The adobe house: other elements

Since these buildings are slightly different from other buildings, other structural elements also have their own requirements.

Foundation

An adobe house is not as light as it might seem, so the best type of base for it is tape. The depth is below the level of soil freezing. Its width should be at least 200 mm greater than the thickness of the walls. Such a difference will make it possible to protect them from water, apply a sufficiently thick layer of plaster.

Concrete often becomes the base material, less often builders use brick or rubble stone. The height of the basement of the adobe building is 500 mm or more. Several layers of waterproofing between the foundation and the walls are also required.

The pile foundation will be more profitable if the depth of soil freezing on the site is more than 900 mm, the site is located on a slope. It will be optimal when the owners plan to build a frame adobe house.

Adobe roof

The relatively lightweight material of the walls suggests the same rafter system with minimal stress. Therefore, the best option is a gable roof, with a slope of 30 to 45 °. But in this case, they are more guided by the wind situation in the region. When choosing a roofing material, preference is given to light types: for example, a soft roof.

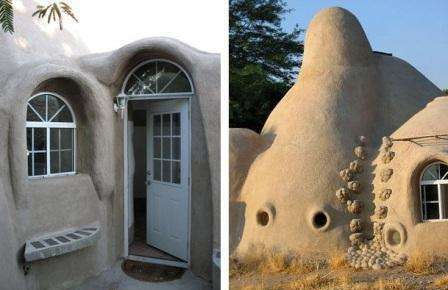

Exterior wall decoration

Without plaster, the blocks will quickly become unusable, so this stage is mandatory. Its layer should be from 50 to 100 mm. Adobe walls are plastered with different mixtures - lime, acrylic, silicate. The main requirement for any finishing materials for adobe walls is their vapor permeability.

Cladding inside

The best way is leveling with the same adobe, painting with lime with the addition of natural pigment. The easiest one is to apply the wallpaper after applying the diluted glue primer. The adobe house "treats" well any kind of plaster, even to gypsum compositions. However, the plasterboard finish is undesirable.

The nuances of building houses from adobe

Exposure to the destructive effects of moisture imposes a number of conditions, which must be observed during the construction of an adobe house.

Walls. Thickness of external walls made of heavy adobe should be at least 500 mm, internal - at least 300 mm. Along the perimeter of the openings in the walls, above the lintels and in the areas where the walls join (step 500 mm vertically), you need to lay reinforcement from reeds or brushwood. The masonry is carried out according to the technology usually used for the construction of walls from blocks, with seams about 10 mm thick.

It is required to lay no more than two brick rows per day (no more than 400 mm in height) so that the solution grasps and dries overnight - following this technique will speed up the drying of the walls and somewhat reduce their shrinkage, allow you to start plastering the walls immediately after construction. Masonry mortar is an adobe dough in which the ratio of clay to sand filler is one to one or four to three.

Wall decoration. Adobe walls without external finishing will quickly deteriorate, so it is extremely necessary to complete it. The plaster layer should be 50–100 mm, which will reliably protect the walls from bad weather and protect them from the penetration of rodents and insects. For plastering walls, acrylic, lime and silicate compounds are suitable - the plaster layer should be waterproof, but permeable to steam.

Cement plaster is not suitable because it practically does not adhere to unbaked clay. You can veneer the walls from the outside with a brick, board or other materials, while it is imperative to maintain an air gap of 50 mm between the adobe wall and the cladding, otherwise the adobe will get wet. The ligation between the outer cladding and the adobe wall is made with 150 mm nails. Interior wall decoration is performed with gypsum plaster, can be tiled using gypsum-based adhesives.

Jumpers. Window and door lintels are made of a board, the width of which is equal to the width of the wall, and the thickness is 50 mm.Jumper boards must be impregnated with waterproofing compounds or wrapped in tar paper.

Window and door frames. It is best if these frames are made of wood, which will reduce the risk of condensation accumulation. When installing boxes of windows and doors, a waterproofing layer is laid along the perimeter of the openings.

Roof. It is better to arrange a steep roof, at an angle of 35 or 40 ° - in this case, the expanding load on the walls will be lower. The minimum length of the overhang, capable of well protecting the walls from rain streams, is 700 mm. Lightweight materials are more suitable as a roof covering - metal or sheet roofing.

Floor. Finished with ceramic tiles on a soil base previously insulated with expanded clay or light adobe.

The growing interest in the construction of houses from adobe or from straw, established over the past decades in Europe and America, is explained not only by the fashion for ecological housing, but also by the constantly growing cost of buildings made of modern materials. Why get into debt bondage to banks and developers, if you can save money and build a full-fledged house from natural materials, literally lying under your feet?

The almost complete absence of building standards for such buildings is not connected at all with their low operational characteristics, but rather with the reluctance to develop these standards, with the traditions of erecting buildings of stone, brick and reinforced concrete, common for the XX-XIX centuries.

rmnt.ru

20.07.18

Completely dried blocks are pre-tested. To do this, take a brick and throw it from a height of human growth. In this case, the block made by yourself should not split.

Also, one of the bricks is specially broken in half and the cut is carefully examined. The material of the block, suitable for the construction of walls, must be absolutely uniform both in composition and in color.

Composition and characteristics of sawdust concrete

The material consists of the following components:

- astringent (cement);

- organic filler (sawdust);

- sand;

- lime or clay.

Specialized additives that improve the adhesion of the components (calcium chloride / nitrate, aluminum sulfate, water glass) can be used.

Physical, technical and operational characteristics of building blocks from sawdust and cement:

- density - 400-850 kg / m3;

- thermal conductivity - 0.07-0.19 W / m · ° С;

- sound absorption coefficient - 0.5-0.7;

- vapor permeability - 30-40%;

- mechanical strength - grade B0.5-3.5;

- frost resistance - 50 cycles;

- fire resistance - non-combustible material.

Dignity

The advantages of sawdust concrete blocks include:

- Strength. The blocks can be used to erect load-bearing walls of buildings up to three stories high.

- Environmental friendliness and safety - the material does not emit substances or microparticles harmful to health.

- Non-flammability. The blocks can withstand without ignition a two-hour exposure to flame and temperatures up to 1200 ° C.

- Water vapor permeability. Due to the porous structure, air exchange through the walls is ensured, and excess moisture is removed. This ensures a favorable microclimate in the house.

- Good noise insulation performance. Walls and partitions absorb sound waves for acoustic comfort.

- Frost resistance. Repeated freezing and thawing of sawdust concrete structures does not lead to their destruction.

- Ease of processing. Sawdust concrete is easily sawn and drilled, resistant to cracking and chips.

- Ease of installation. The blocks are quite bulky, and at the same time have a small mass.

- Durability. Provided they are effectively protected from moisture, block structures serve for decades.

- Affordable price. The use of production waste (sawdust) significantly reduces the cost of the material.

- Possibility of self-production. Using available organic raw materials, you can make blocks of sawdust and cement with your own hands.

We suggest that you familiarize yourself with How to insulate the ceiling of a bath: the better to make insulation and how to do it correctly

disadvantages

An important disadvantage of sawdust concrete is a fairly high moisture absorption. For this reason, it is required:

- before laying the outer walls, equip a plinth made of brick or concrete with a height of at least 0.5 meters from the level of the blind area;

- provide for the departure of the eaves beyond the wall plane at a distance of at least 0.5 meters and equip the roof with a drainage system.

As a protection against moisture, the external facade finish is also used. It is also necessary to give aesthetics to the building, since the geometry of the blocks is unimportant and you have to make thick seams when laying the walls.

The list of disadvantages also includes the duration of the production of blocks from sawdust and cement. At least 3 months should pass from the moment the molds are poured to the use of finished blocks in construction - during this time the material dries up and gains strength.

What are adobe bricks?

This material has several names at once. In Russia, the Turkic word "adobe" has taken root, meaning finely worn straw. The second name "adob" (or "adoba") comes from the Arabic "at-tub". They call it in another way: kalsh, lampach or lempach, dry forest. In construction, adobe is better known as raw brick.

Adobe composition

The main component of adobe is clay soil, which is diluted with water, then thoroughly mixed. Other essential components are fibrous materials - straw, flax fiber. They are cut into pieces having a length of 90 to 160 mm. Sand is added to the composition to reduce the fat content of the clay, because its excess inevitably leads to cracking of the material.

Previously, manure was used to make this building material. It was diluted with water in a 1: 1 ratio, then left to infuse for a day. Now the waste products of cattle are replaced with liquid glass, casein or almost irreplaceable PVA glue. Depending on the requirements for a future building, adobe can be added:

- fire retardants, antiseptics, plasticizers;

- gravel or crushed stone, earth, lime, cement;

- river pebbles or brick fight;

- plant fibers (reeds);

- dry needles (or algae);

- expanded clay, sawdust, perlite.

Fillers are used to increase the thermal insulation properties and tensile strength of adobe bricks, to reduce the specific gravity and prevent shrinkage of structures, to protect against deformation of the walls.

This building material differs from ordinary bricks in the way it is made: it is dried in the air, and not in ovens. One-story buildings are erected from adobe blocks, much less often - fences, however, as a building material for fences, they are used only in those regions where the climate is dry, since an excess of moisture adobe (or adobe) is contraindicated. Over time, the water will inevitably shatter the brick.

Varieties

In construction, 2 types of adobe mixtures are used - light and heavy. The type depends on the ratio of straw to clay.

- Light adobe. It is durable, dense, so it does not sag or burn. The material keeps its shape well, knows how to "breathe". This adobe contains only clay and straw (its - 70-90%), therefore this type of adobe is the most environmentally friendly and inexpensive. It is ideal for the construction of frame houses, in which it can be used as insulation. The disadvantage is the possibility of impurities entering during manufacture.

- Heavy adobe. In these bricks, in contrast to light "stones", there is more clay, often sand is added to the mixture. The proportion of these components can be 40% or more. For this reason, "heavyweight" is used for the construction of load-bearing structures. "Weightless" products are not suitable for this purpose. The heavy type of material will cost more, but its physical properties are much better.

Features of building material

At its core, adobe brick, or adobe, is a building block, the basis of which is a mixture of clay and straw, into which certain additives are introduced to give the desired properties. The main purpose of such a building material is the construction of walls of various outbuildings and fences, in southern regions with a dry climate, especially in rural areas, it is actively used in the construction of residential buildings.

Saman with a very low straw content has a specific gravity of about 1,850 kg / m³, but due to the addition of straw, its density is significantly reduced. Thus, the specific weight of the building material can be increased to 550-600 kg / m³, which ensures a lightweight structure, while the thermal insulation characteristics are at a fairly high level. It should be noted that for all the apparent fragility of the structure, adobe has good strength characteristics. In particular, its ultimate compressive strength, depending on its composition, is in the range of 15-55 kg / cm², which is commensurate with the indicators of cinder blocks.

Saman with a very low straw content has a specific gravity of about 1,850 kg / m³, but due to the addition of straw, its density is significantly reduced. Thus, the specific weight of the building material can be increased to 550-600 kg / m³, which ensures a lightweight structure, while the thermal insulation characteristics are at a fairly high level. It should be noted that for all the apparent fragility of the structure, adobe has good strength characteristics. In particular, its ultimate compressive strength, depending on its composition, is in the range of 15-55 kg / cm², which is commensurate with the indicators of cinder blocks.

The main advantages of adobe blocks include ease of manufacture, which is easily ensured with your own hands, low final cost, fairly high thermal and sound insulation characteristics, fire resistance (with a reduced straw content), environmental friendliness. At the same time, some disadvantages of the material can be noted, these are reduced moisture resistance and frost resistance, rather long drying of the walls and a slow set of strength. In addition, pests attracted by straw can settle inside the raw: rodents, fungi, insects.

Operation of the adobe house

The main advantage of adobe buildings, in addition to the low cost of construction, is, of course, a pleasant microclimate. When our house was not yet lined with brick, but simply plastered with whitewashed clay, in the heat, according to my feelings, it was cooler in it. But perhaps it just seemed to me. In any case, even after the walls are tiled with red bricks, there is never too much stuffiness in our adobe house.

In summer it is cool here, in winter, until the gas was connected, we simply lived with oil heaters (one standard for each room). And even for the relatively harsh climate of the Southern Urals, this was usually enough for us. In any case, it was rarely necessary to heat the stove. The audibility from the street in our house is also zero.

The only drawback of adobe buildings, in my opinion, is the relatively soft walls. To break a well-dried adobe brick that has gained strength, a chisel and a heavy hammer are required. However, for some reason, nails enter such walls almost like butter. And later they, of course, begin to blabber.

Characteristics of adobe

Saman is called a brick made of clay and straw with the addition of water, but exact proportions, as well as a complete set of components, do not exist - the composition of an artificial stone can differ significantly depending on what characteristics are required of it.

The main ingredient of any adobe was and is clay, preference is given to varieties with medium fat content. The viscosity of the mass can be different, therefore, if necessary, add a certain amount of water in order to make it easier to mix the composition. Traditionally, a filler was also used, which increased the strength of the dried clay, holding it together, and somewhat improved thermal conductivity.

Of course, the ingredients described above were all limited in the old days, but today, in the age of developed technologies, the composition of adobe can contain various additives that significantly improve certain qualities of such a brick:

- crushed stone, sand or expanded clay crumbs in half with clay allow the drying building material to avoid strong shrinkage, while maintaining the specified dimensions and shape;

- casein and bone glue, as well as archaic slurry or modern liquid glass can be used instead of water to give uncured adobe blocks any desired shape without spreading;

- lime and cement are known for their ability to quickly release moisture into the environment, therefore they are added to the recipe so that the bricks dry faster and are moisture resistant;

- fibrous cellulose, chopped straw, wood chips or the same manure allow adobe to be also relatively elastic, which increases the resistance of the material to temperature extremes and compression or stretching.

The exact date of the discovery of adobe is unknown, but scientists say that houses from it were built six thousand years ago. At that time, this was almost the only way out for the inhabitants of the steppe and desert zones, where even more traditional wood or natural stone were practically not found. As it happens in any era and in any state, building a house was also associated with huge costs, because the poor population had no choice but to come up with a way of building from what lies underfoot and no one really needs it. Ancient Egypt is considered the birthplace of the first adobe, and from there such material spread to many regions with the described climate conditions.

Modern adobe bricks can have different characteristics, which strongly depend on the components included in its composition and their proportions, but on average, you should get something like this:

- density comparable to ordinary brick - at the level of 1500-1900 kg per cubic meter;

- thermal conductivity depends, first of all, on the amount of straw used (the more there is, the better the walls retain heat), but in general adobe is twice as good as a simple brick in this indicator - 0.1-0.4 W / (m * deg);

- in terms of resistance to compression, adobe blocks are very reminiscent of a modern foam block - in both cases, this indicator ranges from 10-50 kg per square centimeter.

The exact characteristics of adobe and products made from it depend on the composition of the mixture and the percentage of light fillers in it:

- heavy adobe has a density of the order of 1500–1800 kg / m3, that is, it practically coincides with the density of building bricks;

- the thermal conductivity coefficient is two times lower than that of building bricks - about 0.1–0.4 W / m · ° С. The more straw is contained in heavy adobe and the higher its density, the lower its thermal conductivity;

- compressive strength is about 10-50 kg / cm2, this strength range is close to the characteristics of foam and aerated concrete.

Advantages of adobe construction:

- the cheapest construction material, since the raw materials for its production - clay and water - are found everywhere and in abundance;

- absolute environmental friendliness of adobe buildings;

- low heat transfer and high sound insulation of walls;

- fire resistance;

- the ability to absorb excess moisture in rooms.

Minuses:

- poor resistance to moisture, especially at low temperatures - external plastering or overlapping of walls with facing bricks is required;

- the impossibility of conducting construction work in winter conditions;

- buildings erected in a temperate climatic zone dry for a long time and gain strength;

- adobe walls create favorable conditions for rodents, insects and fungi to live in them.

A house made of adobe takes longer to build than houses made of traditional materials - it takes longer for the walls to set their strength characteristics. However, the final estimate of construction costs will be at least twice as low as for a building made of building bricks of a similar area.

How to do it yourself?

You can make adobe brick yourself and at the same time adjust the mechanical properties. Production requires alumina, chopped hay, water, and additional components.The clay ingredient is mixed with plant stems in a 3: 2 ratio, poured with water and additional ingredients are added depending on the required qualities. Sand and earth are added to increase compression resistance, and cow dung and straw are added to stretch. Sawdust and shavings are added to increase thermal insulation. If you put lime on, the product dries faster and becomes water resistant. To make this mixture suitable for housing construction, it is enough to give it the correct shape, size and dry naturally.

What can be made from clay

Clay can be used to make a clay block and brick in Minecraft.

A clay block can also be viewed as a way to save space. Only the reverse process (from block to clay) is impossible. The block, of course, can be placed and destroyed, but this is no longer a craft.

Clay block

To make a clay block you will need:

The second crafting recipe shows how to make a brick in Minecraft. To do this, you just need to burn the clay in the oven, using any suitable object as fuel.

The bricks obtained from crafting can then be used to make a flower pot and / or brick block.

How to paint clay in Minecraft

“Paint the clay” refers specifically to blocks. So, we have already made a clay block out of clay. Now it needs to be burned in the oven. The result is fired clay - block with ID 172.

Burnt clay

Then you need to use dyes according to the following schemes:

This method can be used to repaint the fired clay to transform into.

Clay is one of the building materials in Minecraft. You can get it from clay blocks that are generated at the bottom of reservoirs. Clay is most commonly found in the swamp biome. You can get it, like the earth, in any way. The quickest way to do this is with a shovel.

Breaking a block of clay drops 4 balls of clay. What is remarkable, even when using a shovel with the "Luck III" enchantment, more than 4 balls will not fall out of the clay block.

The nuances of working with adobe

All wooden elements of the house, such as beams, window and door ceilings, must be treated with anstiseptics.

All wooden elements of the house, such as beams, window and door ceilings, must be treated with anstiseptics.

Before starting the installation of an adobe house, you should understand how to build a house from adobe in such a way that the finished building will last as long as possible. There are a number of specific recommendations that have been formed over hundreds of years of using such technology.

So, the recommendations are as follows:

- It is better to make the foundation for an adobe house with a shallow strip with mandatory reinforcement when pouring. The width of the base should exceed the width of the adobe block by 20 cm. At the same time, having made the base, it must be waterproofed on all sides.

- To protect the walls of the adobe house from rodents, the lower part of the building (about 150 cm from the foundation) must be additionally reinforced with a reinforcing mesh and acrylic plaster applied to it. Such a mixture will be too tough for rodents. For the same purpose, you can use a special impregnation for the walls.

- All wooden elements of the house, such as beams, window and door ceilings, must be treated with anstiseptics.

- It is better to equip window sills with drainage systems, and it is advisable to place visors above the upper part of the windows, which will drain rainwater from the walls of the building.

- All wooden thresholds of the house must be waterproofed.

- Exterior and interior decoration of the finished house can only be carried out after the final shrinkage of the house.

- For greater strength of the house, in all places where the walls meet, in the window and door lintels, as well as in the lower parts of the openings, a kind of reinforcement should be laid in the form of reed stems or brushwood. The same can be done every three to four rows of block masonry.

- If work is suspended, then the adobe wall must be covered with a film in case of rain.

- It is better to check clay for construction with specialists for fat content.

- A do-it-yourself adobe house will be stronger if you assemble it from blocks, although a monolithic adobe wall using formwork can also be mounted.

- And most importantly, clay for construction needs to be prepared ahead of time. It is better if she lays the winter on the site under the influence of frost. In this case, she will gain fortresses. It is also worth preparing straw, which is harvested.

- Also, a foundation of monolithic concrete, rubble or rubble concrete is mounted in advance in order to start work in the spring.

Water resistance and thermal insulation characteristics

The material is able to withstand extended periods of rain and is not subject to weathering. For example, in the UK, which is characterized by a high rainfall, there is a huge number of adobe comfortable houses, many of which are more than 500 years old. And in the nine-story medieval houses, built with partial use of adobe, which can be found in Yemen, people have lived for almost 900 years. The special design and composition of the material are capable of providing sufficient seismic resistance.

Saman is distinguished by its great thermal insulation properties compared to brick, stone or concrete, therefore, such houses do not need increased heating in winter and providing coolness in summer. It is a refractory building material that is used to form chimneys and stoves, which is why it is optimal for houses in regions with a high fire hazard.

The adobe buildings are undoubtedly unique, as well as the fact that their operational characteristics and economic qualities deserve the attention of every person who is not indifferent to the ecological future of the Earth.

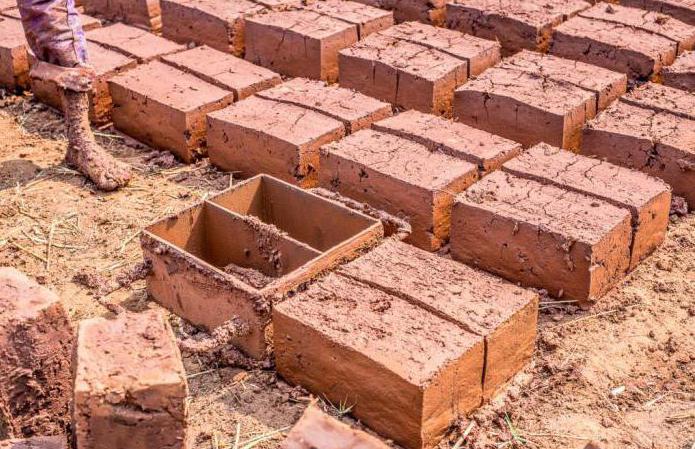

Making adobe blocks

The strength of the structure directly depends on the quality of the adobe. Low block density, their moisture content, irregular shape - all this complicates the installation process and reduces the reliability of the structure. It is necessary to make adobe in advance, because construction will require a lot of blocks, and it takes time to form and dry the material.

Making adobe blocks

To make adobe blocks you will need:

- straw;

- clay;

- water;

- large kneading container;

- boards;

- nails;

- hammer and hacksaw.

Step 1. Assembling the adobe mold

Form for adobe blocks

The form

A box without a bottom measuring 35x18x14 cm is knocked down from boards 2 cm thick. The shape can be made double, but it will be too difficult to lift it. Boards should be chosen as flat as possible, preferably with a smooth surface. There are no standard sizes for adobe, but these parameters are the most practical.

Harvesting adobe blocks

Step 2. Prepare drying areas

To properly dry adobe, you need to prepare 2 sites. To do this, on a flat piece of land, they lay out racks made of bricks or wooden beams, and shields from tightly knocked down boards are attached to them. A canopy is erected over the first site, while the second is left in the open air, but paved under a slight slope.

Step 3. Procurement of material

The most important component of adobe is clay. As a filler, not only straw is used, but also wood chips, dry grass, sand, gravel and cement. The clay should be clean, free of impurities, very plastic and strong. It is very simple to check whether the clay on the site is suitable for construction: dilute a little clay with water and roll a ball. If it does not crack or break when it dries when dropped from a height of 2 m, the clay can be used. It should be borne in mind that about 10 cubic meters of clay is consumed per 1000 blocks, so you need to prepare a sufficient amount of it in advance.

Making adobe blocks

Making adobe blocks

Making adobe blocks

It is better to take straw not fresh, but last year, with a length of 9 to 16 cm. A fine cut is unsuitable for these purposes.To increase the strength of the blocks and increase their water resistance, it is recommended to add lime to the composition. The standard ratio of clay to straw is 4: 6, but the proportions may vary depending on the type of adobe. In light, clay is 10% less, in heavy - 10-20% more than the norm.

Step 4. Forming and drying of blocks

You can prepare a solution for adobe right on the ground by clearing an area of 2x2 m and making a depression in the center. For a small amount of building material, a container in the form of a trough with low sides is suitable; you can also assemble a frame from boards with a thickness of 3 cm and more and sheathe it with galvanized sheets. In such a container, the solution will not mix with the soil, in case of rain it will not be difficult to cover everything with plastic wrap.

How to make an adobe block

The mixture is prepared as follows: pour clay, add water to it, mix well and leave for 12-20 hours. This will allow the clay to acquire maximum viscosity and plasticity. Then add straw or other filler and mix thoroughly. Usually, such a solution is kneaded with feet - it is quite difficult to do it manually. The finished mixture is left for a few more hours for uniform impregnation of all components.

Making an adobe block

To form adobe, take an even wide board, put a mold on it, moisten the surface abundantly with water and sprinkle it with sand and dry fine straw. They pick up the solution with their hands and tamp it into a mold, be sure to seal the corners. Excess material is cleaned off with a trowel or a piece of thin wire, and then pierce the block with a sharp stick in 3-5 places. This is necessary for the adobe to dry evenly.

The open area is sprinkled with straw, sawdust or sand and the workpiece is laid out on it. Here, the opinions of experienced builders are divided: some recommend leaving the block in the form for at least 3 days, others advise to immediately remove the form and dry it flat for 24 hours, and turning it upside down for 3-4 days. In any case, when drying, there must be free space between the blocks for air circulation. It is easy to check the adobe for readiness: if a block thrown from a height of 2 m does not break or soak in water in 2-4 hours, it can be used for construction.

Adobe house: pros and cons

Before considering an adobe house as a possible home, you need to "weigh" its merits and demerits. Without such an analysis, it is impossible to proceed to further reflections, since there are almost always pitfalls on the way to any goal.

Dignity

The following arguments can attract future home builders to adobe:

- the opportunity to get building material absolutely free;

- no unnecessary spending on attracting construction equipment;

- excellent thermal insulation and sound insulation;

- the relative ease of construction of the building;

- long service life of the structure;

- good vapor permeability;

- ideal microclimate;

- environmental friendliness of adobe;

- its light weight.

In this list, the possibility of saving is not in vain in the first place. If we consider all building materials, then adobe is the undisputed leader in this nomination, it simply has no worthy competitors. It is this quality that often becomes a decisive factor for builders who build a house on their own.

disadvantages

On the other side of the scale is:

- a long set of strength in regions with a temperate climate;

- the complete inability of the raw brick to resist moisture well;

- there is always a risk of fire in such a "straw" house;

- the tedious process of making adobe bricks with your own hands;

- dependence on weather: construction is possible only on warm, "dry" days;

- a living threat: these are ubiquitous rodents that may like a new "victim", insects, molds;

- the need to make higher ceilings: the adobe house is distinguished by a long and quite noticeable shrinkage, therefore, when designing, it is imperative to take this feature into account - add a few tens of centimeters to the "growth" of the building.

All the disadvantages concerning the weak points of the adobe material can be relatively easily crossed out by the high-quality protection of the walls of the future building. The chance to make an adobe house of any shape is another advantage, so for creative people it is a real find.

There are still contraindications for an eco-friendly adobe house.This material is not recommended to be used if:

- if the building is supposed to be built on a steep slope, where the soil is not reliable;

- when the site intended for the building is in the shade of large trees, which it is a pity to cut down;

- if an emergency occurs in the area from time to time - floods.

In other cases, there are no serious obstacles to construction.

How to deal with imperfection?

Insecurity and biological threat are the main disadvantages of such structures. Yes, adobe historical monuments have survived to this day, but to a greater extent this applies to those buildings that are located in ideal conditions - in a dry, hot climate.

In mid-latitudes, the owners will have to constantly monitor the condition of the walls, quickly eliminate each damage. Just one defect, left unattended, by the "efforts" of rain and frost in a few years will lead to the structure being in an emergency condition. To protect the walls as much as possible, the overhangs of the roof slopes are made large enough.

The influence of the biological factor is somewhat exaggerated, since it is quite simple to protect an adobe house from living enemies. Coloring with lime, to which copper sulfate is added, as a rule, successfully relieves the encroachments of rodents, insects, and mold. The lower part of the building is additionally protected with a reinforcing mesh, acrylic plaster is applied to it.

Conclusion

You can make bricks from adobe and dry them naturally in the sun, and then fold them under a ventilated canopy. If you use a brick made of clay and straw for the construction of buildings, then it will not be highly water resistant. However, this material is quite widespread in the southern regions, where there is a low amount of precipitation. Having built a building from this brick, you will get a comfortable temperature inside it, even in the summer heat. You can make such bricks yourself, excluding the use of additional mechanisms.

Toxicosis: causes, consequences, treatment The assumption that nausea worries a woman only in the morning is incorrect. It can last all day, but is most pronounced in the morning. It comes from.

Financial Lessons for Teens: What Should Teens Know Before Going to University? As students, adolescents face the brutal realities of adulthood. Now they are beginning to understand that it is impossible to spend all their income on.

These 10 little things a man always notices in a woman Do you think your man knows nothing about female psychology? This is not true. Not a single trifle will hide from the gaze of your partner who loves you. And here are 10 things.

Why are some babies born with the "kiss of an angel"? Angels, as we all know, are kind to people and their health. If your child has the so-called kiss of an angel, then you have nothing to do.

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s do not worry about the shape and length of their hairstyles. It seems that youth is created for experiments on appearance and daring curls. However, already the last.

Charlie Gard died a week before his first birthday Charlie Gard, the terminally ill baby that the whole world is talking about, died on July 28, a week before his first birthday.