Technology and installation methods

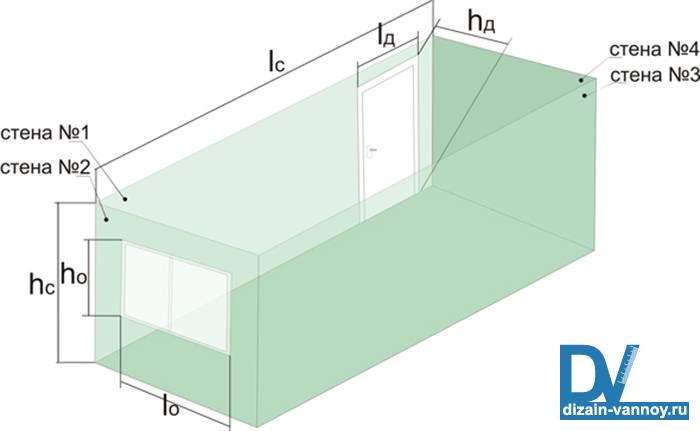

The strips are mounted on the tongue-and-groove principle with a contact depth that allows you to quickly assemble and disassemble the coating. There are two main installation methods: on a frame (crate) and without it. In the first case, a metal base with rectangular openings is assembled. In the second, such a crate is not needed, only approximately flat walls and a base of glue or cement are enough. The disadvantage of this option is the complexity of replacing individual elements. The ceiling is finished only with a frame method, and this is due to the possibility of hiding communications and placing built-in lighting devices in some places, for example, spotlights. The material is glued to the walls - to create the most durable surface. Plastic structures last longer if they do not sag from pressure at the edges. If the frame method is used, it is better to glue the plastic to the pre-attached drywall.

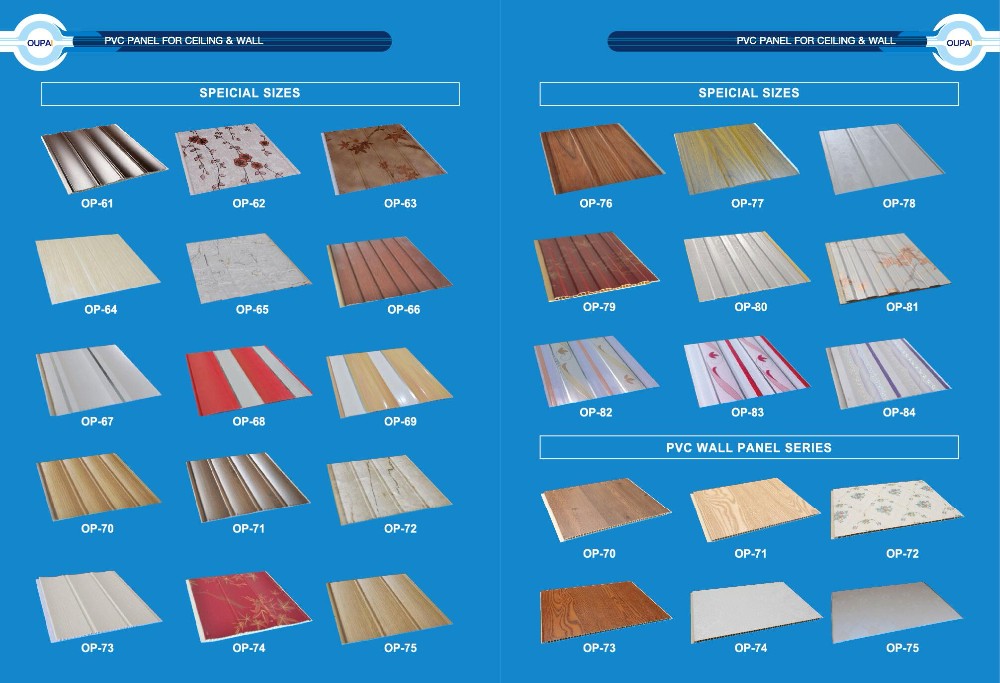

Types of plastic panels

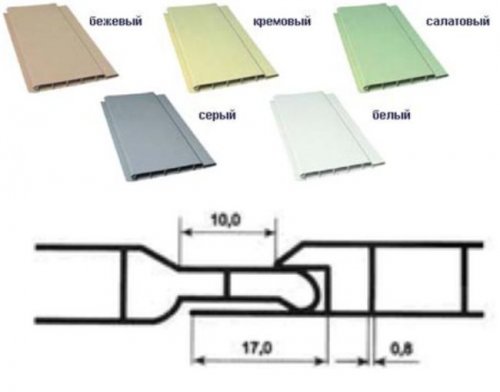

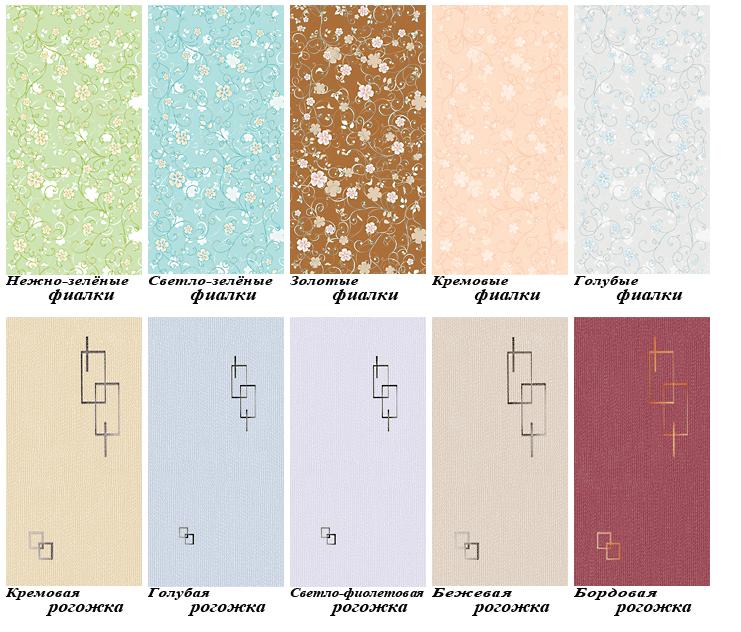

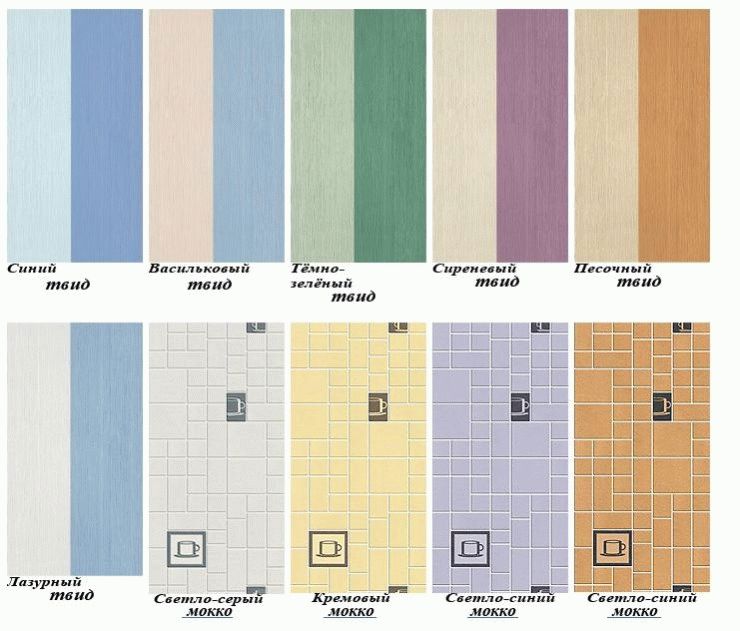

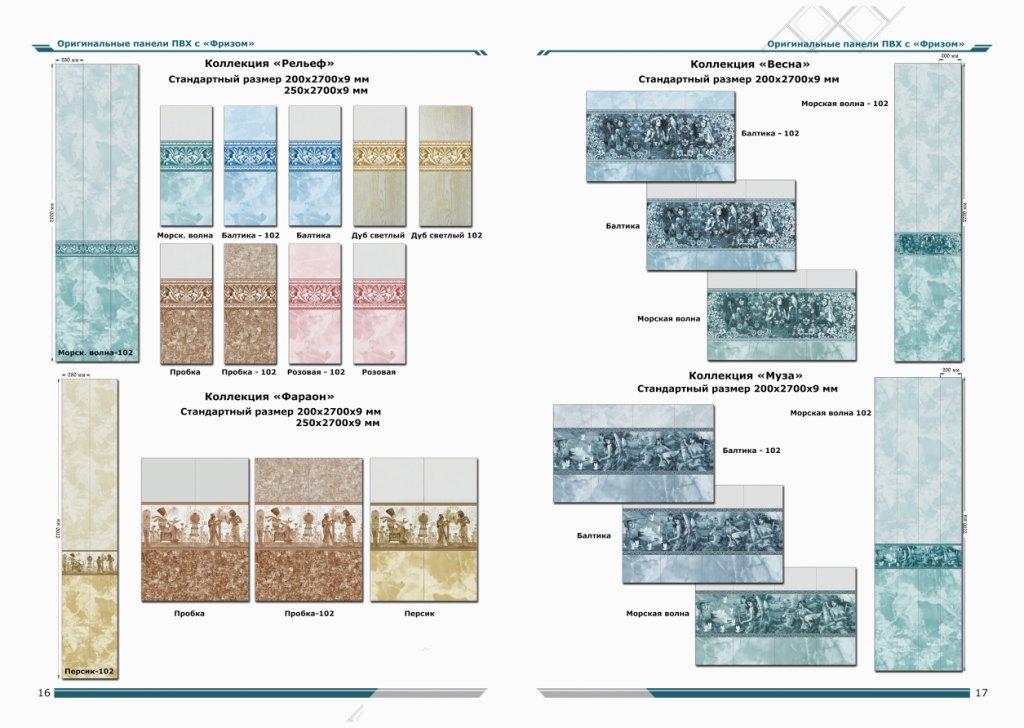

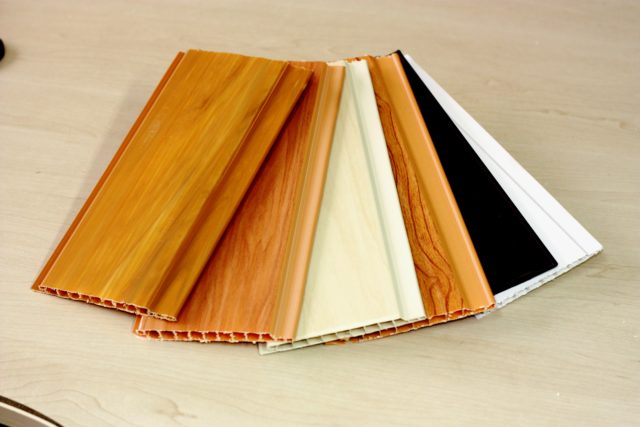

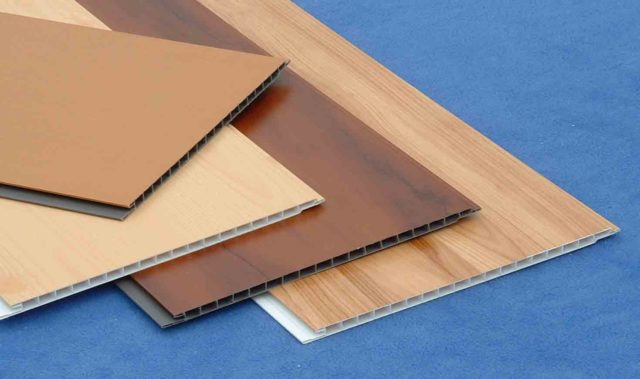

There are different material options. The surface can be monochromatic (white or colored), as well as with a pattern. For the ceiling, light shades are usually chosen that increase the volume.

Patterns should be treated with caution - they can quickly get bored over a large area. If you choose a drawing, it is better to stay on an unobtrusive, without pronounced contrast.

By the type of application of the image, they are distinguished:

- Painted on top is a cheaper option, but the layer is unstable and peels off quickly, and also smells unpleasant when heated (for example, on a sunny balcony). For such panels, a softer plastic is taken, which is why the structure is easily punctured.

- With thermal printing - similar to the previous one, but with more pattern options.

- Varnished - the protective layer makes the pattern more resistant, but scratches over time.

- Laminated - covered with a film. They differ in texture, are resistant to ultraviolet light (do not fade, do not smell). The plastic is denser, thicker and more durable, and the film additionally strengthens the surface. Often imitates different types of wood.

- Decorative - with a relief and a pattern reminiscent of brickwork, stone, tiles, etc. The texture is selected so that the edges are joined to each other without noticeable boundaries. The result is the impression of a single surface. The most expensive type, mainly used for walls.

The last type of PVC ceiling panels can have different smoothness, laminated ones are always matte, and the rest are glossy. This affects the perception of the ceiling. Shiny appears to be higher, but glare from direct light sources is unpleasant to the eye.

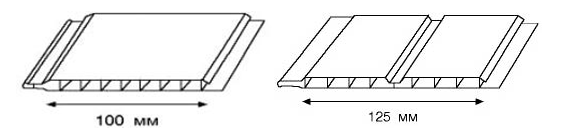

In addition, the panels differ in shape. For some, due to the edges at the edges, there is a gap between the parts. They are often available in sizes similar to wood trim. This option is even called plastic clapboard.

With seamless panels, the gap is much less noticeable, since they are located "joint to joint". Such products are usually wider.

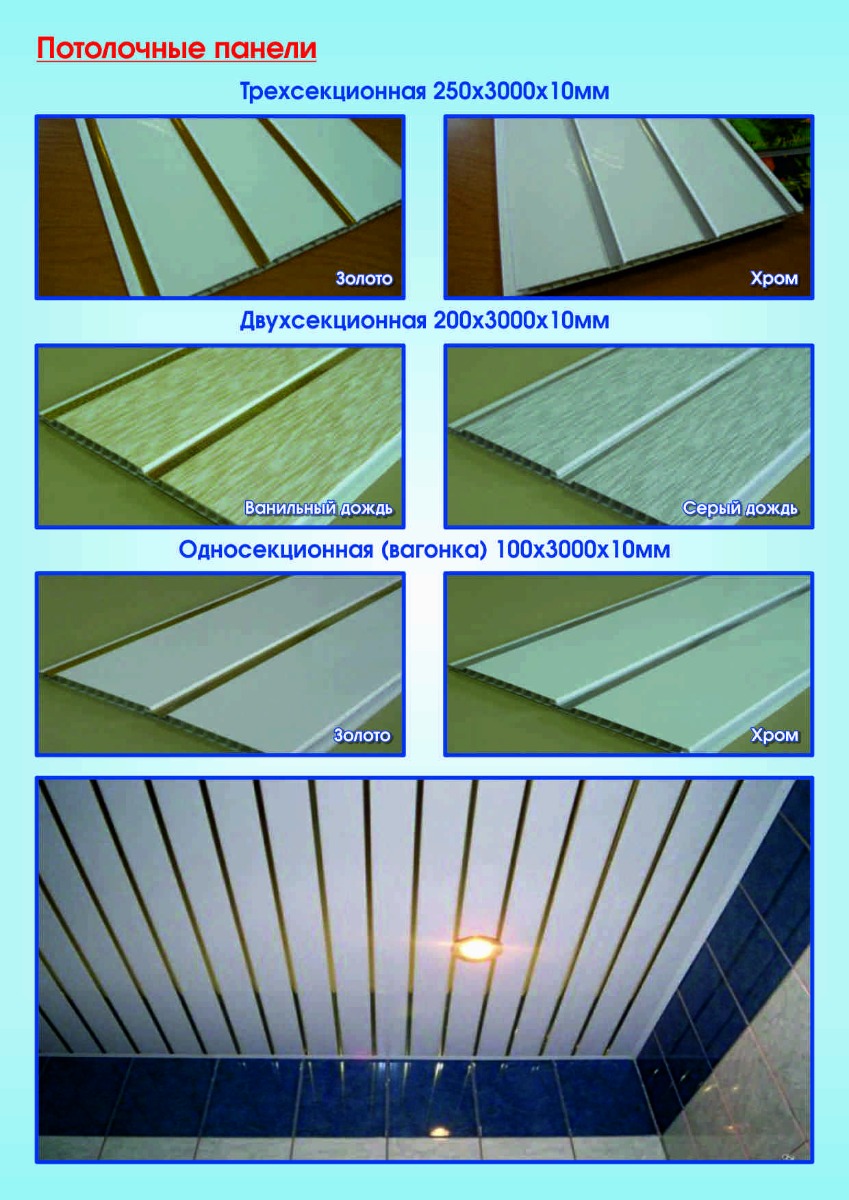

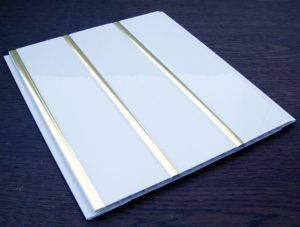

Another type is panels that imitate a slatted ceiling. Longitudinal grooves are located on the surface, dividing the panel along its length (two-section or three-section ones are more common). Thin inserts of a different color (for example, chrome-plated or imitating gilding) can be located between the stripes.

Which panels are best for you?

The design of a bathroom made of plastic panels begins with the right choice. Today there are many different types of pvc panels for the bathroom, they differ both in shape and size, as well as in texture and method of attachment.

By its shape, 3 types of plastic panels can be distinguished:

Rack and pinion. In appearance, they resemble an ordinary lining.They come in different widths, they are installed both on the frame and on glue. Planks are convenient for finishing in a non-standard bathroom with different angles and projections. In addition, with their help, you can visually raise the ceilings (if installed vertically) or move the walls apart (if installed horizontally). The width of standard products is in the range of 10-30 cm, the height is 90-300 cm.

Tiled. A budget alternative to tile has the same shape - a square. They often imitate mosaics, marble or concrete. The main advantage of this type is the integrity of the structure, which is achieved through special fasteners on the tiles. The sizes of the tiles vary from 10 * 10 cm, but 30 * 30, 100 * 100 cm are considered standard.

Leafy

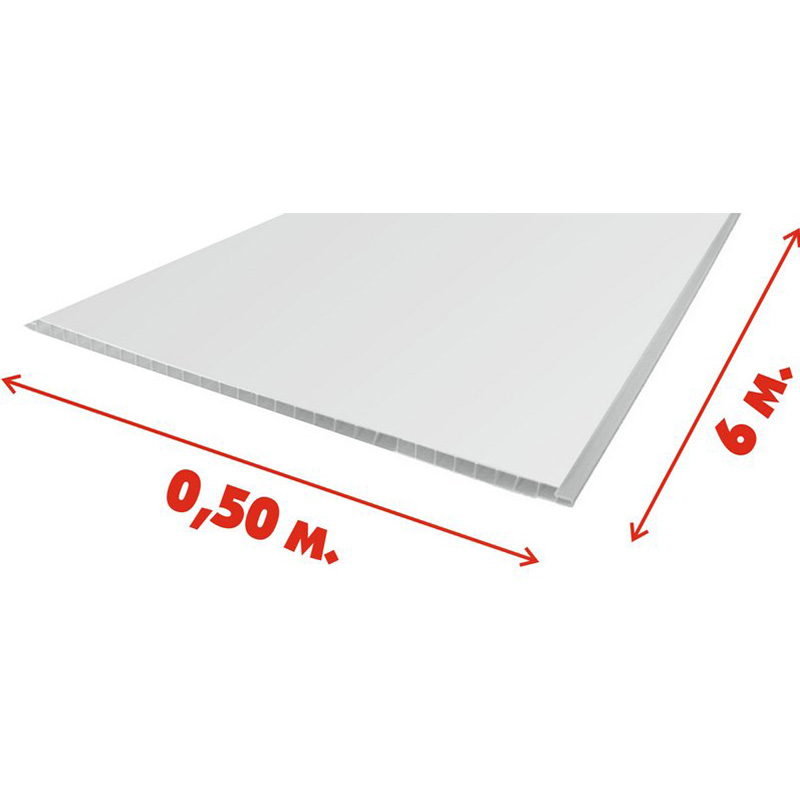

The larger the material, the fewer joints, and this is important for the bathroom. After all, moisture penetrating into the joints provokes the formation of a fungus

In addition, even a large bathroom with large sheets can be repaired in just a few hours. The width of the leaf reaches 50 cm, and the length is 260-300 cm.

Conclusion: For the design of the bathroom, determine the priorities: visual correction of the room, the absence of joints or the speed of installation. This will tell you the ideal shape of the pvc panels.

They are distinguished by thickness:

- Up to 0.5 cm. This thin and fragile material is best used for ceiling decoration.

- 0.8-1 cm. Thick panels are more durable and suitable for wall decoration. In addition, they are protected from mechanical stress and burnout in the sun.

Conclusion: For wall cladding in the bathroom, use strips 0.8-1 cm thick.

Pictured is a bathroom finished with black plastic panels

PVC panels also differ in surface treatment technology and appearance:

- Offset printing. UV resistant, protected from moisture, scratches and other damage. Reinforced with varnish.

- Thermal printing. There is no protective lacquer coating, the pattern can be easily damaged and even erased.

- Lamination. Embossed film on the panel is considered the most durable option and has the highest resistance to damage.

Conclusion: It is recommended to use offset printing in the bathroom, and it is better to install laminated lamellas around the bathroom itself.

Another difference between PVC panels is the connection method.

- Seamless. Most often these are ceiling slats. It is assumed that the installation is as close to each other as possible, the seam becomes almost invisible.

- Rusty. Otherwise - chamfered lamellas. They also adhere to each other, forming a single canvas. They decorate the walls and ceiling.

- Embossed. The uneven coating of the plastic panels masks the seam, making the space solid. This is the most suitable option for walls, moreover, it is resistant to damage. But the cost of such finishing will increase significantly.

Conclusion: Decorate the walls in the bathroom with embossed or rustic panels.

There are 2 ways of fastening:

- Wireframe. Lamellas are installed on wooden or metal battens. The main advantage of the method is that there is no need to prepare the walls. In addition, communications can be hidden in the frame - pipes, ventilation or wires. The disadvantages are the cost (the frame can be more expensive than the planks themselves) and a decrease in the area of the bathroom by 5-7 cm.

- Frameless. The panels are fixed directly to the wall using glue, self-tapping screws or staples. Suitable only for flat walls and makes it difficult to replace 1-2 slats if necessary. But at the same time it does not make the room smaller and saves time and money on the frame.

Conclusion: Choose the installation method based on the size of your bathroom and the smoothness of the walls in it.

To summarize - when choosing pvc panels for a bathroom, first of all, pay attention to the following nuances:

- thickness from 0.8 cm;

- offset printing or lamination;

- embossed or chamfered lamellas;

- availability of a certificate of environmental safety;

- the number of stiffeners - the more, the better;

- serviceability of lock connections;

- the quality of the coating and the correct alignment of the pattern.

PVC panels: applications

This finishing material is versatile. It is used in rooms with normal or high humidity, for walls or ceilings. The limitation of use is only a low temperature - in the cold, PVC becomes brittle and breaks with little physical impact.

Decorating the bathroom and toilet with plastic is easy. At the same time, flaws, irregularities of the walls are hidden. You can also hide protruding water supply or sewage pipes - in this case, you will have to assemble a box from a metal profile or a frame from a bar.

Kitchen aprons along the plastic working area look aesthetically pleasing and beautiful

PVC sheet panels with decorative design are suitable for an apron in the sink area, a work area in the kitchen. These are glued to the wall and do not require a frame device. They are easy to clean, but do not tolerate the use of abrasive cleaning agents.

pvc kitchen aprons online

Types of plastic wall panels

By the type of connection between the panels, they are divided into three categories:

- seamless slats;

- embossed panels;

- beveled plastic strips.

Seamless slats

Thorn-and-groove connection allows installation of a continuous covering

Thorn-and-groove connection allows installation of a continuous covering

Unobtrusive joints of the panels are provided with a tongue-and-groove locking system.

One panel with its lateral protruding edge enters the groove of the next lamella, due to this, it is formed almost in the form of a solid cladding plane.

It is not recommended to mount panels directly on walls. It is not worth it to waste time and materials to obtain the perfect flat surface of the fence, in order to then close it with cladding.

Embossed panels

On its side, the panel has a thin rim, which fits completely into the groove of the next strip to a width of 5 mm.

On its side, the panel has a thin rim, which fits completely into the groove of the next strip to a width of 5 mm.

Vertical grooves on the finishing plane visually form the appearance of a fence made of wooden boards (lining).

Beveled plastic panels

Panels of this type can be quite wide. The side surface of the lamella ends with a decorative strip (chamfer). The connection method is similar to that of relief panels.

Recommendations for working with plastic when finishing

If the wall is flat, then the material can be attached directly to it. It makes sense to make a frame when you need to close the old finish (wallpaper, paint, tiles) or level the wall without plaster.

In addition, the lathing improves sound insulation, helps to retain heat, and leaves space for ventilation behind the plastic.

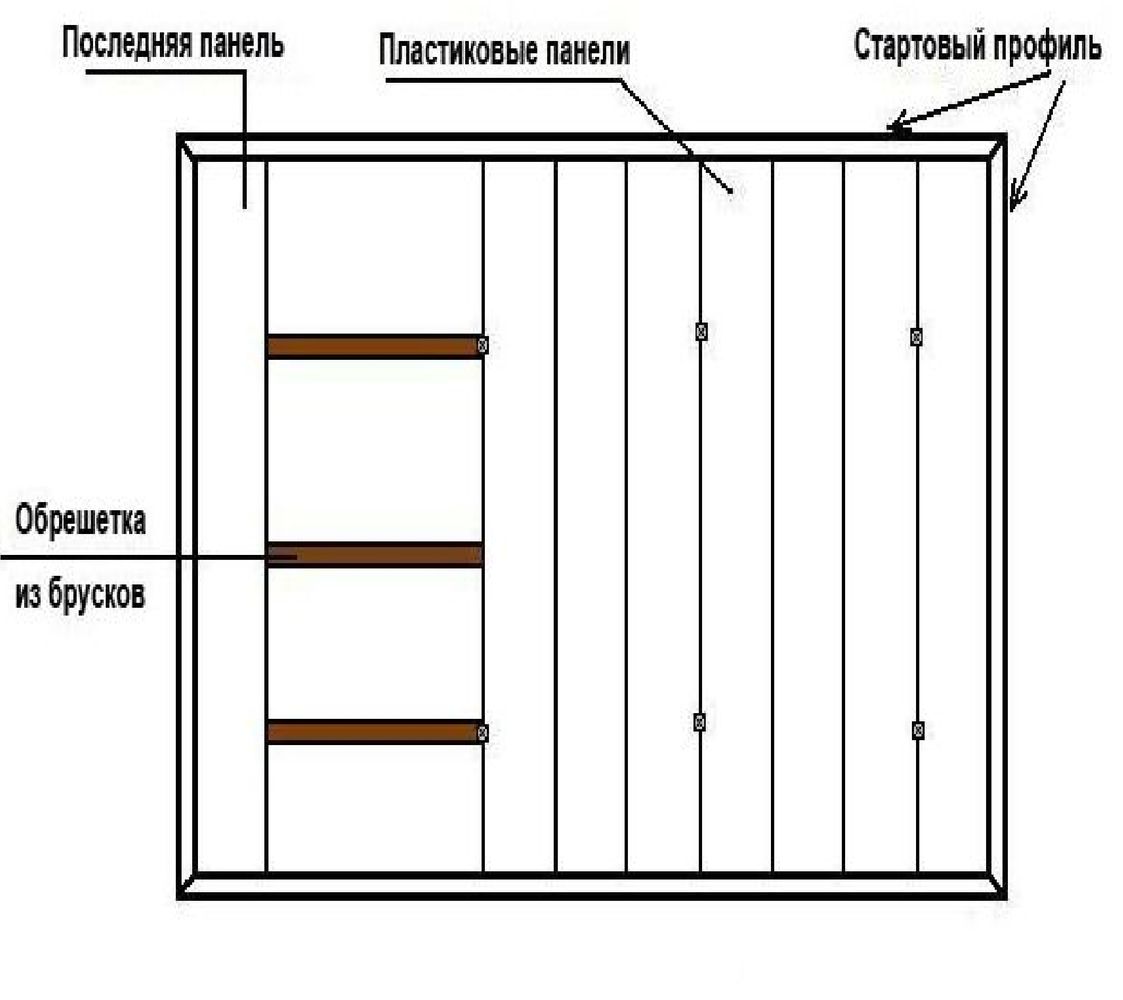

It is economical and simple to make a base from wood. Modern antibacterial compounds contribute to the long service life of timber structures. The bars are installed parallel to the direction of the PVC panels, after 50-60 cm.

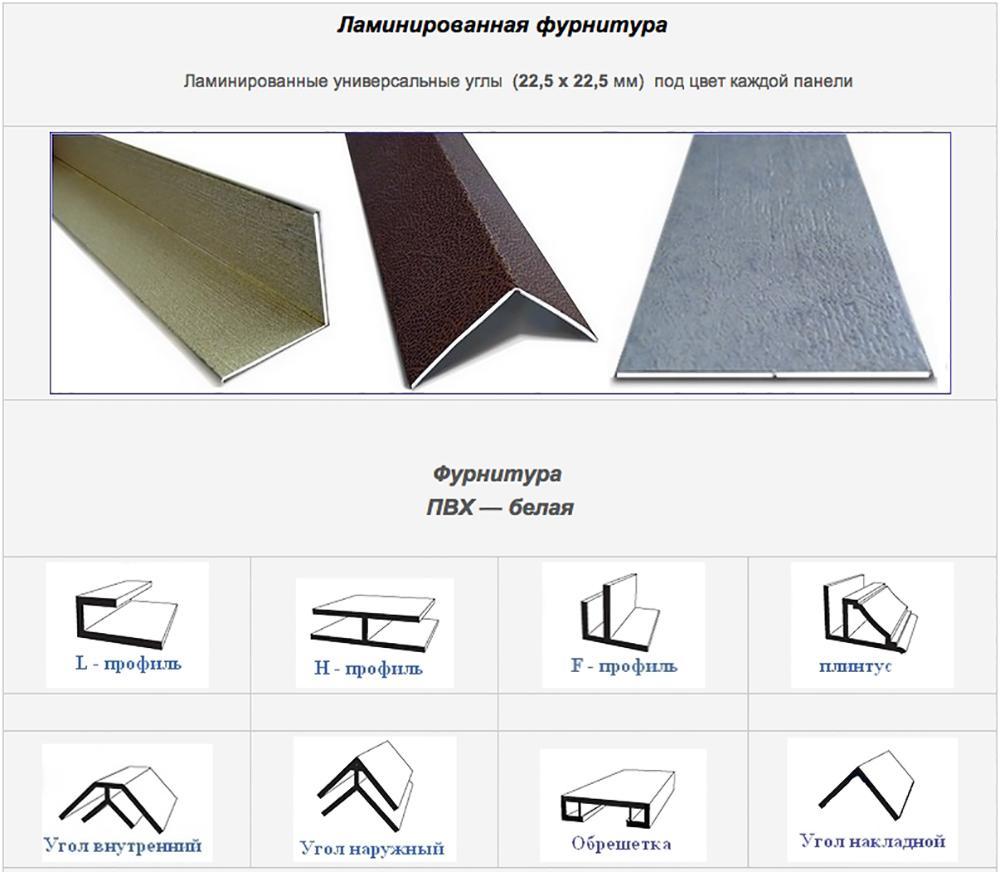

The frame is also made of U-shaped plastic profiles. Its advantage is that it is insensitive to moisture, lightweight, does not deform from temperature extremes, and is not electrically conductive.

The profile must be fixed in increments of no more than 30 cm, with self-tapping screws or dowels every 0.5-1 m. For joining the U-shaped parts to each other, cuts are made at 90˚, 45˚, 30˚. To attach the plastic, you need clamps (clamps).

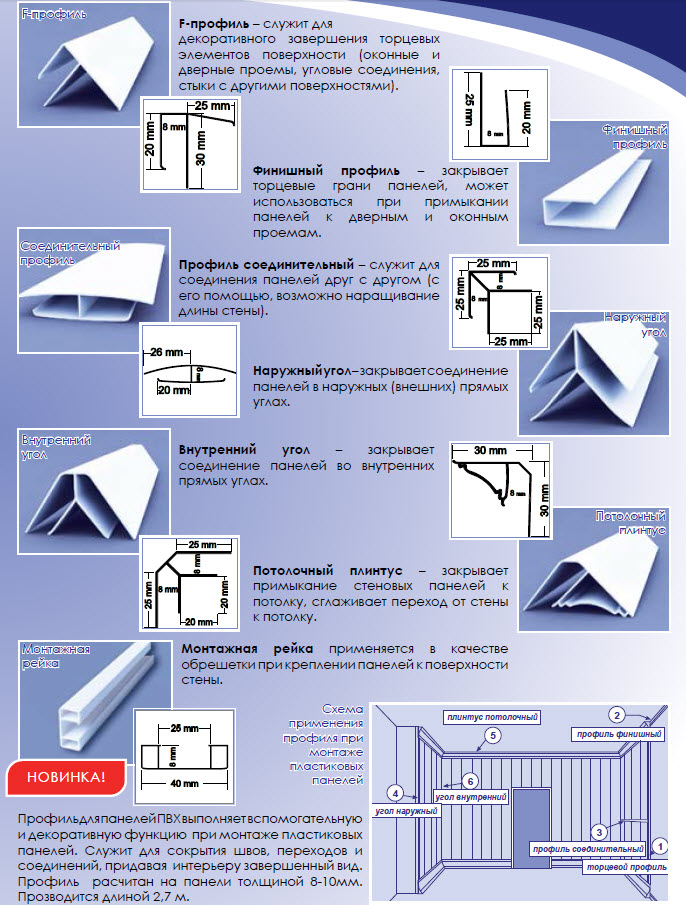

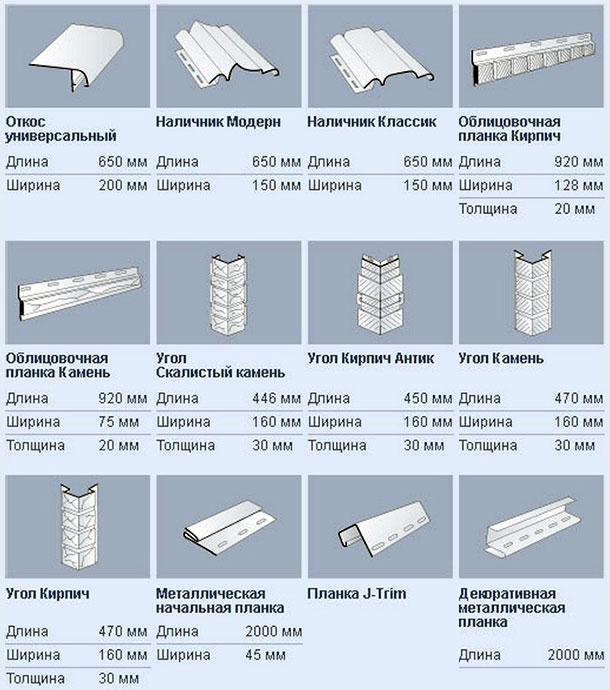

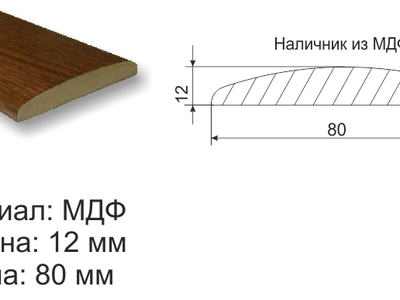

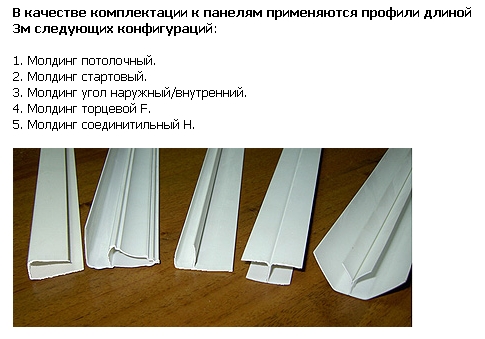

To work with panels, you will need moldings:

- internal and external corners;

- joints;

- the edges; skirting boards;

- finishing elements;

- F-profiles.

Living rooms

If treated with an antiseptic, then it is acceptable to make the frame in the living room from a wooden bar.

The premises are finished with wood, stone, white brick. Use decorative, laminated or mirror plastic.

One of the walls can be decorated with other forms of PVC material. Apply rectangular or square designs 0.3-0.98 m in size, highlight the seams.

Bathroom and toilet

For a bathroom, it is better to make a frame from a galvanized profile or plastic.The material is more suitable without a relief - fungus or mold can form from high humidity, and the textured surface is poorly cleaned.

Bathroom panels go well with ceramic tiles, textured plaster, or paint. The main thing is to choose the right shades. It will work out well if you alternate the width and contrast of the elements.

Prints and patterns in different colors will help create an original drawing. PVC panels for the bathroom go well with a slatted ceiling, into which mirror inserts can be made.

Kitchens

An inexpensive alternative to ceramics for finishing the kitchen can be economical panels (panels at low prices).

You can choose combinations for brick and natural stone masonry, mosaic, drawing or ornament.

There are tiled modular options, of which images are made; patterns are combined to decorate the kitchen completely or its individual zones.

Some additional tips:

When buying plastic material, you should pay attention to the absence of surface flaws, crumpled joints. There should be no translucency at the stiffeners.

Tears and cracks should not form if you press lightly on the product.

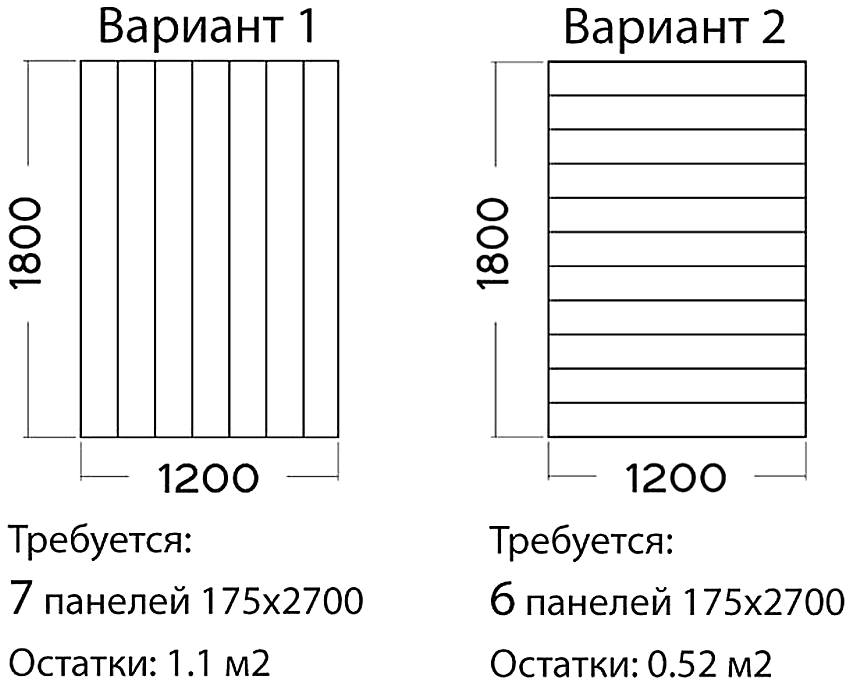

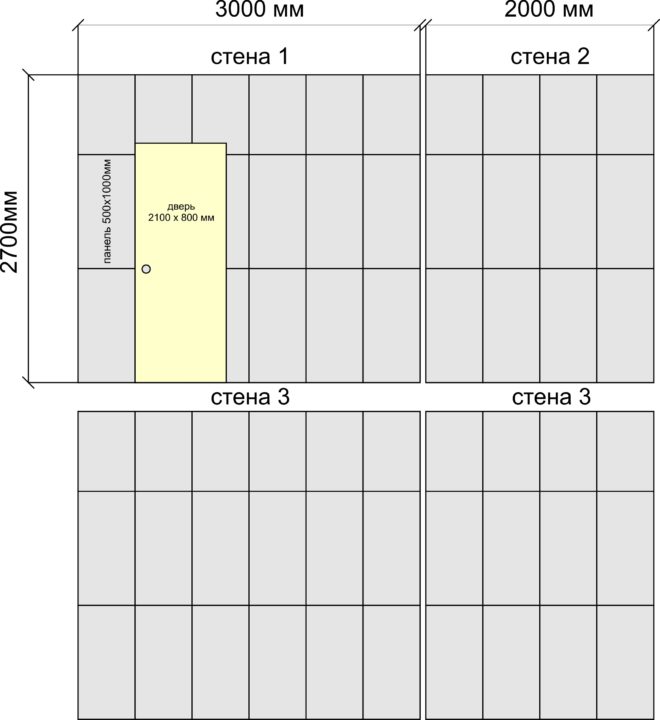

Select the width of the panels so that there is less waste

For small apartments, it is impractical to use a panel with a width of 500-600 mm.

The quality of the material can be checked by bending it. There should be no cracks or cracks.

In most cases, the more expensive the material, the better it works.

Leave (from mildew and mildew) ventilation holes.

If you want to make backlights or lamps built into it on the ceiling from PVC panels, it will not hurt to make a markup and prepare holes in advance.

Tips and tricks for working with panels

It is better to install the planks with the efforts of two people, first of all, when it comes to lining the ceiling or gluing skirting boards. When drilling and cutting panels, you need to protect your eyes with special goggles. Cut the strips with a hacksaw for metal or a hand saw. The skirting boards are attached to the plates with glue - one narrow strip is applied to the wall, the other to the finishing material. The nails in the panels are hammered carefully and slowly, because the dents formed on the PVC cannot be leveled. Installation of panels starts from the left corner of the room. The first step is to set the inner corner. The panels are mounted on the wall after installing the upper and lower skirting boards, since they need to be inserted into their connectors. Remove dirt and plaque from the finished coating only with soapy water. Aggressive cleaning agents cause yellowness over time.

A few more tips:

- The selection of the ideal size takes into account the parameters of the nests: unsuccessful calculations will lead to loss or formation of bends.

- A surface without a frame must be primed first.

Features of ceiling plastic panels

It is clear that the use of PVC for finishing the ceiling can be perceived in different ways, many apartment owners believe that this is a rather risky event, primarily due to the flammability of plastic. In fact, this is not as critical as it might seem at first glance. In any apartment or living space, there is always plenty of flammable interior items and furnishings, including PVC materials.

Polyvinyl chloride is not worse or better than other plastics, but before making your choice in favor of PVC panels, you should know about some of the features of their device:

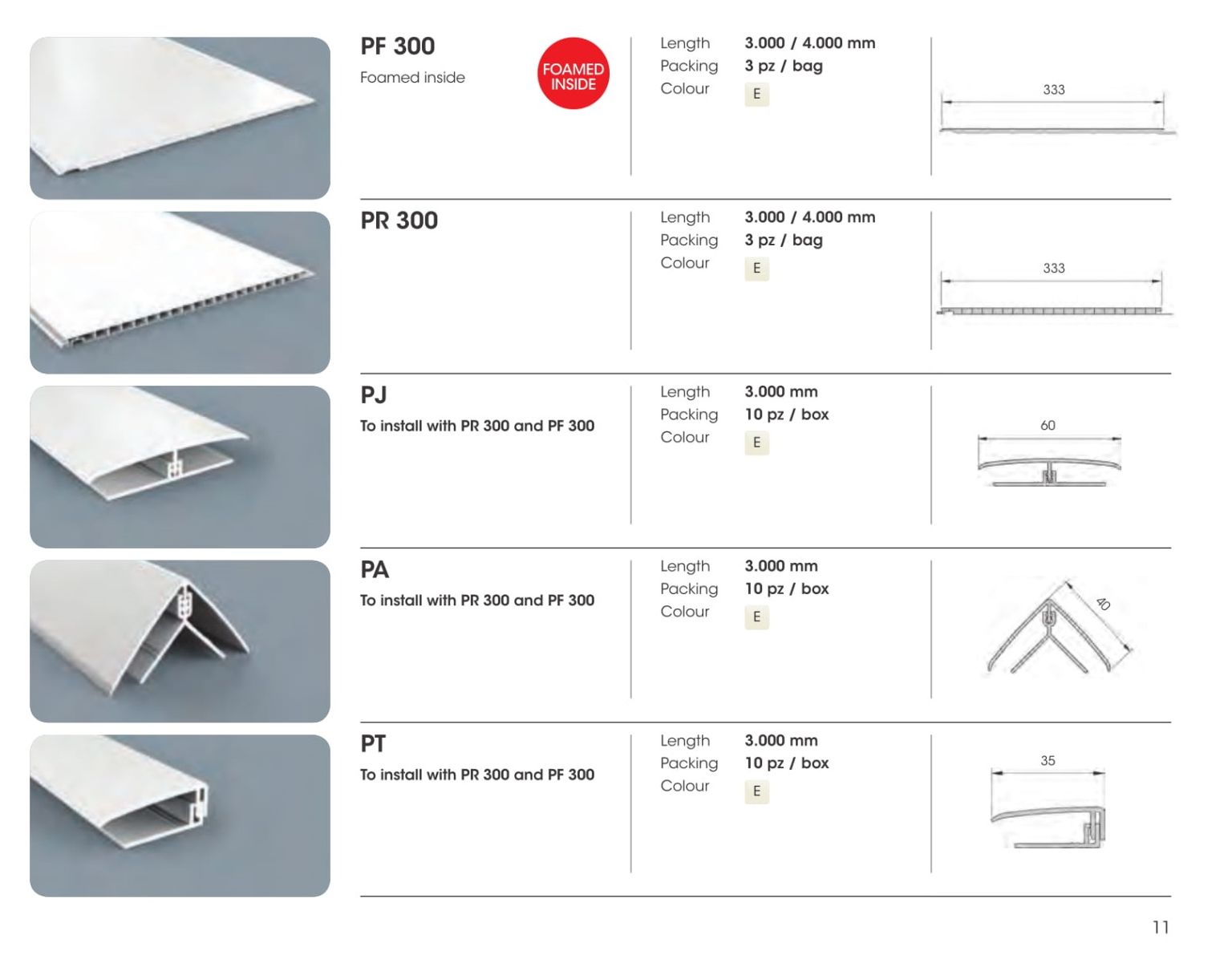

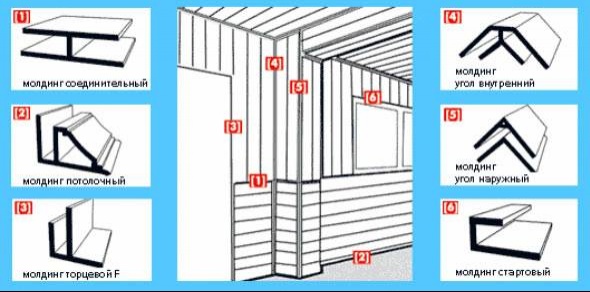

- A decorative PVC plate or lamella is a hollow panel, inside of which, with a step equal to the thickness of the material, stiffeners are soldered;

- The slab is made by extruding the melt through profiled dies - dies, therefore, the structure is cast and hollow, without pressed or glued seams;

- Standard PVC ceiling cladding is produced in the form of narrow and flat panels, up to 6 m long.

On the lateral end surface of the lamella there is a special locking profile, with the help of which several PVC boards can be connected in one plane without the formation of a through joint.

Important! The large length of the lamella and the considerable range of models of various widths make the panels convenient for mounting ceilings of various sizes. In this sense, PVC panel is much more convenient to install on the ceiling than analogues, MDF, OSB and decorative plywood

Vinyl boards for wood

What we pay attention to

Fastening of PVC panels is carried out in a type-setting way, when one lamella is joined to another with locks and at the same time is laid on a wooden frame or profile crate. The plastic itself is attached with metal clips, glue or ordinary wallpaper nails.

In addition to PVC ceiling panels, there is a fairly large number of PVC slabs and lamellas on the market intended for wall and facade decoration. Such material is much thicker and stronger than the one that goes to the ceiling lining.

Important! For continuous facing of floors, it is lamellar materials that are used. On the market you can find square slabs 60x60 cm, used by some craftsmen for gluing to the ceiling, similar to polystyrene or polyurethane

In fact, these are parts for Armstrong type suspended ceilings. They do not have locks and are not used for self-cladding of the ceiling surface.

PVC panels intended for finishing the ceiling are somewhat thinner than wall panels, it is believed that due to the "hardened" plastic, they are less durable and require more careful handling, especially when cutting or transporting. In addition, ceiling cladding is almost always produced in either a glossy or semi-matt format. You can, of course, install a PVC wall panel on the ceiling, but the appearance will not be as expressive, so it is better to leave such experiments for balconies and utility rooms.

Unpleasant features of PVC ceiling cladding

It is clear that the use of polyvinyl chloride guarantees the absence of such unpleasant phenomena as watering, swelling of the cladding due to condensation, there is no mold and mildew on PVC panels, the polymer perfectly tolerates washing and cleaning with modern detergents for washing dishes and walls.

But PVC has a couple of features that it is better to know about in advance.

- Firstly, the material does not allow air to pass through at all, therefore, the ceiling cladding with PVC panels worsens the atmosphere of the room. Water vapor is not removed as efficiently as with conventional painted or whitewashed ceilings.

- Secondly, the PVC surface perfectly reflects sound and noise, without scattering it or reducing the intensity of the sound wave. Therefore, if you cover with panels, for example, the ceiling in the kitchen, then all the sounds and noises accompanying the cooking process will be perfectly audible in the farthest corner of the apartment.

The device and properties of plastic panels

Products consist of two plates interconnected by stiffening ribs. One of the plates is the front side, which has a decor corresponding to the developed model. PVC panels are specially made so that their connection is durable and invisible. For this, their lateral edges are equipped with projections and grooves.

Plastic panels have the following advantages:

- Presentable appearance. The modern design has made it possible to create surfaces with a high artistic component.

- Waterproof. Polymer slats do not absorb moisture at all and are resistant to mold.

- Sufficient mechanical strength. This factor makes it possible to wash the finished planes using a certain pressure.

- Flexibility to avoid breakage of the slats during transport and installation.

- Low specific gravity. There is no additional load on the bearing surface.

- A variety of parameters, textures and colors of products. This quality makes it possible to unfold the imagination of designers.

- Ecological cleanliness. PVC panels can be used in any room, including hospital wards and kindergartens.

- Ease of processing and installation. You can cut the material with an ordinary clerical knife.

- The ability to disassemble the finished surface. This will come in handy when you need access to communications or to replace fragments of a suspended ceiling or wall.

- Non-flammability. The material does not support combustion.

- Low price. Plastic products are available to all segments of the population.

- Durability. Indoor plastic panels can last for several decades. Wide operating temperature range. Products do not lose their qualities, both in frost and hot environments.

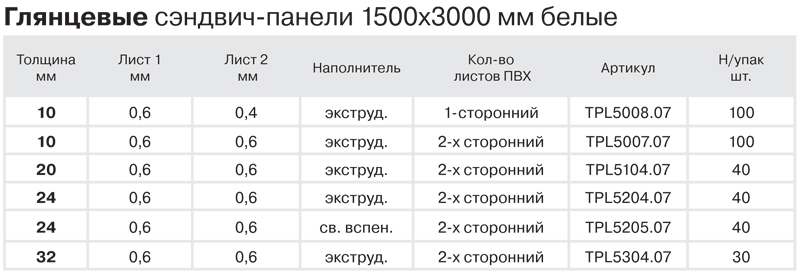

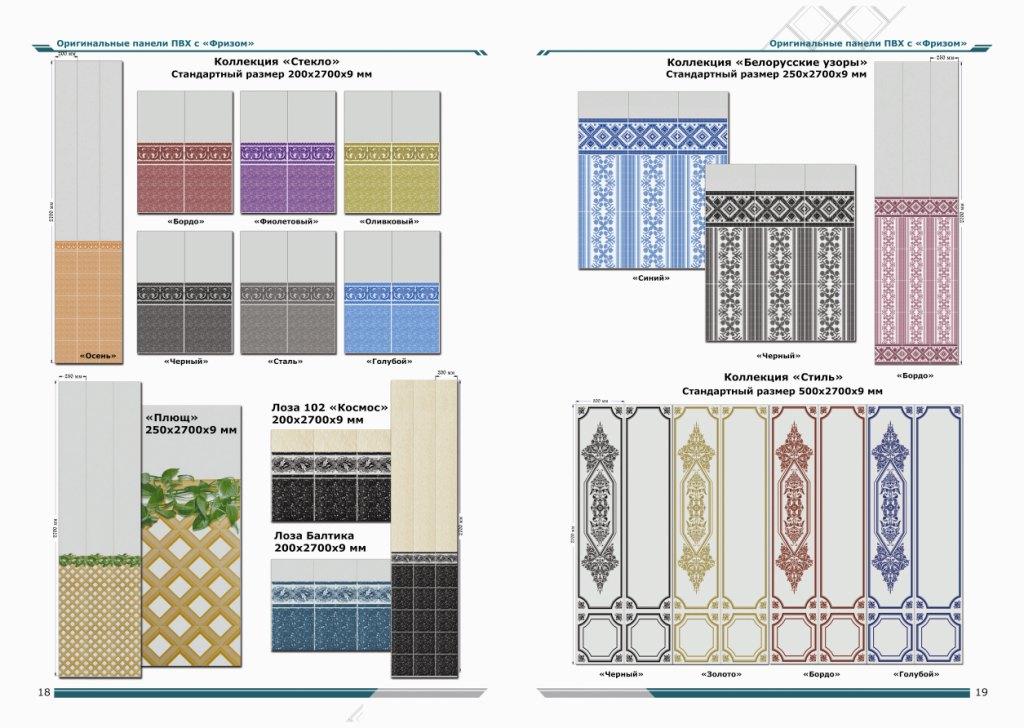

Panels of this size are in great demand and distribution.

Panels of this size are in great demand and distribution.

Plastic panels have certain disadvantages, which are that their surface can be easily scratched or squeezed. In addition, from strong heating, the material deforms and melts.

It's interesting: Knauf Perlfix glue - features and characteristics

Panel options

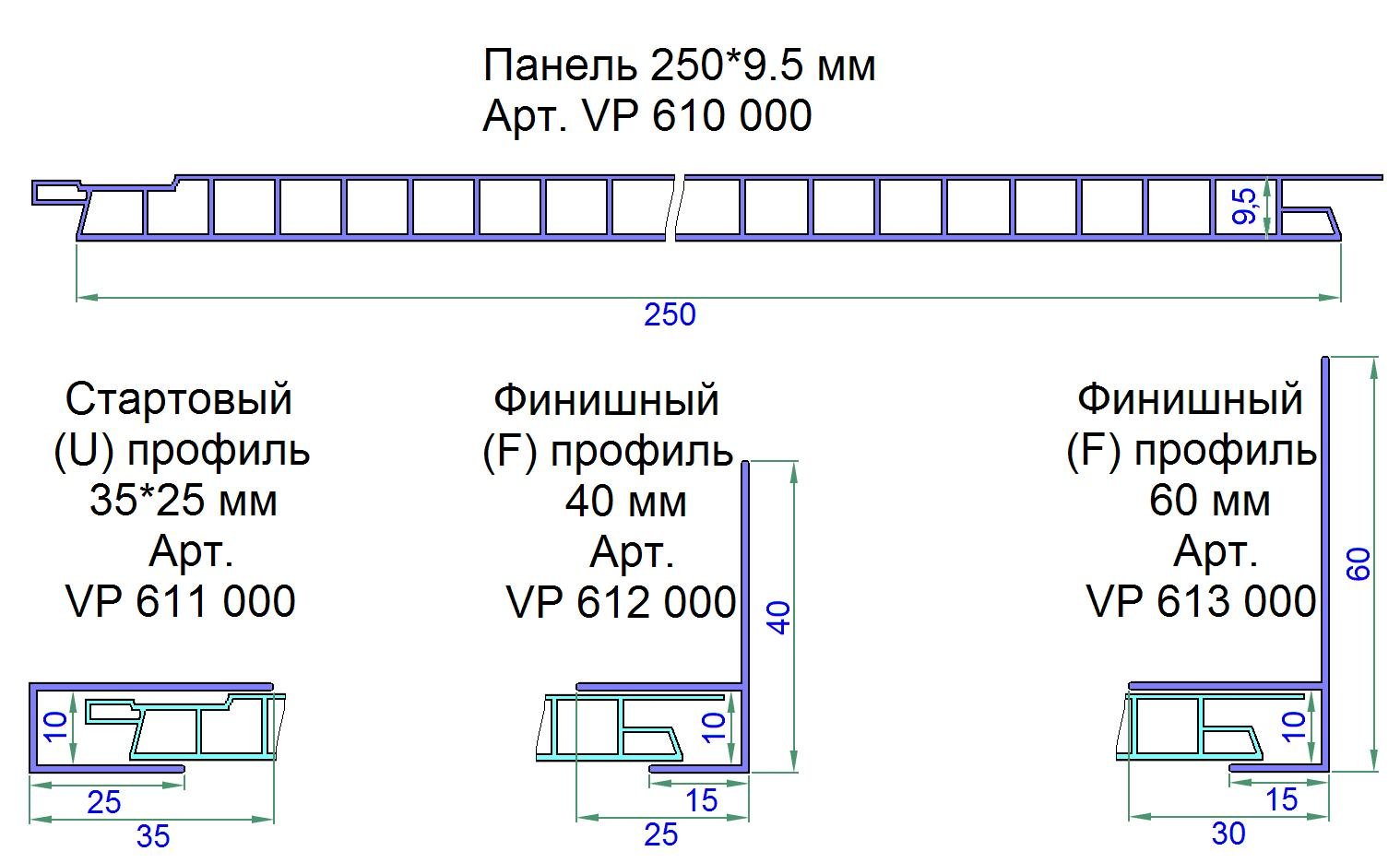

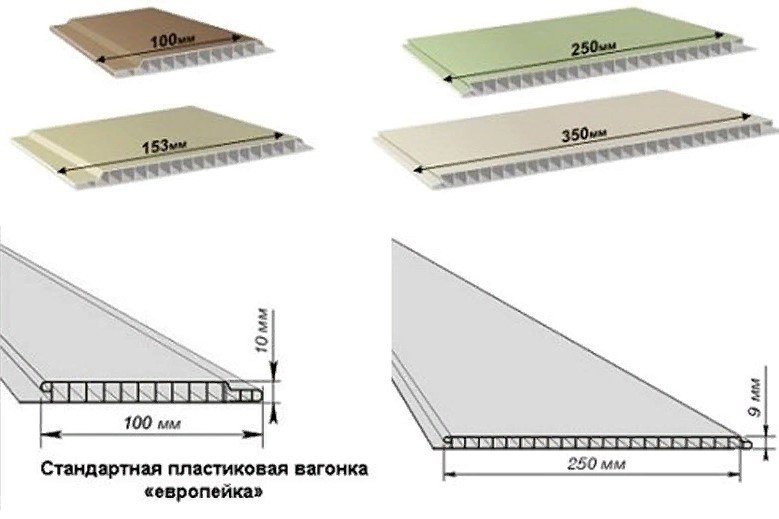

The parameters depend on the connection option and the variety of sizes of PVC panels.

The methods of connecting panels to each other are divided into three groups.

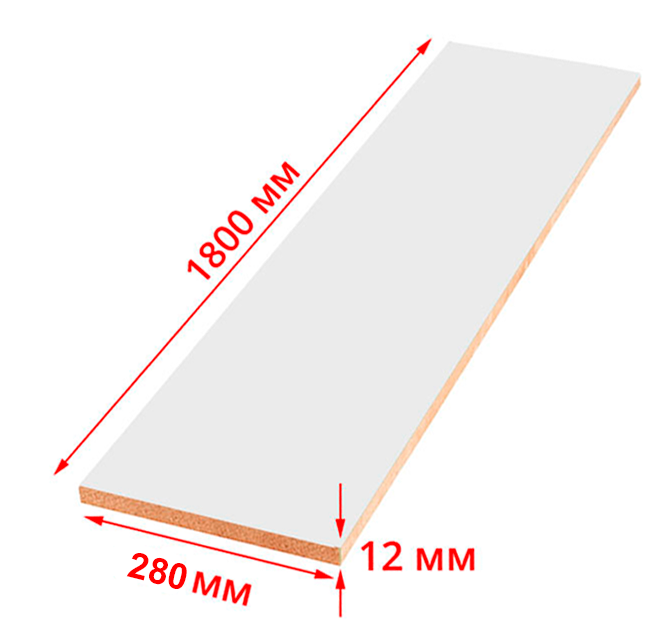

- Suture or slatted lamellas copy the lining, which is characterized by such a connection. The seam is clearly visible and is part of the design. The panels are characterized by high rigidity and resistance to involuntary disturbances. Looks like regular finishing boards. Standard size: width - from 12-30 cm, length - from 0.9-3 m, 6 m, thickness - 4-10 mm.

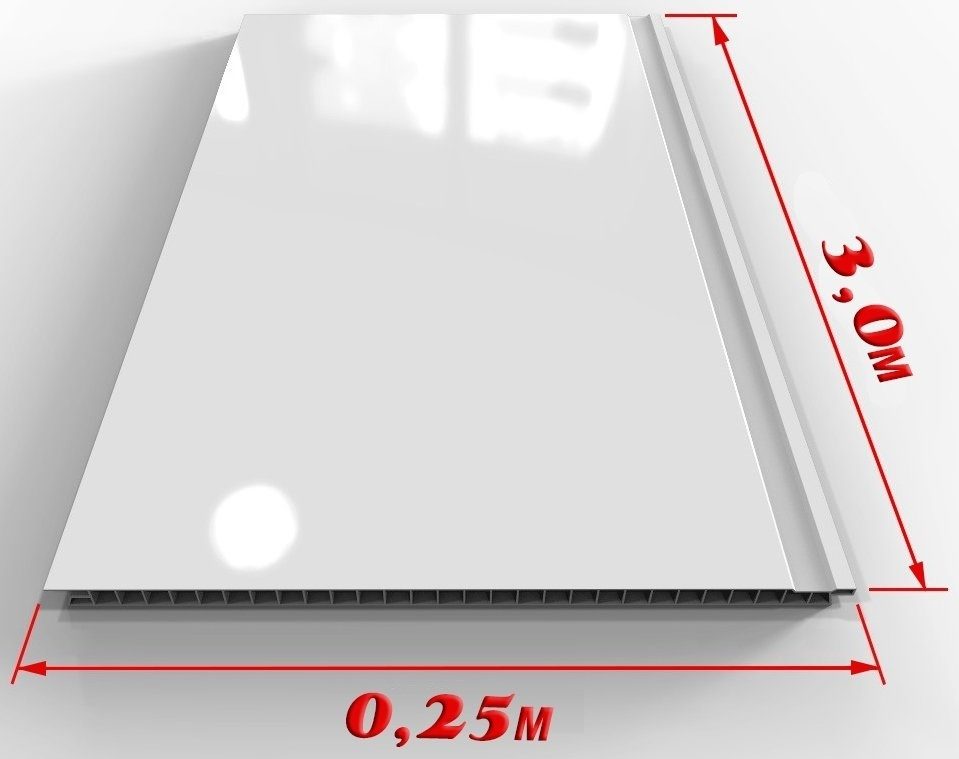

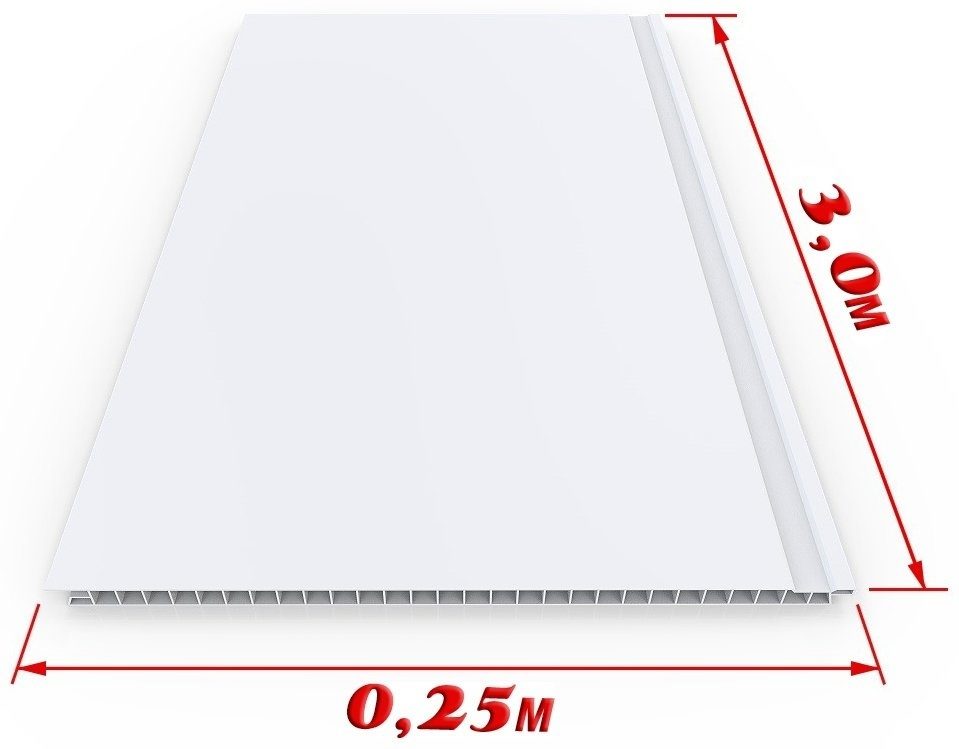

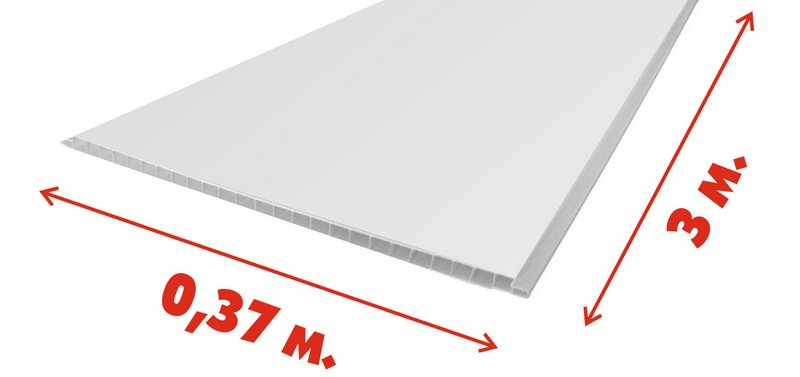

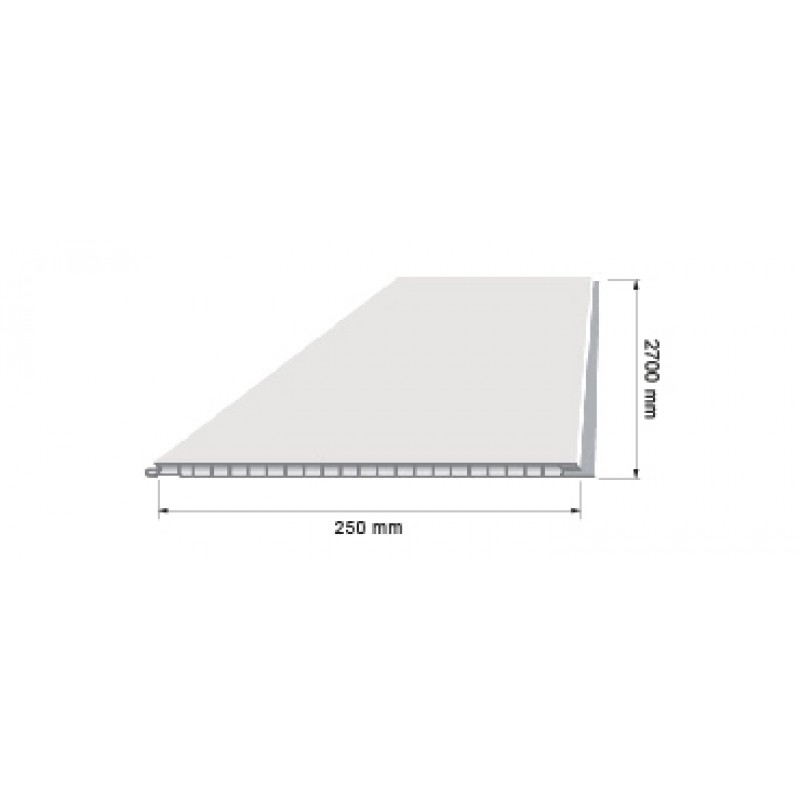

- Seamless joints are connected without a visible joint; with proper installation, a flat surface with barely visible joints is obtained. The result of installation and assembly depends on the quality of the material. Standard size: width - 15-50 cm, length - 2.7 m, 3 m, thickness - 4-10 mm.

- Rust version. To connect this group, a decorative recess is made in the profile - a groove, which has the shape of a protrusion, due to which a flat embossed surface is obtained.

There are several types of PVC panels depending on the size.

Tiled

The tile material is similar to ceramic tile. To create an unusual interior, you can combine monochromatic options with plates that imitate natural stone, have a pattern or are decorated with mosaics when laying.

Standard size: 30x30 cm, 98x98 cm, 100x100 cm, thickness 1-5 mm.

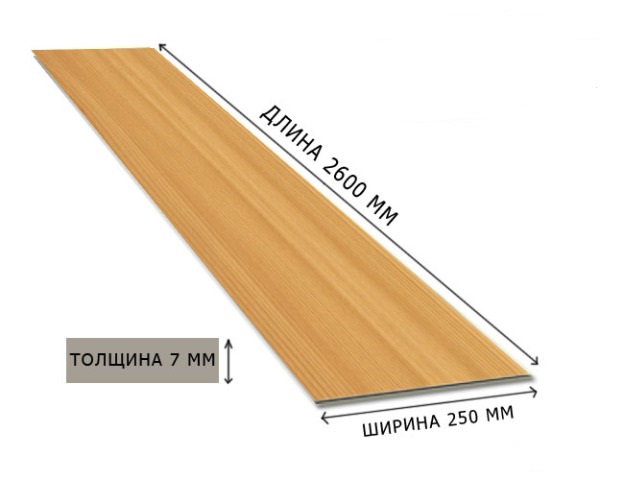

Wall

Used for wall decoration. A variety of shades, textures, textures offers to make the interior of the house stylish and bright.

Standard size: width - 15-50 cm, length - 2.6 / 2.7 / 3 m; thickness - 6-10 mm.

Leafy

They are large in size. When working with this type of panels, a significant area is covered - it will be unusual and interesting to design.

Standard size: width - 50-122 cm, length - 0.9-2.44 m, thickness - 1-6 mm.

Lining

It has a smooth glossy surface and is available in a variety of colors. The connection takes place according to the tongue-and-groove locking system, which allows installation without difficulties. Vertical laying of boards visually makes the ceiling higher, and horizontal - expands the wall.

Standard size: width - 10-30 cm, length - 0.9-3 m, thickness - 4-8 mm.