Movable threaded eye with ball bearing for lifting in all directions

• Steel grade - 8 • The hinge pivots in the direction of the load • Surface treatment - painting • Safety factor 4: 1 • EU mark • On request hinges with extended thread • Not subject to heat treatment

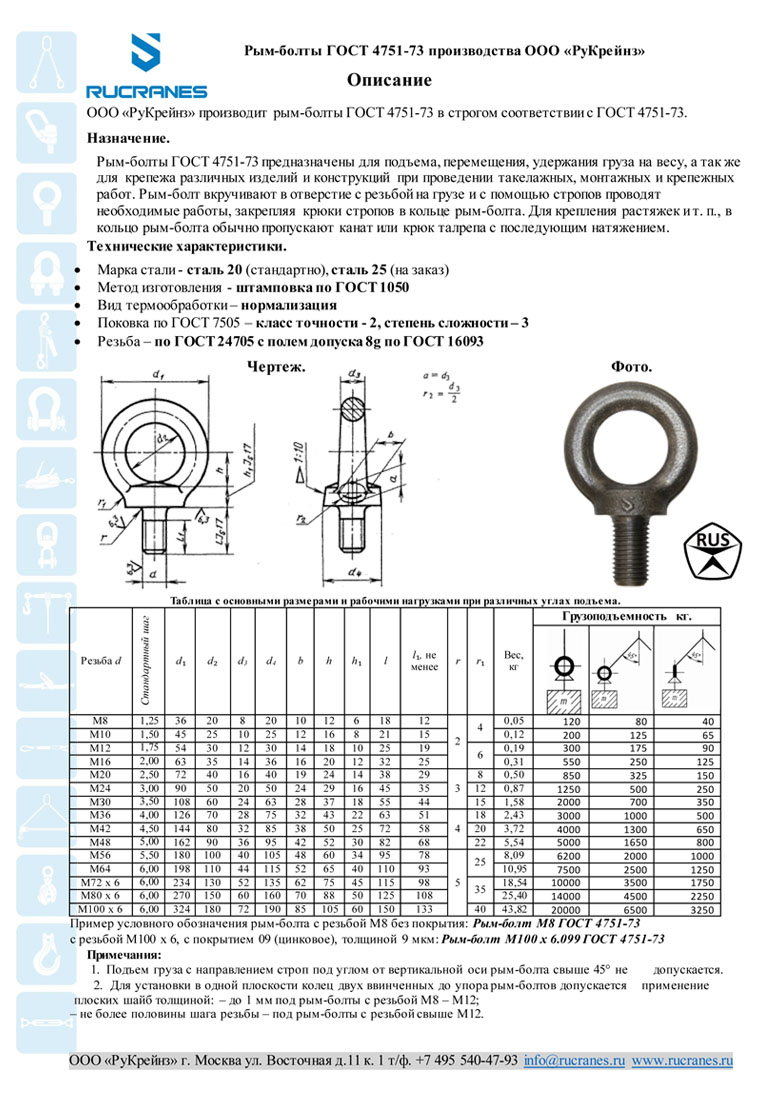

| Thread diameter, d | Working load along the bolt axis, tn | Working load at side lifting, tn | b, mm | e, mm | g, mm | t, mm | Lifting loop size, mm | Weight, kg | Designation |

| M10 | 0,60 | 0,3 | 36 | 18 | 51 | 41 | 14x55x30 | 0,4 | NS8KL1003 |

| M12 | 1,00 | 0,5 | 36 | 18 | 51 | 41 | 14x55x30 | 0,4 | NS8KL1205 |

| M16 | 2,00 | 1,1 | 36 | 40 | 52 | 42 | 14x55x30 | 0,5 | NS8KL161 |

| M20 | 4,00 | 2,0 | 50 | 49 | 68 | 56 | 16x70x34 | 1,0 | NS8KL202 |

| M24 | 6,30 | 3,2 | 57 | 40 | 78 | 65,5 | 18x85x37 | 1,5 | NS8KL2432 |

| M30 | 10,6 | 5,3 | 66 | 35 | 97 | 80,5 | 20x85x37 | 2,2 | NS8KL3053 |

| M30 | 11,8 | 8,0 | 80 | 35 | 112 | 92 | 22x115x50 | 3,6 | NS8KL308 |

| M36 | 11,8 | 10,0 | 80 | 90 | 109 | 89,5 | 22x115x50 | 4,2 | NS8KL368 |

| M42 | 15,0 | 10,0 | 80 | 50 | 109 | 89,5 | 25x115x50 | 3,7 | NS8KL4210 |

| M45 | 15,0 | 10,0 | 80 | 60 | 109 | 89,5 | 25x115x50 | 4,2 | NS8KL4510 |

| M48 | 15,0 | 10,0 | 80 | 50 | 109 | 89,5 | 25x115x50 | 4,0 | NS8KL4810 |

| M56 | 25,0 | 15,0 | 117 | 84 | 310 | 280 | 32x152x70 | 11,6 | NS8KL5615 |

| M64 | 25,0 | 15,0 | 117 | 95 | 310 | 280 | 32x152x70 | 12,6 | NS8KL6415 |

| M72 | 35,0 | 25,0 | 160 | 108 | 211 | 165 | 40x173x68 | 29,0 | NS8KL72 |

| M80 | 35,0 | 30,0 | 170 | 120 | 211 | 165 | 40x173x68 | 29,0 | NS8KL80 |

| M90 | 35,0 | 35,0 | 170 | 135 | 211 | 165 | 40x173x68 | 29,0 | NS8KL90 |

Appointment

The eye-nut is intended for lifting various overall structures, holding objects in weight, moving structures, for cargo transportation or rigging.

And also this hardware has a fairly wide scope. They are used:

- in construction (most often they play a special role in the performance of high-rise work);

- in shipbuilding;

- in the production of vehicles (for example, with the help of such fasteners, you can tow an idle car);

- in industry;

- at home;

- in agriculture.

During operation, the fasteners are screwed onto the threaded rod of the stud or screw, the size of which must match the size of the nut sleeve.

What it is?

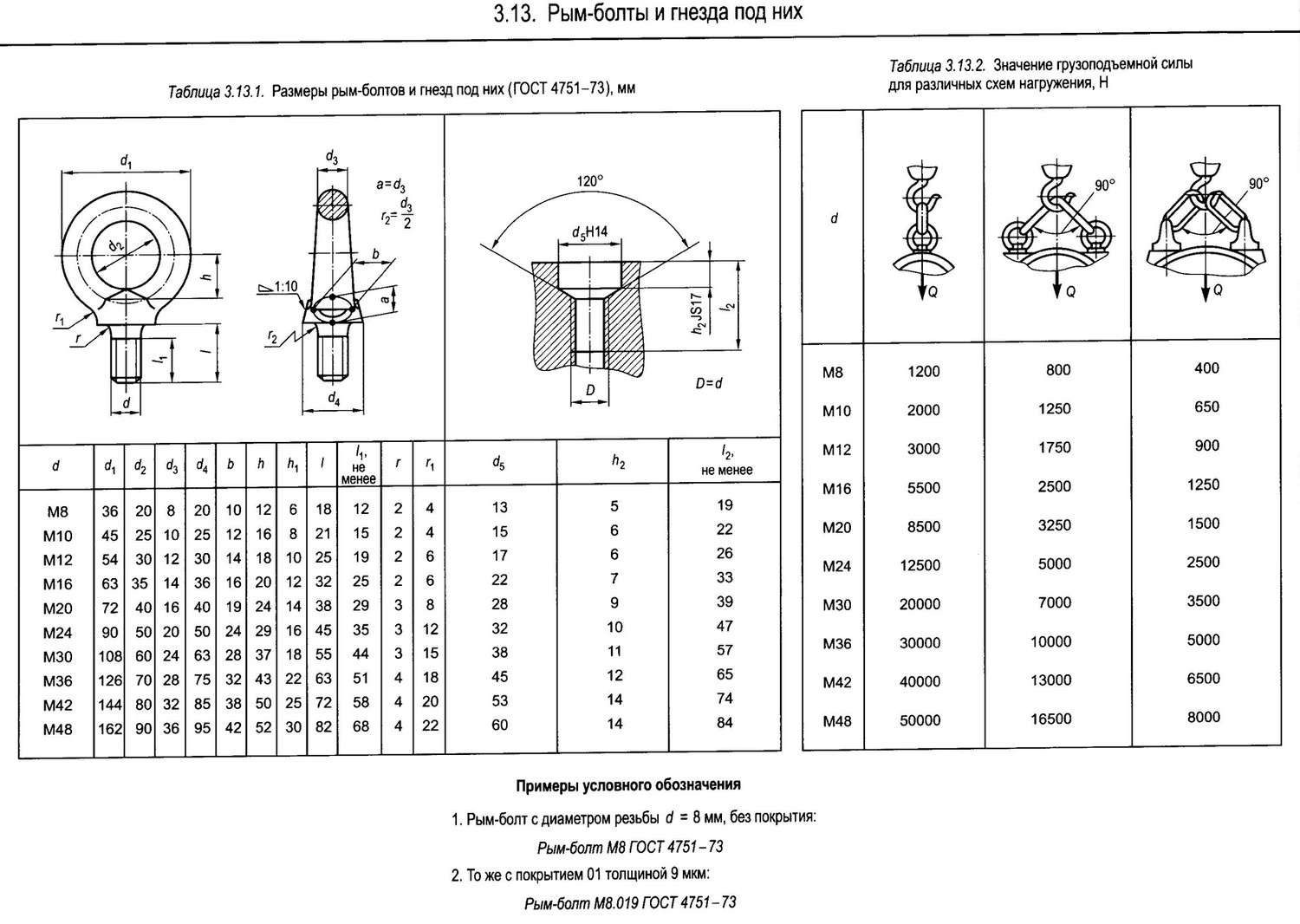

On Russian territory There are no GOST standards for the eye nut, it is produced according to DIN582. This is the world standard.

A traditional nut is a female threaded fastener. The connection is made in combination with screw bolts or studs. The prefix "eye" is translated as "ring". That is, an eye nut is a ring connected to a nut. Its main feature is the thread located at an angle of 90 degrees relative to its ring. Threads can be metric or imperial.

Here are the main advantages of such fasteners.

- There is no need for a wrench to tighten the hardware. This can be done using any lever inserted into the ring.

- The technological characteristics according to the international standard are very high - the steel nut can withstand heavy loads. And also the products have an increased carrying capacity - up to 21,600 kilograms.

- Resistant to rusting in high humidity conditions.

- Low price.

The unusual shape of the hardware allows you to screw the eye nut very tightly, unlike the usual one, where it is necessary to use a wrench.

Operating tips

It is necessary to start the installation of the eyebolt with the preparation of the hole. The process is carried out using a drill, then the installation of fasteners is already taking place. Accordingly, for a secure installation, the drill must be identical to the diameter of the bolt.

Installation specifications:

- fasteners must be tightly tightened;

- the screw rod must be screwed at least 90% into the surface - this parameter can be adjusted using a special washer or gasket;

- only one rope, chain, rope and more can be connected to one bolt;

- before installation, all interacting elements (bolt and hole) must be cleaned of dust and dirt;

- when installing fasteners, you need to ensure that the screw part correctly fits into the prepared hole;

- the axis of the hardware must be at right angles to the axis of the hole.

Consider separately the installation conditions for the anchor eyebolt.

- The length of the fastener is selected according to the thickness of the surface. The anchor is screwed into the concrete by at least 5 centimeters.

- The place where the fasteners will be installed must be selected correctly the first time. Dismantling and reinstallation is very difficult.

- The mounting hole must be compatible with the bolt diameter. To screw in the hardware, an effort must be made.

- As with conventional eyebolts, the anchor hole is cleaned of dirt before installation.

- The spacer type is driven in with a hammer.

In the next video, you can take a look at the production of eye bolts according to GOST 4751 73.

Classification

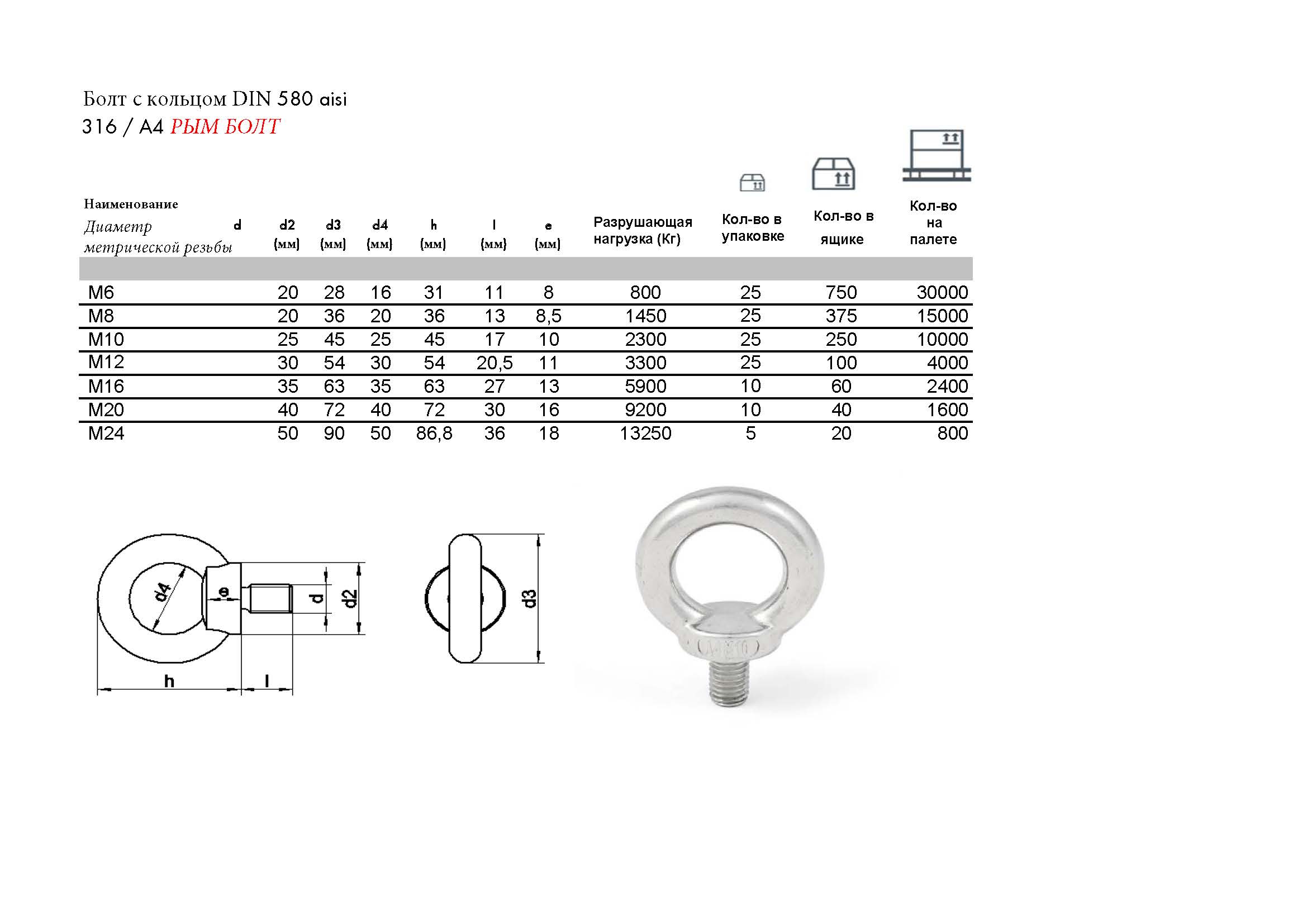

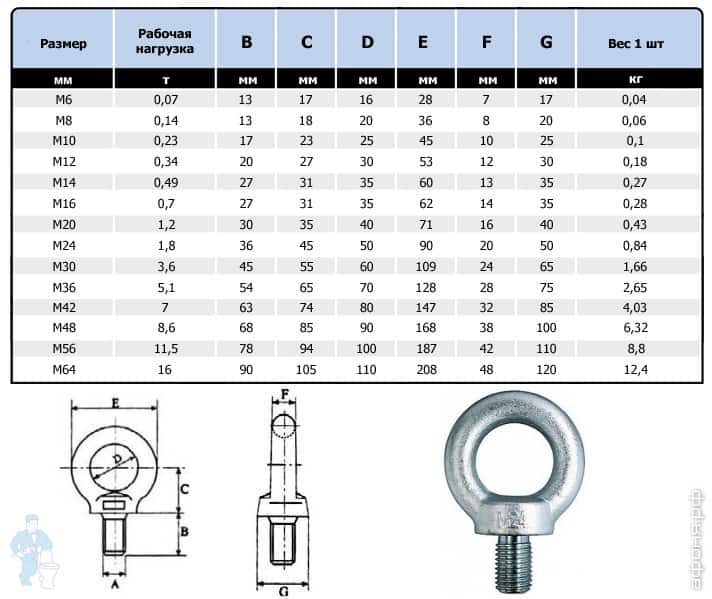

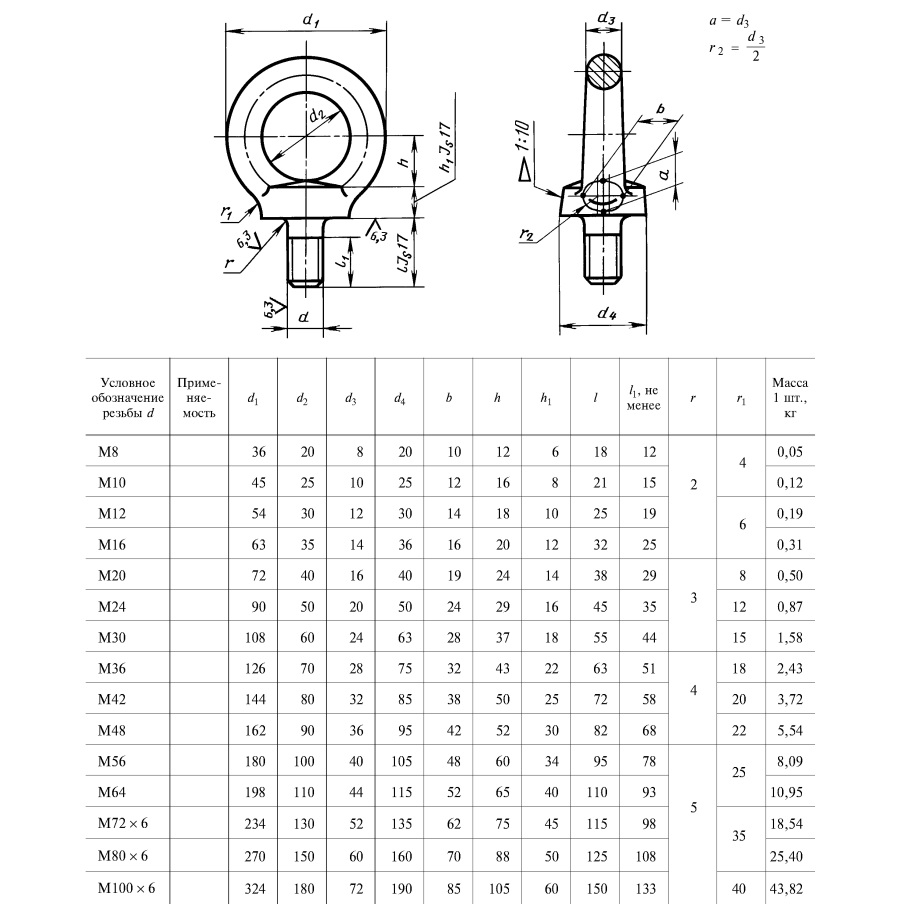

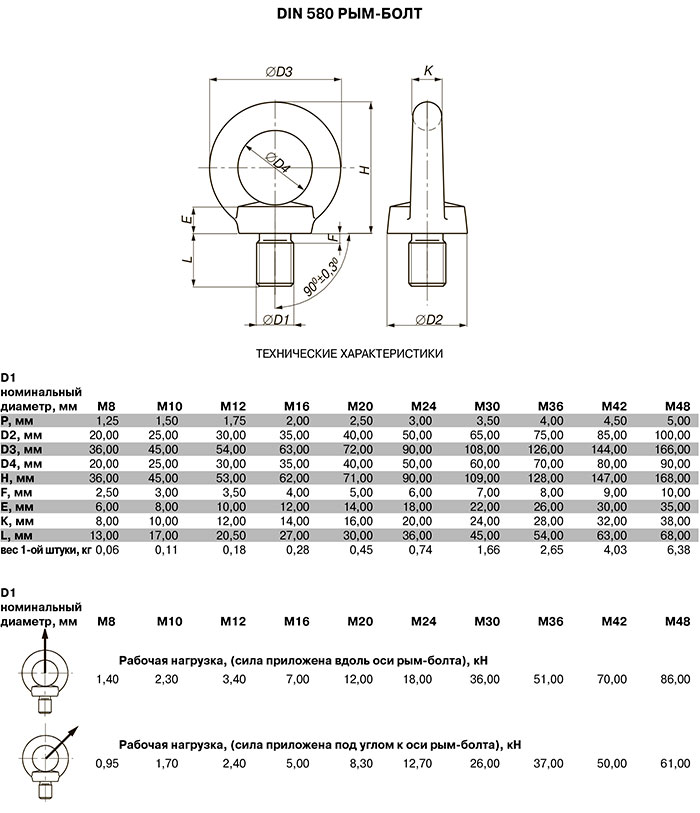

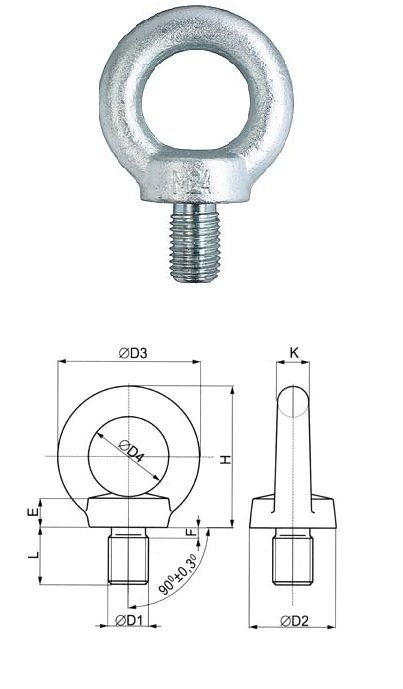

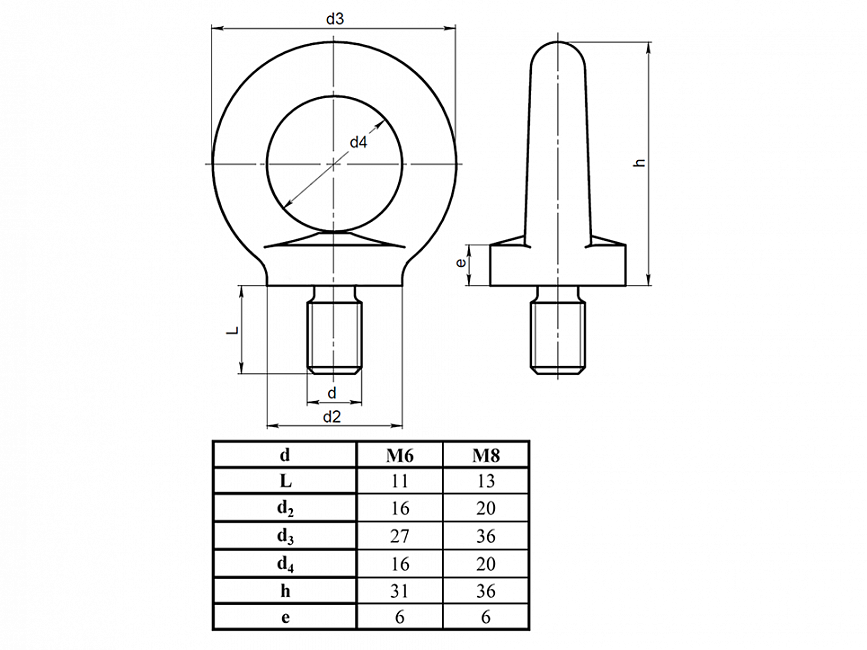

The dimensions of the nuts are also set according to DIN582 standards.

The side of the ring of the eye nut is marked with information on dimensions, material and manufacturer.

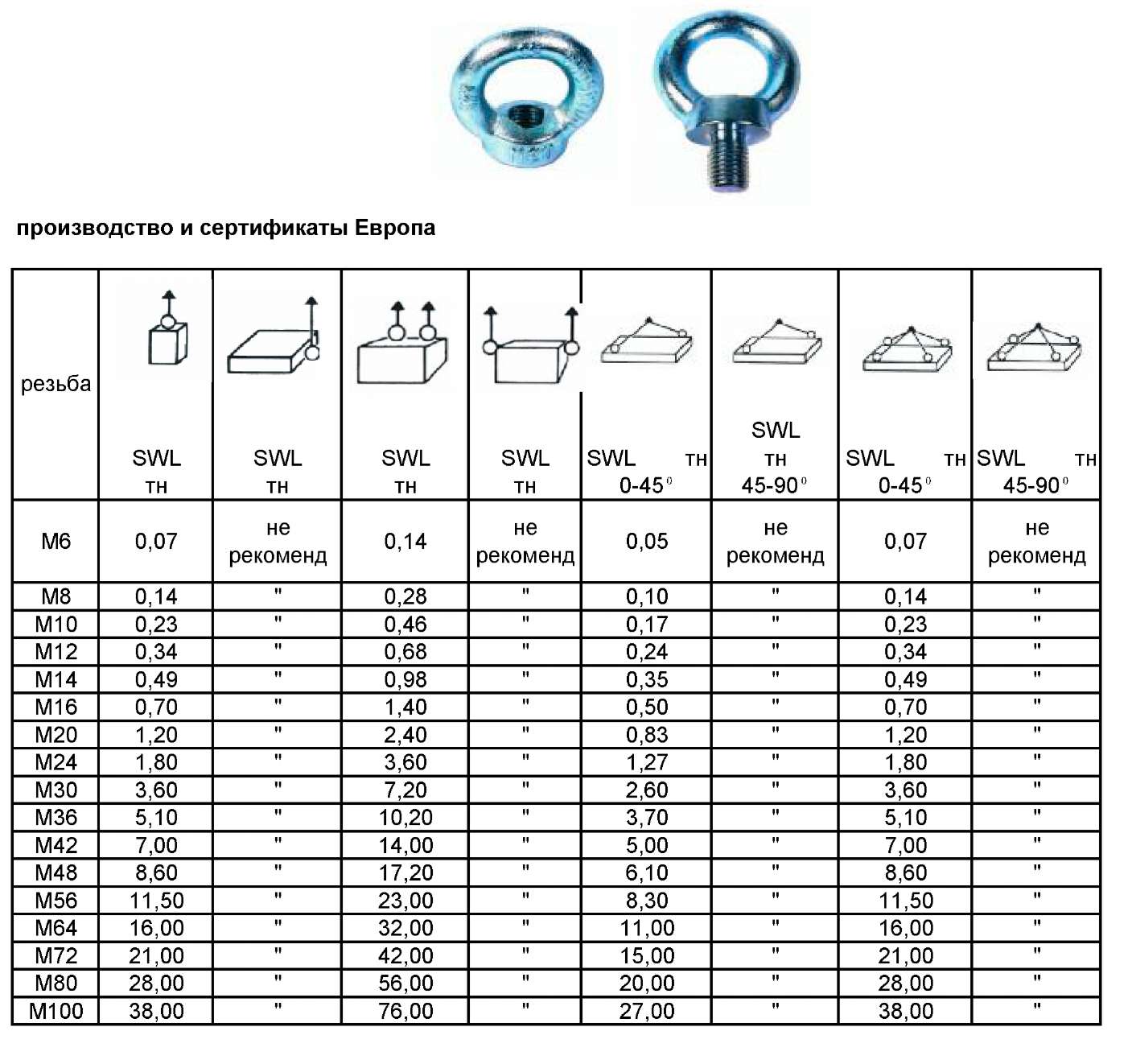

The size of the threaded surface varies and can be M6, M8, M10, M12, M16, M18, M20, M24, M26, M30, M36, from M42 to M48. They also produce hardware of non-standard sizes, for example, M4, M5, M7, M22, M27, M33, M39, M39x2, M100. According to DIN, such parameters are not recommended to be manufactured, and they can only be purchased on order. The most common are hardware with sizes M8-M16.

And also nuts are classified:

- by the type of the ring - round, oval or in the form of a rounded rectangle;

- by the size of the sleeve - low or high (elongated);

- by load - non-power and power;

- by thread type - with a fine metric thread, that is, when the size is indicated in millimeters, or with an inch thread, respectively, here the size will be in inches.

The inch dimension first began to gain popularity in the United States and Great Britain, while the metric system was common in Europe and Asia. Accordingly, there was a problem with the compatibility of various kinds of fasteners. In the future, Great Britain adopted the metric measurement, abandoning the inch.

In appearance, it is impossible to distinguish the American thread measurement system from the metric one, since their profile angle is identical - 60 degrees. It is possible to distinguish by marking: in the metric system, the strength class is indicated by numbers, in the inch system - by lines. Fasteners with different types of threads will never be interchangeable, since a gap or gap is formed in the structure during make-up. The only difficulty that arises during the installation of the eye nut is the correct connection of the two elements.

By the type of the eye-nut head, it can be of three modifications:

- A - head in the form of a loop;

- B - power option, enlarged head;

- D - reduced head.

By the size of the diameter of the ring, or by its thickness

Some fasteners have a pivot hinge that will pivot in the direction of the load, and a weld-on hinge on ball bearings - here it will rotate 360 degrees in all directions. They are made of stainless steel, later covered with paint.

Important! According to the international standard, for eye nuts, not the ultimate, but the breaking load is established, that is, when irreversible changes begin to occur with the part. These are two different definitions, so when selected, the load capacity is reduced by 60%

When choosing an eye nut, you need to take into account the area in which it will be used, and for how long, how much weight the cargo will have, what safety rules are provided.

It is advisable to purchase a nut together with a screw or stud in order to check the size and pitch of the thread - correctly selected fasteners will make the structure or mechanism reliable and durable. Their strength should also be identical, but higher strength of the nut is allowed, but not vice versa. If the stud is stronger during tightening, the threads of the eye nut may break. It is worth remembering that damage to the rod is easy to identify, since the rupture occurs abruptly and is difficult to miss. And with the nut, the opposite is true - the stripped thread is almost impossible to see.

This fastener is very popular and widespread in many areas, therefore, when choosing and operating, you need to remember a few rules:

- no deformations on the nut itself and defects on the ring are allowed;

- the used fasteners must be solid, the welding of various damages is unacceptable;

- the parameters of the size of the threaded part depend on the weight of the structure to be lifted;

- the surface of the hardware must be cleaned of dirt, shavings, scale;

- lifting the load, its movement should occur evenly and without sudden movements;

- after unscrewing the nut, its appearance should remain unchanged, that is, there should be no cracks, breaks, bent parts and other deformations;

- the angle between the fastener sleeve and the sling should not exceed 45 degrees;

- the axis of the sling should be located in the plane of the ring;

- the temperature regime for nuts is very wide - operation is possible both at -20 and +200 degrees Celsius;

- the choice of the manufacturer also plays an important role.

You can find out what an eye bolt and an eye nut are from the video below.

Features of production

For the manufacture of eye bolts, two technologies are used - casting (forging) and stamping. Steel is used either carbon or alloyed. These are high-strength types of metal, the differences of which are in the direction of application, that is, some eye bolts can be used for any purpose, others - for conditions of high humidity. Low-carbon steel products undergo a mandatory galvanizing process, thanks to which they do not corrode. Alloy steel hardware is no less durable, but their surface can rust over time. In total, there are several methods of galvanizing.

- Galvanic. Fasteners are placed in the container where the dissolved zinc salts are located. Then electricity is passed through - thanks to this action, the zinc particles remain on the bolts.

- Hot. Products are placed in zinc heated to a temperature of 465 ° C. This method is used most often as it is more economical and reliable. Hot-dip galvanizing increases the anti-corrosion resistance of the bolts.

- Diffuse. Parts are processed with zinc powder at a temperature of 290-450 ° C or with zinc vapor at 800-900 ° C. This method can be compared to a hot one, the only drawback is that the appearance of the finished product "suffers".

- Cold. A special solution containing zinc powder is applied to the finished parts. Here, the rust resistance is higher than with electroplating, but lower than with hot-dip galvanized.

Manufacturing by casting is complex, but fasteners are more accurate and stronger. The eye bolts made in this way can differ in size (several millimeters), but this difference is allowed by GOST standards. The stamping method is simple - here the work takes place on specialized machines. The heated metal is poured into molds.

For some fasteners, there is an additional item - this is the heat treatment process. Burrs may appear on the bolt ring during production using this method. This is acceptable because they can be easily removed without causing damage to the fasteners themselves.

What are they?

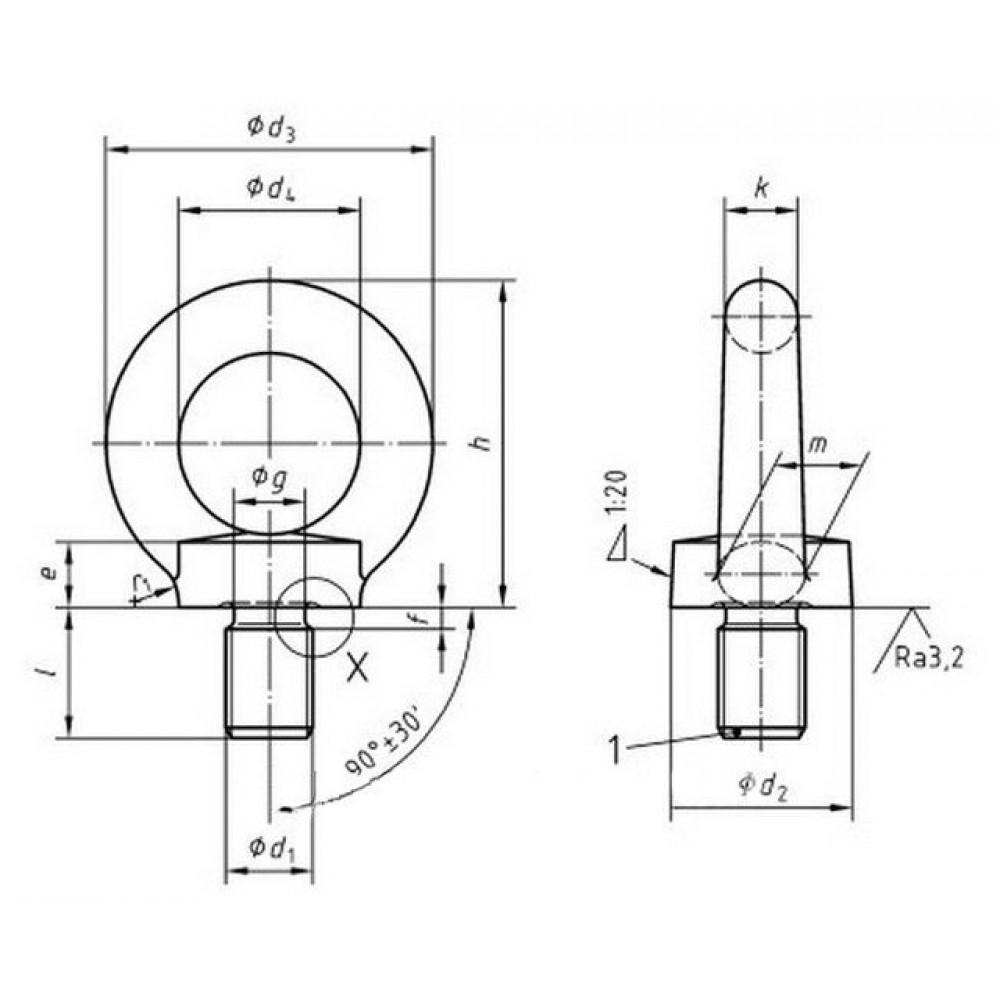

An eye bolt or a bolt with a ring - this is what fasteners are called in plain language. There are 2 options for the design of the eyebolt:

- the ring is attached to the rod strictly perpendicularly;

- the ring is installed in a special groove, it can rotate in different directions.

In addition to hardware made according to standards, there are other types.

Elongated. Has a long threaded rod.

-

Anchor. Used when working with concrete structures or natural stone. The product is distinguished by the presence of a nut, a washer and a spacer. It is convenient to install fasteners with an anchor on problem substrates. There are 4 types of anchor bolts.

- Wedge - looks like a sleeve, inside which there are rings.

- Hammered - a special type of bolt, its edges are made of soft metal, which deform when hammered. Thus, anchoring in the surface is carried out.

- Expandable fasteners are the most popular and versatile fasteners. It is made in the form of a rod with slots, thanks to which the walls seem to "open up" when screwed in.

- Spacer - This bolt is also very popular. Most often used in the construction industry. It looks like a cone, the rod of which expands after screwing in. Applicable only for concrete and brick.

According to the type of material, fasteners are galvanized and alloyed or stainless. What the carrying capacity will be depends on the degree of fastening - axial, at an angle of 45 °, if the bolt is installed on the side.According to GOST and DIN standards, the width of the shoulder, that is, the protrusion of the screw part, varies from 17 to 120 millimeters. Each eyebolt has its own specifications. Fasteners differ in the size of the thread diameter and the diameter of the shoulder, in the pitch of the screw thread, in the load from the diameter, in the inner and outer dimensions of the ring and its thickness, in the length of the threaded part, in the permissible tensile load at an angle of 45 ° and relative to its axis.

Designated as M4, M5, M6, M8, M10, M12, M14, M16, M20, M24, M30, M36, M42, M48, M56, M64, M72, M80 and M100. For all these characteristics, the carrying capacity can vary from 80 kilograms to 40 tons.

What are they made of?

According to the international standard, eye nuts must be made of durable materials:

- carbon steel grades C1030 and C1045;

- stainless or high-alloy steel grades 304 (A2) and 316 (A4);

- if these are non-ferrous alloys or metals, brass, silicon bronze, titanium and aluminum are suitable.

Fasteners, which are made from steels of standard grades, must be covered with an anti-corrosion coating. This can be hot-dip galvanized, anodizing for aluminum hardware, or bluing, also known as blackening or oxidation.

What kind of performance the fastener will have depends on how it was manufactured - it can be casting / forging or stamping. The hot stamping method is more popular: a mold is installed in the press, in which the workpiece is already located. The material is "squeezed" under high pressure. To improve technical characteristics and increase the service life, the part is coated with a layer of zinc or tin. After the nut is ready, it is cleaned of dirt and scale. The forging method is not as popular as it is too expensive and time consuming.