How does anaerobic sealant differ from the rest

Due to its liquid form, the anaerobic thread sealant can penetrate into all crevices, it adheres firmly to the surface and locks the connection without the use of a special key. It is very easy to use, even a beginner can cope with this task. Therefore, whether an expert or a novice, everyone can work with this sealant.

The rest of the gaskets, which include silicone and other polymers, are becoming obsolete. They are of inferior quality and fall short of the level of anaerobic thread sealants. Everything is fixed so firmly and reliably that you can independently disconnect the connection only with strong heat and using a key.

The life of anaerobic thread sealant is quite long. In moderate conditions, it is able to perform its functions for 5 years. But in an extreme environment, the service life is at least 1 year. Due to its wide viscosity range, the sealant can be used for gaps with a thickness of 0.07 to 0.5 mm. Let's take a closer look at the advantages that a thread sealant has.

Pros of sealant:

- The expense is quite economical.

- Excellent temperatures at which sealing can be performed. Some of them can be used at -196 to 150 degrees Celsius, and others at -60 to 300 degrees.

- After hardening, the anaerobic sealant becomes resistant to mechanical stress.

- The operating temperature range is also wide.

- It is also pleasing that the product does not react in any way to an aggressive environment and vibration of pipes. They do not affect the strength of the bond.

- It does not dissolve in water.

- Since thread sealants are used for metal and plastic, it is possible to connect products of different structure.

- Pressure greater than 50 atmospheres does not affect the integrity of the connection.

- Anaerobic sealant is fairly easy to use. It is practical and of high quality.

- The cost is also quite affordable. If we talk about the ratio of price and quality, then everything is just fine here.

All this made the products very popular and widely used. Let the FUM tape be cheaper, but it does not guarantee that the quality of the connection of water pipes that the sealant has

And this is very important. However, thread sealants have some disadvantages:

- use them for pipes with a diameter of M80 or more is not recommended;

- application is possible when the surface is absolutely dry;

- if you work at low temperatures, the solution cures longer.

These are not too critical remarks. But, users note another feature of thread sealants - their cost

But, if we take into account the advantages, economical consumption and the quality of the finished connection, then no one will pay attention to the price. Everyone knows that quality comes at a price

Colors

Thread sealants are available in a wide range of colors. There are no general concepts of what this or that shade means. It all depends on the manufacturer. In this regard, it makes sense to consider the color of the sealant in relation to the company that produced it.

Along the way, the manufacturers themselves will be considered.

Green. The most popular is the green fixing gel for threads from the Russian manufacturer SantechMaster. It provides the weakest fixation, and therefore it is possible to untwist the joint using an ordinary key.

The green sealant has a limited spectrum of action. It is only suitable for processing pipes less than an inch and a half in diameter.

The average cost of this product is 410 rubles per 60 g tube.

Most of all, this option is suitable for pipes made of ferrous metal, for example, cast iron. The temperature at which the sealant does not lose its properties is from -60 to +150 degrees. You can work with it at temperatures from +5 degrees.

As in the previous case, the average cost is 410 rubles for a 60 g tube.

You can use a sealant if the temperature exceeds 15 degrees. Otherwise, there is no guarantee that the subsequent work of the retainer will be as effective as possible.

The price for a 60 g tube is 410 rubles.

The maximum pipe diameter that can be processed is 3 inches, and joints can be made from pipes of the same material or from different materials. Optimum tightness is achieved at a humidity of no more than 40%, while the temperature of the air or surface does not affect the polymerization.

The average price for a 100 ml tube is 685 rubles.

- Orange. This is the color of Scotch-Weld Anaerobic Gel Sealant. It is mainly used in the automotive industry, as it tightly glues parts together. In order to further destroy the joint, you need to use strong heating, otherwise the pipe will have to be broken.

- Yellow. QuickSpacer Anaerobic Adhesive Sealant is only suitable for sealing metal pipes or fittings. The already low rate of its polymerization increases if this option is used with iron alloys.

You can work with this sealant at temperatures from +10 to +40 degrees. In addition to the sealant itself, it will be necessary to purchase an activator spray from the same company, otherwise the fixer will not "grab".

The average price is 420 rubles for a tube of 50 grams.

Selection criteria and rules for applying the composition

For the correct choice of sanitary silicone sealant, you should pay attention to some features that will help distinguish a quality product from an unusable one. These include:

These include:

Shelf life. It is far from uncommon that the store sells building materials that have expired, and most often they are sold at a discount.

Regardless of the cost, it is not worth buying them, since the compositions completely lose their properties and will not give the desired result.

It is important that the packaging is securely closed, because if there is even the slightest crack, the sealant will simply dry out when oxygen is available, and the purchase will go to the trash.

The composition should be read to examine the suitability of the material for a particular purpose. For plumbing equipment, only a special composition is used, since others, upon contact with water and moisture, will not only turn black, but will also cause the formation of a fungus.

Brand name

It is much better to choose those plumbing sealants that are made by a well-known manufacturer, are in demand and have extremely positive reviews.

For a purchase, it is worth choosing specialized construction stores that can provide a certificate confirming the quality of products and compliance with the GOST standard.

A high-quality seam and connection can be made only when:

- Quality sealant;

- Correct application;

- Competently selected composition depending on the purpose.

The most suitable form is considered to be a cartridge that is inserted into the gun, since you can adjust the amount of the applied composition and cut off the supply if not needed. For those who prefer standard packaging, a regular tube is perfect.

Materials for sealing threaded connections

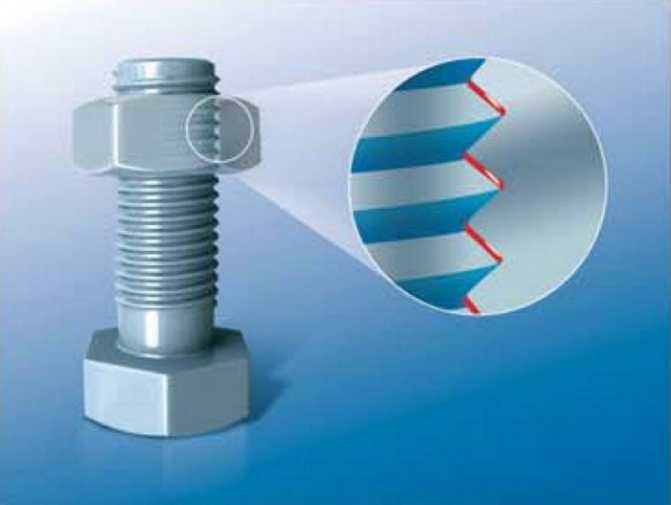

Threaded connections

Fig. 1 Metric thread.

Threaded connection - detachable connection of machine parts. The parts are connected to each other using a helical or spiral surface.This connection is one of the most common because of its reliability, versatility and many other advantages.

The most common thread for general industrial use today is the ISO thread, which has two versions that coincide in all sizes: Metric, the most common in Europe and Russia, and the Unified National, common in the United States. This thread is used in all industries (except for the oil and gas industry).

BSW inch thread is used for fittings and connections of gas, water and sewerage fittings. In Russia, cylindrical inch GOST 6357-81 is widely used for these purposes. This thread is recommended to be replaced by an ISO thread.

American National NPT Pipe Threads used for fittings and connections comply with GOST 6111-52 per inch tapered, as well as British Standard BSPT Tapered Pipe Threads meet GOST 6211-81 for tapered pipe threads.

Seals for threaded connections.

Unfortunately, not one of the threaded connections has absolute tightness, this is especially true for gas and high-pressure pipelines. To solve the problems of sealing threaded connections, various seals are used.

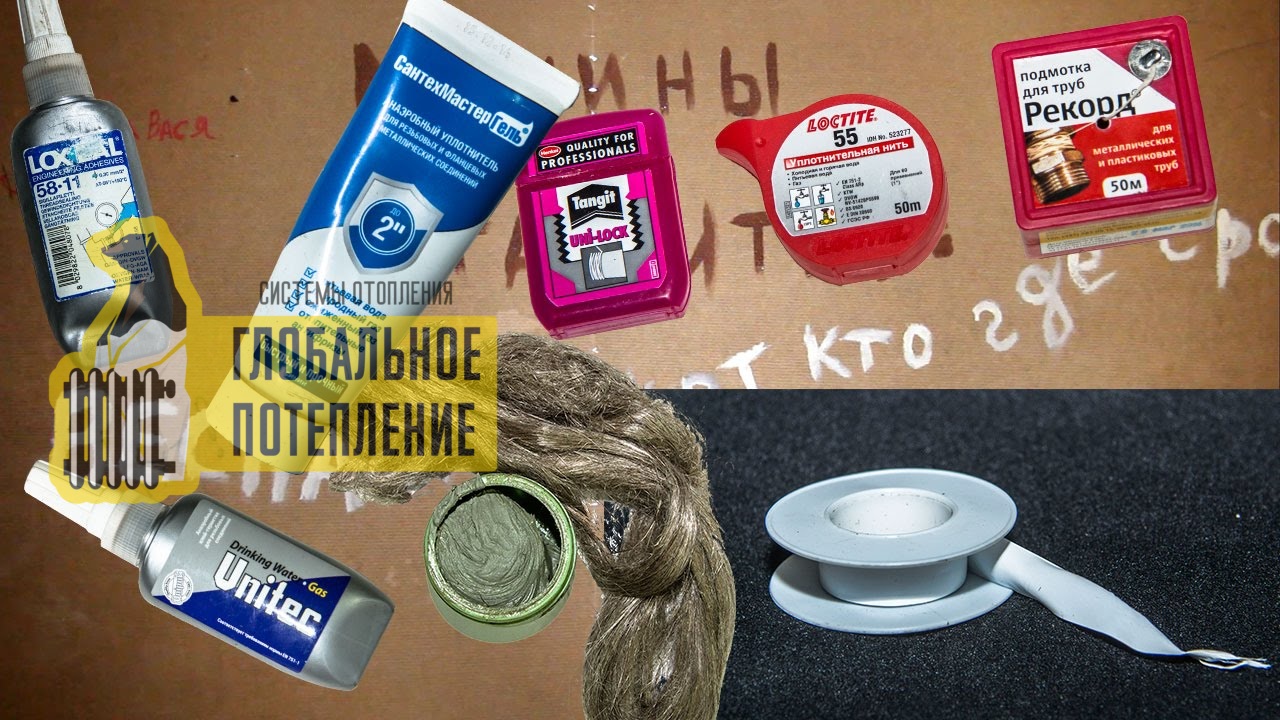

1. Linen strand.

Linen strand with red lead on drying oil is still a very common method of sealing threaded connections. Practically on this method, the entire installation of water pipes, heating systems and gas pipelines is based, since this is indicated in the SNiP for plumbing systems and for gas supply. There are other methods of using the flax span, for example, in combination with various sealants and pastes, the main task of which is to prevent corrosion processes in the threaded joint and to extend the life of the seal. Iron red is often used, which, unlike red lead, does not protect the thread surface of steel fittings from corrosion. It is also known to replace this type of seal with a "dry strand", that is, without any paint, which causes significant corrosion of the thread, especially when used on heating and water supply systems.

The disadvantages of using this method of sealing are obvious - the complexity and the need for careful adherence to technology, large tightening efforts of fittings during assembly, low manufacturability. At high temperatures, for example when sealing heating systems, thermal destruction of flax fibers is possible. Also, in some cases, the disadvantage may be the difficult dismantling of the connection.

However, the linen strand is still used mainly due to its low cost and availability.

2. Sealants.

Tightness is achieved by filling the turn-to-turn space of the threaded connection with a special substance selected in accordance with the operating conditions of the system. In general, today, sealants are the optimal sealing method, combining ease of installation, corrosion protection and efficiency. Can be divided into three main classes: non-curing sealants, curing sealants, and anaerobic sealants.

2.1. Non-hardening sealants.

They are viscous pastes based on synthetic resins and polymers with fillers. They effectively protect metal surfaces from corrosion, and work well not only in threaded connections. Suitable for vibration applications. Can be used in combination with various cushioning materials. The obvious advantage is the ease of assembly and disassembly of the connection. The use of non-hardening sealants is not recommended for joints with high pressure, differential pressure and temperature. Not suitable for use in aggressive and explosive environments.

Gas pipe connection

Small welded steel pipes are usually used for gas pipeline systems with a cross section of 1 / 2-2. Threaded steel pipes without a seam are used in gas pipelines, the cross-section of which is much larger than the 1 / 2-2 connection mark for gas pipes.

The optimal choice for the part of the pipeline located underground is bituminized seamless steel pipes. They have the most suitable threaded connection and jute casing. Bituminous and bell-shaped steel casings are regularly used. Often, gas supply systems use the same principle of connection to each other as in water supply systems. This method is called a fitting. It consists in the fact that the sockets are sealed like sewer pipes, and the welded ones are fastened together.

The sealant is usually a material made of hemp fibers, pre-impregnated with linseed oil or linseed oil. Do not use seals, which can cause difficulties during subsequent dismantling, clogging or obstructing connections.

Gas pipeline shut-off valves can be closed in two ways: manually or with a key. They do not need to be compacted, but precisely fit tightly to each other.

In the basement, the pipes do not have to be closed; they should be mounted in compliance with the gap between the wall using brackets and clamps. In places where pipes pass through the wall or where they overlap, they are covered with a special protective tube. The pipe connection should not be located at the transition itself, but before and after it.

In slag concrete masonry, the gas pipeline system must be protected, for example, with anti-corrosion paint or other insulating shell. Pipes passing in the grooves of the walls are fixed on them with hooks, and the grooves are properly sealed.

Flax grease to seal the threaded connection

Oil paint

But about the lubricant, I saw references in books. In the books of the Soviet era, it was proposed to seal (lubricate) flax with oil paint. And old plumbers use this method successfully. Oil paint, of course, is something. She first lubricates, and then glues the joint almost tightly. I ran into one like this. I took apart one heating and cursed everything in the world. Almost every compound I had to heat almost to red. Only then could I unleash it. Note that it is not always possible to just wield a hairdryer or a burner like this. There are all sorts of factors, such as wallpaper on the walls, that you don't want to burn. But you have to.

Silicone sealant

After I used this sealant, I read the warning that it is just silicone sealant that cannot be used in threaded connections. That the sealant is an acid that corrodes the threads completely.

I am glad to inform you. It's a bullshit! As already mentioned in the announcement of the cycle, I changed the plumbing wiring, assembled on silicone 10 years ago. When examining the threads in a magnifying glass, I did not find any (!!!) traces of the action of the sealant on the threads. Moreover, the thread under the sealant retained its virgin shine! Another thing is that it was not easy to tear off the flax with sealant from the thread! But even then I very quickly found a way. I cleaned the threads with a heavy metal brush. As I said, the threads under the sealant loosened well and stayed pristine, which allowed me to reuse many of the non-ferrous parts.

The next two pictures illustrate the above, namely that the silicone sealant did not spoil the thread, but, on the contrary, made it better. Even the section of the pipe that was exposed to air was worse preserved than the thread under the sealant (in the case of a galvanized pipe).

Modern materials for compaction (lubrication) of flax

Remember I told you about my conversation with a professional? So it was he who told and showed me a tube of special ointment for sealing threaded connections. I bought one and tried it out. I'll be honest. This is something amazing. The effect is amazing.Now I have forgotten about silicone sealant forever and have no idea how I used to live and work.

Modern means for lubricating and sealing flax in threads

Briefly speaking! This ointment is terribly greasy. It is non-drying. Its main advantage is that now I can practically not worry about the amount of flax in the thread. That is, now I can twist the thread a little thicker and wind it around the thread a little less carefully. In some way incomprehensible to me, all the flax is crushed and laid down in the thread without much effort on my part. I untwisted some connections. Linen seems to become part of the carving. Globally, the likelihood of messing up the connection has decreased. Well, and the best part is that at the substantial price of the tube, the consumption of the ointment is more than modest.

By the way!

I made a video for the first time and posted it on Youtube. Direct link to it: Direct link to video in Youtube

It turned out to be practically impossible to remove the used thread from the thread without the help of a metal brush.

The promoted connection (the one that was made in the film)

Please note that all threads are completely in the grooves in which you need. As I said, flax has practically grown into the carvings.

This means the connection was extremely reliable.

I suppose we owe this effect entirely to the super tube seal.

Failed threaded connection

But, on the contrary, a failed connection. It was made "on silicone sealant"

Pay attention to the fact that the flax went a couple of turns and then began to wrinkle like an accordion. And nevertheless, the connection stood for 10 years and it would not have been known how long

Probably forever. And we fixed the quality only when we untwisted the connection.

Advantages and disadvantages

After reviewing the theoretical information regarding anaerobic thread sealants, you can compile a list of their positive and negative features. Since there are many times more advantages than disadvantages, you should start with the first ones.

The advantages are several.

- High heat capacity of joints. The sealant will not degrade even when exposed to strong temperature fluctuations. Typically, the acceptable level varies between -200 degrees and +300 degrees. All this allows the use of liquid anaerobic gels when connecting heating radiators or water pipes with hot water.

- Durability and strength. The joint will not disintegrate, will not crack under the influence of mechanical loads or vibrations, so you can be calm about the fact that the pipe may leak due to the fact that the water was let through the pipes a little more intensively.

- Saving. In the long term, it turns out to save on repair and renewal of the sealant on the pipe joints. In addition, the composition itself is also economical during operation. It will literally need a drop to process a whole thread.

- Chemical resistance. This feature is one of those that influenced the popularization of anaerobic sealants. Unlike improvised materials and some professional ones, gels and pastes with anaerobic properties easily tolerate the effects of chemical compounds and substances such as gasoline, antifreeze and the like.

- Lack of water solubility. After passing the polymerization process, the sealant does not dissolve with water, does not dissolve in it, so it can be safely used when sealing water pipes, without fear that over time the sealant will completely dissolve and the pipe will leak.

- Versatility. This means that the fixture can be used when working with various materials, including in cases where one part is made of one material, and the other is made of another. So, the most common example is the connection of a plastic pipe with a metal one.

- Ability to withstand high pressure. Resistance to resist pressure should be taken out as a separate feature, since it is most often of interest to buyers.Joints treated with an anaerobic sealant are able to withstand a pressure of 40-50 atmospheres.

In addition to the listed advantages, the tool also has a number of disadvantages.

- Correlation with temperatures. The pour point should be between 15 and 25 degrees. In a room that is too cold, the polymerization time of the sealant will greatly increase and its properties may change.

- Diameter limitation. It is impossible to find an anaerobic gel that can be applied to pipes with a diameter of more than 4 cm without losing the lion's share of its technical characteristics.

- Dependence on surface cleanliness. Before applying the fixative, the surface must be properly prepared: clean, degrease and dry. Otherwise, it will not be possible to completely seal the joint.

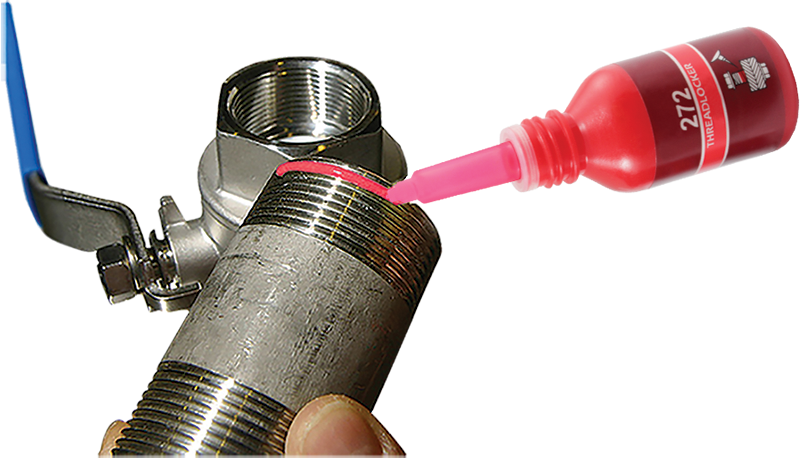

- Difficulty in dismantling. Only temporary green sealants can be removed manually. Blues will need special equipment such as a hair dryer. It is generally impossible to dismantle the red ones: the pipe will have to be sawed.

What types of materials for water supply can you work with

Before installing the water supply system, it is worthwhile to study in detail the materials that are used for sealing. Let's consider them.

Liquid sealants based on synthetics. Silicone Sanitary pipe sealant water supply developed not so long ago. Its distinctive feature is the ability to preserve plasticity after drying.

And it should be noted that this design is suitable even for a joint working under high pressure. Even a strong pressure of water will not move this silicone protection from its place.

Having opted for a silicone sealant, you need to take into account that not every brand of it can be used for contact with hot water. This problem occurs due to the fact that these materials soften under the influence of high temperatures.

And you also need to keep in mind that this type of sealant has a certain level of toxicity. Accordingly, its application must be done very carefully.

Watch the video

During installation work, you must take care of protective equipment (in this case, gloves and a respirator are meant). Such requirements are dictated by the fact that during the solidification of this product, highly concentrated acetic acid evaporates. This can be dangerous for the sealant.

The advantages of silicone sealant include: ease of use; protection against corrosive processes; creation of lubrication.

But anaerobic sealant does not have all the above-mentioned disadvantages.

It is able to freeze without air access, but only when installed on a metal base. These two conditions can be created in the middle of a threaded connection. In this case, the dimensions of the sealing product do not change.

This sealant has a high level of thermal and chemical resistance. And the pressure that it can withstand is no less than the pipes themselves can withstand. These gels are adhesive to metal, so the joint is strong and rigid, even if it is not tightened very tightly. On an open surface, it does not harden, and its excess is easily removed with a rag or washed off with water.

The photo shows that the sealant, after solidification, turned into a powdery mass. When applying a new sealing layer, it is not necessary to remove the remnants of the previous treatment, this will not affect the quality of the joint.

Fum - tape. A sealant in the form of fum tape for water supply pipes perfectly protects threads from corrosive formations, does not corrode. This tape has a smooth surface, which makes the assembly process easier. Unfortunately, this material does not withstand vibration and mechanical stress.

For sealing, this tape is mainly used for threaded connections.But, for a structure located on the weight, it is not suitable, due to its poor resistance to vibration. The vibration generated by the water flow can weaken the tape and hence the sealing. Ultimately, under these conditions, a leak is formed.

Solid sealants. This is a very common form for sealing joints in the construction market and is not very popular with plumbers. For sealing, such products are used very rarely.

Watch the video

Dry flax. This option is also not very successful. Organic fiber is hygroscopic, and such joints are not very reliable. The use of flax and paint is more reliable. Thus, the fiber is protected from moisture, and such a connection lasts a little longer.

Dry flax has been used to decorate water supply for a very long time, and in this matter this material can rightfully be called one of the "pioneers". Initially, flax was used together with hemp fiber, but soon the last component was abandoned.

Today, flax is not common in the water supply network. As it has already been said - it is a natural product, and from contact with moisture, it quickly turns sour. Flax is also negatively affected by high temperatures. Because of this, it loses its strength, and "pours" out of the compound.

Plumbing thread is called more reliable for sealing, but it is expensive. Although in terms of strength it is absolutely not inferior to fum - tape. The disadvantages of this material are distinguished not only by its high cost, but also by some of the difficulties of assembly operations.

It takes some effort to seal. These requirements dictate the installation rules, which stipulate that the thread should be placed evenly on the elements.

If these rules for working with sealant are not taken into account, then you can simply spoil the thread on the pipe.

Characteristic properties

All sealants have a special set of qualities that you need to know and be able to evaluate:

Fluidity. This refers to the viscosity of the sealant. So, if you need to close up a small gap, then it is better to choose a gel or paste. Their texture is great for this. If we are talking about sealing a large gap, then it is necessary to purchase the most liquid composition. Remember that the larger the gap, the thinner the sealant should be. So he can fill in all the cracks, tightly holding the pipe connection.

Temperature. The working temperature range of sealants is not infinite. At a certain temperature, they will no longer firmly fix the pipe, which can lead to leakage. For most of the samples on the market, the temperature range is 200 degrees - from -50 to +150. This is usually more than enough.

If it is necessary to seal pipes carrying a colder substance (for example, pipes for liquefied gas), then you need to pay attention to specialized samples.

Strength. Strength means how much force must be applied to separate the joint. If a sealant of low strength was used, then it will be enough to apply a strong force with your hands. The fitting, sealed with medium strength sealant, can only be unscrewed when using an accessory. It is impossible to dismantle the sealant of strong fixation: the joint will have to be broken.

Polymerization rate. The packages indicate how long it takes for the sealant to completely cure. You can start using pipes only after this time has expired.

Maximum thread diameter that can be fixed. It just so happened that not all sealants work on not all pipes. In the case of an incorrectly selected composition, the beneficial effect of its use is reduced to zero.

Possibilities of use. Some sealants are not suitable for fixing drinking water pipes, as they release toxic compounds into the water

You need to pay close attention to this factor.

Sealing with other materials

In addition to the aforementioned seals, the following are often used for sealing:

- epoxy resin. It is clear that the principle of its action is the same as that of the glue of the same name, produced on its basis. using this substance, they connect the risers of the sewer system;

- Portland cement. With its help, more than one sealing mixture is produced, which, in combination with an asbestos rope, is used to caulk the socket joints of the pipes of the cast-iron sewage system;

- petroleum bitumen or asphalt mastic. These substances are very effective in cases where ceramic or cast iron sockets need to be sealed;

- technical gray. When using this substance, the sealing of cast iron joints and similar sockets is almost ideal.

They are installed on pipelines, car windows, house windows. Such products are excellent waterproofers, dock seals. They can also be used as depreciation materials.

For their manufacture, special rubber is used, which is highly resistant to oils, gasoline, water, and high temperatures.

How tight should the plumbing parts be tightened?

This is a very good question. Do I need to wind one part on top of another and tighten it at the same time? According to the textbooks, yes. Experience has shown that this is not always possible. It happens that a completely twisted and tightened corner looks at all in the wrong direction. I'm not worried and turn the corner a little so that it looks where it should be. And such a connection has never let me down. In short, I will continue to "cheat" in this way. And as you wish.

So that is all. If someone liked this material, I'll just be happy. If you didn’t like it, then I’m sorry!

Master of long description of short processes Dmitry Belkin

Article created on 08.10.2013

Article edited 11.01.2014

Linen

Sealing threaded joints with linen thread is one of the oldest and most proven methods. Flax is sold in any plumbing store, in the markets.

When buying, be sure to pay attention to the following signs:

- elasticity of the thread;

- lack of debris, unpleasant odor;

- small thickness of the strands.

Flax in its pure form begins to rot quickly upon contact with water, during temperature changes, and in heating systems it completely burns out. In addition, the material does not contribute to the prevention of rusting of metal pipes and fittings, unlike more modern sealants.

To neutralize these shortcomings, the thread is impregnated with special compounds (pastes). Densely grated natural red lead is often used. The cheapest option is to make the pasta yourself, taking whitewash and adding drying oil until you get a mass like sour cream. It is applied to a linen thread in a thin layer, smeared and dried.

Red lead is more suitable for working with steel pipes: it oxidizes the top layer of iron to an insoluble compound that does not allow oxygen to pass through, working like a bluing. The stores also sell ready-made linen thread sealing pastes:

- Unipak (soap, chalk, paraffin, water, mineral oil).

- Multipak (paraffin oil with mineral additives).

- Pastum GAS (organic binders, special fillers, additives and anticorrosive additives).

- Gebatout 2 (white mineral oil, thickener, synthetic polymer, mineral filler).

If these means are not at hand, for better sealing of gas connections, flax can be impregnated with ordinary oil paint or automotive sealants.

The work is carried out as follows: a strand of flax with a thickness of 2 matches is separated from the general coil, wound on the thread, starting from the far end and ending at the end of the pipe. After that, the flax is coated with a paste, the connection is collected (when twisting, an effort should be felt).

How to use?

It is worth mentioning in advance that anaerobic gels and pastes are available ready for use. It is not necessary to additionally prepare solutions and compositions. The container in which they are sold is designed for the drug to be applied directly from it, although you can use all kinds of brushes if it is more convenient.

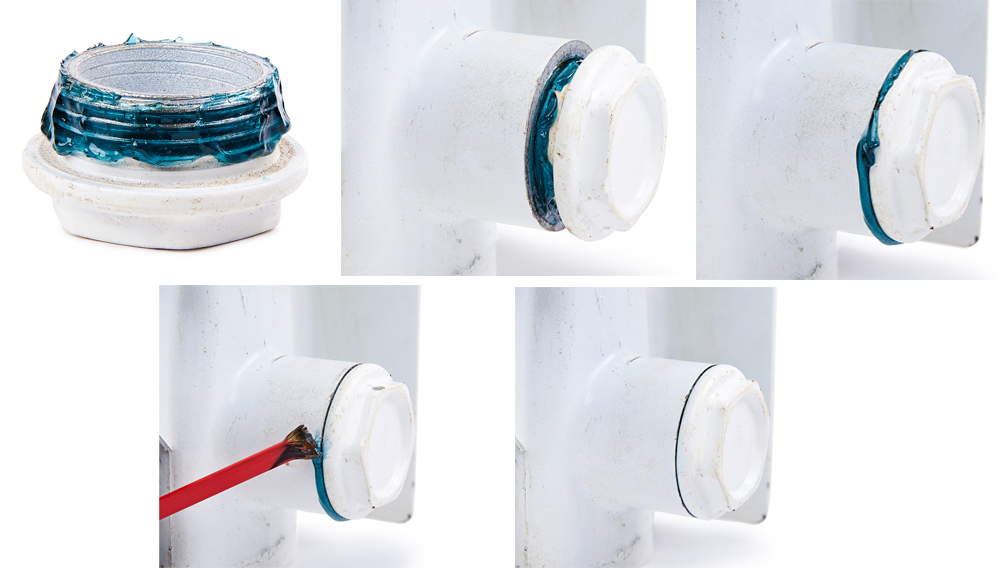

The order of work.

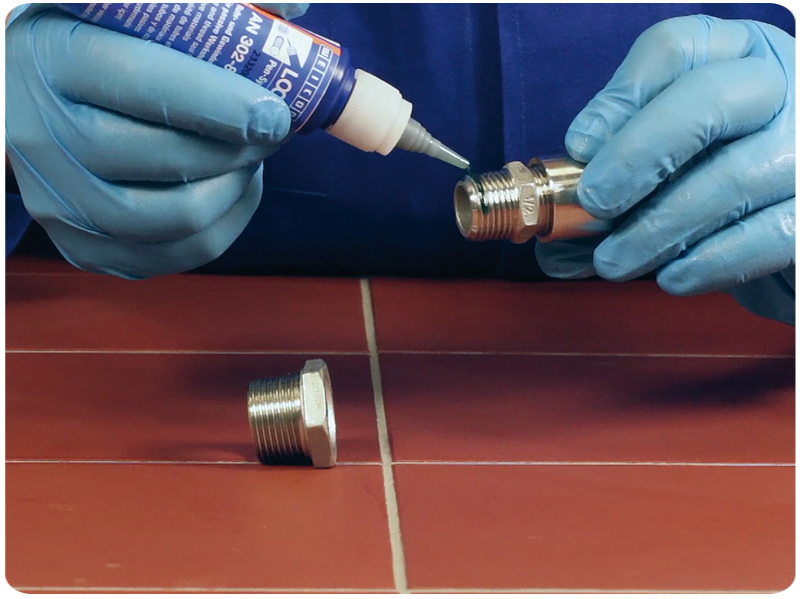

The surface is thoroughly cleaned. Any traces of rust, corrosion are removed. If there are traces of old sealant at the place of application, then it is not necessary to completely remove it: small particles will not affect the quality of the seal in any way. If the pipe is new, then it is enough to walk along the thread with a wire brush to improve the adhesive properties.

The cleaned surface is degreased. For this, all kinds of compositions are suitable, for example, white spirit. Degreasing must be done thoroughly, without missing a single crack.

It is important that the anaerobic gel adheres well. A special activator must be applied to the plastic thread.

- Next, the composition itself is prepared. The tube shakes well. Only then can the package be opened.

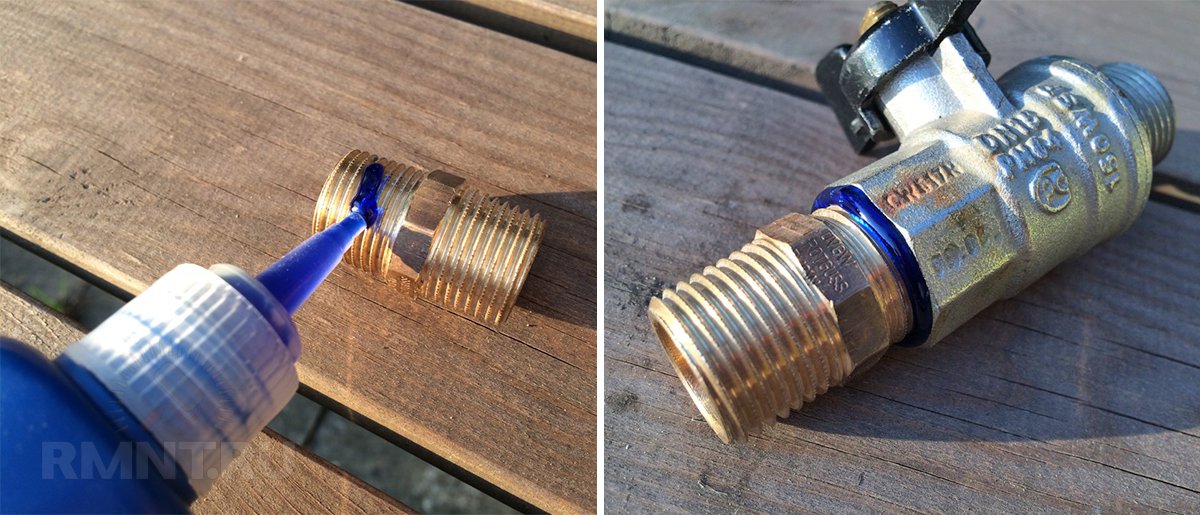

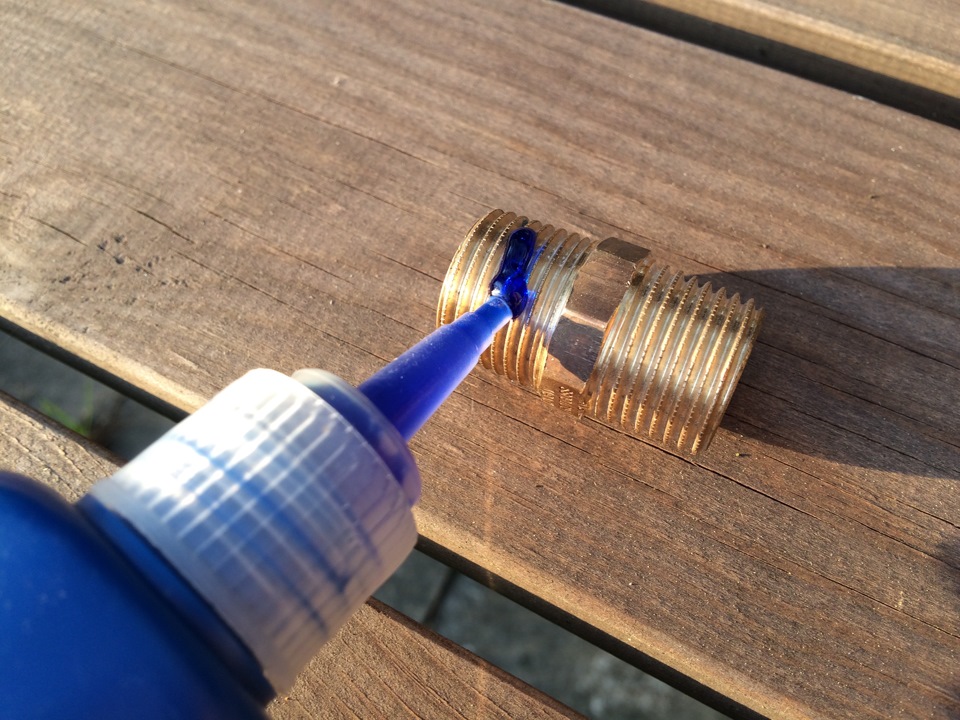

- The sealant is applied to the joint with a thick layer along the entire thread. Some masters advise to apply the composition only on a few turns, since this does not greatly affect the tightness of the joint, however, if you are processing a pipe that will be under high pressure in the future, it is better not to risk it. For optimal sealing, the sealant is applied not only from the outside of the joint, but also from the inside: this way an optimal effect can be achieved.

- Tighten the connection after applying the gel. To do this, you do not need to exert excessive force, just tighten by hand. If the sealant has come out, it is collected with a napkin. The composition does not freeze in air, so the sealant can be reused by applying to another compound.

- Next, the joint is checked for tightness. To do this, after 15-25 minutes, you need to create a slight pressure of 10-15 atmospheres by letting in water or gas. If everything is in order, then you must wait until it hardens completely.

- Full polymerization takes place in a day. After this time, a second test is performed, but the pressure should already be 40 atmospheres. If everything is working properly, then pipes can be used. If not, then dismantle and reseal.

-

If it is necessary to dismantle the joint, then the order of work will be as follows:

- the flow of hot air from the construction hair dryer is directed to the junction;

- the moment is expected when the retainer turns into crumb;

- the connection is disassembled with a key;

- the remains of anaerobic gel or paste are removed with a cloth.