Calculation of the composition of concrete

The SMS is characterized by the following indicators:

- low water-cement ratio (0.38–0.4);

- high workability rate (up to 70%);

- absence of large pores and capillaries in the structure;

- compressive strength B60-B80, but it can reach up to 100 MPa;

- modulus of elasticity - in the range of 30–36 GPa;

- the content of air bubbles is not more than 6%;

- mobility P5;

- frost resistance F400;

- water resistance W62 and higher;

As a result, we have the following advantages of SCC in comparison with classical concretes:

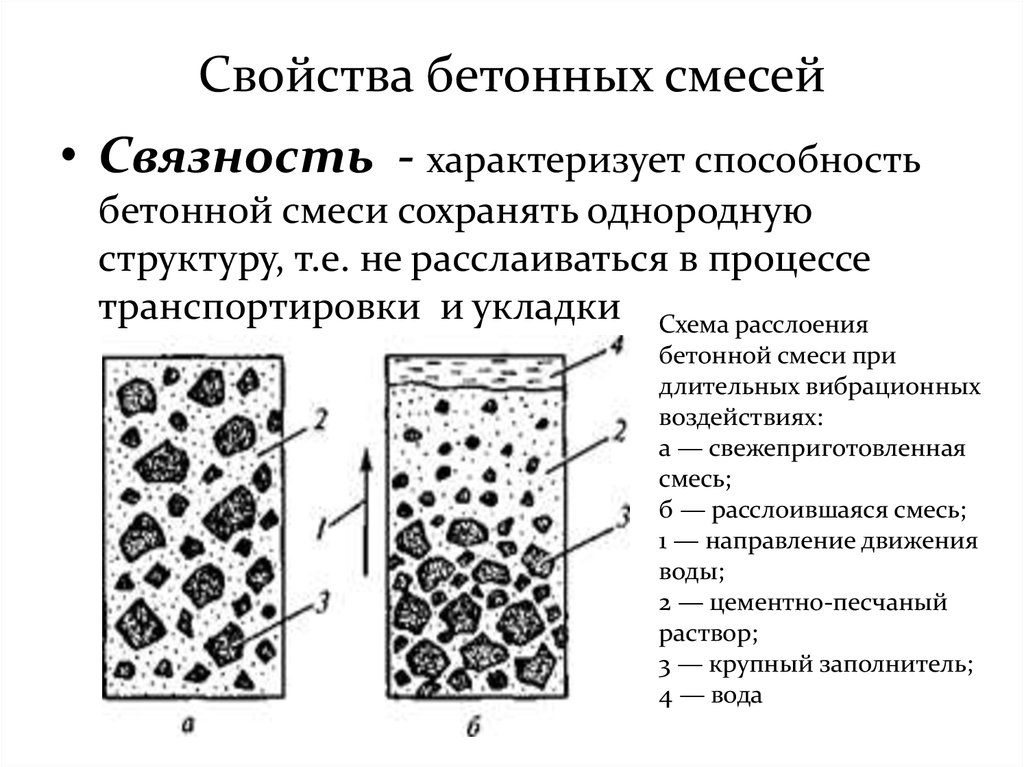

- High mobility, non-delamination even in conditions of long-term material transportation.

- Refusal to use vibrators.

- High structural strength and perfect surface quality of finished products.

- Possibility of stacking in thin-walled, densely reinforced structures of complex geometric shapes.

- Significant reduction in construction time.

- The cost of production is commensurate with the cost of producing standard heavy mixtures, and if we analyze the economic effect of using this type of material, then even lower.

Classification

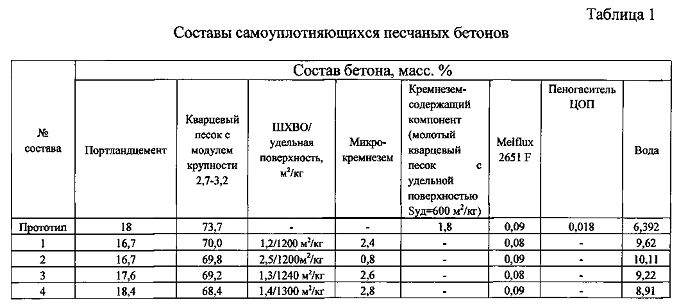

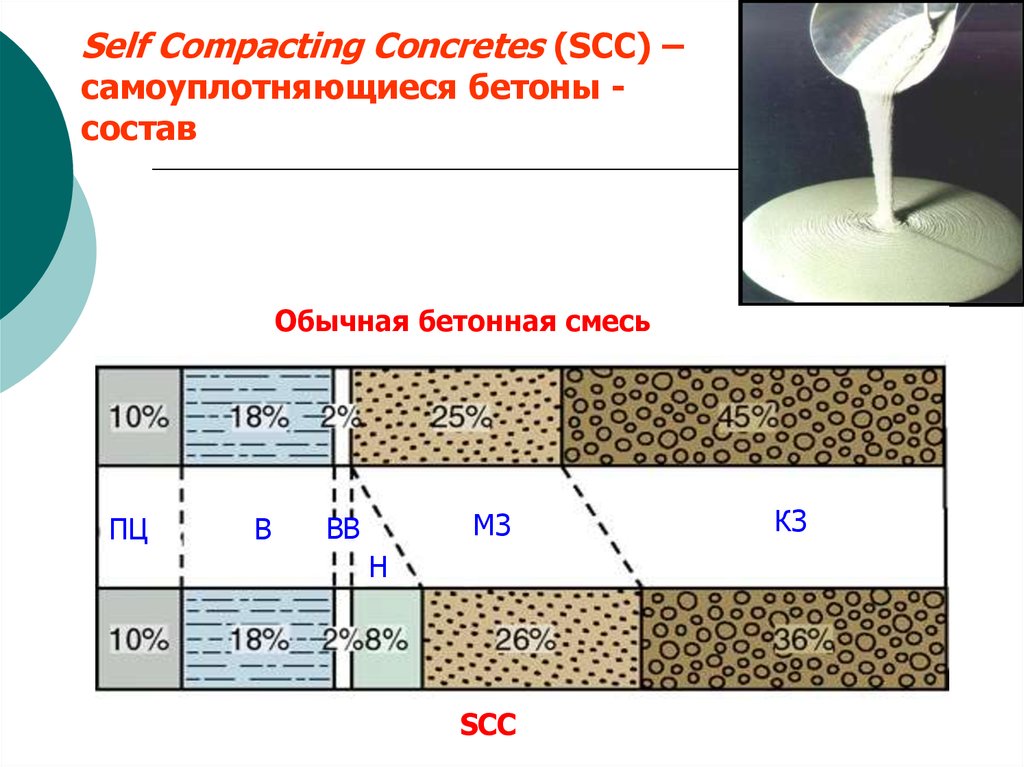

Depending on the method of ensuring resistance to water separation and delamination, there are two basic types of self-compacting solutions:

- fine-dispersed type - a significant increase in the volume of the fine-dispersed fraction in comparison with ordinary concrete;

- stabilizing type - making solutions using stabilizing additives.

Fine aggregate

Fine aggregate

Finely dispersed aggregates increase the resistance of self-compacting mixtures to delamination and reduce the blocking of the movement of concrete mortar when it flows in densely reinforced structures.

It:

- granulated blast-furnace slag;

- limestone powders;

- fly ash;

- siliceous entrainment.

The volume of finely dispersed suspension in the SCC

The volume of finely dispersed suspension in the SCC

Stabilizing additives allow optimal viscosity to be achieved while providing the perfect balance between delamination resistance and flow, the opposite properties that occur when water is added.

Stabilizing additives

Stabilizing additives

When a stabilizing modifier is introduced, a stable microgel is formed on the surface of the cement grains, which ensures the formation of a "supporting framework" in the cement paste and prevents delamination. At the same time, the formed structural skeleton allows the aggregate (crushed stone, sand) to move freely, thereby, without disturbing the workability of the solution.

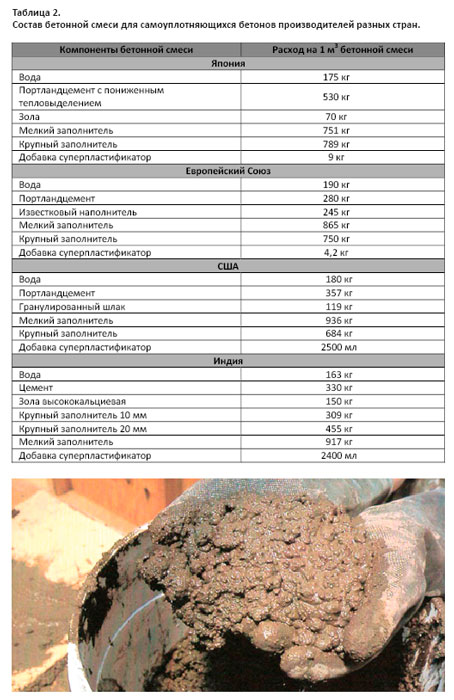

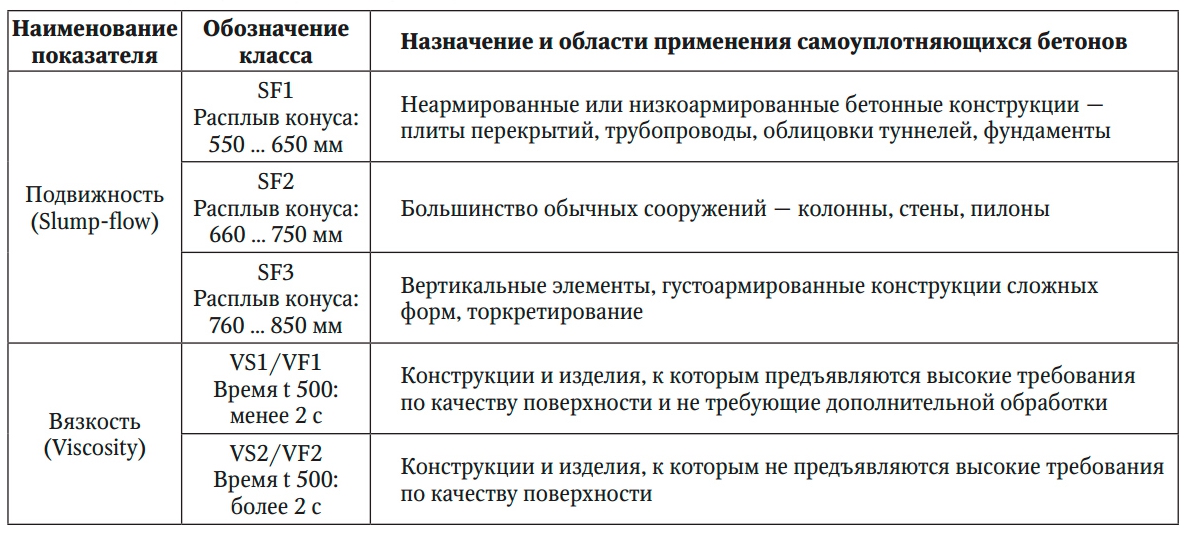

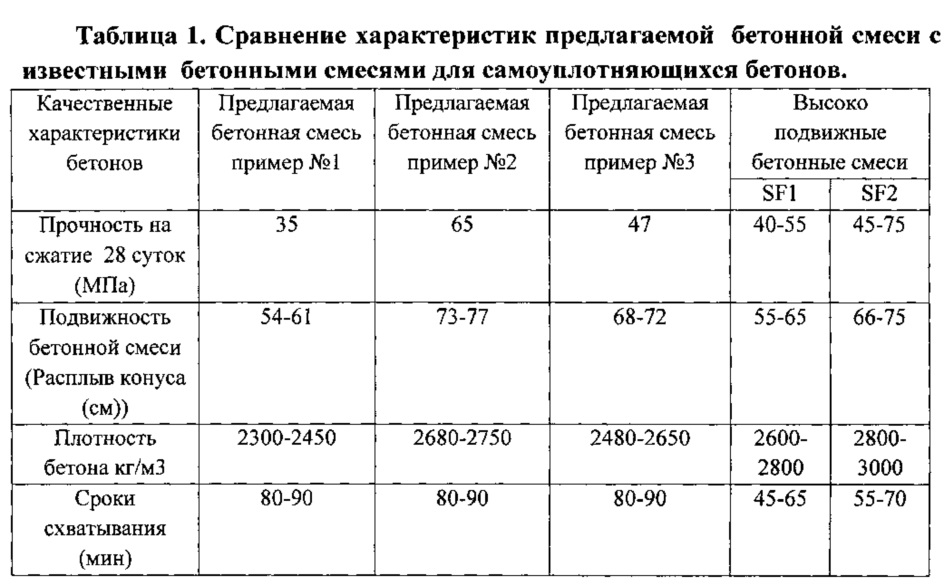

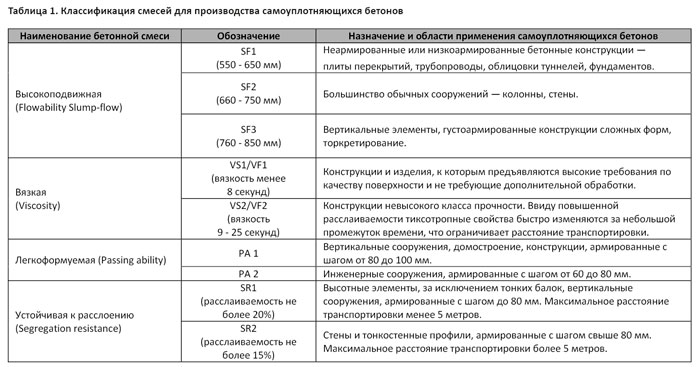

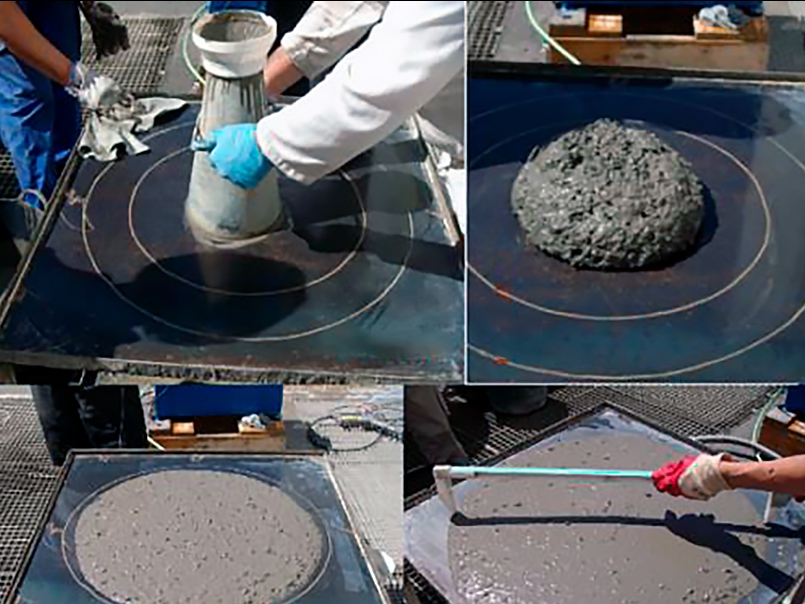

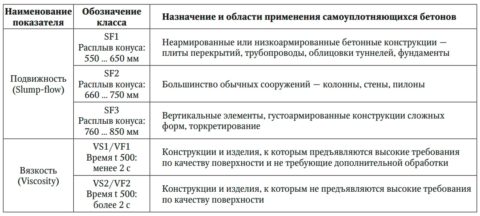

In international practice, according to quality indicators, the following classification of self-sealing compounds is adopted:

- SF1 – SF3 - workability classes (cone spread);

- VS1 – VS2 - viscosity classes, method T500 (time required for spreading of a standard concrete cone around a circle with a diameter of 500 mm);

- VF1 – VF2 - viscosity classes, taken into account the time of material flow through the V-shaped funnel;

- PA1 – PA2 - classes investigating the possibility of a self-compacting suspension to pass obstacles (reinforcement resistance) in an L-shaped tank;

- SR1 – SR2 - grades for peeling resistance, investigated the magnitude of peeling by the sieve method.

Based on the indicators of the above test methods, the purpose and scope of application of self-compacting mixtures is determined (see table below).

Self-compacting concrete - application

Self-compacting concrete - application

The process of pouring concrete structures

Monolithic and precast concrete are made in strict accordance with the technology

It is imperative to pay attention to each of the stages of creating a structure in order to achieve the desired parameters and properties.

Formwork construction

The creation of a monolithic reinforced concrete structure begins with the installation of formwork, which will not allow the liquid solution to spread and will support the concrete at all stages of solidification.

What are the types of formwork:

- Collapsible panel - includes several separate blocks for rigidity, can be made independently at the facility.

- Block - used for a single fill of not one, but several walls at once without overlapping with a supporting structure.

- Pneumatic - with a durable shell, air permeable, it is made for complex cavities of small volumes.

- Volume-adjustable - for the installation of monolithic ceilings, walls in high-rise buildings, is constructed with the involvement of a crane.

- Sliding - used to create high-rise buildings, installed around the perimeter, in the process of solidification of the monolith at different levels, it gradually rises up with jacks.

- Fixed - for decorative finishing.

- Tunnel - for filling two overlapping walls with mortar.

The creation of formwork during the construction of a structure is one of the simplest stages of construction.

It is important to properly strengthen the shields, check the evenness of the building level, choose sufficiently rigid and reliable materials so that the structure does not deform under the influence of the weight of the mortar.

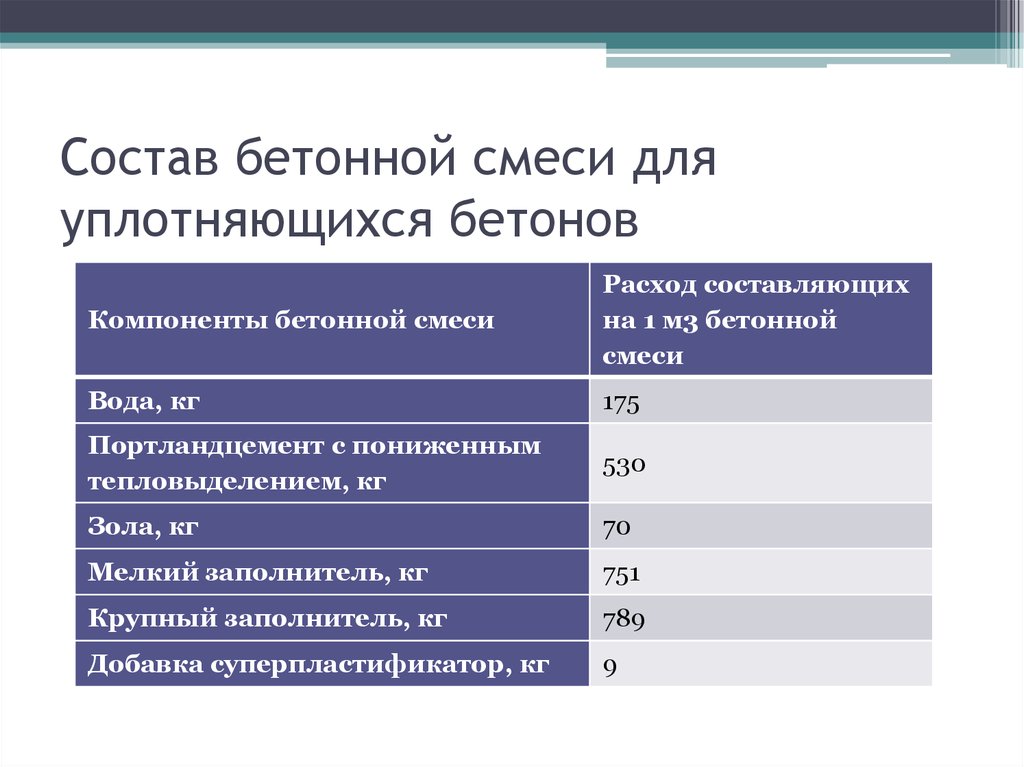

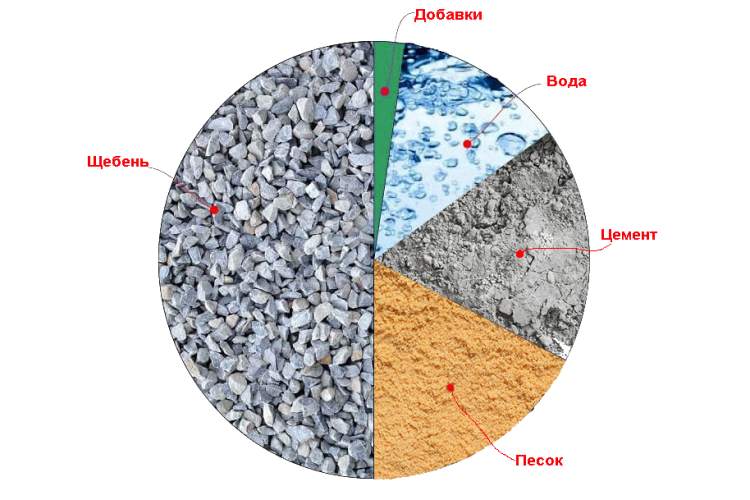

Preparation of the solution

After the installation of the formwork, a solution is prepared, which for pouring monolithic reinforced concrete should include the following components: a part of cement of at least M350 grade, 2 parts of sifted fine sand, 3 parts of filler (crushed stone, gravel), water in sufficient quantity to obtain a solution of the desired consistency. First, all dry substances are mixed, only after thorough mixing is added a little water.

To improve the characteristics of the solution, detergents are added to it (a teaspoon of anti-fat agent on a bucket of liquid concrete will increase strength, reduce shrinkage), PVA glue (200 milliliters per bucket to improve fluidity and increase the adhesion of materials), water glass (to increase heat resistance and accelerate setting at the initial stages of pouring).

The cement mortar can be prepared in a concrete mixer on your own, or you can order the required volume and organize its continuous supply to the object.

Reinforcement and pouring

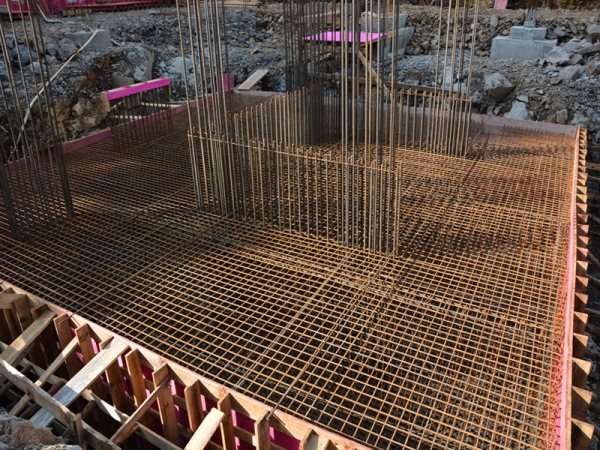

The reinforcing frame of monolithic reinforced concrete is created from steel ribbed rods of different diameters. In the formation of large elements, rods with a cross section of 15-25 millimeters are used, for ordinary walls they are taken with a cross section of up to 10 millimeters. The frame is tied with a knitting wire, lowered into the formwork. The reinforcement should stand on special clamps at a height of at least 30-50 millimeters from the concrete surface.

After the reinforcement is completed, concrete is poured: the formwork is gradually filled in by feeding liquid concrete from the gutter. Small objects are filled in at a time, large ones are divided into captures (horizontally) and tiers (vertically). First of all, the grips of one tier are filled, then the reinforced concrete structure is sequentially poured further.

After completion of the pouring, the mortar is compacted with a vibrating tool. Dry the concrete by covering it with a film so that the water does not evaporate quickly and the concrete is strong. The first days, it is advisable to periodically spray it with water to exclude cracks.

Application and styling features

SCC is used in the construction of various facilities, in particular for the construction of hydraulic structures (piers, port buildings, breakwaters, dams of hydroelectric power plants).

This material is also widely used in the following areas:

- In the production of prefabricated reinforced concrete elements and structures.

- For the construction of monolithic screed floors.

- For strengthening and strengthening buildings and supporting structures.

- When erecting objects that require an initially high-quality flat surface that does not require additional processing (for example, a runway).

- When building from concrete of various structures with a high content of reinforcing elements.

- For the construction of fences or thin-walled rooms (for example, when the building requires a minimum weight of load-bearing and supporting floors).

When laying self-compacting concrete, it is worth remembering some of the features and nuances of using this material. So, for example, due to the increased content of superplasticizers, the setting time of the concrete mixture is significantly increased. Self-compacting concrete, when transported in a concrete mixer for more than one hour, begins to lose its self-compacting property, plasticizers also negatively perceive long-term transportation and, as a result, the mobility of the solution is lost. Professionals recommend not to save money and produce SMS directly at the construction site.

When transporting concrete through a pipeline more than 200 meters long to the working area, delamination and, as a result, mass heterogeneity may appear. This point should also be taken into account especially carefully and try, if possible, to avoid using long supply pipelines when filling. The presence of a heterogeneous composition and layering can adversely affect the final result and significantly reduce the physical and mechanical properties of the finished structure.

Before pouring the self-compacting concrete into the formwork, make sure that there is no liquid, as even a small amount of water can disturb the composition. If there is water, then it is worth removing it, and it is desirable that the surface be dry at all, this will significantly improve the adhesion coefficient

When pouring the SCC, it is important that all components are fed continuously, otherwise the homogeneity may be disturbed and the quality of the final result may be reduced. For some time, the solution should not be touched, since it does not need to be compacted, and any manipulations can disrupt the uniformity and create surface irregularities after solidification.

Important: If during transportation or storage the self-compacting mixture has lost some of its quality characteristics and thickened, they can be restored with special chemical thinners, which are fed directly into the concrete mixer and mixed until the mass is homogeneous and its original properties are restored. To improve the quality characteristics of class-B15 concrete in the process of preparing the working mixture, the following additives can be used:

To improve the quality characteristics of class-B15 concrete in the process of preparing the working mixture, the following additives can be used:

- sand and crushed stone of smaller fractions - when they are used, the strength increases significantly, but the viscosity also increases (since the surface area of the particles of the fine fraction in the total amount is much larger than that of the coarse one;

- the addition of micro- and ultradispersed filler to the mixture also significantly increases the strength, reduces the risk of corrosion on the reinforcement and the appearance of cracks during shrinkage and subsequent operation.

Main advantages

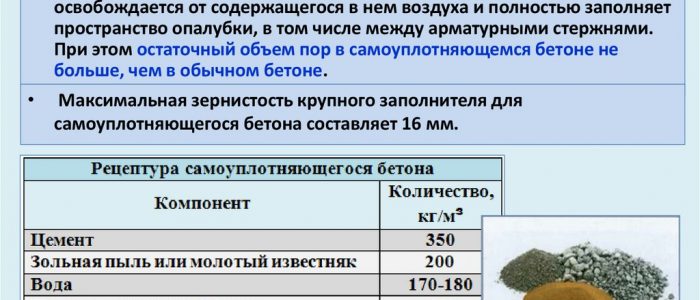

When pouring a mixture of this type, all parts of the formwork are filled equally quickly and without voids. That is, self-compacting concrete can be used not only in the construction of, for example, residential buildings, but also in complex architectural structures. In addition, such mixtures are simply ideal for pouring densely reinforced structures. Air bubbles do not form in their thickness near the frame elements, and the layer itself is as homogeneous as possible.

You will be interested in: Ready putties for walls: types, purpose, manufacturers

Another undoubted advantage of self-compacting concrete is that the structures poured from it have absolutely flat surfaces. There is no need to take any actions to correct them at the final stage.For example, when pouring floors from such concrete, there is no need to use leveling material before installing the finished floor.

You will be interested in: Bulk insulation: overview, types, tips and reviews

Builders who use such concrete in their work, of course, consider it a great advantage that there is no need to purchase expensive vibration equipment. Such concrete is compacted simply under its own weight. Therefore, filling various kinds of structures with its use turns into a very simple procedure.

Vibration equipment is known to be very noisy. Since it is not necessary to use such aggregates when laying self-compacting concrete, it is possible to work with this material even at night.

Self-compacting mixtures are, of course, more expensive than conventional cement ones. However, due to the absence of the need to use vibration equipment, structures from them are often obtained even cheaper.

In terms of performance, these two types of solutions are similar. Mixes of heavy and self-compacting concrete make it possible to build structures that are equally strong and durable. Sometimes, structures built using mortars of the latter type have even better performance characteristics.

You will be interested in: Concrete design

Key Features

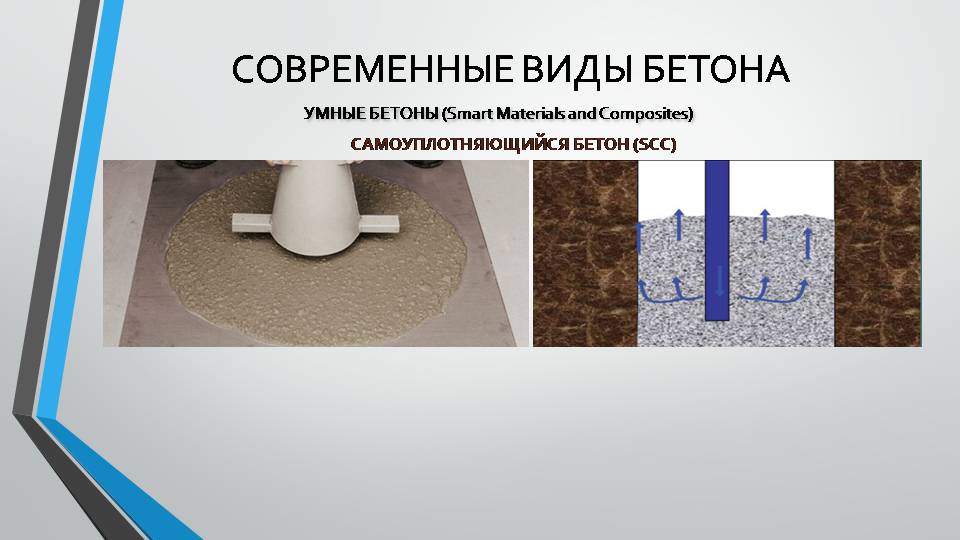

Vibrating screed, which can now be abandoned

The material that will be discussed in this article is unique, as it has the ability to compact under its own weight. Simply put, when ordinary mortars are poured into the formwork, a concrete compactor is needed. The type of solutions we are considering is itself capable of completely filling any forms, even in the manufacture of densely reinforced structures.

The technology is new, but, despite this, it finds more and more applications. The most promising area of using such concretes is the industrial production of concrete products and the installation of monolithic structures, such as, for example, high-strength seamless concrete floors. The technology is in no less demand for gunning concreting, strengthening and restoration of already operating structures.

A bit of history

In the photo - casting of supports using self-climbing formwork

In the 70s of the last century, a number of high-strength concretes modified with a number of superplasticizer additives were developed. For example, in 1970, such compositions were used in the construction of monolithic structures on oil-producing platforms operated in particularly difficult climatic conditions.

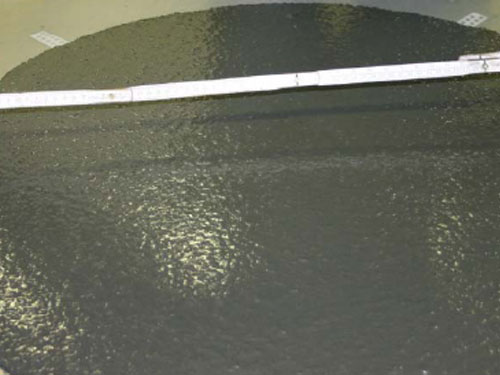

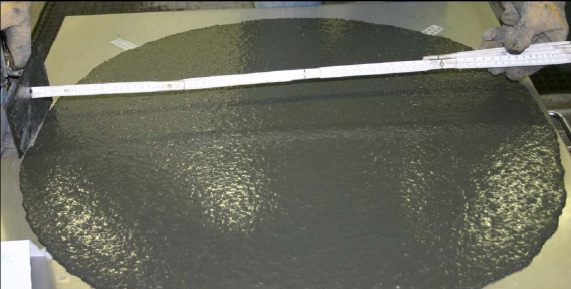

In the photo - the consistency of solutions with a self-compacting function

During the construction and subsequent operation of these structures, recommendations and restrictions were formulated in relation to the introduction of superplasticizers:

- The introduction of superplasticizers at a certain dosage can result in a slowdown in the setting of the mixture.

- When transporting the mixture for 1 hour or more, the effectiveness of the introduced additive decreases, as a result, the degree of mobility of the solution decreases.

- The use of superplasticizers provokes stratification of a dense mixture during transportation through a pipeline over a distance of more than 200 meters. As a result, the quality of finished products is significantly reduced. This circumstance must be especially taken into account when carrying out industrial construction with the use of special gas pumps.

The widespread conduct of grandiose construction projects dictated the need for the production of fundamentally new concretes that meet the highest operational requirements. Among these requirements, special mention should be made of the tight deadlines required both for concreting and for gaining brand strength with a finished product.

The solution was found through a number of theoretical studies and practical implementations, implemented in order to:

- effective use of multifraction aggregates;

- introduction of ultradispersed and microdispersed fillers designed to increase the corrosion resistance and strength of materials reinforced with metal structures;

- control of the rheology of highly mobile mixtures;

- production of fundamentally new types of modifiers and other regulators of concrete performance.

In 1986, Japanese scientists developed a particularly durable self-compacting concrete composition with a number of unique qualities. The new material was named Self-Compacting Concrete.

A unique property of the mortar is the possibility of compaction due to the mechanical load of its own weight. As a result, the development of a new type of material made it possible not to use a concrete compactor.

The industrial use of the solution began in 1996 of the last century, a little later, full-fledged tests of the material were carried out in natural conditions. And only in 2004, the features of the operation of self-compacting concretes were finally determined, and their classification was carried out:

Classification of mixtures used in the manufacture of self-compacting concrete

In the photo - filling the formwork with a reinforcing frame with self-compacting concrete

- For unreinforced or low-reinforced concrete structures (pipelines, floor slabs, foundations, tunnel lining, etc.), highly mobile SF1 mixtures are used. Mixtures of SF2 and SF3 are used for conventional structures, including vertical structures and complex architectural forms.

- Viscous mixtures such as VS1, VF1 or VS2, VF2 are used for the manufacture of structures and products with high quality surface treatment and for structures of low strength class.

- In the construction of vertical structures and structures reinforced with a pitch of not more than 100 mm, easily formable mixtures PA 1 and PA 2 are used.

- For the construction of high-rise elements (except for thin beams) and vertical structures with a reinforcement pitch of no more than 80 mm, SR1 and SR2 mixtures resistant to delamination are used.

Application environment

Monolithic reinforced concrete is used in individual and large-scale construction, to perform a variety of tasks - using this technology, they build cottages, private one-story houses, buildings with a large number of floors, and many other structures. Before the construction of the foundation, floors, walls, all calculations must be carried out, the expected loads are determined, and the steel is correctly chosen.

What is being built using the technology of monolithic reinforced concrete:

- Strip foundation - usually laid under walls and columns.

- A monolithic slab under the base of the entire structure is the easiest option. Modifications with box and ribbed plates are possible.

- Pile foundations are the current choice for soft soils.

- Internal and external load-bearing structures.

- Columns of various cross-sectional shapes used as vertical supports with or instead of walls.

- Production of ribbed, hollow or solid monolith slabs for floor joists.

- Various types of flights of stairs - can be performed by spiral, straight, combined.

- A wide variety of decorative architectural elements - due to the good plasticity of concrete, different columns, pediments, arches can be designed.

- Tunnels - for metro, laid under carriageways, complex bridges.

- Bridges - monolithic reinforced concrete is ideal for the construction of such facilities.

- Areas that will withstand serious loads - test sites, airfields and others.

Where is the SMS applied?

The performance characteristics and composition allow the use of self-compacting concrete in various areas of construction.Compositions differing in mobility and viscosity are used for pouring structures of complex shapes, including those with dense reinforcement, of vertical concrete elements of buildings and structures. According to building codes SMS is applied:

- for the production of precast concrete elements and structures;

- when erecting structures for hydraulic structures;

- for the repair and restoration of objects, including with the use of gunning;

- when installing a solid floor without seams, designed for high loads;

- to obtain durable surfaces that do not require additional processing;

- when pouring elements with a dense reinforcing mesh;

- in the construction of buildings and structures, the strength of which is subject to increased requirements;

- for the production of Lego bricks;

- for thin and durable elements with a minimum weight - partitions, fencing elements.

How to do it yourself

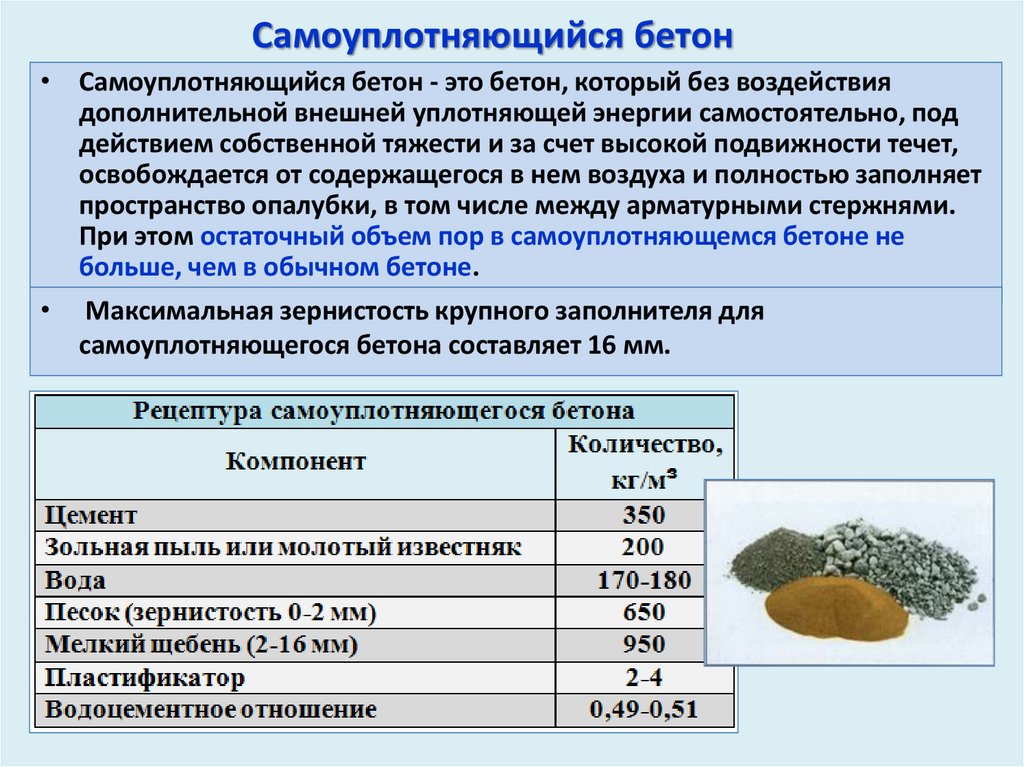

The technology for creating artificial stone includes the use of already known components. Home craftsmen use the following proportions:

- liquid glass - 250 g;

- potassium hydroxide - 200 g;

- slag and fly ash - 750 g each;

- water - 130 g.

But what kind of sand concrete is best used for floor screed can be found here from the article.

The recipe is designed for the preparation of 1 liter of concrete mixture. After making calculations, you can get the consumption of components to create the required amount of environmentally friendly concrete. To date, there are no scientific publications with an exact composition. When creating a concrete mixture according to this recipe, some changes in its quantitative composition may be necessary.

The video tells how to make geopolymer concrete with your own hands:

All of these components can be easily purchased from the retail network. However, it should be borne in mind that the cost of ready-mixed concrete based on polymerization technology will be higher than that of a concrete mixture from Portland cement. The mixture sets very quickly. To slow down this process, tetraborate decahydrate is introduced into the formulation. Additionally, water-based resins, latexes and PVA can be added to the composition.

Cooking technology

First you need to prepare tools and containers. You will need:

- gloves, goggles, overalls, respirator and other means of protection against aggressive substances;

- mixing container;

- a mixing tool that does not react with alkalis (wooden spatula);

- scales to control the observance of proportions;

- molds for ebb (formwork).

From the article you can find out what kind of concrete can be used for the foundation of a house.

When mixing the components of geopolymer concrete, heat is generated. This must be taken into account when choosing a mixing vessel.

If there is a need to accelerate the solidification of the mixture, electrolytes can be laid in the formwork, but this is important to take into account when calculating the proportion of concrete for the foundation of the house

KOH is pretty aggressive. On contact with the skin, and especially the mucous membranes, it causes severe burns. You need to work with him with glasses and gloves.

It is equally necessary to work with potassium metasilicate (water glass) with equal care. It also has a crystallized structure and is very hygroscopic.

Composite concrete is one of the few existing methods of slag and ash disposal. Fly ash is a waste product from the combustion of solid fuels. This component can be up to 75% in the composition of geopolymer concrete mixture. The substance has a dubious environmental record. But its use makes concrete durable and strong.

All components are mixed in a concrete mixer in the following sequence:

- pour water;

- slag and fly ash are poured;

- the components mix well;

- add polymers;

- mix the concrete until tender.

Pour the molds in a dry place. When solidified, this type of concrete forms a film. It tends to swell on contact with water. To prevent this from happening, you need to protect the filled forms from high humidity.

But if everything is done correctly, then as a result you will get the material:

- with high compressive strength;

- with low shrinkage;

- with resistance to high temperatures and acids;

- comparable to granite in impermeability.

Features of laying concrete mix

In the photo - pouring self-compacting concrete into the formwork

By and large, self-compacting concrete is laid in much the same way as most other mortars.

But there are some things to keep in mind:

Ensure that there is no water in the formwork for the concrete product before proceeding with the installation. If there is water, it must be completely removed, since even a small amount of it can cause the mixture to stratify.

Material feeding into framed formwork

- Before being used for installation, the mortar must travel a sufficient distance to allow the air contained in it to escape. As a rule, this distance is the length of the hoses from the concrete pump to the formwork.

If filling is done without using a pump, this distance should be created artificially. - The instructions for laying the ready-made mortar do not provide for downtime. If a technological break is necessary for one reason or another, it should not exceed half an hour.

The fact is that due to long-term contact with open air, the surface of the material is compacted. The resulting compaction will prevent mixing of the two layers of the mortar to be laid in succession.

According to statistics, even minor downtime during installation can contribute to the loss of the concrete's ability to self-compact.

Delivery of mortar into the formwork from a low height

If the mixture is laid in formwork, from which it is difficult to naturally evacuate air, concreting requires a special approach.

For example, when filling the shape of narrow columns, you should not dump the mixture down. It will be better to lower the sleeve inside the formwork and gradually raise it as the form is filled. The lower the height from which concrete is fed into the formwork, the less air will be dissolved in its thickness, and the more efficiently it will be removed from the mold.