing

Silicone sanitary sealant suitable for:

- For sealing joints;

- Filling gaps between plumbing fixtures and walls;

- For sealing doors and windows;

- Mirror mounts;

- For fixing glass elements on the door in the bathroom.

Applicable:

- in bathrooms,

- in kitchens,

- bathrooms,

- swimming pools,

- in any rooms that are characterized by high humidity and there is a risk of fungus.

A silicone sealant is available in the following packaging:

- 300-315 ml cartridge. For him you will need to purchase a construction gun. Only he will provide a uniform layer of sealant;

- 85 ml tube;

- Spray 200 ml. It allows the sealant to be applied without special tools.

When choosing a composition, pay attention to the label. It should indicate the terms of use.

Construction silicone sealant is available in different colors. This is required so that the seam does not stand out from the surface, because silicone rubber is usually not stained.

You can color the sealant if it contains organic elements. This will require a special dye.

When opened, the silicone sealant retains its qualities for several days.

Application rules

It is important to use building silicone correctly in plumbing. Only in this case it will not lose its elasticity, it will not crack.

Apply the sealant as follows:

Surface preparation. It is required to clean the surface from dirt and rust. After that, it is sanded and degreased.

Sealing. The substance cartridge is inserted into the assembly gun

Then, while pulling the trigger, you need to carefully process the seam. The line should ideally be continuous

If the sealant accidentally gets into an area that was not intended to be treated, you can wipe it off with a tissue or a damp cloth.

Seam formation. The seam is performed (formed) only 5 minutes after applying the composition.You can form it with your hands, wearing rubber gloves, or with a spatula moistened with soapy water. Do not touch the sealant with bare hands, as the silicone contains acid that can damage the skin.

Treatment. Excess sealant can be removed with paper. In the event that the composition has already set, unwanted layers can be eliminated using a special solvent or mechanically.

The finish. Silicone sealant sets in 20 minutes. Keep in mind that after this period it is undesirable to edit the joints (joints).

Additional recommendations:

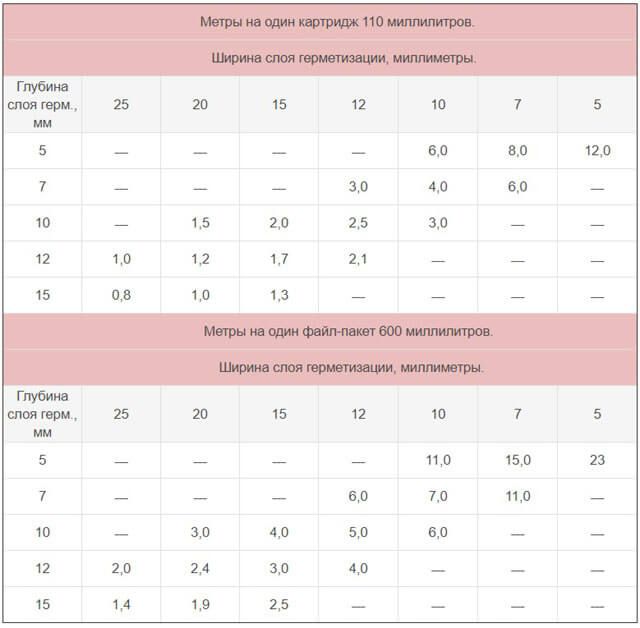

Optimum joint width: 5-30 mm; The depth of the silicone layer should be twice the width; What if you want to create a deep seam? In this case, you can use the sealing tape.

It is attached using the same silicone; It is recommended with caution to use silicone glue with synthetics, brass, copper, lead, since when interacting with them, the sealant can release substances harmful to humans

Deleting

There are two ways to remove sanitary silicone sealant from various surfaces: mechanically or using special cleaning agents.

The first method can be used if you need to remove fresh, not yet cured silicone sealant. You can simply pick it up with a knife blade, and then collect it with your hands. A sharp knife can also be used to scrape off a thick layer of old, long-set sanitary sealant.

If the layer of silicone sealant is thin enough and does not lend itself to mechanical stress, solvents and silicone removers will come to the rescue. Both ordinary acetone or white spirit are suitable, as well as specialized products that can soften silicone without damaging the surface. These include, for example, Silicone Remover, Sili-Kill and Permaloid.

Additional Information: Sanitary silicone sealant moment instructions for use

The next step is to partially solidify, which should be expected after 3 hours. If the layer is thin, then the sealant can completely harden after this time. Curing is achieved at room temperature within 24 hours.

If the seam turned out to be deep enough, and its width is large, then the process in this case is delayed for a longer amount of time. After final drying within a week, the strength of the joint increases, for this reason the surface should be left for a longer time.

Secondly, the sealant should be selected with an eye to the material with which it will be in contact. For example, if the sealant will be used on non-acid-resistant materials such as glass, non-ferrous metals or natural stone, you must purchase an acid-free sealant. Aggressive sealants containing acids have a strong vinegar odor.

- expiration date - the “old” sealant may peel off or not at all fasten the structural parts;

- plasticity - the parameter shows at what air temperature you can work with it, what is its elasticity, this is important when working outdoors at low temperatures;

- the quality of adhesion of a certain brand;

- shrinkage - shows how much the sealant will shrink when exposed to air and moisture. Normally, the silicone sealant should shrink no more than 2%.

The peculiarities include the fact that the manufacture of products is based on maximum environmental protection in strict accordance with all indicators of high quality. There are more than 200 types in the names of goods, but the main part is occupied by the sealant. Also, products such as polyurethane foam and self-adhesive tape are popular.

Before purchasing, consumers ask themselves how much Moment sanitary silicone sealant dries.In the case of this composition, you can follow the recommendations from the manufacturer. A film will form within 15 minutes if the ambient relative humidity is 50%.

Whereas the ambient temperature should be 23 ° C. This composition will harden in a day if its thickness is 2 mm. Sealant moment silicone universal white reviews?

This curing rate is to be expected under the mentioned conditions.

“Moment of Silicotech” makes the joint surface smooth and even. If necessary, immediately after application, the product can be adjusted and smoothed with wet hands - it is easily washed off from the hands and tools that were used in the work. In the process, make sure that the "Moment" does not go beyond the seam.

If this does happen, then remove the excess sealant with a damp cloth.

The bathroom differs in many ways from all other rooms in the house. A special microclimate is maintained here, the main features of which are high air humidity and temperature drops. Therefore, for the renovation of the bathroom, special finishing and building materials are used, intended for use in rooms with high levels of humidity and with changing temperature conditions.

Types of neutral silicone sealants

Sanitary neutral sealant - resistant to external irritants. Designed for sealing and grouting most building materials, both porous and smooth (concrete, stone, plastic, glass, ceramics, PVC, acrylic, polycarbonate, etc.). Ideal for sealing partitions, walls, windows, door frames, for sealing facades and creating elastic layers. Although this type of sealant is not recommended for use in humid environments, there are improved versions of sanitary neutral silicone that are characterized by increased resistance to humidity and a minimum cure time (up to 30 minutes from the moment of application).

Sanitary Neutral Silicone Sealant

Sanitary Neutral Silicone Sealant

Neutral silicone for masonry work is highly resistant to weather conditions, including UV rays. This type of sealant has a high content of fungicides (chemicals that prevent the formation of fungi and mold). It is characterized by excellent adhesion to porous surfaces without causing discoloration. Neutral masonry silicone is widely used for grouting and bonding natural stone (granite, marble), glass, PVC and acrylic surfaces.

Neutral Silicone Masonry Sealant

Neutral Silicone Masonry Sealant

Construction neutral silicone is an indispensable tool for construction and repair. It is used both outdoors and indoors, has excellent adhesion to various building materials, including plaster and metals. Recommended for creating inactive joints (up to 7%) in walls, window and doorways. Does not discolor materials and forms a smooth surface that is easy to paint.

Construction neutral silicone

Neutral Mirror Silicone is a one-component adhesive sealant used to bond and seal mirrored surfaces and create dimensional mirror structures.

Silicone neutral sealant with a high level of hygiene, as a rule, is used in rooms with special requirements for cleanliness and sterility (laboratories, hospital wards, children's rooms, catering establishments). It has excellent adhesion to various building and cladding materials, and is resistant to weather conditions and UV radiation. The composition is supplemented with an increased amount of antibacterial substances.

Silicone Mirror Sealant

Silicone Mirror Sealant

Roofing silicone sealant has good adhesion to bituminous materials, concrete, brick, ceramics, wood, metals and most types of plastics. Indispensable when carrying out various construction and repair work on the roof. It is used to create sealed elastic joints when sealing tiles, for sealing structures of roof windows, chimneys, plates for connecting individual roofing elements. It perfectly tolerates changes in weather conditions.

Roofing Silicone Sealant

Roofing Silicone Sealant

Aquarium silicone sealant does not contain any solvents, fillers or plasticizers. Silicone glue-seal for glass is resistant to ultraviolet radiation, non-toxic and completely harmless to living organisms. Has increased adhesion to smooth glossy surfaces. Perfect for gluing and sealing glass containers (aquarium, terrarium, florarium), self-creation of original glass decorative elements (vases, pseudo-stained glass), glass shelves and showcases.

Aquarium Silicone Sealant

Aquarium Silicone Sealant

Silicone sealants are indispensable for various construction, repair and finishing works. Despite their huge range and different uses, all silicones share several characteristics in common - strength, flexibility, water resistance and ease of use.

Efimov A.E.