Wood chip blocks

After preparing the organic material, wood-concrete blocks can be made directly.

- Chips need to be poured into a concrete mixer, add water and cement. The ratios should be as follows: four parts of water and three parts of cement are added to three parts of crushed wood.

- Stir the mixture until it is smooth and slightly crumbly in appearance. But at the same time, a lump can be made from such a mass.

- The block mold is pre-processed with milk of lime.

- The finished solution is poured into the container in layers. Each ball must be tamped well.

- After the mold is half filled with the mixture, you need to make one layer of ordinary concrete, put a reinforcing mesh and pour the concrete mixture again. After that, the form is filled to the end with a mass with chips. Blocks can be made without a grid, but such blanks are much stronger and more durable. Each compacted layer must be pierced in several places with sharpened reinforcement. This will remove air bubbles.

- When a couple of centimeters remain to the edges of the container, you need to fill in the plaster solution and smooth the surface well. This method will allow you to get finished blocks from the already plastered side.

- Such material freezes for a day.

- The finished block cannot be used immediately. It is better to leave it in the air under a film for fourteen days at a high air temperature. If the degrees outside show a mark below 10, then the hydration period also increases.

How to make wood concrete with your own hands

After assessing the main working points, you can start the process of production of wood concrete

It is important to consider for what purposes the material will be used - private or commercial. In the first case, it is not necessary to buy expensive units and equipment.

Equipment

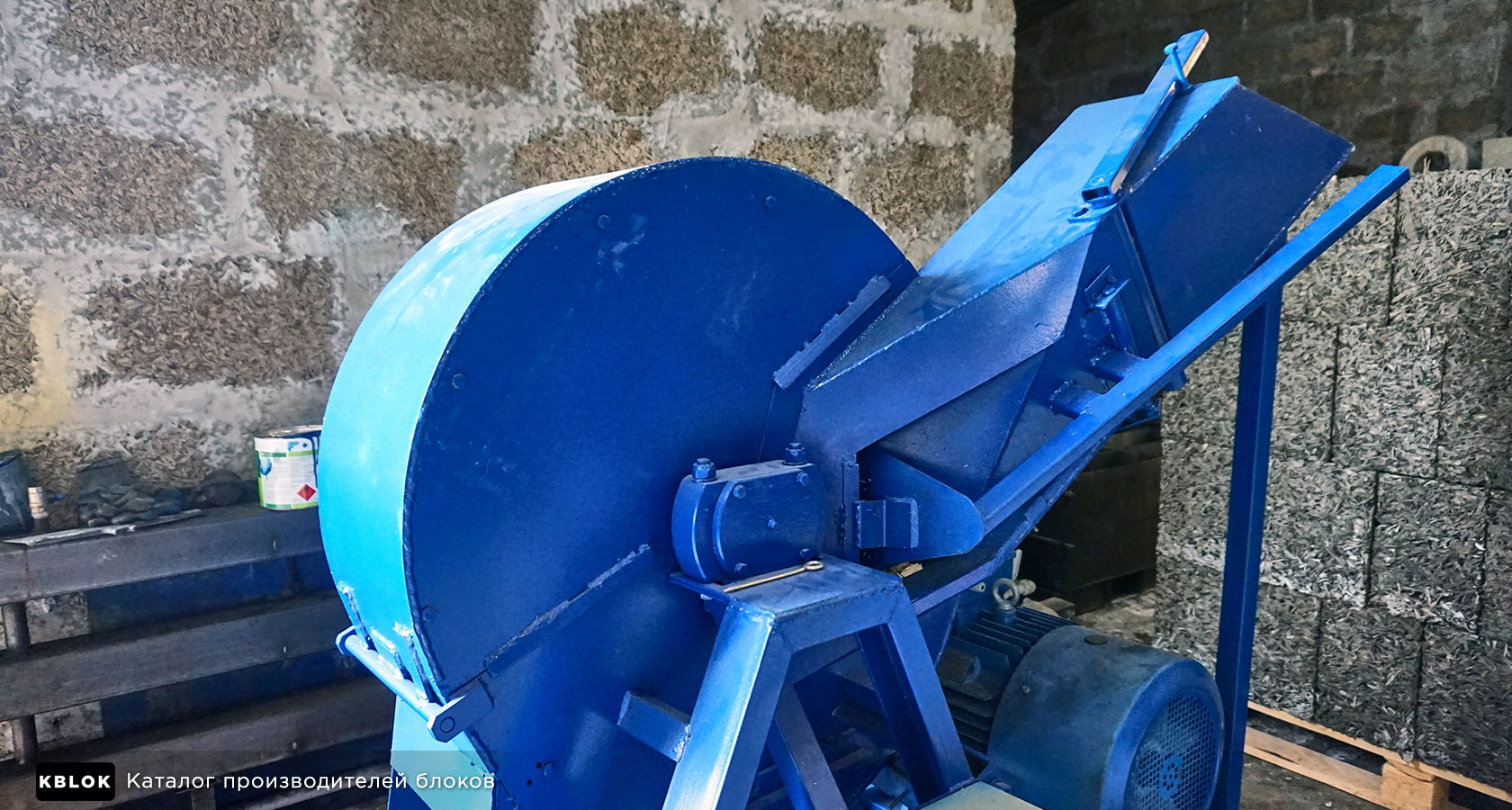

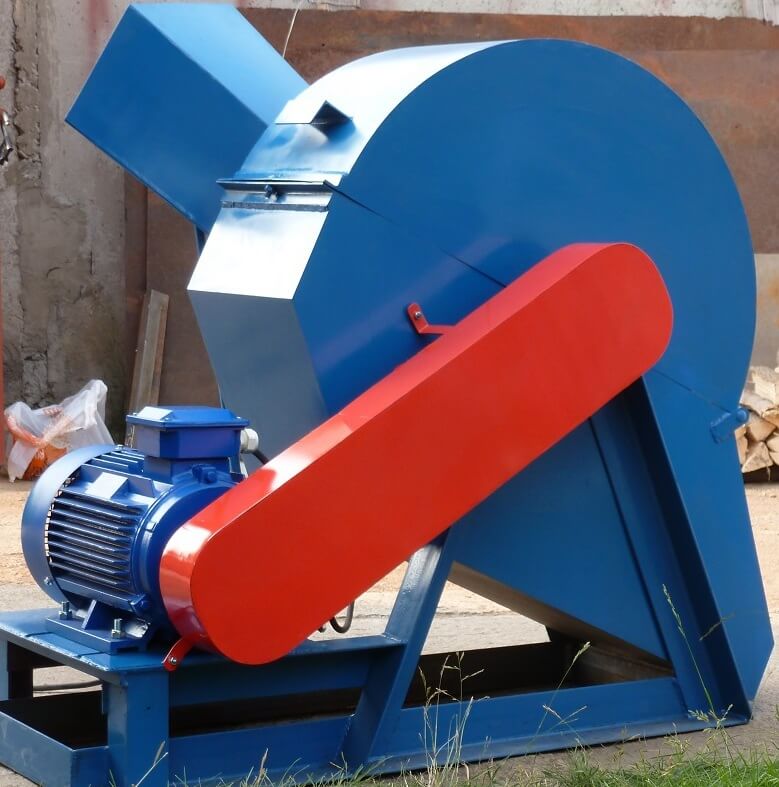

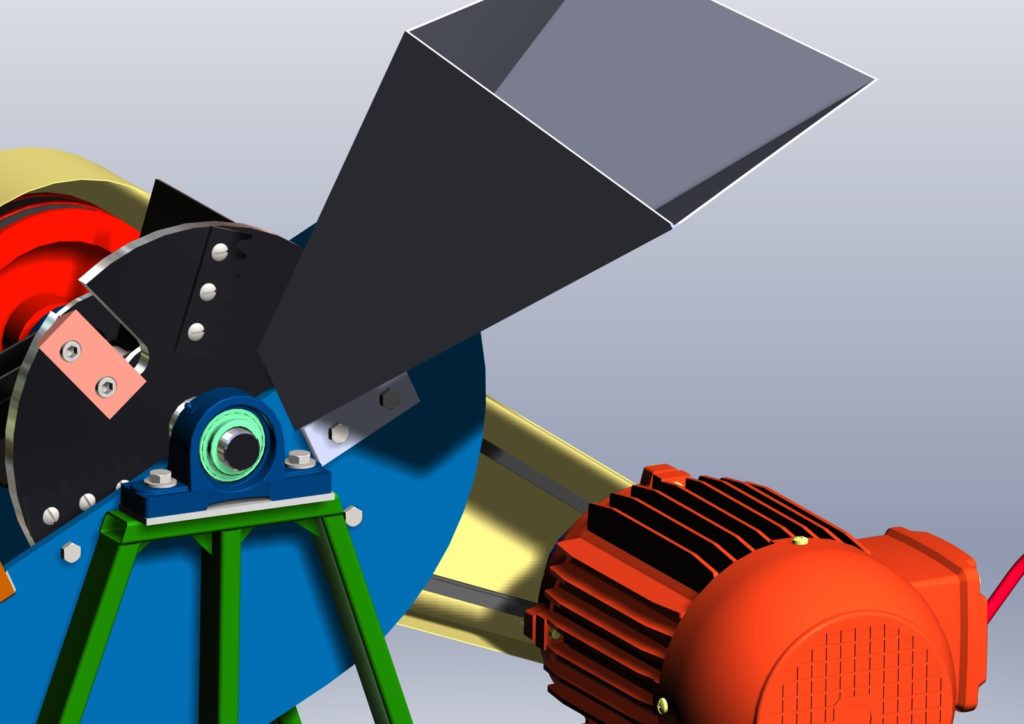

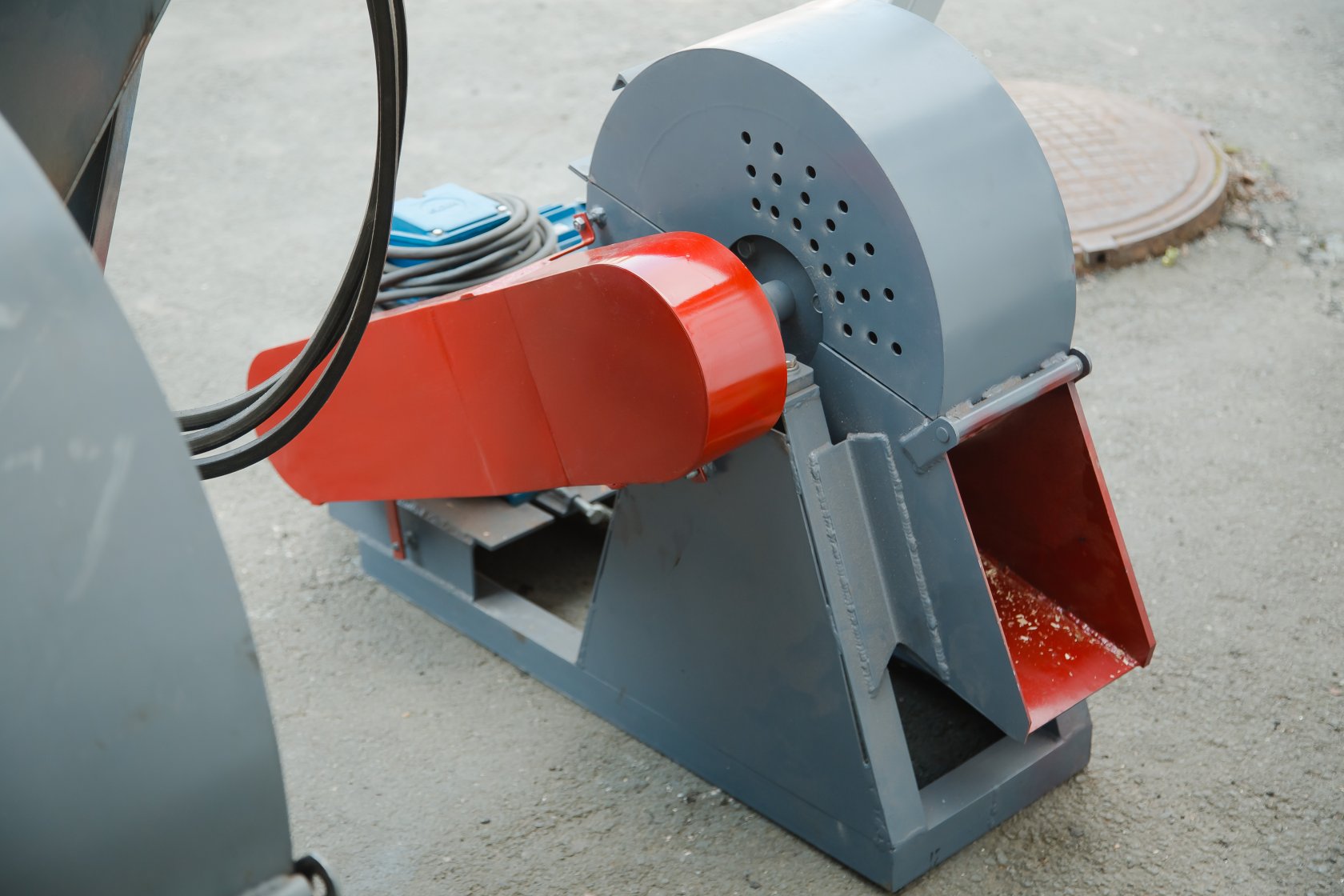

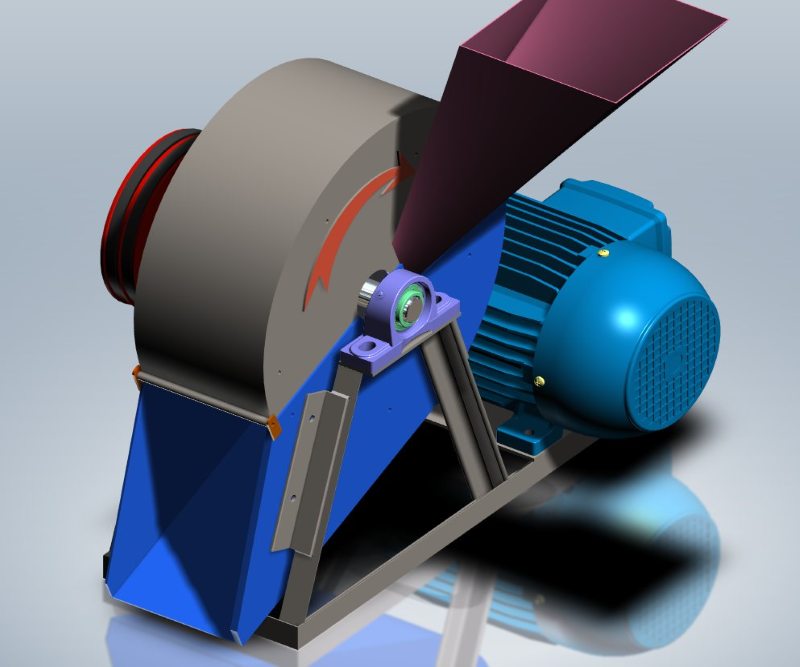

The key unit for home-made wood concrete blocks is a wood chip cutter. You can build it yourself by ordering the main part from turners. In this case, the costs will be reduced by 4 times. The cutting elements should be set at a minimum angle and the wood chip throat should be fixed vertically.

A homemade wood chip cutter consists of the following nodes:

- Automobile spring.

- Metal studs.

- 2 bearings per axle.

- Axis.

For the manufacture of the last part, it is better to use a hexagon, having previously organized the seats for the bearings. There are a lot of training videos and instructions on the implementation of such a project on the Internet.

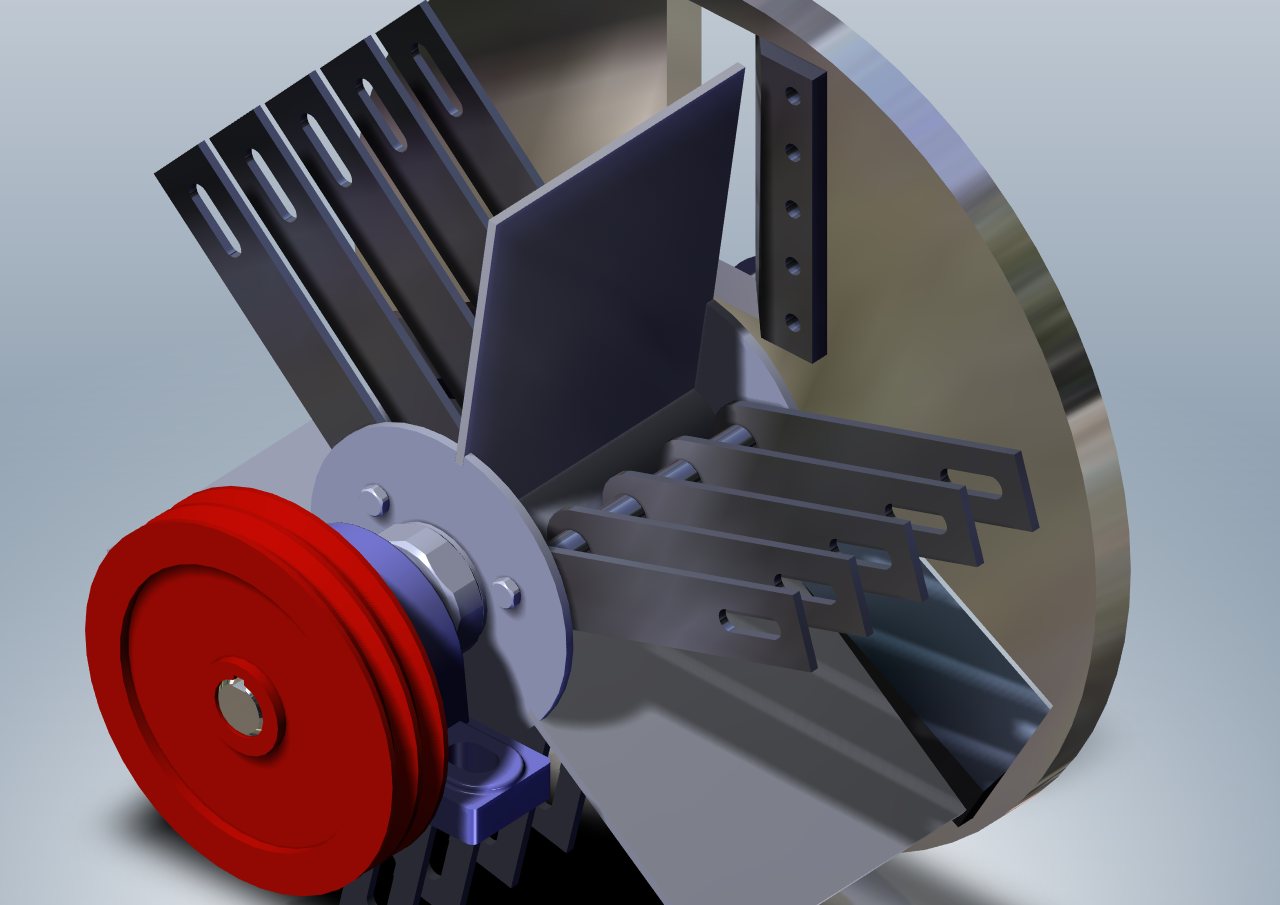

Making a hammer machine

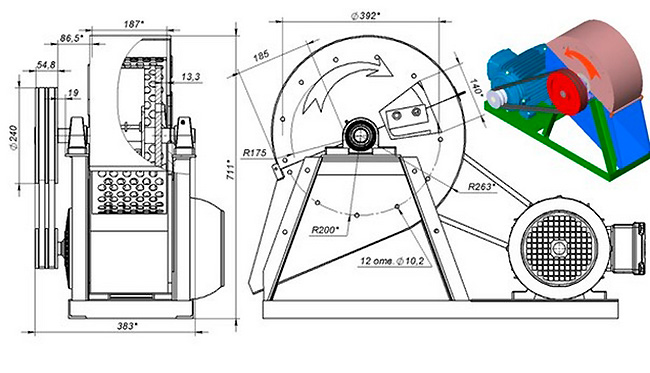

The next step is to build a hammer machine. In the 2 discs for the axles, holes must be made and a washer with a width of 10-20 mm must be fixed. On one side of the axle, thread the nut. If you have a lathe, it is best to machine the shaft and remove the blade disc from it to create a rectangular protrusion to hold the second disc.

If possible, it is necessary to arrange 2 height differences for the discs, while the final shaft thickness should be at least 50 mm.

The finished shaft is mounted on bearings and a support. If the size of the outer casing is less than required, it will have to be replaced or redone. The outlet is closed with steel mesh with an optimal diameter.

Silos and forms

Industrial silos and molds are sold in standard sizes that match the parameters of aerated or foam concrete. For wood concrete, dimensions of 20, 40 or 60 cm are characteristic. It is problematic to create blanks with your own hands, therefore it is better to cut metal sheets with a grinder and prepare a type-setting form.

Development of technology

The most difficult stage is the development of technology in order to determine all the subtleties of the equipment operation. It is best to divide the application of chemicals into several separate steps. To begin with, sodium chloride and aluminum sulfate are added, and the rest of the additives are placed in the hopper before mixing.

Liquid glass is used later, when the chips are ready. The final solution is poured into molds, rammed and left to harden for a while. The setting process takes 2-3 days, after which the molds are dismantled and the blocks are placed to dry.

We make a wood chip cutter for wood concrete with our own hands

To make a wood chip cutter from wood concrete, you need to prepare all the necessary parts, after which you can start assembling the unit. Some details are worth looking for, others are quite possible to do on your own.

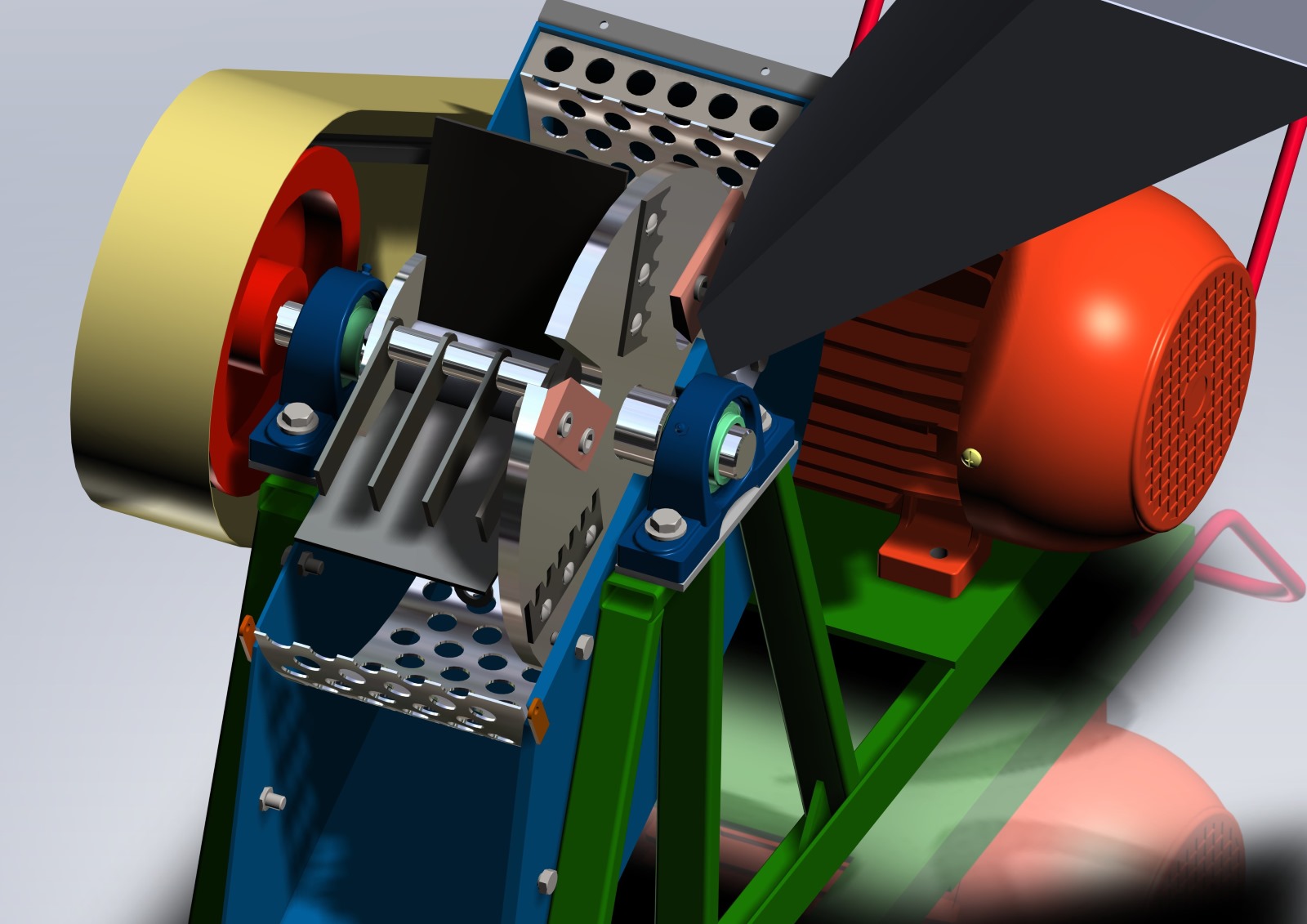

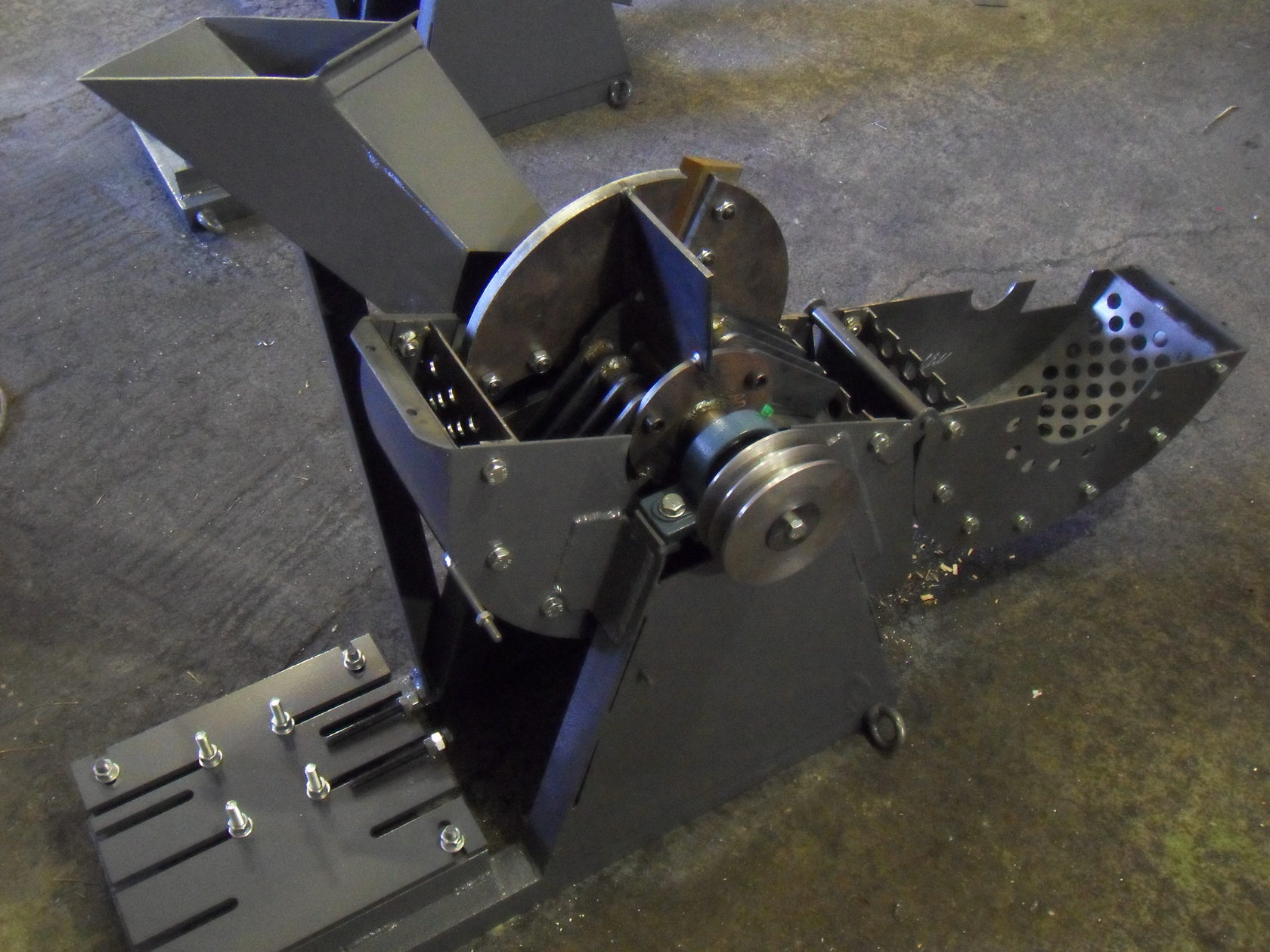

Disc with knives

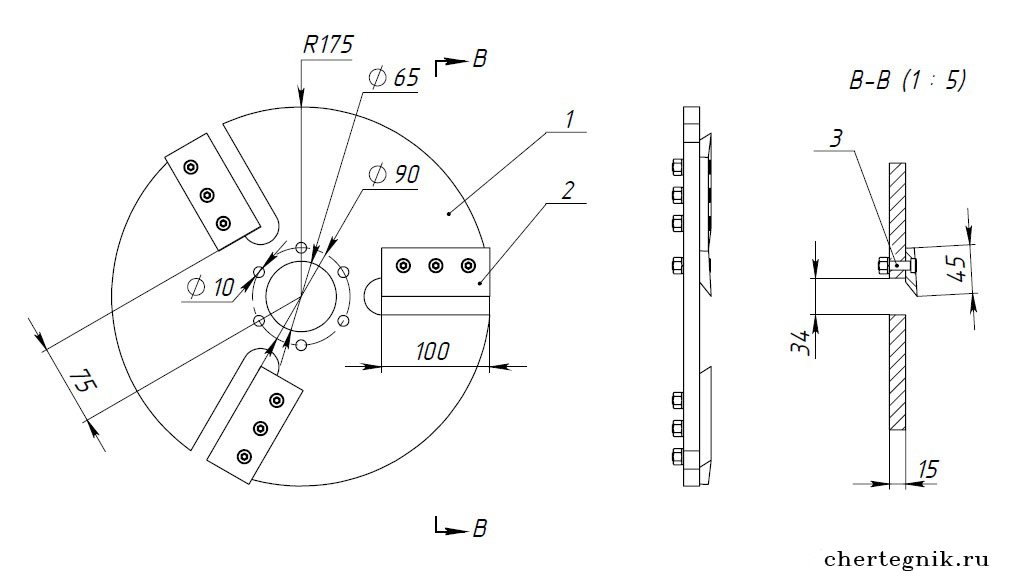

The diameter of the disc should be up to 30-35 centimeters, the thickness - 2 centimeters. To eliminate the possibility of hard / large pieces of raw material jamming, the disc must operate on the flywheel principle, therefore it is made heavy.

You can take a metal blank or cut it out of a piece of sheet steel, then one central hole is cut into the parts (to fit the shaft, taking into account the keyway), several mounting holes are also made, 3 grooves through which the cut pieces of wood will be sent under the rotating hammers.

To make knives, they take car springs, make 2 holes in each of the knives, followed by their countersinking (you need to drown the screw heads as much as possible), fasten them to the disk using bolts with a special countersunk head for a hexagon, due to which it is possible to create a reliable and tight connection ... In addition, in this case, the bolts will not be able to turn when the nuts are tightened on the other side.

Hammers

This part is a flat plate up to 5 millimeters thick, located in the rotor. Hammers are responsible for additional grinding of raw materials, it is better to buy them ready-made. Between the hammers themselves directly in the crusher, the distance should be 24 millimeters.

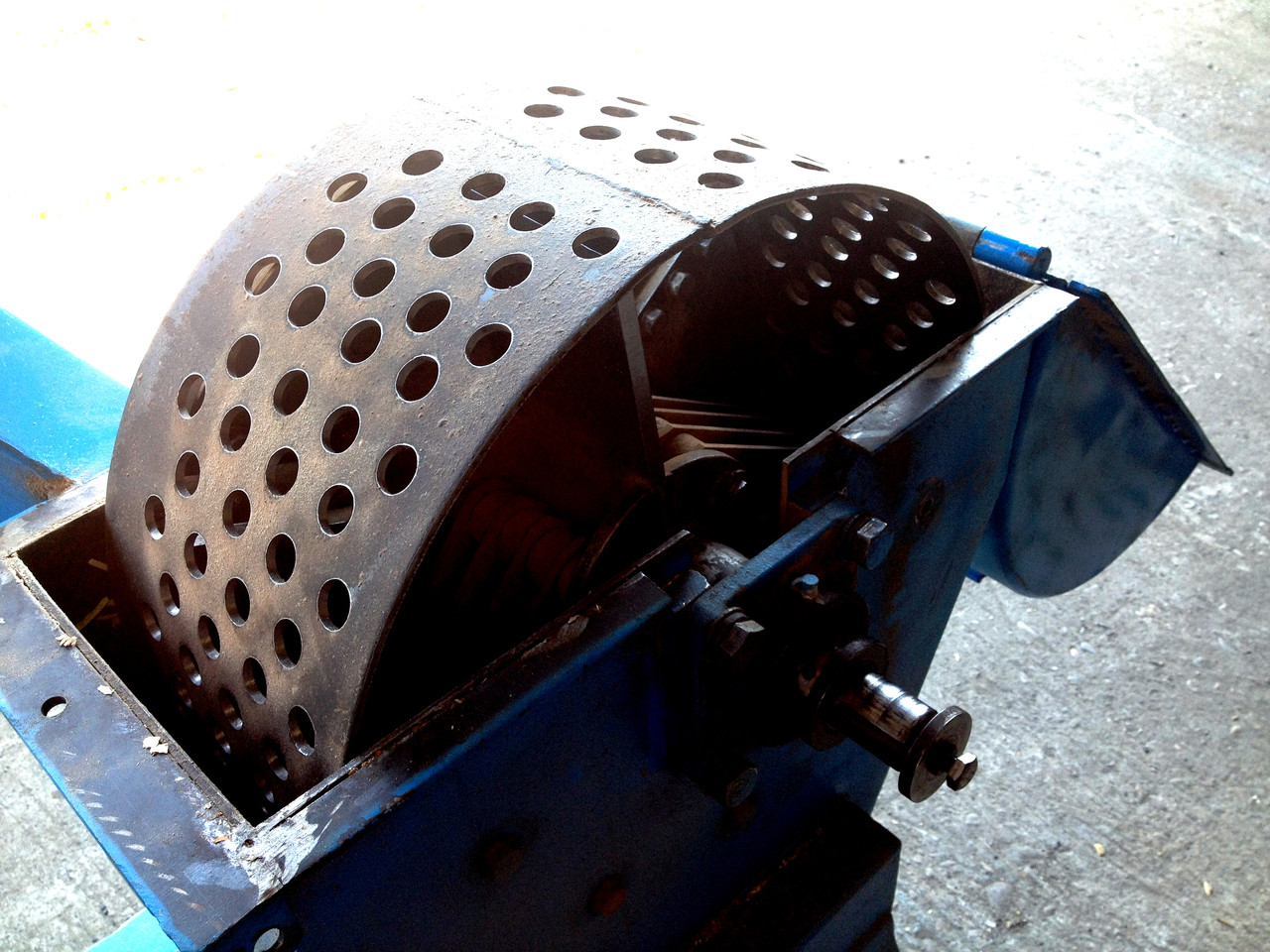

Sieve for wood chips

To make a sieve, inside which the grinding chamber will be located, take a metal cylinder with a diameter of 30-35 centimeters, made of a sheet of metal 94.2-100 centimeters long.

In the cylinder itself, cells with a cross section of 8-12 millimeters are made, preferably using a core or punch (do not drill), so that the edges of the cells are torn or sharp.

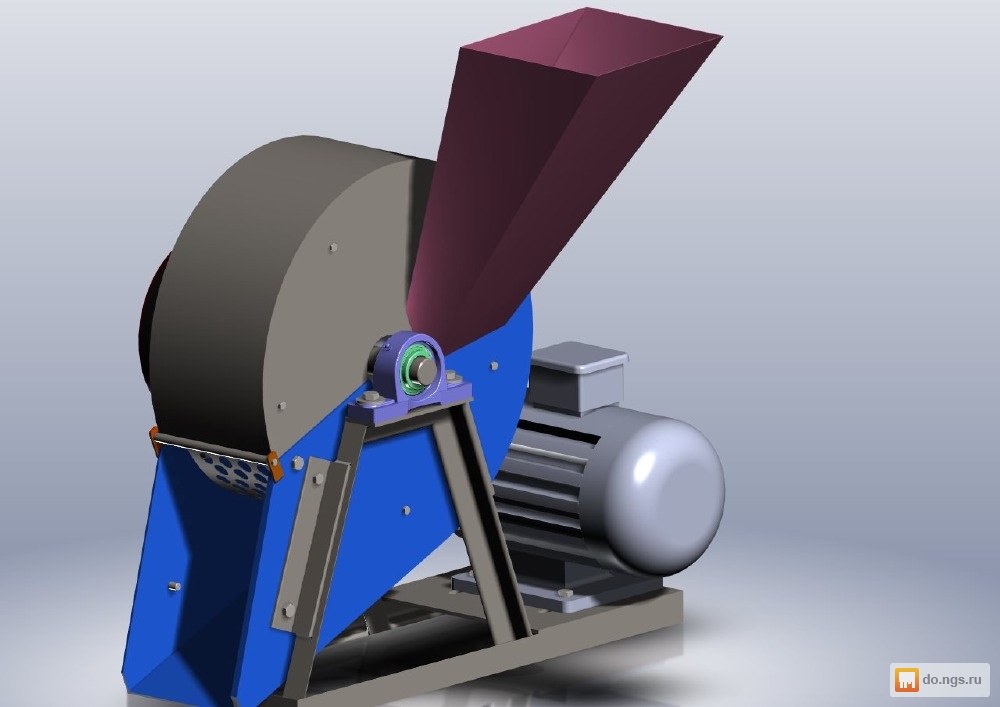

Protective cover, funnel, receiving hopper and frame

To create a protective casing, the receiving funnel of the receiving hopper, sheet metal with a thickness of 8-12 millimeters can be used. Sheets are cut to size, welded according to the drawing. Parts are cut according to previously known sizes and "patterns" (they can be prepared in advance using thick cardboard). Stiffeners are made from pipes, channels or corners.

The cutting unit itself should not cling even minimally to the walls of the unit body, preferably its free placement in the body, therefore the optimal flywheel diameter is made in size less than the body size by about 3-5 centimeters.

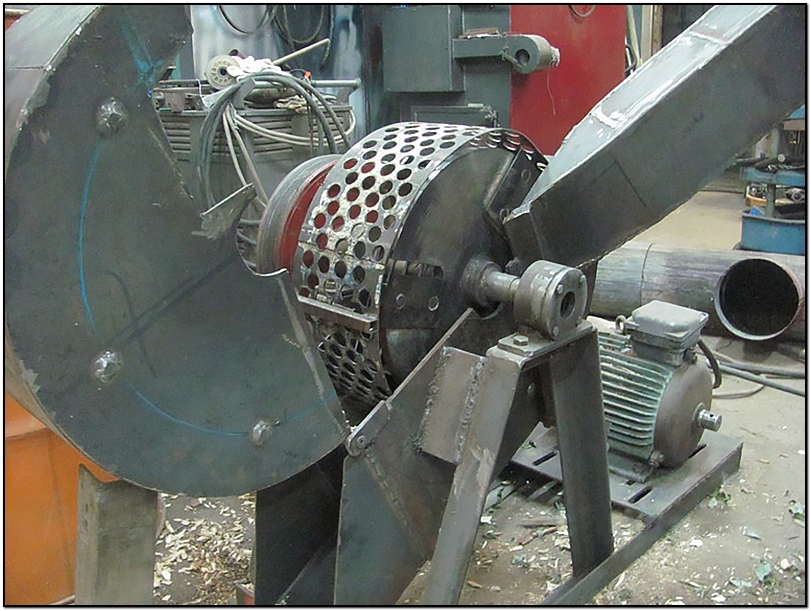

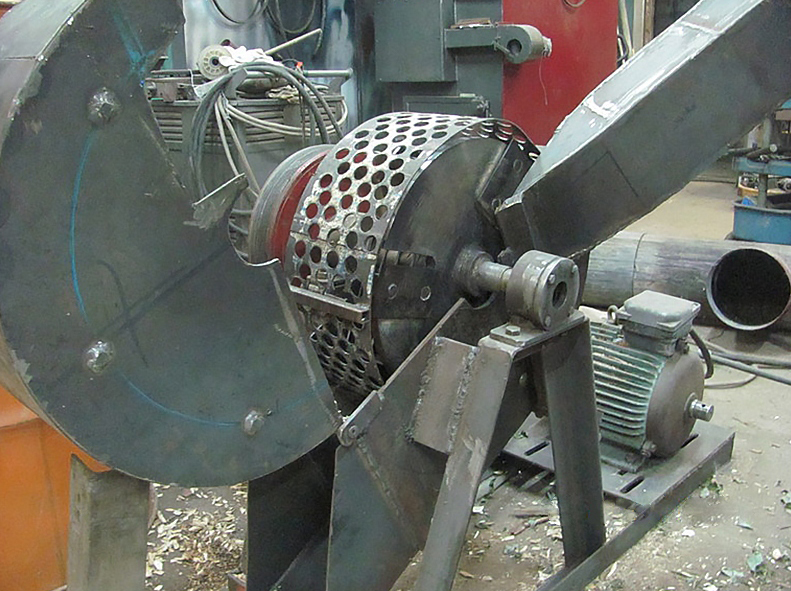

The main parts of the crushing unit: these are the shaft journals, on which support bearings, hammers and a cutting disc are mounted. To form a working shaft, it is enough to cut holes, inlet / outlet sockets intended for feeding raw materials, leaving chips.

Bunker for receiving raw materials welded at an angle to the body. Electric or mechanical drives are mounted at the final stage: the electric motor is attached to the frame, then pulleys of the required size, all nodes are connected by a belt drive. Usually, ordinary car belts of the corresponding diameter are taken for this purpose.

Engine

It is on the type of engine that the volume of operating costs and the performance of the chip cutter will depend.The electric motor is considered the most environmentally friendly option, it is lighter than the internal combustion engine, makes less noise, but also shows lower power. It is worth remembering that an electric wood chip cutter will depend on voltage surges in the network.

The device on a more powerful gasoline engine will work longer, more efficiently, does not require a network and an outlet. But the internal combustion engine makes a lot of noise, significantly pollutes the air, and requires constant maintenance and regular refueling.

Provided that the assembled wood chip cutter is designed accurately and there is no run in alignment, you can use a coaxial circuit instead of a belt connection, mounting the shaft connection through a coupling.

Buy or make wood chips with your own hands

As soon as a private developer decided to independently make wood concrete blocks, the question arises whether it is more profitable to buy or make wood chips for building blanks. If you plan to build a small country house, then buying ready-made raw materials will reduce working hours and financial costs.

Specialized equipment for the manufacture of wood chips is an expensive technique. Chemical treatment takes time.

If a decision is made to produce wood-concrete blocks in large quantities, or to engage in construction activities, then it is more profitable to independently produce wood chips.

The process of making wood chips for wood concrete with your own hands consists in a sequence of actions:

- selection of suitable wood;

- receiving chips using special equipment;

- processing of wood chips with chemical reagents in order to remove sugars.

Requirements for wood chips for wood concrete blocks:

- Lack of impurities: stones, ice, clay, sand.

- No rot, mold or other damage.

- The content of bark is within 10%, needles - 5% of the total mass.

- Standard size 40105 mm.

When making wood concrete with your own hands, the presence of sawdust up to 30% is allowed. In this case, the consumption of cement increases, and the strength indicators of the finished material decrease. Arbolite blocks with an admixture of sawdust are distinguished by increased heat-saving properties. They are used as an insulating building material.

What sawdust is needed for wood concrete? Sawdust of coniferous and deciduous woods is used, as well as for the preparation of chips. In order to purchase, it is possible to contact woodworking enterprises.

Forming jumper blocks

The mortar is poured into suitable forms using buckets or shovels. The ramming device is created from a bar and is used only after the container is completely filled with a solution with the formation of a small slide on top.

There is no need to tamp after each layer has been poured. The randomness of the mixture ensures high quality. When laying, you can press down on individual areas a little so that the material fits tightly. Tamping with an incomplete shape is a mistake and leads to delimitation of layers and a poor quality of their setting.

The mixture should be in the form for 2-3 days, after which it must be dismantled and the contents placed in the open air to dry. In the absence of financial constraints, it is recommended to purchase a vibrating table that ensures the compaction of the material in the molds.

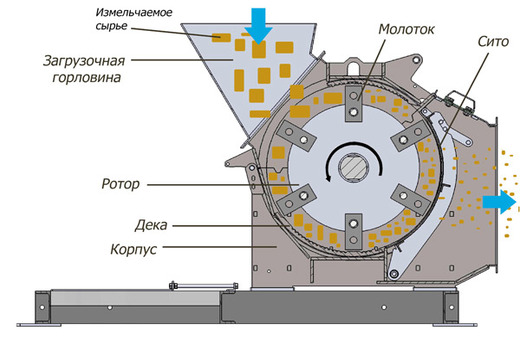

Production principle

The principle of operation of wood chips is reduced to several stages.

First, waste - boards, slabs, trimmings, knots and other raw materials - are put into the hopper. From there, all this is fed into a closed chamber, where a powerful disk rotates on the shaft. The flat disc has slots. In addition, several knives are attached to it. The knives move at an angle. This divides the wood to be processed into small bevel cut plates.

Through the disc slots, the plates penetrate into the drum, where the steel fingers perform further grinding. The pins and plates are mounted on the same shaft as the disc. The plates are installed very close to the drum.They move the crushed chips along the inner surface of the drum.

The lower part of the drum is equipped with a mesh with cells that provide the specified chip sizes. The cell size varies from 10 to 15 mm in diameter. As soon as the ready-to-use chips reach the bottom zone in the vertical direction, they pass through the net into the pallet. The remaining particles rotate, held by the plates, another circle. During this time, their position is constantly changing. Having reached the bottom in the desired direction, they also end up in the pallet.

Chip cutters can be either electric or petrol powered. The engine power of a small device is in the range of four to six kilowatts, in more solid ones it reaches 10-15 kW. The capacity of the device depends on the power. With its increase, the volume of production per hour of operation of the mechanism increases.

How to make a wood chip cutter with your own hands: drawings, construction device

At the final stage, the chips with the help of the blades fall on the sieve and fly out of the chip cutter through the unloading hole. At the entrance, the receiving hopper is designed as a funnel in order to simplify the supply of raw materials for processing and to make this process safe for hands.

With an increase in the rotational speed of the shaft with a disc, a certain amount of wood raw material can be ground into dust naturally, this is bad, although the performance of the chip cutter increases.

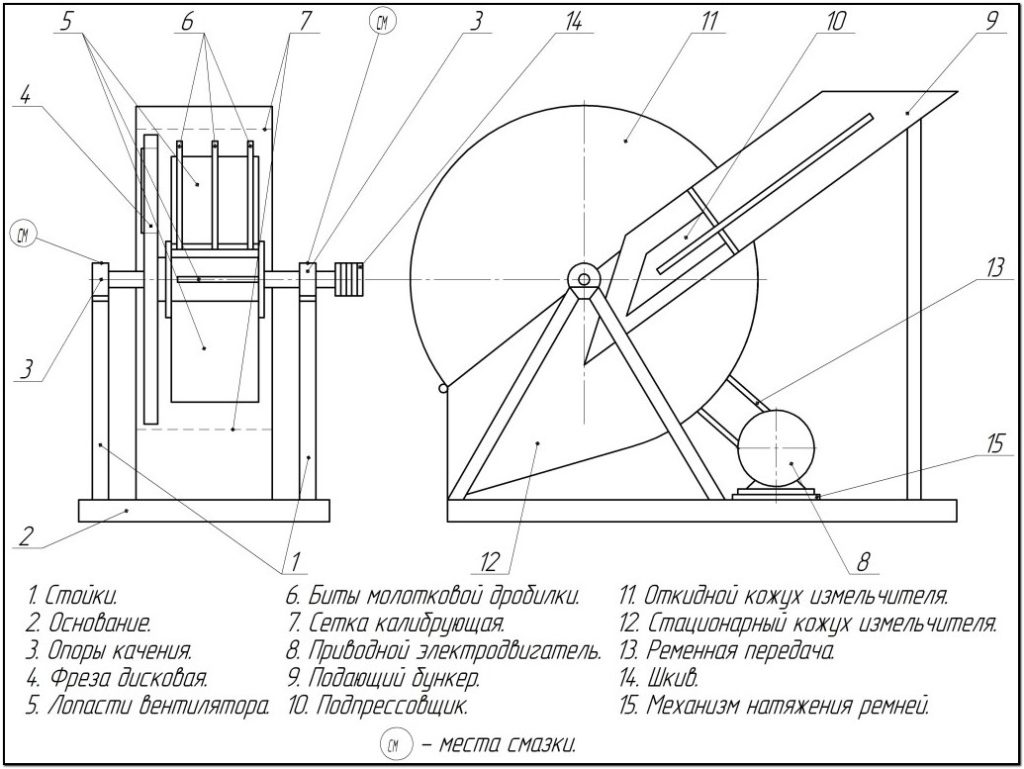

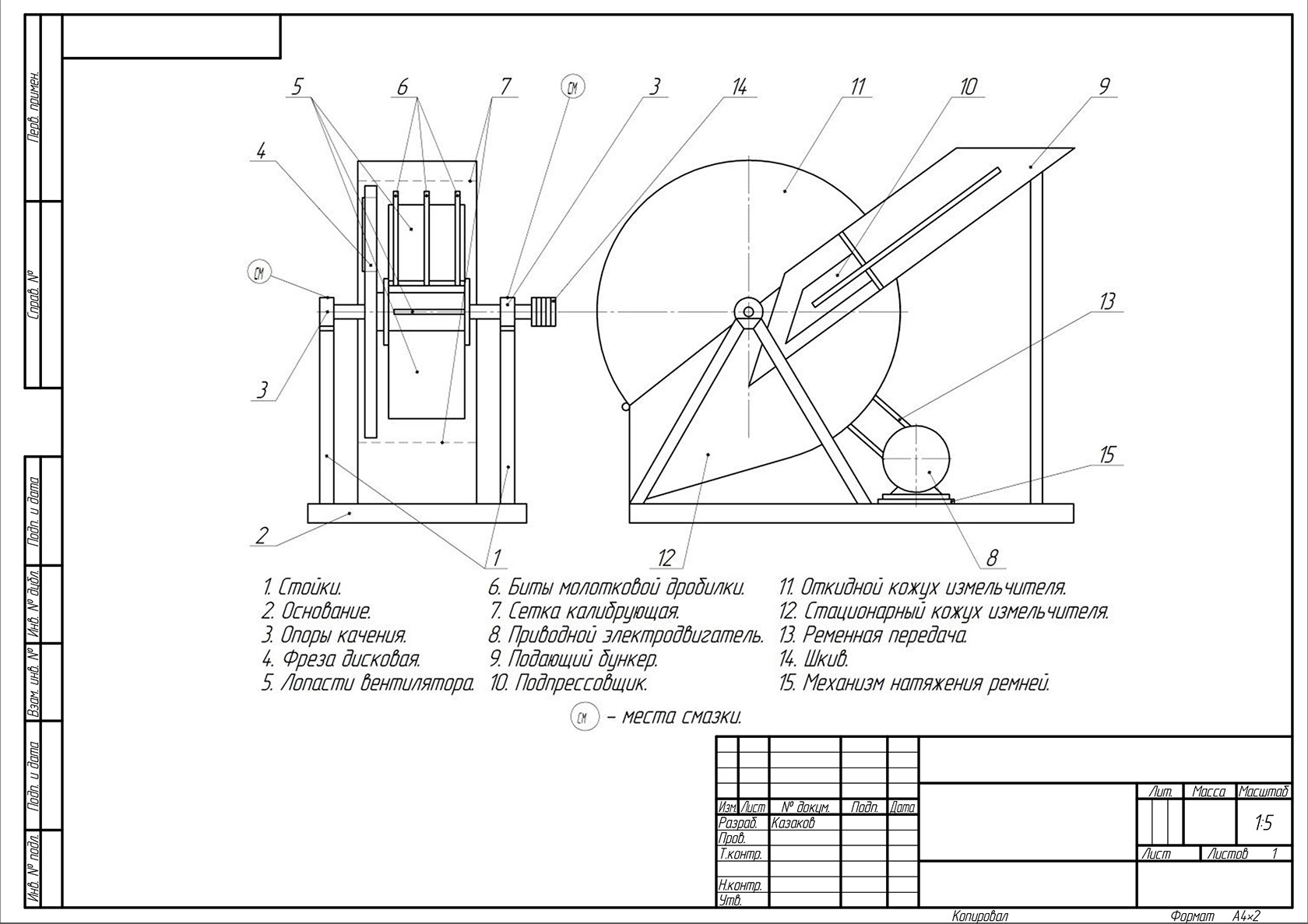

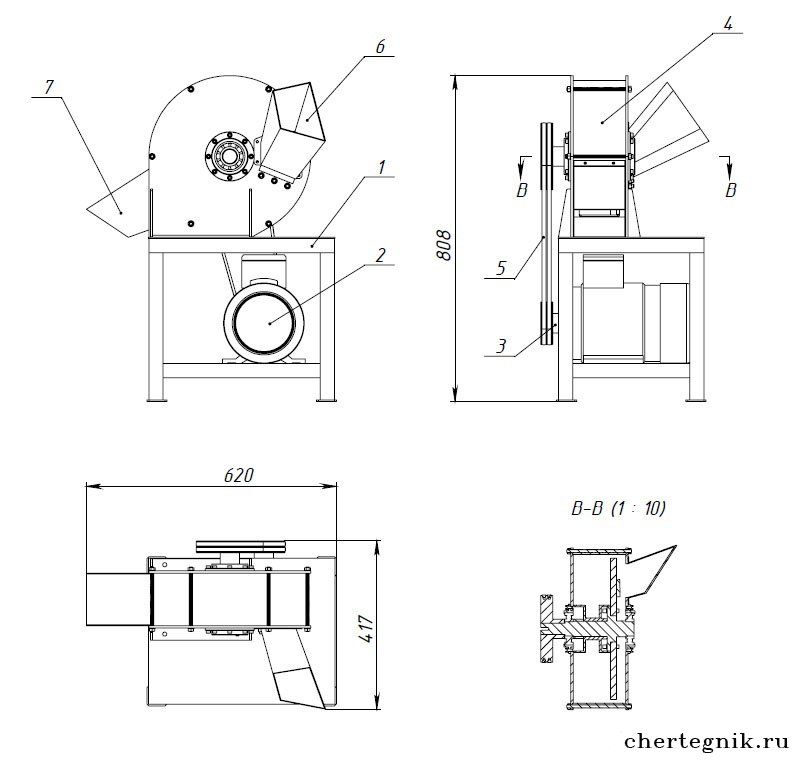

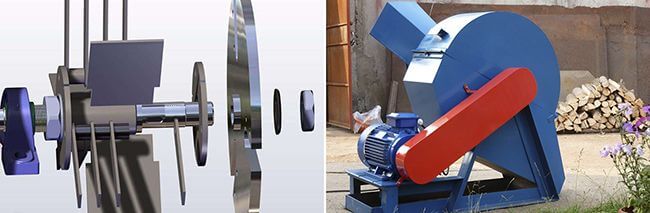

The necessary drawings, according to which a homemade rotary hammer crusher can be made for the production of wood concrete, are presented below. Since the equipment is homemade, the dimensions of the parts will have to be selected based on their own material. Working drawings of different wood chips may differ in size and in the presence of certain units, but the principle of operation remains the same. After applying voltage B to the equipment, the electric motor transfers its rotation by means of a V-belt transmission to a drum with blades 4 through a pulley 14 and a shaft.

It is only necessary to put wood waste into the feeding hopper, which is immediately processed into chips of optimal length up to 25 mm... Having assembled a wood chipper for wood concrete with your own hands and keeping the distance between the hammers in a wood concrete crusher, you can produce wood chips up to 25 millimeters long and about 5 millimeters wide. Such chips are ideal for making wood concrete blocks or making monolithic wood concrete. It is performed at a certain angle, due to which the branches are not thrown back.

If you plan to build a house from self-made wood concrete blocks or monolithic wood concrete, then you need wood chips. Using it, you will significantly improve the quality of the blocks, and even later, after the completion of all construction work, it will come in handy as a garden shredder for processing waste left after the autumn harvesting of the garden, as well as trimming shrubs and trees. You can make a wood chip cutter for wood concrete using a certain set of tools and materials at hand. The main units of the machine are a chipping disc with knives and a rotor with hammers and blades.

Before constructing a wood chip cutter with your own hands, you need to prepare all the details. To make a disc, you need a metal sheet with a thickness of mm.

What a chip cutter consists of

The diameter of the finished product should be approximately mm. A hole is made in the center where the key is placed, and along the outer perimeter there are symmetrical slots. Chips will be discharged through them.

Holes are prepared for fastening the knives. A do-it-yourself chip cutter can be assembled using a finished disc. In any case, the disk will simultaneously be a flywheel.

To prepare knives, each of which should have two holes, it is most often recommended to take springs from a car. The chipper knives are fixed with bolts, which are unscrewed and tightened with a hex wrench.This fact is explained by the fact that the screws for the screwdriver are not tightened so tightly. Hammers are understood as flat metal plates, the thickness of which is about 5 mm.

They are located on the rotor. These are the parts that are better to buy ready-made. It is necessary to prepare a sieve. When installing the knives in the chipper, it is necessary to ensure the required alignment of the knives behind the plane of the disc.

The difference in the exhibition of knives should not exceed 0.2 mm.

Grinding mode

The cutting edges of the knives should lie in the same plane, the gap between the cutting knives and counter-knives should be uniform 0.

After sharpening the knives at the required angle, perform additional sharpening on the reverse side of the chamfer at a width of 0. After each regrinding, the knives must be at rest for at least x hours to relieve fatigue stresses. Note: Chipping knives made of other steel grades are accompanied by additional information to the instructions.

About company. Photo gallery Video gallery. Available in warehouse: 26 units Shipment of Junkkari hjg chipper to Drovokol hydraulic wood splitting machine Japa Finland Quantity: 1 pc. Palax Motti firewood packer Quantity: 4 pcs.

Packer for firewood Palax Packer Quantity: 2 pcs. HJ - Tractor-driven wood chipper with hydraulic feed Quantity: 3 pcs. Sharpening machine - IRM Quantity: 1 pc. Band sawmill ZL- 60V Quantity: 1 pc. W-Forrest - rotary mulcher up to mm diameter. Quantity: 1pc Spare parts ordering. Chippers Wood chippers. Wood splitting equipment Wood splitters and cleavers.

What should be the chips?

Wood filler for wood concrete has its own GOST. At the level of the state standard for wood chips, strict requirements are established.

Three main parameters are highlighted:

- length is not more than 30 mm;

- width is not more than 10 mm;

- thickness is not more than 5 mm.

The optimal dimensions in width and length are also indicated:

- length - 20 mm;

- width - 5 mm.

New requirements appeared with the adoption of GOST 54854-2011. Before that, there was another GOST with less requirements. Then it was allowed to use longer chips - up to 40 mm. In 2018, "liberties" in the size of the filler are not allowed.

The standard also regulates the presence of impurities: bark, leaves, needles. The material should be cleaned from earth, sand, clay, and in winter - from snow. Mold and decay are unacceptable.

Recycling branches

In the process of beautification of plantings in city parks, during logging, during work on a personal plot, etc. wood waste is inevitably formed, the lion's share of which is ordinary branches. Their disposal today involves one of the following methods:

- Removal of branches to the dump. An extremely irrational and outdated method, but which is still the case.

- Burning. A method widely used by all gardeners. It requires adherence to special safety rules, allows, as a result of the process, to obtain wood ash, which is used as a good fertilizer.

- Recycling. The most economically and environmentally friendly way. It includes several different methods that are successfully implemented both in industrial enterprises and on the scale of personal subsidiary plots.

We collect the chip cutter

We carry out the assembly in the following sequence:

- we assemble the chipping block: we put bearings, a disk with knives and hammers on the shaft;

- we prepare the body for installation: we cut out the holes for the working shaft, receiving hopper and unloading of chips; we drill the necessary holes for the assembly bolts and weld the hopper funnel at an angle;

- we assemble the drive: we fix the engine on the frame, mount the pulleys and put on a belt (you can use a car belt);

- we attach the chipper block to the frame and close it with a protective case (to avoid accidents);

- we make an idle test run.

Advice! During the first week, it is recommended to use a wood chip cutter for making wood concrete in the minimum load mode and for a short time in order to avoid jamming of the bearings, which can occur as a result of their overheating.

Rules for choosing wood chips for smoking

Shavings, wood chips or sawdust are bought or produced on their own.

When choosing, take into account the size, structure and type of wood, since the characteristics of smoking smoke, the taste and aroma of the finished dish depend on this.

Basic rules for making wood chips at home:

- The wood is chosen healthy, without mold, signs of decay and damage by insects.

- Raw materials should be free of bark, which contaminates the walls of the smokehouse and gives the smoke an unpleasant taste due to the high resin content.

- The wood chips should be moderately moist. Too moist will smolder badly with the formation of a large amount of water vapor. Overdried easily ignites, and an open flame melts off fat, and the dish turns out to be tough.

- The optimal size of pieces of wood is 2-3 cm.

You should not use coniferous wood for the production of firewood and chips, since it contains a large amount of resins and gives the dish bitterness. For the same reason - due to the high concentration of resinous substances, birch is rarely chosen for smoking.

The universal types of wood are aspen and alder. They give clean smoke without hazardous impurities and are suitable for smoking any product.

Thanks to alder shavings, delicacies acquire a beautiful golden brown color, a slightly sour taste and a rich tart aroma.

Multi-component mixtures based on alder and aspen are also popular. For best results, the chips should contain at least 60% alder or aspen shavings or fruit tree wood.

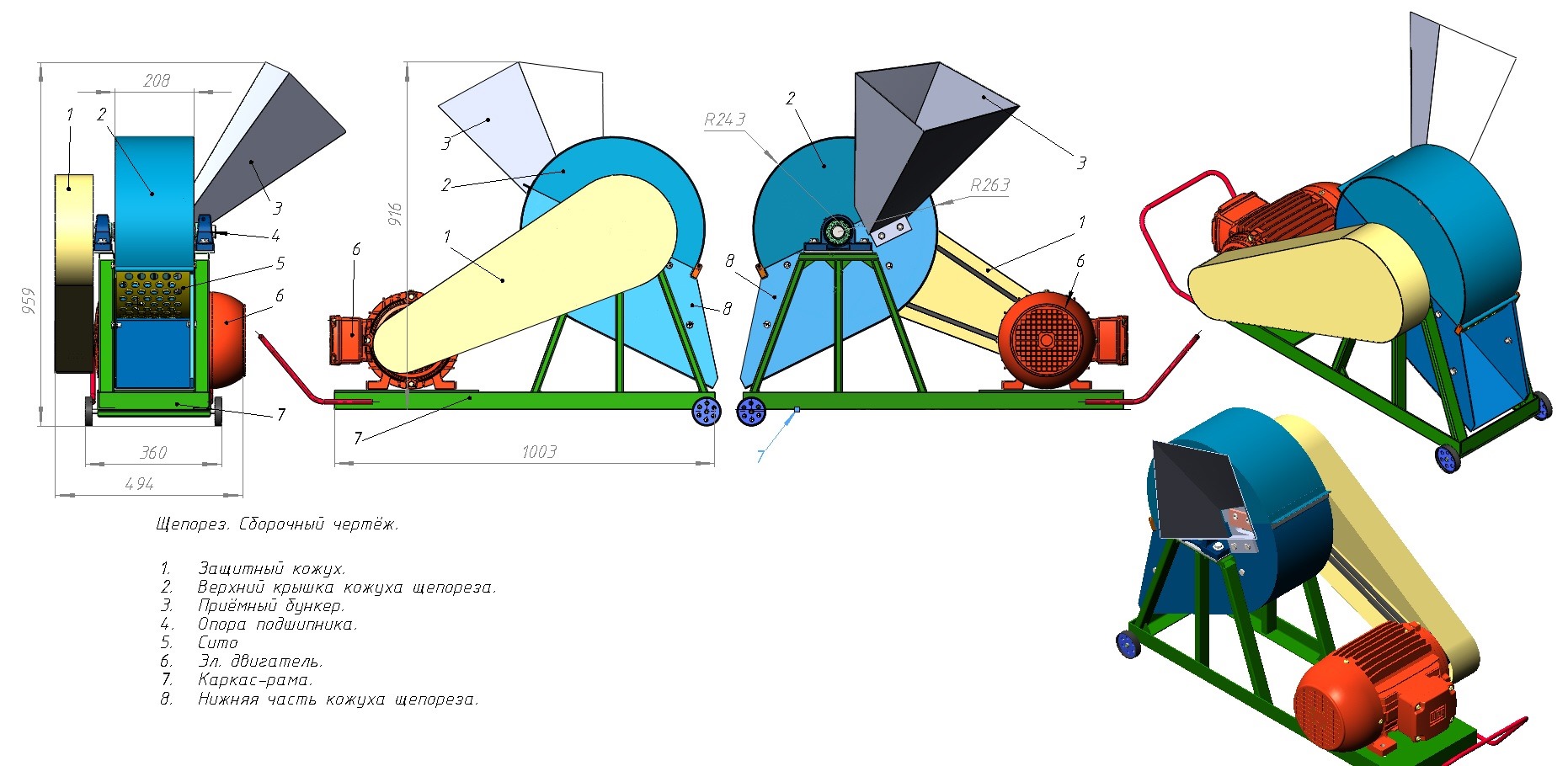

Machine assembly rules

It is necessary to strictly adhere to the sequence of assembly operations.

- The chopping unit is being assembled. A disc with knives, hammers and bearings inside their housings are "pushed" onto the shaft.

- The lower stationary part of the body is installed on the bed.

- A shredding unit with a sieve is inserted inside, the first must be inserted into the second.

- The grinder rests on the frame by means of bearings, which are immediately bolted to the frame.

- The sieve must be attached to the fixed part of the housing with screws or bolts. For this, ears are welded to it in advance.

- A large pulley is pushed onto the end of the shaft protruding from one bearing.

- An electric motor is installed, put on the belt pulleys.

- The funnel is welded or bolted to the chipper body.

- The upper hinged part of the case is mounted on the hinges.

We can assume that the wood chopper for arbolite is made by hand. It remains only to carry out the electrical installation and the first start-up of the equipment. For an electric motor, three phases are required and an automatic machine selected for its power must be installed. There are two wiring options:

- assemble a separate unit and install with a start button directly on the bed;

- leave the button on the machine, and mount the machine in the switchboard of the room.

The first option is better, because it makes it possible to move the wood concrete chip cutter (with a used or new electric motor) to any place, like a full-fledged equipment.

Technological equipment for the production of wood chips

A woodworking shredder is the best option for obtaining chips with the correct needle shape and acceptable particle size. Its only drawback is its high cost.

For DIY manufacturing, it is recommended to use specialized chipping machines, otherwise chip cutters.

The machines differ from each other in their principle of operation.The choice of an acceptable option is determined by the volume of production, the properties of the feedstock, the possibility of placement on the construction site, and the technical features of processing.

Types of chipping equipment:

- Disc chippers. Some of the models have an adjustment of the position and tilt of the knives. This makes it possible to obtain chips of various sizes. They are capable of processing wooden blanks of any shape.

- Drum-type chippers. They allow you to recycle both wooden beams and waste from furniture production, logging farms. The machines are equipped with a large-sized feed hopper, into which the raw materials are fed. Then there is a drum mechanism with double-sided knives.

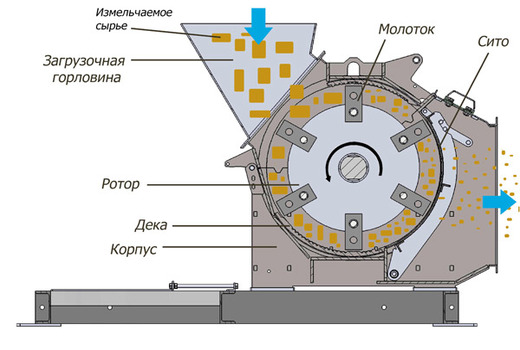

- Hammer type crushers. They are produced with one working shaft or with two shafts. They are a rotary device equipped with hammers and bumpers. Once inside, wood for arbolite moves between hammers and special dividing plates, wedges and crushed from impacts, and then sifted through a sieve into the outlet compartment. The final size of the chips depends on the dimensions of the sieve mesh.

All three types of machines have manual loading of raw materials. To ensure occupational safety, it is preferable to use long timber pieces. Use a shovel or other suitable long-handled tool to load smaller material.