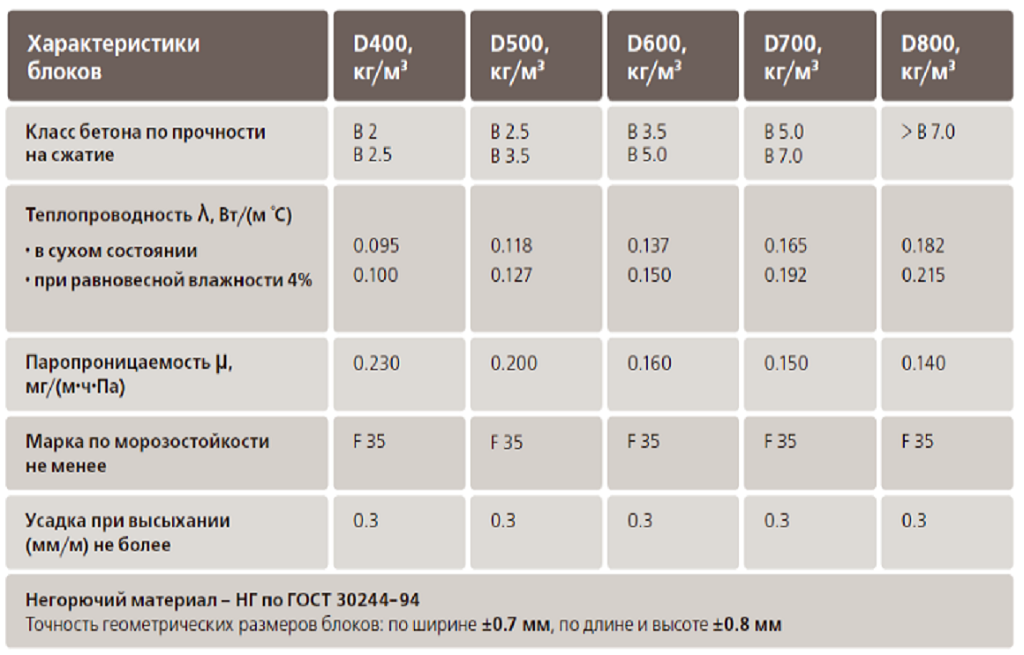

What products are made from Sibit

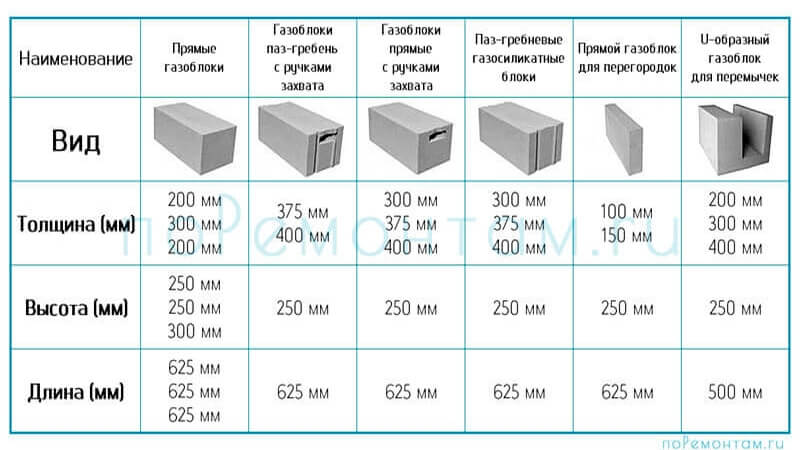

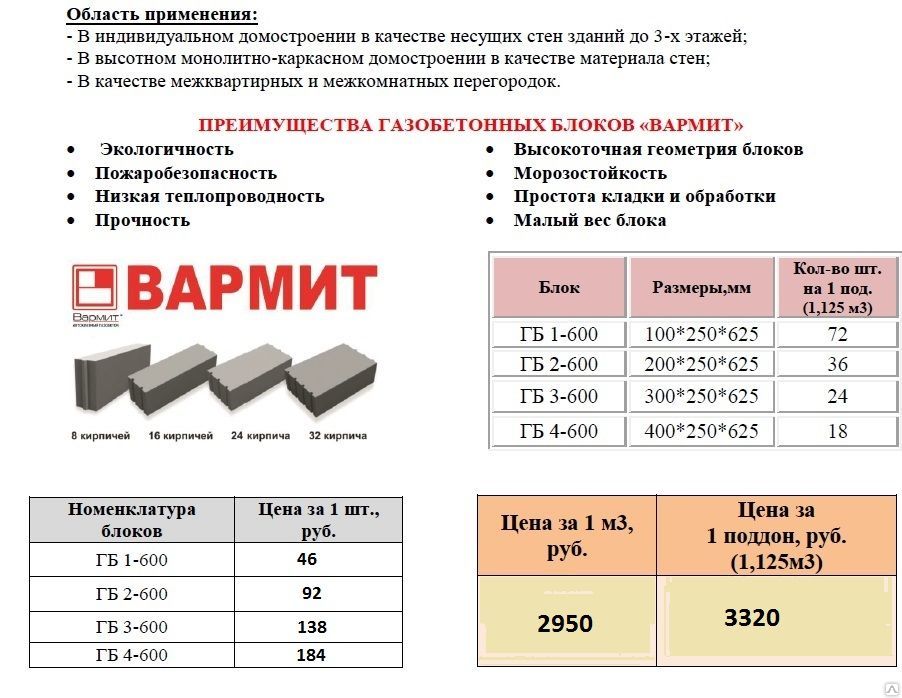

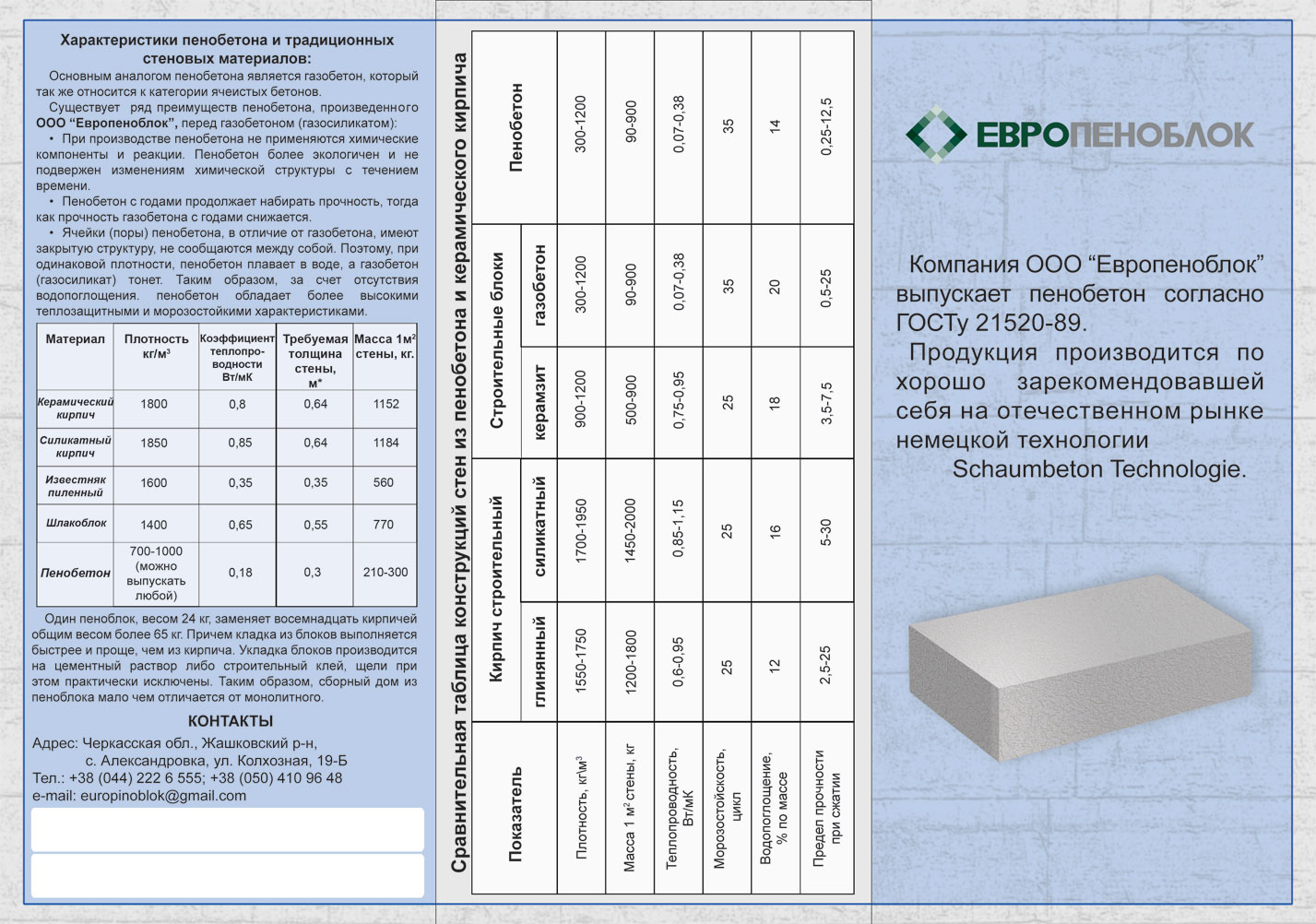

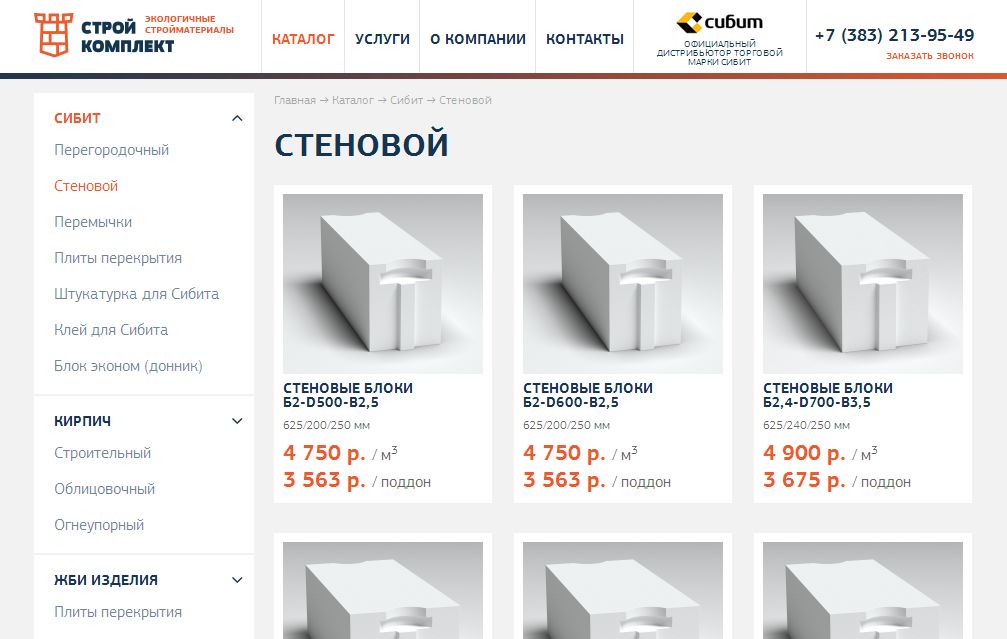

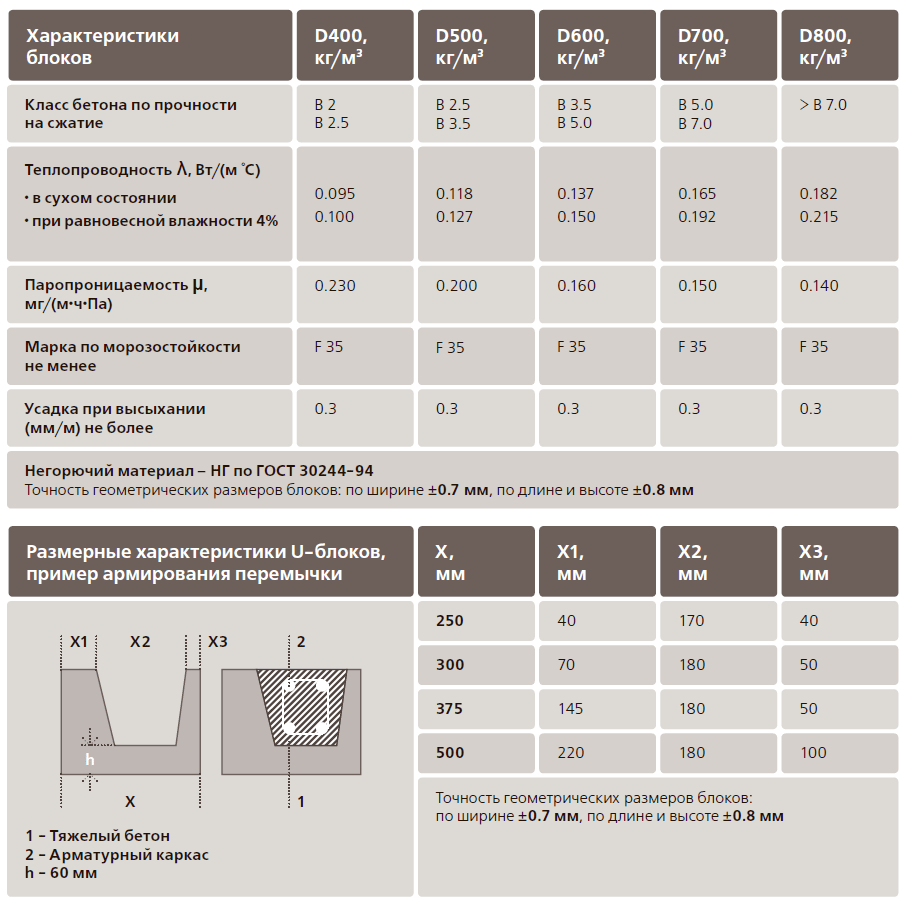

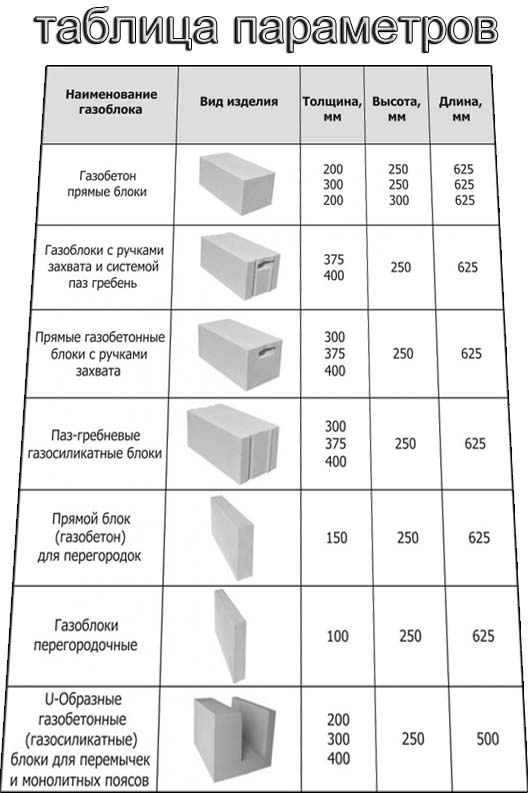

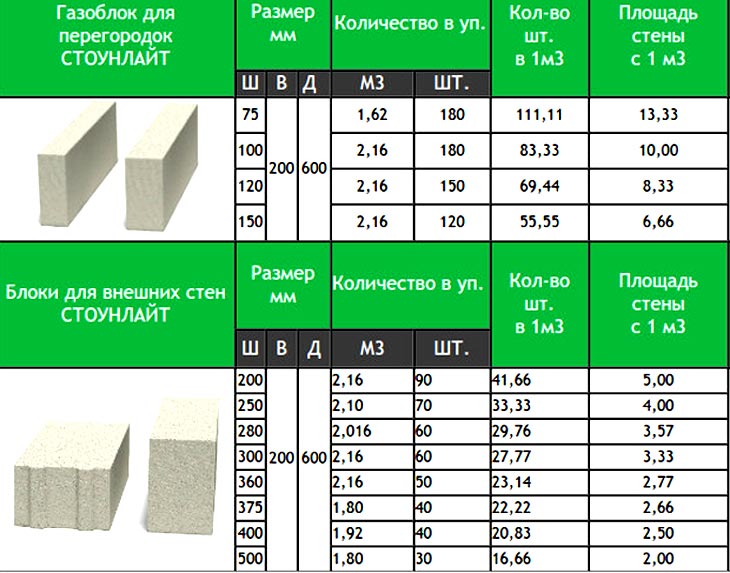

The entire range of Sibit is in great demand among developers in Eastern and Western Siberia. The main place in the assortment is occupied by main blocks, partition blocks, additional blocks. In addition, the company produces reinforced lintels, floor slabs, and thermal insulation panels. The dimensions of aerated concrete products are shown in the table:

| product name | Brand | Sibit block sizes, mm | ||

|---|---|---|---|---|

|

length |

width |

height |

||

|

Wall blocks |

B 2 |

600 |

200 |

250 |

|

B 3 |

600 |

300 |

250 |

|

|

B 4 |

600 |

400 |

250 |

|

|

Partition blocks |

B 1 (D 600) |

625 |

100 |

250 |

|

B 1 (2- D 600) |

625 |

120 |

250 |

|

|

B 1 (2- D 600) |

625 |

150 |

250 |

|

|

Jumpers |

2610-3100 |

100-300 |

250-600 |

|

|

Overlapping |

1940-5940 |

600 |

240 |

When it is necessary to calculate the need for materials for building a house, a wall block with dimensions of 200 * 300 * 600 mm is usually taken as a basis. Its volume is 0.036 m³, that is, 1: 0.036 = 27.78 pieces are placed in one cubic meter of masonry. Calculations are carried out in a similar way for other standard sizes of Sibit gas blocks.

Shipment from the factory and delivery to consumers is carried out on special pallets and packed with protective film. How many pieces of sibit fit in a pallet? It depends on the size of the site itself. Several types of pallets are available. Based on the traditional block size 20 * 30 * 60 cm, they come in the following capacity:

- 25 pieces or 0.9 m³;

- 40 pieces or 1.44 m³;

- 50 pieces or 1.8 m³.

It is not recommended to transport and handle sibit products without pallets, unpacked. Since, due to its porous structure, it has increased fragility.

Average consumption of glue per 1 m3

Manufacturer, in addition to technical characteristics, on the packages indicates the consumption of glue in kg per 1 m². Such information will not tell the user much. It is necessary to know the dimensions of the gas blocks and make calculations for 1 cubic meter. m.

It should be borne in mind that the indicators are valid if the surface of the blocks is flat, the porosity is insignificant. Taking into account the realities, which are not always the most favorable, they buy with a margin of about 6 kg.

How much solution is actually needed is impossible to say. Conditions that are individual for each case play an important role.

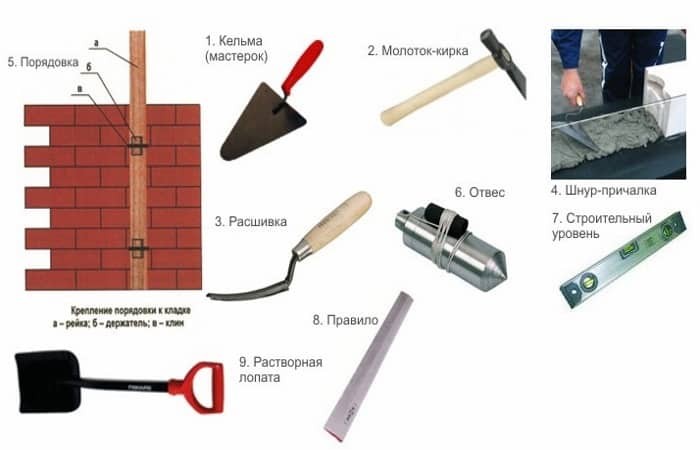

Choice of tools

For the construction of a structure from gas blocks, you will need materials:

- roulette;

- building level;

- construction mixer or drill with special attachments;

- rubber hammer;

- manual wall chaser;

- toothed trowel;

- corner;

- hand saw;

- electrofreza;

- grater;

- container for mixing the solution.

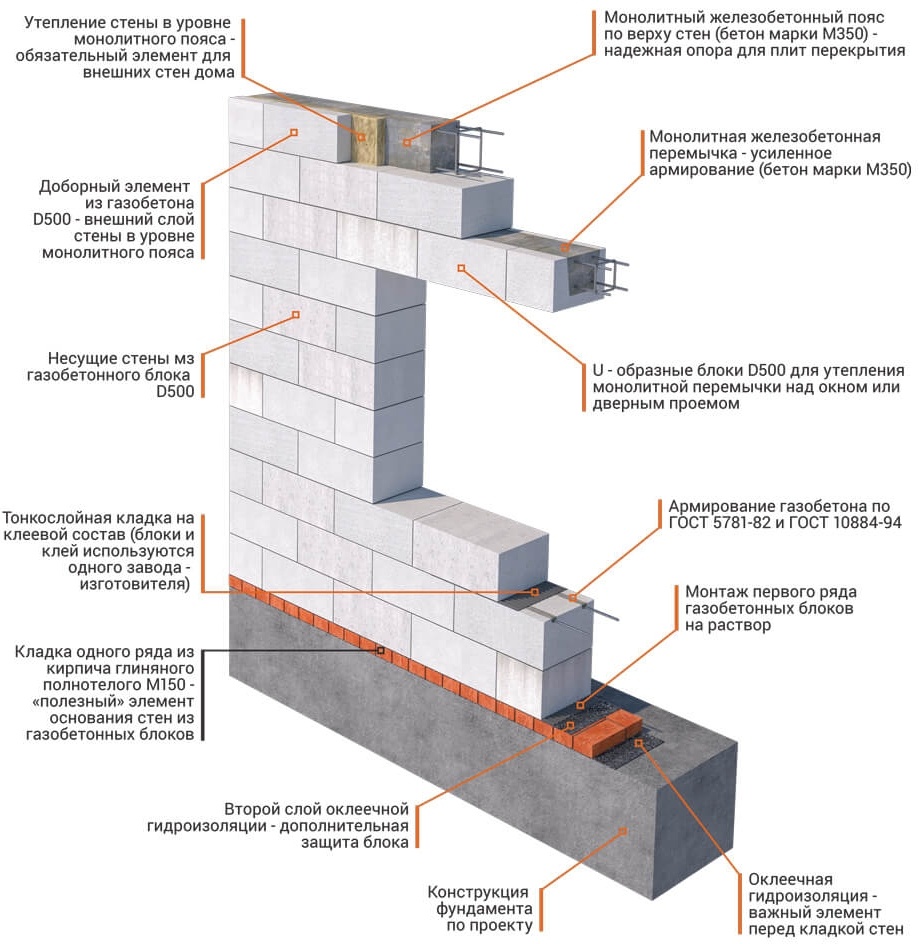

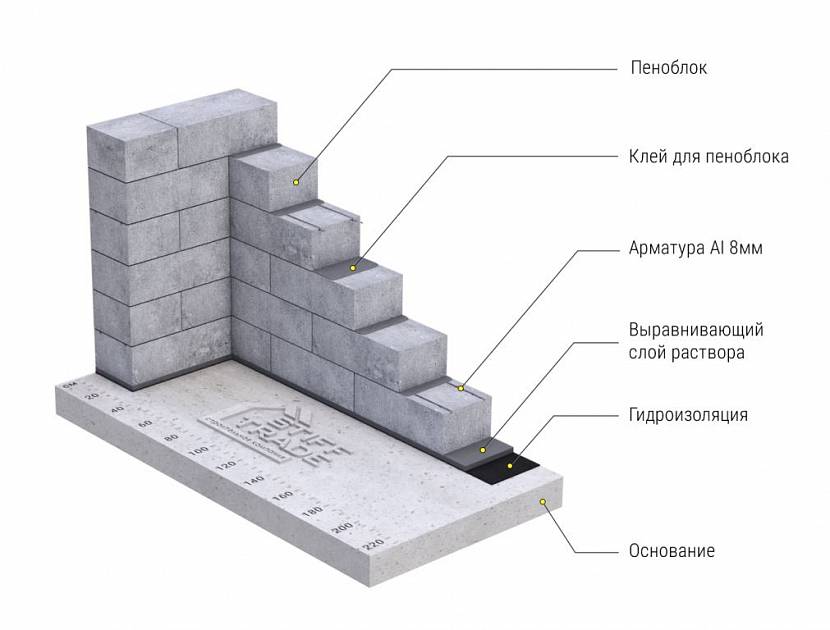

Before starting construction, you need to purchase a sufficient number of gas blocks and dry glue mixture or materials for preparation cement-sand mortar... It is better to take both gas blocks and masonry materials with a small margin (10-15% over the calculated amount). It is imperative that reinforcement and roll waterproofing material will be needed during the construction process, so they also need to be purchased in advance.

Kit .

Kit .

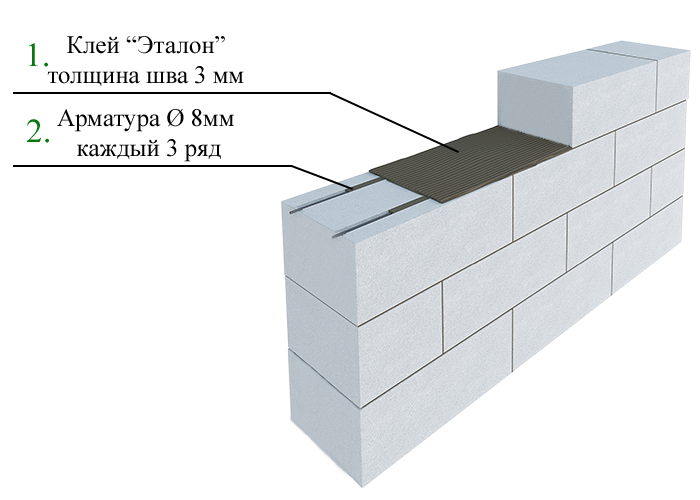

Sibit block laying

Working with Sibit blocks is not much different from ordinary brickwork or other block products

That is, the exact deduction of angles and special attention to the first row, constant control of verticality with a plumb line and horizontalness with a spirit level. It's good if you can use a laser level

But there are still some nuances.

- Blocks can be easily processed with the simplest tools. They can be sawn, cut, trimmed, that is, prepare all the necessary additional elements at the construction site.

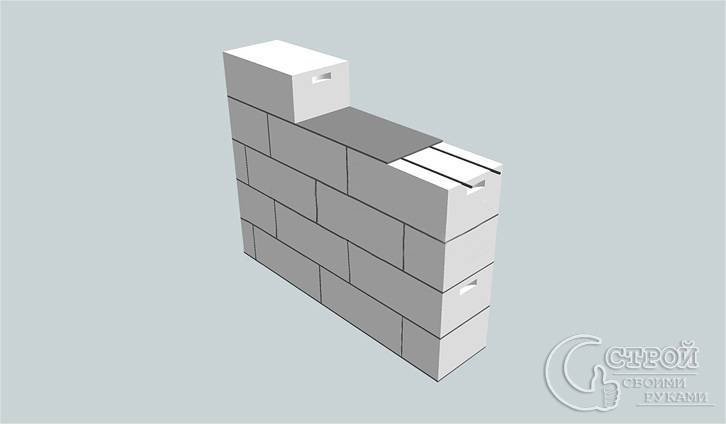

- For masonry, it is recommended to use special glue for sibit. It will provide reliable adhesion of the blocks to each other. Although the first row for waterproofing the foundation can also be laid on a masonry cement-sand mortar.

- The outer and inner surfaces of the walls of the building should be covered with finishing materials.

- For the decoration of door and window openings from above, it is advisable to use reinforced lintels made of sibit.

Aerated concrete products are lightweight, durable and reliable. However, hanging cabinets do not hold well on porous walls. When arranging furniture and decorating rooms, you must use fasteners specifically designed for porous surfaces.

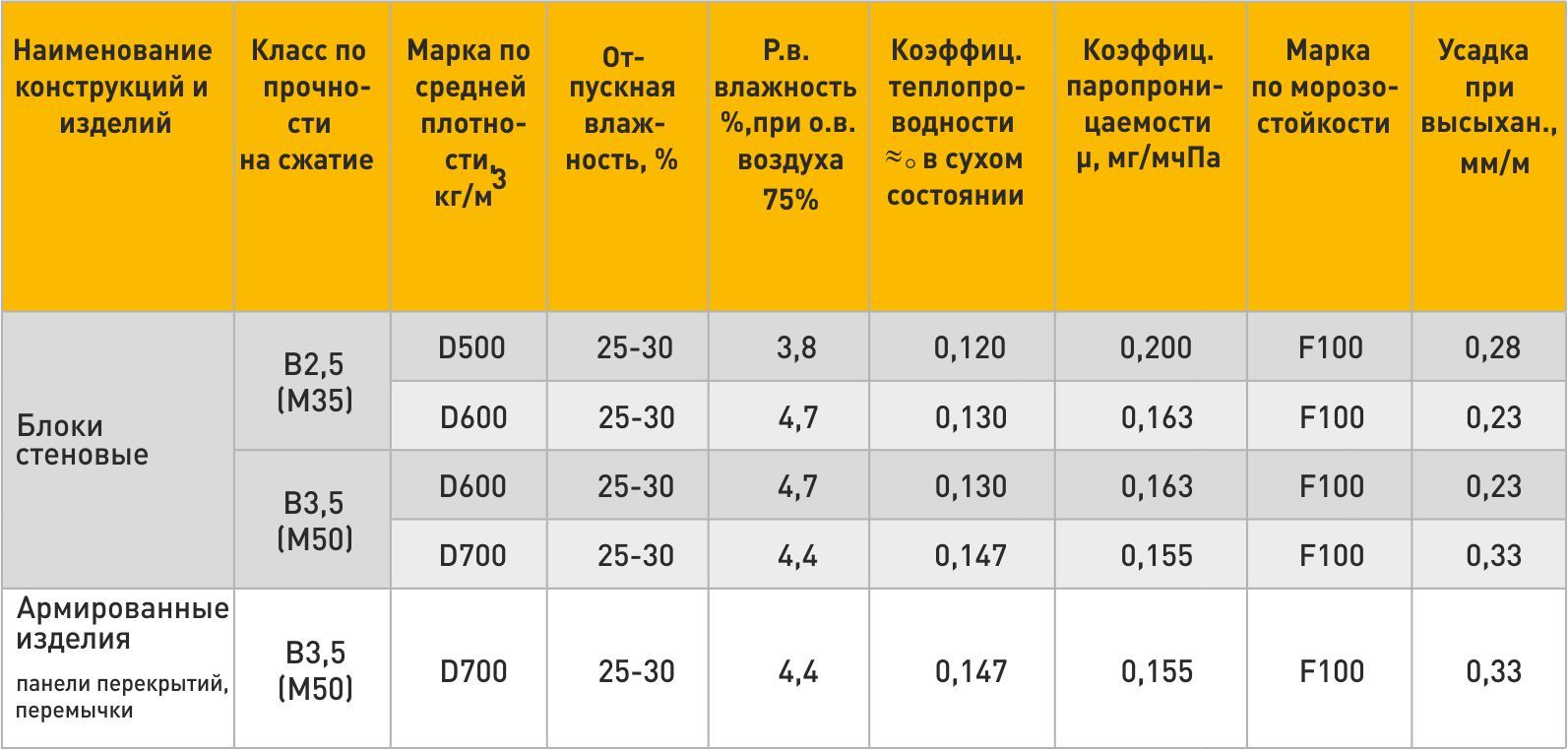

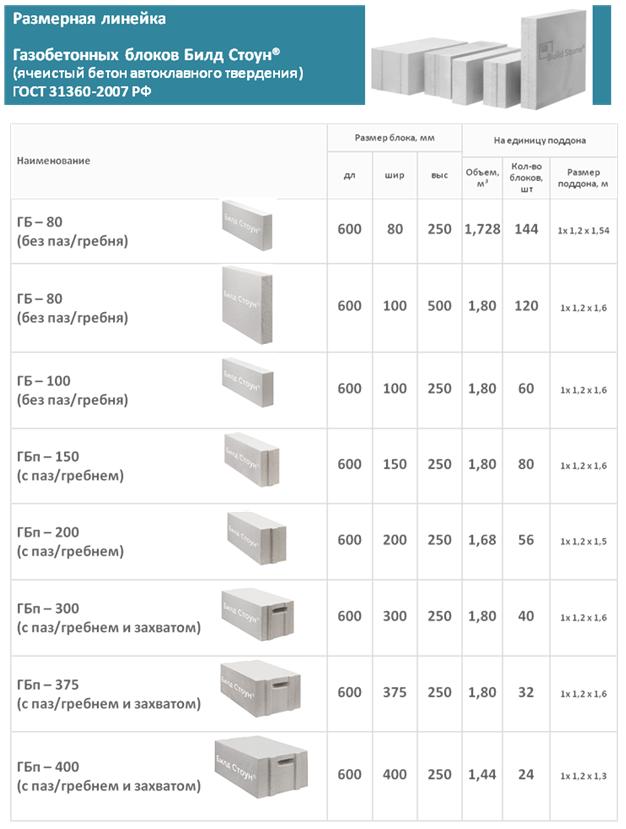

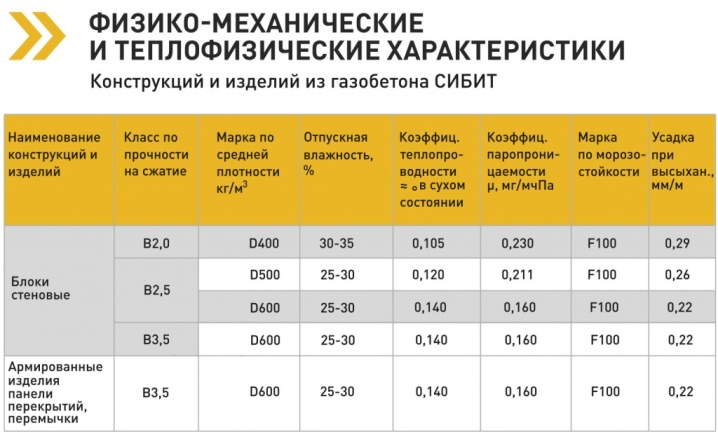

Characteristics of aerated concrete "Sibit"

Aerated concrete is one of the varieties of aerated concrete, among which foam concrete and aerated concrete are also distinguished.

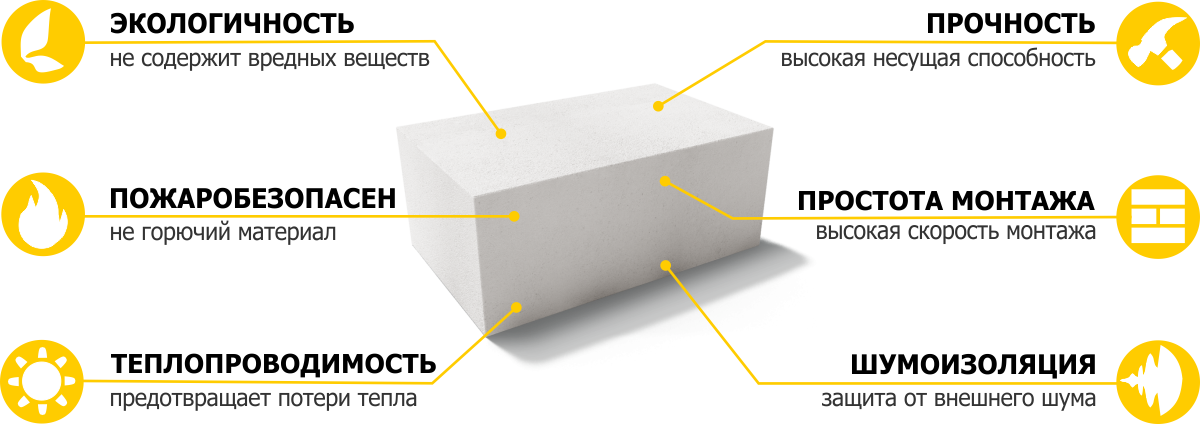

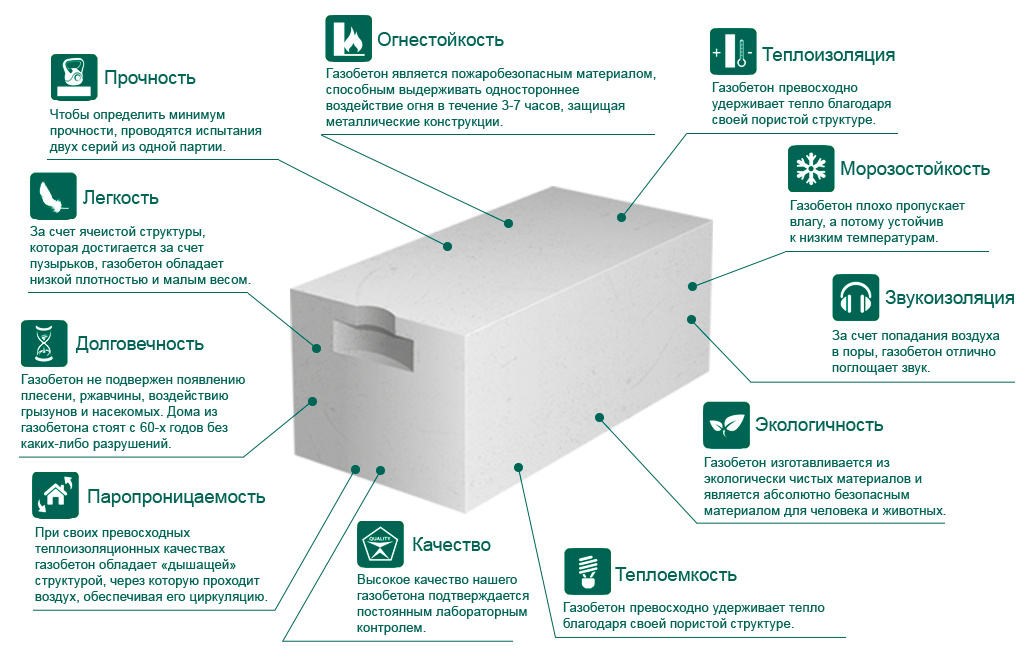

Unlike other building blocks - bricks or foam concrete, gas blocks "Sibit", according to experts, have the best performance in many characteristics. Among them, the following properties can be distinguished:

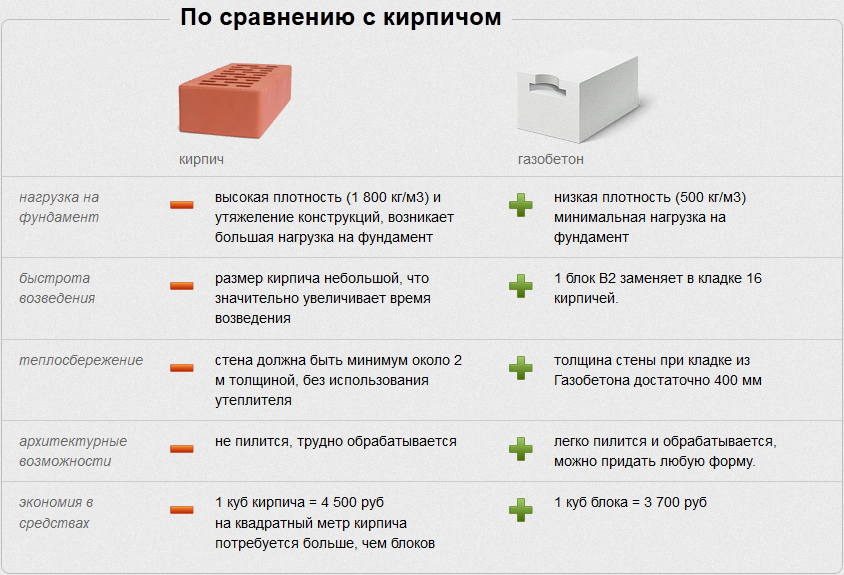

- Weight and size - due to the porous structure, the blocks have less weight, as a result of which the load on the foundation is 10% lower than, for example, brickwork. The dimensions of the products allow the construction of structures much faster, and this, in turn, reduces labor costs.

- Indicators of thermal conductivity and vapor permeability of Sibit aerated concrete keep heat well and allow the room to maintain a comfortable microclimate.

- The material has high strength and allows the use of "Sibit" for the manufacture of floor slabs and load-bearing structures. It is environmentally friendly and fire resistant, withstands up to 3-7 hours of exposure to open fire without losing its technological properties.

The blocks are frost-resistant and can withstand temperature extremes, the pores in the structure of the material absorb water and protect the aerated concrete from destruction.

> Key indicators

| Vapor permeability | Wall thickness | Density | Thermal conductivity | Frost resistance |

| 0.17 g / m | 600 mm | 400-700 kg / m3 | 0.16 W / m * K | 200 cycles |

What should be the optimal flow rate

The binder mixture contains cement, fine sieved sand and modifiers. Artificial stone is a porous material, so it must be laid on a plastic mixture.

Manufacturers indicate on their product packaging how much glue is used per 1 m². In terms of cubes, the minimum quantity per 1 m³ for some companies is 20 kg. Experts calculate the consumption of the mixture in conditions of average temperature and humidity indicators. In practice, more composition is required, because the construction conditions make their own adjustments.

Walls and floors are insulated with aerated concrete blocks. In this case, the cement mortar is not suitable - the thermal conductivity is too high. They use special mixtures, the consumption of which is the same as for the construction of a building.

In practice, the consumption exceeds the declared by the manufacturer by at least 1.5 times.

In practice, the consumption exceeds the declared by the manufacturer by at least 1.5 times.

The optimal value is considered to be 25-30 kg. If this indicator differs greatly from the one declared by the manufacturer, it means that mistakes have been made in the technology.

When constructing objects with a large cubic capacity, overruns or, conversely, savings may result. Many factors play a role: the quality of the gas blocks, the thickness of the layer, the experience of the bricklayer.

Manufacturers calculate the consumption, assuming the thickness of the glue line is 1 mm.

It is optimal for the following reasons:

- cold bridges are not formed, heat loss is excluded;

- the evenness of the masonry is effectively emphasized;

- a thin layer is stronger than a thick one.

You should not be afraid of overspending due to the fact that a lot of the mixture has been prepared, it will harden from untimely use. The properties of the binder composition for gas blocks in this respect are different from those of other similar mixtures. Plasticity remains for a long time if the glue is mixed periodically.

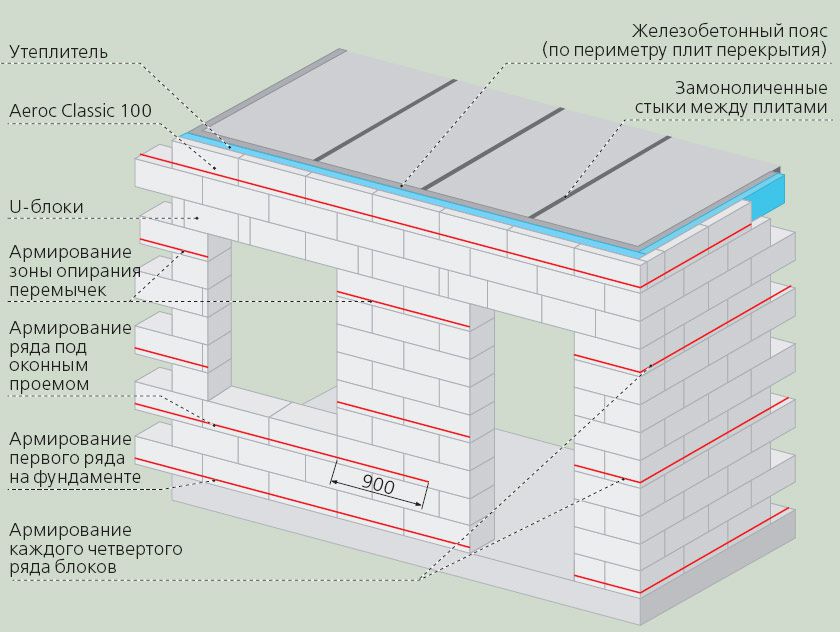

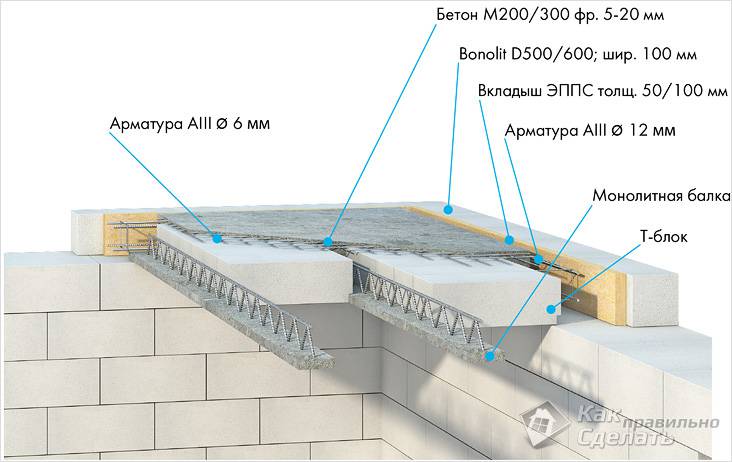

Floor installation

The overlap should be done in cases where the house is being built with several floors and before arranging the roof. There are several ways how to make a floor: from wooden beams, a metal frame or from ready-made concrete slabs that are installed on an armored belt. It is clear that such plates cannot be lifted manually, so you cannot do without the help of a crane.If you make an overlap of beams, their ends must be cut off at an angle of 60–80˚, walked with an antiseptic, wrapped in roofing felt and installed in niches, to a depth of 150 mm. Install the beams in increments of 1–1.5 m. After that, the lathing is knocked out of the boards and the flooring is laid.

Overlapping on beams

Overlapping on beams

Overlappings can be divided into the following types:

- basement covering separating the basement and the first floor;

- intermediate floor that separates the floors;

- attic floor separating the floor and the attic;

- attic floor separating the floor from the attic.

Floor types

Floor types

Aerated concrete block calculator

The network has many resources that allow you to calculate the required number of aerated concrete blocks. To do this, you need to specify the following data for your building:

- The total length of the outer walls.

- The height of the walls.

- The dimensions of the unit you will be using.

- The cost of a cubic meter of material.

- The area of doors and windows.

- The total length of all internal partitions.

- Dimensions of blocks used to create partitions.

- The area of windows and doors placed on partitions.

- These calculations will help you calculate the exact number of gas blocks, as well as their approximate cost.

Reinforcement of walls

Since aerated concrete is not highly durable, it is strengthened with iron rods. The frequency of reinforcement depends on the seismic activity in the region where the construction is taking place. In conditions of increased seismicity, the reinforcement is laid through a row, starting from the first. Where seismicity is low, 4-row reinforcement is sufficient.

Reinforcement is performed as follows:

- Grooves (grooves) are cut on the surface of the masonry. This is done with a wall chaser, hammer drill or grinder. The depth and width of the strobes should exceed the diameter of the reinforcement by 2-3 mm.

- The grooves are cleaned of dust and crumbs. They are treated with a primer.

- The grooves are filled with glue to 1/3 of the volume. The reinforcement is pressed into the glue. The top of the rod should be below the level of the masonry. Excess glue is removed with a spatula and used again.

If steel mesh is used for reinforcement, then gating can be omitted. Docking is carried out with an adhesive solution. Walls with a height of more than 300 cm are also reinforced flat. First, the mesh is fixed with staples, then covered with a starting putty.

What it is?

Sibit is a brand of aerated concrete, the word is made up of two other names: the Siberia plant and the Itong company. The production is located in the city of Novosibirsk, using the technologies and equipment of a German company, which is the first manufacturer of autoclaved concrete. The material is lightweight, but durable, which explains its popularity. There are several advantages of Sibit.

- Low thermal conductivity. In comparison with brick, this figure is 4 times less. Sibit buildings can save up to 20% on heating, which is quite profitable, especially in the northern regions. In summer, the indoor temperature will remain at a comfortable level.

- Cold resistance. According to the GOST regulations, aerated concrete structures must withstand a certain number of winter cycles. Sibit's frost resistance is much higher than the minimum parameters. Blocks maintain their performance for 200 cycles due to their bubble structure. Moisture can accumulate in the pores and then evaporate freely, so the concrete does not crack.

- Ease. Compared to brickwork, a square meter laid out of sibit blocks weighs 5 times less. This allows you to save on pouring the foundation, avoiding the need to install powerful supports. In addition, installation work does not require the use of special equipment and takes less time.

- Water vapor permeability. Indicators are 0.17 g / m2, which is 6 times higher than that of bricks. This characteristic allows you to understand how breathable the material is. With the free evaporation of moisture in the room, an optimal microclimate will be maintained.The house from Sibit will not have problems with mold and fungi, residents will not suffer from dry air.

- Fire safety. Aerated concrete is made from natural components that are not prone to flammability. Depending on the characteristics of the structure, it will be able to withstand a fire load from 3 to 7 hours if you use Sibit blocks for construction.

- Versatility. Plates from this material can be used for the installation of floors and roofs. They allow you to turn the attic into a residential attic and maintain a comfortable temperature there, as well as save a little during construction. Also, walls are erected from sibit, but it is not recommended to load them with heavy objects - this can be considered a small minus. When designing an interior, it is better to provide for floor cabinets, and not wall cabinets.

Among the shortcomings, you can include the need for finishing - you will have to purchase additional materials to create a comfortable and attractive indoor environment. Outside, the building will also need to be protected from negative atmospheric influences. In addition, when erecting a building on several floors, it will be necessary to install a frame support. Despite some drawbacks, Sibit still outperforms other popular materials.

- The foam block contains artificial additives, and its shape does not always differ in ideal geometry. Autoclaved concrete is environmentally friendly and manufactured to exacting standards.

- Gas silicate is similar in composition, however, it is less resistant to frost and more expensive.

- Wood concrete is afraid of the cold and weighs more, it is not so convenient to work with it.

- The heat block has a lower thermal conductivity, in this it wins, but it contains a dubious component - expanded polystyrene, and when handling it, extreme accuracy is needed so as not to spoil the material.

- Expanded clay concrete is stronger, but it needs additional insulation. Also, the blocks are smaller in size, so installation will take longer.

Internal partitions made of aerated concrete

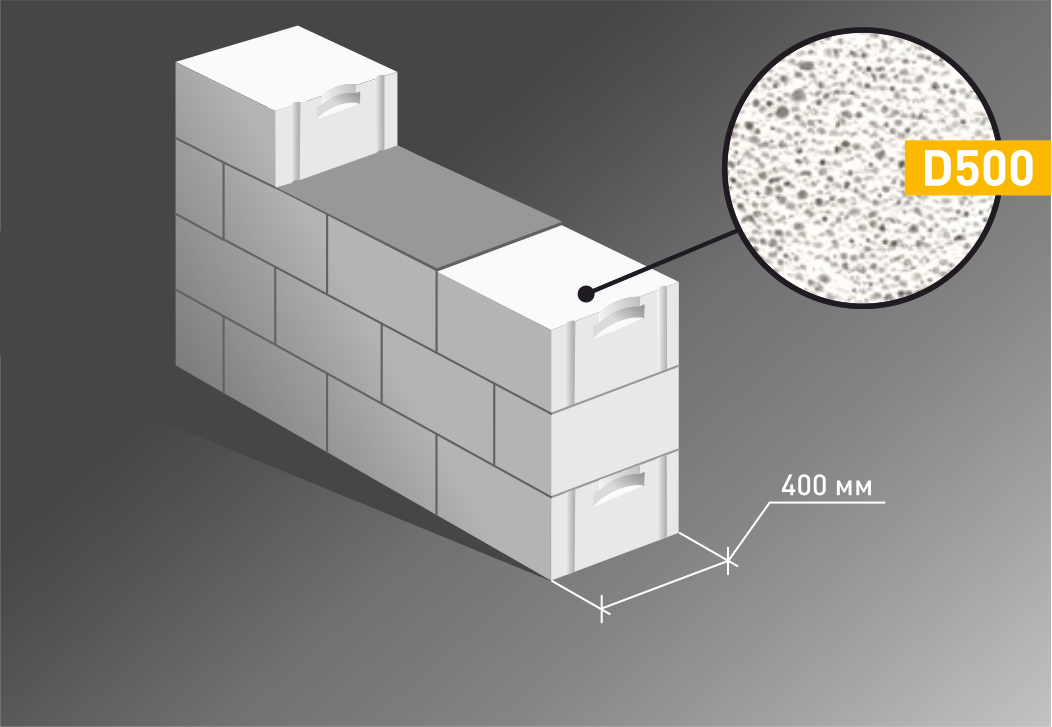

The thickness of the aerated concrete partition must be selected in accordance with several factors, including the calculation of the bearing capacity and height.

When choosing blocks for the construction of non-load-bearing partitions, it is imperative to pay attention to the height indicators:

- the height of the structure being erected does not exceed three meters - building material 10 cm thick;

- the height of the internal partition varies from three to five meters - the building material is 20 cm thick.

If you need to get the most accurate data without performing independent calculations, you can use standard tabular information, taking into account the interface with the upper floor and the length of the structure being erected. It is also necessary to attach particular importance to the following recommendations for the choice of building material:

- determination of operational loads on internal partitions allows you to choose the optimal material;

- it is best to erect non-bearing interior walls from products of the D500 or D600 brand, having a length of 625 mm and a width of 75-200 mm, which creates a strength of 150 kg;

- installation of non-supporting structures allows the use of products with a density of D350 or D400, which helps to obtain standard noise insulation up to 52 dB;

- the parameters of sound insulation directly depend not only on the thickness of the building blocks, but also on the indicators of the density of the material, therefore, the higher the density, the better the sound insulation properties of aerated concrete.

With the length of the partition structure of eight meters or more, as well as the height exceeding four meters, in order to increase the strength characteristics, it is necessary to strengthen the frame with the help of load-bearing reinforced concrete structures. The required strength of the partition is also achieved due to the adhesive layer holding the block elements together.

Affordable cost, manufacturability and excellent quality characteristics have made aerated concrete blocks popular and in demand in the market of modern building materials.Correctly calculated wall thickness made of aerated concrete allows to provide the erected structures with a high level of strength, as well as maximum resistance to almost any static load or shock factors.

How many in 1 m3 of aerated concrete blocks in a pallet

To calculate how many blocks fit on a pallet, you need to know exactly the size of the blocks and the size of the pallet. Typically, a pallet holds 40-180 blocks, depending on their size. But pallets can be different, therefore, usually when ordering material, this parameter will be found out from the manager. Knowing how many pieces of aerated concrete a pallet holds, they indicate their number, and they can also understand whether it will be possible to deliver aerated concrete in one transport trip.

On the other hand, usually cubic meters are used to calculate the number of gas blocks needed for work. The same indicator is indicated when ordering material, and the buyer is not particularly worried about the number of pallets. But if you want to organize the delivery of gas blocks to the object yourself, it happens that you need to know the number of pieces on a pallet.

The table below shows the number of blocks of different sizes on pallets: