What cells of the netting mesh happen?

Weaving type

Allocate a diamond-shaped or classic mesh.

Visually, they are quite similar, however, the square mesh netting, which is intertwined at an angle of 90 °, is slightly widespread and more durable than the rhombic mesh netting, which is intertwined at an acute angle of 60 ° (GOST 5336-80).

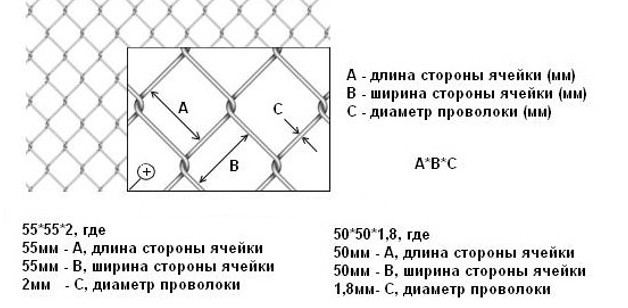

Mesh size

Manufacturers offer a wide range of chain-link mesh with cells of various sizes. It should be noted that the size of the cell is determined by three parameters: the length and width of the sides, as well as the diameter of the wire from which the mesh is made. These parameters are in direct proportion to each other.

Grid chain-link cell 20x20 In this manner, if indicated - a grid-chain-link cell 20x20 mm, this means that its sides are equal in size 20x20 millimeters, taking into account the diameter of the wire and the node of its connection.

Grid chain-link cell 20x20 In this manner, if indicated - a grid-chain-link cell 20x20 mm, this means that its sides are equal in size 20x20 millimeters, taking into account the diameter of the wire and the node of its connection.

The mesh sizes of the chain-link mesh range from 5x5 mm to 100x100 mm. The gradation of all sizes is shown in the table.

Grid chain-link cell 5x5 mm is the minimum cell size. A thin mesh (small) mesh is often the strongest and most compact. It is used to sift bulk materials or to make animal cages.

The maximum mesh size of the chain-link is 100x100 mm.

Note. The smaller the mesh size, the stronger the mesh will be, but the more weight and less light transmission it will have.

According to the accuracy of the dimensions of the mesh, the chain-link are combined into two groups:

- the mesh of the 1st group has the minimum permissible deviation in size;

- group 2 mesh can have more significant deviations.

Notes. The permissible deviation is, in accordance with GOST 6727-80, from +0.05 mm to - 0.15 mm.

Views

Reinforcement mesh consists of a set of rods located perpendicular to each other. At the points of contact, the reinforcement is fixed by means of spot welding. The material is classified according to the location and diameter of the rods, the wire used and some other parameters.

To determine the mesh class, the diameter of the reinforcement used is taken into account:

- 3-10 mm. - lightweight materials used for plastering;

- 12-40 mm. - heavy products intended for reinforcing concrete structures.

The size of the rods used determines the specific weight of the product, its cost.

The reinforcement is located in the material with the following directions of the rods:

- longitudinal-transverse;

- constructive (distribution), transverse or longitudinal.

The grid is made with rectangular or square cells. Their sizes range from 50x50 to 500x500. In rolled products, wire with a cross-sectional diameter of no more than 5 mm is used.

The grid is made with rectangular or square cells. Their sizes range from 50x50 to 500x500. In rolled products, wire with a cross-sectional diameter of no more than 5 mm is used.

Grids with cells 100x100, 150x150 and 200x200 are in demand.

Types of reinforcement mesh for welding accuracy:

- increased accuracy;

- normal accuracy.

There are the following types of welded mesh for its purpose:

- Road - designed for the reconstruction or construction of new access roads, footpaths, roadways. Often these products are used in industrial facilities for floor reinforcement. The cell in the welded material can be in the range of 5-20 cm. With an increase in the reinforcement pitch, the resistance of the finished object to mechanical loads and strength properties decrease.

- Reinforcing - used to increase the stability and strength of each structural element. It is used for arranging the foundation, making monolithic structures from reinforced concrete. The items are 6 meters long and 1-2 meters wide.

- Masonry - designed for reinforcing brickwork, strengthening when pouring floors with sand-cement or concrete mixtures, etc. Available in cards and rolls. For internal partitions and walls, a mesh with a size of 11-25 cm is used. The width of the material is selected according to the thickness of the brickwork. External walls are plastered using a mesh 1-2 m long and 38-64 cm wide.

The main advantage of rolled mesh in comparison with the material in the cards is flexibility.This allows you to change the shape of the product, cut and bend it at different angles.

The mesh is also produced according to individual orders with a change in the size and pitch of the cells.

Reinforcement mesh in rolls

According to technical characteristics and purpose in the state standard, building grids are divided into five types:

- - lightweight with an offset installation of rods, the width of the web to its length is related as 10: 9;

- - lightweight with transverse reinforcement along the width of the canvas;

- - heavy with transverse working reinforcement;

- - heavy with transverse and longitudinal reinforcement;

- - heavy with a longitudinal arrangement of distribution rods of large cross-section. The extreme transverse rods are stacked with a prefabricated pitch of 10, 20 and 30 cm.

The cross-section of unidirectional bars and the basic pitches of unidirectional reinforcing bars are the same.

The symbol "P" is used in the marking to denote reinforcing meshes of increased and ordinary accuracy of execution. This criterion is determined by the type of welding.

Important! Galvanized products are used in environments with negative chemical influences or aggressive conditions.

Applications

Beacon fittings

Reinforcement meshes are widely used in the field of landscape, agricultural, industrial, individual construction. The type of mesh is determined in accordance with the requirements of the structure, strength indicators. Roll materials are used to:

- strengthening the walls of pits and ditches;

- construction of fences, aviaries, fences, etc .;

- frame design for greenhouses and greenhouses;

- strengthening the foundation;

- arrangement of screeds, concrete and warm floors;

- reinforcement of plaster;

- installation of thermal insulation material;

- manufacturing of panels, slabs and other concrete products;

- erection of supports and bridges;

- strengthening of tunnels, road beds, porous blocks or brick walls, reinforced concrete structures.

For each individual case, an accurate calculation of the amount of required reinforcement mesh is made.

Thanks to the reinforcement of structures with a metal mesh, the following effect is achieved:

- the terms of installation of the structure are reduced due to the complete readiness of the product for work;

- the quality of the structure is improved due to the higher strength with the mesh;

- saves time and materials. For example, in comparison with rolled metal products, manual knitting of reinforcement is not required;

- the production cycle is shortened due to the corresponding technical characteristics and geometric dimensions.

Marking

Regulatory documentation for construction contains the distribution of reinforcing steels into 6 main classes: A-I - A-VI. From the second to the fifth class, the products have a ribbed periodic section profile. The strength level of the metal is indicated by Roman numerals. The letter “T” in the marking designates the thermal hardening of products in hot-rolled steels.

There are 2 classes of reinforcing wire:

- B-I - distribution structural fittings;

- B-II - lightweight work mesh.

If there is a ribbed surface of the wire, add the letter “P” to the designation.

The used reinforcing steels for building meshes are classified according to the current GOST:

- B-I and BP-I - structural reinforcement in heavy meshes, working reinforcement in light meshes;

- A-I and A-II - hot-rolled steel for the production of reinforcing bars in light meshes as working reinforcement, in heavy meshes as structural distribution;

- A-III - hot-rolled steel for increased mesh strength, the cross-section of which is in the range of 1.2-4 cm;

- At-III-C - the presence of thermally hardened properties for heavy meshes of working reinforcement.

- С - welded structures;

- d, d1 - cross-sectional diameters of longitudinal and transverse rods, respectively;

- a - the value of the release in the reinforcing mesh of the transverse rods;

- a1, a2 - release of longitudinal rods;

- b, l - width and length of the web.

Example.Product marking 3 С - 20 A-II / 15 A-II - 150x480 indicates a welded reinforcement mesh of type 3 with working reinforcement A-II and a diameter in the longitudinal direction of 20 mm, and in the transverse direction - 15 mm, in a length of 480 mm and a width 150 mm.

Anti-corrosion protection

Due to the fact that the mesh is woven from thin wire, the issue of corrosion protection of this material is very relevant. Different types of this material have different protective coatings that prevent rusting. More often the mesh is made of galvanized steel. When applied with a hot-dip galvanized zinc coating, the material lasts up to 20 years. Cold or galvanized galvanizing provides less durable protection.

Galvanized mesh can be coated with a polymer coating. Such material lasts longer and has a neat, attractive look.

Almost everywhere the chain-link is covered with polyvinyl chloride. High-quality applied PVC coating provides resistance to atmospheric influences and aggressive environmental components. With such a coating, the material reliably serves up to 50 years, if the polymer does not break down. The polymeric coating of the mesh provides decorative properties. It contains dye, so you can choose any color for the fence, and there are many options.

Popular varieties

Among the diverse range of standard sizes of welded galvanized mesh, the following are in demand:

- 6x6x0.6 - for finishing works to protect frame houses from rodents;

- 25x25x1 - reinforcement of plaster and screed;

- 25x25x1.6 - construction of enclosures and corrals;

- 25x25x1.8 - used as a barrier for various objects, for reinforcing plaster, masonry, screeds, foundations and floors;

- 30x30x3 - construction of fences, for anti-vandal protection, for separating materials into separate fractions by size;

- 50x50x4 - erection of gabions, reinforcement of masonry from foam blocks and bricks, floor screeds;

- 100x100x4 - reinforcement of reinforced concrete structures, construction of corrals.

2 Calculation of the mass of 1 m2 of a non-standard mesh - simple solutions to a difficult question

The manufacturers of the chain-link can, at their own discretion or the request of the customer, produce it with characteristics that differ from those indicated in the above table. These may be the following deviations from the parameters regulated by the standard 5336:

- The thickness of the wire used for the manufacture does not correspond to the established standard. For example, a chain-link with cell number 15 according to GOST 5336 should be made of wire with a diameter of 2 mm. And the manufacturer can make this mesh from wire with a different thickness.

- The shape of the grid cells does not correspond to the established standard. For example, a chain-link with a cell side size of 5 according to GOST 5336 should be made only rhombic. And the manufacturer can make it with square cells.

Of course, in order to find out the weight of 1 m2 of such non-standard nets, it is best to weigh them 1 roll, and then make a calculation. That is, divide the readings of the scales (total mass of the roll) by its area. This will obtain the most accurate value for the weight of 1 m2 of chain-link made with any of the above deviations from GOST. The total area of the roll, as everyone remembers, is calculated by multiplying its width by its length. If for some reason it is impossible to weigh a non-standard mesh, use the methods below for approximate calculation and correction of standard weight values.

For a grid with non-standard cells, a correction factor applies

For a grid with non-standard cells, a correction factor applies

If the thickness of the used wire does not correspond to the established standard 5336, the sequence of calculations is as follows. First, divide the standard diameter for a given cell number (see the above or the GOST 5336 table) by the diameter of the wire from which the mesh is actually made. The resulting coefficient is squared, that is, we multiply by itself.And then, by the result obtained, we divide the mass of 1 m2 indicated in the GOST for the mesh with the given cell number and the standard wire diameter.

If the chain-link does not correspond to the shape of the cells established by the standard, then you just need to use an approximate correction factor of 1.12. Moreover, when, instead of square, the mesh has rhombic cells, it is necessary to multiply the mass of 1 m2 indicated in GOST for the product with the given cell number and standard wire diameter by 1.12. And when instead of rhombic squares, on the contrary, divide by 1.12. The resulting value will be the mass of 1 m2 of such a non-standard mesh. And when the chain-link differs from the standard one both in the shape of the cells and in the diameter of the wire, make both of the above calculations. The sequence of execution does not matter.

Features of production: from galvanized and low-carbon steel wire

Welded galvanized sheet can be obtained in two ways.

Galvanized wire is perpendicular to each other, welding is carried out. This technology does not provide the highest level of corrosion resistance, since the welded joints are not additionally processed and there is a (albeit small) probability of corrosion formation. But there is also a positive point - in the manufacture of canvases, less zinc is consumed, which allows you to save on production.

Low carbon wire is perpendicular to each other and spot welded. The finished sheet is galvanized, the welded joints are "fixed" with a coating, which prevents corrosion.

Galvanizing is done in two ways. The first of them is hot-dip galvanizing, the process of which includes several stages, the material is cleaned, degreased, etched, washed, dried and then passed through molten zinc. Coating is carried out on a special processing line. The disadvantages of this technology are the high cost and unevenness of the resulting zinc layer.

Plating by means of electroplating technology produces a monolithic and uniform but thin coating. An important advantage of the technology is the complete absence of the risk of coating flaking. This effective and inexpensive method is most popular when working with meshes.

Advantages, comparison with non-galvanized and PVC

The industry offers welded mesh with different surface types: non-galvanized, galvanized and PVC coated. When choosing the best solution, you should know the advantages and characteristics of each variety. The positive and individual characteristics of galvanized welded mesh are discussed above.

Non-galvanized mesh

Non-galvanized welded mesh is uncoated, not weather resistant, and therefore very short-lived. But the materials have an important advantage - low cost. Therefore, it is suitable only for solving temporary problems or when implementing projects where the type of materials is not so important. For example, the construction of fences on a construction site, fences on a private territory (when carrying out repair work), it is also possible to build solid structures, but they will have to be painted periodically.

Galvanized welded mesh with PVC coating

The welded mesh with PVC coating has the best performance characteristics. A layer of polyvinyl chloride is applied to a sheet of low-carbon or galvanized wire. The polymer coating provides resistance not only to weathering, but also to the influence of alkalis and acids. In addition, the products have an attractive design, at the request of the client, the surface can be given any color, the standard solution is green. Thus, the mesh combines beauty and durability. The disadvantage is the higher (in comparison with other varieties) price. Welded PVC mesh is the optimal solution for the construction of fences in the coastal area.

Scopes of application: for a fence, from rodents, for gabions and so on

Welded galvanized mesh is used primarily for the construction of protective structures. Fences are suitable for fencing construction sites, sports fields and stadiums, summer cottages, industrial buildings, warehouses, industrial buildings, commercial areas, etc. Gabions are an interesting design solution for private and public spaces.

Galvanized welded mesh gabion. Protect Photos

Often used in construction:

- When pouring the floor. The preparation of the rough and final base requires a reinforcement procedure, where mesh materials are an inexpensive, reliable and durable solution.

- Underfloor heating equipment. In this case, the mesh acts not only to strengthen the coating, but also to fix the pipe to the floor.

- When laying bricks and blocks, a special mesh is used - galvanized masonry. The construction of one-story buildings involves strengthening the structure. Craftsmen perform reinforcement of every fourth row.

- When forming an armored belt. The construction of buildings with more than one floor, the floors of which are made of reinforced concrete slabs, requires the use of an armored belt. Mesh is an excellent alternative to reinforcement, which will need to be tied during work, forming a frame. It is easier and faster to work with the mesh, it is suitable for reinforcing ceilings, the construction of which is carried out using cement mortar and glue.

- Plastering works. The materials are used for work inside and outside, they are suitable for reinforcing the coating of various thicknesses, but not more than 50 mm.

- Strengthening foundations. The use of mesh helps to protect objects from cracking and the appearance of unwanted deformations, provides resistance to moisture and temperature extremes.

- Road construction. The use of welded products makes it possible to increase the strength of the roadway and increase its service life. Also, the grid acts as the basis for laying paving slabs, concreting entrances.

Agriculture is another industry where galvanized welded mesh has been successfully applied. Here the netting is used in the manufacture of cages, the construction of corrals and enclosures.

In addition, coated materials are successfully used for:

- production of various frames;

- sheathing of pipelines;

- protection against rodents: mice and moles;

- making mouse and rat traps;

- obstruction of ventilation openings;

- making feeders for fishing and much more.

In these areas of activity, not only welded mesh is used, but other types of materials with a zinc coating: CPVS, chain-link, woven, as well as various types of Magnier (hexagonal cloths).

The main dimensions of the netting

According to the shape of the cells, the grid is:

- square (grids with cells of 20 mm and more);

- rhombic (mesh with cells from 15 mm and more).

By surface type:

- galvanized mesh netting;

- without cover;

- made of PVC coated wire;

- made of galvanized PVC-coated wire in different colors.

The dimensions of the chain-link mesh (height, width, diameter of its cells) are defined in GOST 5336-80. It is he who regulates the production of quality material.

The dimensions of the netting, as a rule, depend on its type. So, the material has a length of 10 m. The height is usually 1.5 m. These are the standard dimensions of the chain-link mesh. But this material can be found with a height of 1.2 and even 3 meters.

Sometimes manufacturers, meeting their customers halfway, produce non-standard rolls, the dimensions of which are 10-20 m in length, cells - 10-20 mm.

Height and length

It is especially important to take into account the size of the roll if you plan to make a fence from a chain-link mesh. The height of the fence will not exceed the width of the roll

The standard value is 150 cm. The net width is the height of the roll.

If you go directly to the manufacturer of the building material, you can purchase other sizes. Rolls with a height of 2-3 m are usually made to order.However, such dimensions are rarely used for the construction of fences. It is the 1.5-meter rolls that are the most popular.

With the length, everything is much more interesting, the standard size is 10 m, but you can find on sale up to 18 m per roll. This limitation exists for a reason. If the size is too large, the roll turns out to be very weighty. The chain-link will be problematic even to simply move around the site alone.

The mesh can be sold not only in rolls, but also in sections. The section version looks like a metal corner with a stretched chain-link. The sections are purchased in the required quantity and are used directly for the fence, gates. Interestingly, the rolls can be combined with each other, so the 18 meter limit does not affect the size of the fence.

How to choose?

The chain-link mesh is used for various purposes in everyday life and during construction work. A fence made of such material is used in summer cottages, where you do not need to create a shadow zone or hide something from prying eyes. It is very easy to install such a fence and it does not take much time. Usually the chain-link allows you to separate the garden or divide the yard itself into zones. A mesh with a small mesh makes a good material for making cages. So, the animal will be clearly visible, there will be constant air circulation inside, and the animal will not run away anywhere. In factories and in other industrial areas, such a chain-link is used for protective fences of some hazardous areas.

Fine mesh is also quite common in construction. It allows you to reinforce pipes and plaster, is used in the manufacture of self-leveling floor. The netting can be sold with or without coating. The latter option is ideal for the construction industry.

The black mesh should be used where it is not in contact with the environment, where there is no risk of metal oxidation.

A fine coated mesh is worth choosing when you need to hold something. So, the material will come in handy when arranging a sports field or tennis court.

When choosing a chain-link mesh, you should be guided only by the purpose of the purchase. Making a simple fence will require galvanized material, possibly with a decorative finish. The size can be quite large.

Netting net roll weight

There is no unequivocal answer to the question of how much a roll of chain-link mesh weighs. The fact is that its value depends on many parameters of the woven mesh:

type of finish coating of the wire. The lightest will be a roll of non-galvanized mesh. A galvanized mesh netting, the weight of which increases by the thickness of the zinc coating, will be somewhat heavier than a non-galvanized one. However, it is problematic to reveal this even by weighing. And to estimate "by eye", it is completely impossible. The most significant will be the weight of the chain-link polymer mesh. This is due to the fact that the polymer coating completely covers the wire, which means that it increases its mass;

cell size. The smaller the cells, the more wire is spent on weaving the netting of the chain-link. And despite the fact that the diameter of the wire is smaller, the weight of 1 m2 of the netting of the chain-link increases. Thus, the weight of the netting of the 20x20 chain-link will be 2.52 kg / sq. M., And the weight of the netting of the chain-link 50x50 - only 1.03 kg / sq. M. with the same wire diameter of 2 mm;

the diameter of the wire used. This factor directly affects the weight of the netting roll. In this case, the thickness of the wire is determined by the size of the cell. So, for a fine-mesh mesh, a wire with a thickness of up to 2 mm is used, but for cells with a size of 100x100, a thickness of 4-6 mm is already needed. Naturally, the weight of the roll will also increase depending on this parameter;

roll length and width. The geometrical dimensions of the roll are generally standard. The market is supplied with a mesh with a width of 1500 mm and a length of 10 m. However, the mesh of other standard sizes can be made on request. Up to 4 meters wide and up to 15 meters long. Accordingly, the weight of non-standard rolls will be different. Moreover, the weight of 1 sq. the netting the chain-link must remain unchanged.

Weight of 1 m2 mesh netting in the table

Mesh chain-link - weight 1 m2 (table)

tolerances.As in any production, it is impossible to make the netting mesh perfect over the entire area. According to GOST 5336 80, tolerances are regulated: for the diameter of the wire, for the size of the cells and for the geometry of the roll. Thickness tolerance is +0.05 - - 0.15 mm (for 5 mm wire.) Width tolerances are indicated in the table:

mesh roll volume chain-link. The volume depends on how the roll is wound: Material prepared for the site

- Euronoil (compact) differs in that all mesh turns are laid very tightly, and the roll diameter decreases;

- standard winding - this is the traditional approach, which has a larger roll diameter, and therefore a larger volume.

On average, the diameter of a standard 10-meter roll is 250-300 mm, and the volume is easy to calculate, knowing the length of the mesh.

Taking into account the above parameters, the weight of the netting roll is calculated.

Selection recommendations

It is important to buy a quality product, then the fence will last longer

It is recommended to pay attention to the following nuances when choosing a chain-link mesh:

- weaving - even or not;

- each spiral is returned to the base;

- spirals of the suite without gaps.

The chain-link is sold in rolls

It is important to inspect the packaging - the dressing is in three places, the ends are tightly closed. Attached is a shipping label with manufacturer and dimensions

The fence gives a sense of security, however, before erection, some points are taken into account. It makes no sense to build a dense and expensive fence, if, for example, the house itself is not completed. Mesh netting is a cheap and easy-to-install material.

We take a mesh netting?

Not really

Previous

What kind of metal euro shtaketnik to choose for a fence in the country: dimensions, do-it-yourself installation

Next

Galvanized welded wire mesh for fence made of steel wire in rolls - advantages, selection and installation

Mesh height and width

The indicator for the width of the roll is the height of the estimated fence with an allowance. Correct calculations will allow you to take the mesh of the height that the fence covers. However, in the event of a mistake, this material can be easily trimmed - simply by biting into unnecessary cells.

When buying, you should be guided by the fact that it is necessary to add at least another 20 cm to the width.This will be the distance between the bottom of the fence and the ground. The chain-link is not recommended to be installed close to the ground, therefore, an allowance is needed.

Typically, the height of the fence is 1.5 meters. Translucent by the sun and does not interfere with the view, protecting the boundaries of the site. Less often they buy a roll of 1.2 m. The fence comes out lower than required.

So, the width of the net roll is equal to the height of the future fence. The roll length is taken into account, which is usually 10 meters.

Low carbon, bleached wire:

- Length 10 meters, Width 1.5 meters, Wire with a diameter of 1.0 millimeters, Cell size 10 * 10 millimeters - weight 19 kilograms;

- Length 10 meters, Width 1.5 meters, Wire with a diameter of 1.2 millimeters, Cell size 10 * 10 millimeters - weight 28 kilograms;

- Length 10 meters, Width 1.5 meters, Wire with a diameter of 1.4 millimeters, Cell size 10 * 10 millimeters - weight 35 kilograms;

- Length 10 meters, Width 1.5 meters, Wire with a diameter of 1.0 millimeters, Cell size 15 * 15 millimeters - weight 15 kilograms;

- Length 10 meters, Width 1.5 meters, Wire with a diameter of 1.2 millimeters, Cell size 15 * 15 millimeters - weight 19 kilograms;

- Length 10 meters, Width 1.5 meters, Wire with a diameter of 1.4 millimeters, Cell size 15 * 15 millimeters - weight 26 kilograms;

- Length 10 meters, Width 1.5 meters, Wire with a diameter of 1.0 millimeters, Cell size 20 * 20 millimeters - weight 15 kilograms;

- Length 10 meters, Width 1.5 meters, Wire with a diameter of 1.2 millimeters, Cell size 20 * 20 millimeters - weight 20 kilograms;

- Length 10 meters, Width 1.5 meters, Wire with a diameter of 1.4 millimeters, Cell size 20 * 20 millimeters - weight 24 kilograms;

Characteristics of roll materials: length and width, mesh size and more

Depending on the specific parameters of the reinforcing mesh, such as the geometric dimensions of the web, cells, the thickness and material of the bars, the weight and area of the product vary significantly. This can be seen in the table below.

| Diameter

section, mm. |

The size

cells, mm. |

Open cards according to GOST | Area in 1 t.

products, sq. m. |

The weight

in 1 sq. m, kg. |

|||

| By lenght | By width | ||||||

| min | max | min | max | ||||

| 3 | 50x50 | 1500 | 6200 | 350 | 2000 | 480,7 | 2,08 |

| 100x100 | 500 | 2700 | 961,5 | 1,04 | |||

| 150x150 | 500 | 2700 | 1428,6 | 0,7 | |||

| 200x200 | 500 | 2700 | 1923,1 | 0,52 | |||

| 4 | 50x50 | 350 | 1500 | 271,7 | 3,68 | ||

| 100x100 | 500 | 2700 | 543,5 | 1,84 | |||

| 150x150 | 1200 | 2700 | 815,2 | 1,227 | |||

| 200x200 | 1200 | 2700 | 1086,9 | 0,92 | |||

| 5 | 50x50 | 1200 | 1500 | 173,6 | 5,76 | ||

| 100x100 | 1200 | 2400 | 347,2 | 2,88 | |||

| 150x150 | 1200 | 2400 | 520,8 | 1,92 | |||

| 200x200 | 1200 | 2400 | 694,4 | 1,44 | |||

| 6 | 100x100 | 1000 | 2400 | 225,2 | 4,44 | ||

| 150x150 | 500 | 2400 | 330,0 | 3,03 | |||

| 200x200 | 700 | 2400 | 450,5 | 2,22 | |||

| 8 | 100x100 | 1000 | 2400 | 126,6 | 7,9 | ||

| 150x150 | 500 | 2400 | 185,2 | 5,4 | |||

| 200x200 | 700 | 2400 | 253,2 | 3,95 | |||

| 10 | 100x100 | 1000 | 2400 | 80,8 | 12,38 | ||

| 150x150 | 500 | 2400 | 118,2 | 8,46 | |||

| 200x200 | 700 | 2400 | 161,6 | 6,19 | |||

|

12 |

100x100 | 1000 | 2400 | 56,2 | 17,8 | ||

| 150x150 | 500 | 2400 | 83,3 | 12 | |||

| 200x200 | 700 | 2400 | 111,11 | 9 | |||

| 14 | 150x150 | 500 | 2400 | 60,6 | 16,5 | ||

| 200x200 | 700 | 2400 | 80,6 | 12,4 | |||

| 16 | 200x200 | 700 | 2400 | 62,5 | 16 |

The market for building technologies and materials is constantly evolving and updated with cheaper, functional positions. Products made of composite materials can compete with metal meshes. Despite the existing disadvantages of such reinforcement, it belongs to the most durable means. Increases the service life of the protective layer of the mesh rods.

Marking

The main dimensions are standardized by GOST 5336-80. The marking of a steel wire product contains:

- accuracy group;

- type of cell (only diamond-shaped - "P" is indicated);

- chain-link mesh number;

- the diameter of the raw material for weaving;

- state standard number - GOST.

For example, "2P10 1.4 GOST 5336-80" is defined as group 2 with a cell of 10 mm and a thickness of 1.4 mm.

| Mesh size, mm (mesh No.) | Wire diameter, mm | Roll height, m |

| 5, 6, 8 | 1,2-1,6 | 1 |

| 10, 12, 15 | 1,2-1,6 | 1; 1,5 |

| 20, 25, 35 | 1,8-2,5 | 1; 1,5; 2 |

| 45, 50, 60 | 2,5-3,0 | 1,5; 2 |

| 80 | 4,0 | 2; 2,5; 3 |

| 100 | 5,0 | 2; 2,5; 3 |

GOST 5336-80 regulates product manufacturing standards. The assortment is reduced to two groups: raw materials and external coating. In addition, the netting of the chain-link is qualified by the type of weaving.

Raw material characteristics:

- Low-carbon steel (the material is plastic, therefore it is suitable for the construction of fences with uneven borders and reliefs. But more tension is required).

- Stainless steel (the chain-link is rigid, suitable for fences on a flat surface, easier to assemble).

The advantages and disadvantages of each:

- Galvanized - easily bends and rusts under the influence of the external environment.

- Not galvanized black, short-lived, and therefore cheap. Manufactured from low carbon wire.

- Polymer - many colors, designed for conditions with an external aggressive environment.

Each type of product is additionally coated with a special solution. It provides resistance to corrosion, temperature extremes. Visually, apart from the color, the grids do not differ in any way.

Weaving types

Weaving is a shape of cells, with two types: in the form of rhombuses and squares. Rhombic is widespread. According to the technology, the acute angle is 60 °. Grids vary in cell sizes.

Cell size

The size is determined by the total distance (clearance) between opposite sides of the weave. Standardized view: from 5 to 100 mm. However, the size of the weave is adjusted according to the customer's order.

GOST sets the wire diameter for a specific mesh size. So, for the manufacture of a 10x10 mesh, it is permissible to take raw materials in the range of 1.4-1.6 mm. The diameter increases as the clearance increases. The thicker the raw materials and the shallower the gaps, the stronger the fence will be.

Wire thickness

The netting is made of round bars of different diameters. The range ranges from 1.2mm to 5mm. The production process is regulated by TU 14-4-1563 (state technical condition).

Did you manage to figure out the labeling?

Yes, thanks, not really

Application

A chain-link mesh is used, the price of which is indicated below, in everyday life and construction. A fence made of such a material is very convenient and practical, for example, in summer cottages, where they value the absence of shadow zones and ease of installation.

Fine mesh is used in the manufacture of cages in poultry houses, rabbitries and animal farms. Protective partitions are made from such a mesh at industrial enterprises; it is used during construction during the installation of self-leveling floors, for plaster reinforcement, for reinforcing the thermal insulation of pipes.

For plastering, reinforcement or other tasks where there is no direct contact of the material with the environment, a black uncoated mesh is used.

Wicker mesh is also used for fencing tennis courts, sports grounds, screening materials, fixing mine workings in mines and mines, fixing earthen slopes.

Aesthetic mesh made of wire with different coatings. Galvanized wire mesh is widespread. It is aesthetically pleasing, less susceptible to corrosion, and is sold at an affordable price. The nets, which are made of galvanized wire, can last three times longer than non-galvanized nets.

When choosing these or those sizes of the chain-link mesh, it is necessary to really assess how expedient and profitable it is to use material with certain characteristics.