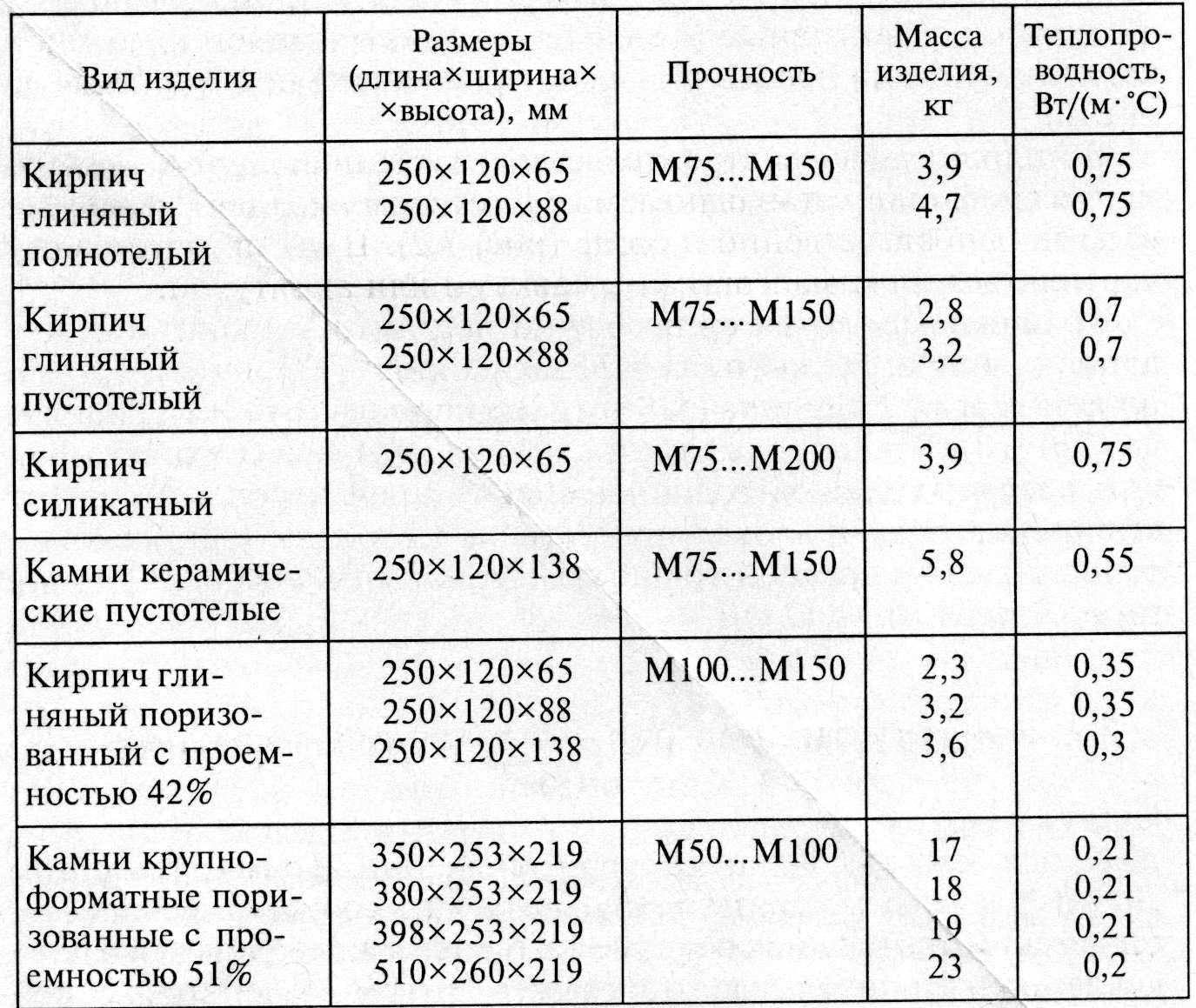

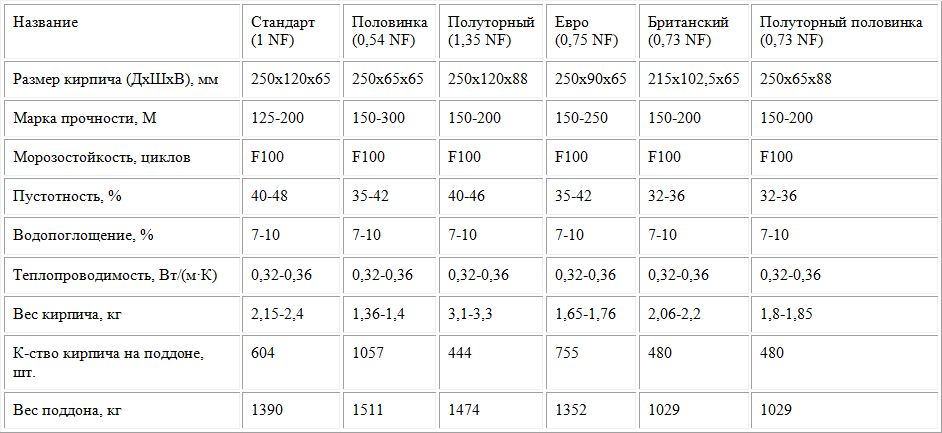

Weight characteristics of materials

For the manufacture of brick stone used in the construction industry, various materials are used, differing in performance and production characteristics of the process. All factors together set the parameters of the brick material, which is considered the most common of all the others.

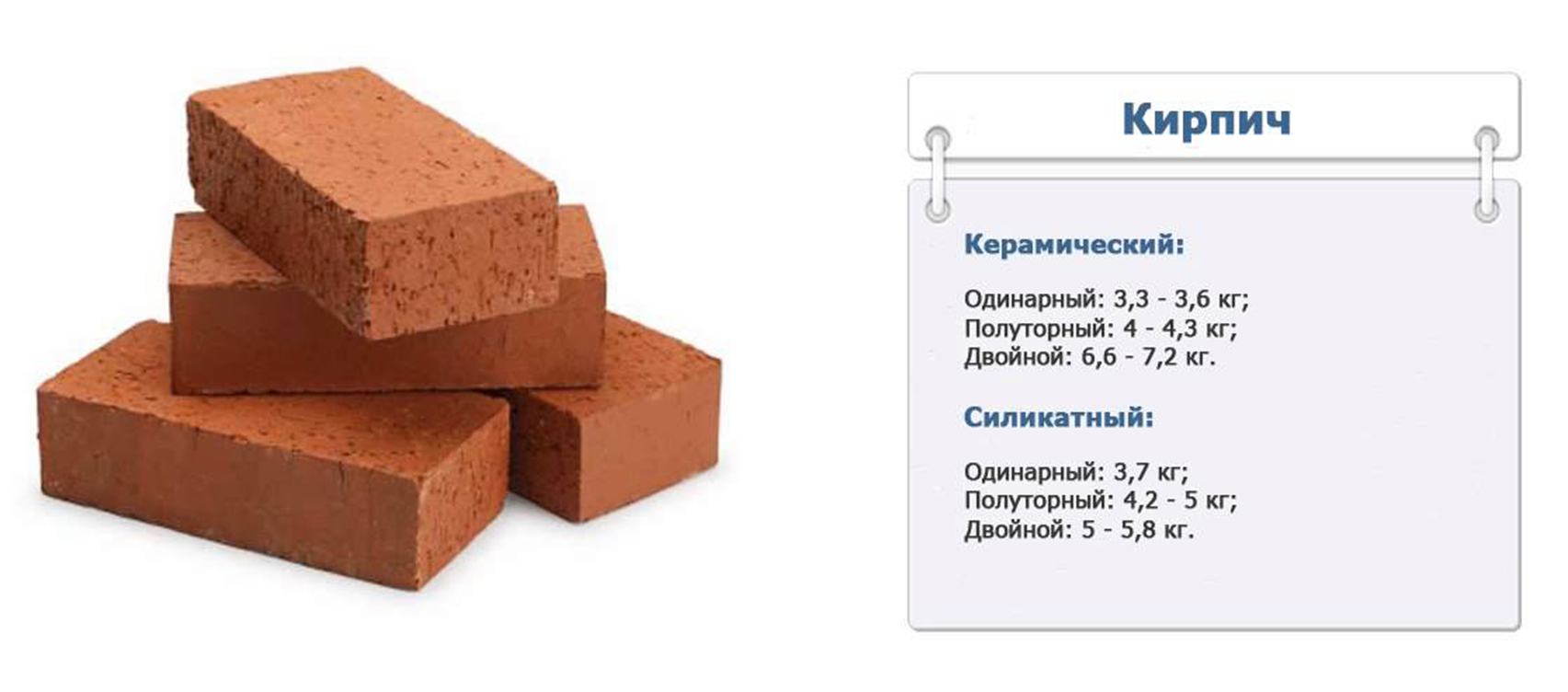

Ordinary brick

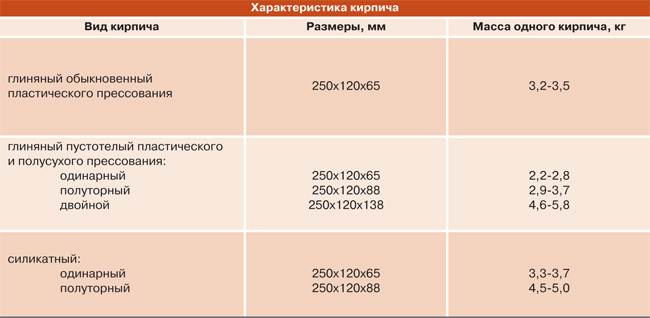

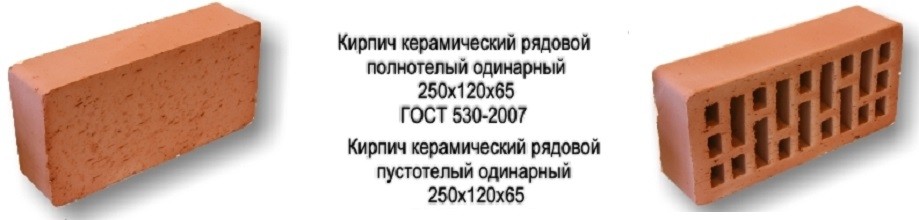

Ceramic brick stone is obtained from fired clay. The material has a high strength index, perfectly retains thermal energy, and successfully withstands environmental influences. Moreover, its weight is quite large - from 3.5 to 3.8 kg. To reduce this figure, manufacturers began to manufacture the hollow material, keeping its original dimensions. The weight of such a brick is only 2.5 kg.

It follows from this that the solid dimensions of the material ready to work do not always mean that it weighs a lot, because this indicator depends on the structural structure of the stone.

The specific gravity of brickwork of 1 m3, lined with solid bricks, will be equal to a similar volume of hollow material, because it is determined without taking into account hollow sections, but the volumetric weight will differ significantly.

In addition to these types, a brick stone is made for wall decoration, which differs in other dimensions.

This material used in the construction industry has a long history of origin, because it used to be made of clay, dried and put into business. The degree of strength of such a material, as well as the service life, left much to be desired, because the stone quickly collapsed from the effects of moisture and the sun.

Today, ceramic material is fired in kiln installations that create the required temperature regime.

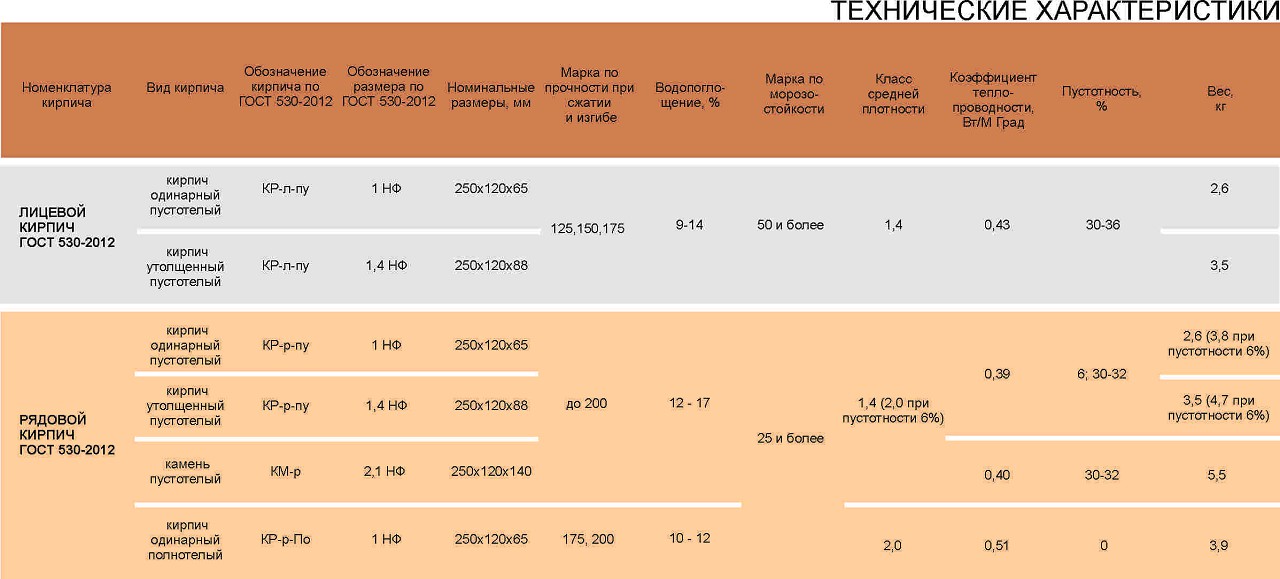

When choosing a ceramic stone, you should pay attention to its main parameters:

- the weight of 1 m3 of ceramic brickwork reaches 1.7 - 1.9 tons;

- the heat conductivity index is 0.65 - 0.7;

- the water absorption coefficient does not exceed eight percent, which is made possible only due to the porosity of the structure;

- the brand of brick stone depends on its strength and compressive resistance, denoted by numbers from 75 to 200;

- a special characteristic is frost resistance. It is determined in a cyclical way, and, if the material is of high quality, it can withstand up to fifteen freezing and thawing processes.

A large number of brick stone properties depend on the firing temperature.

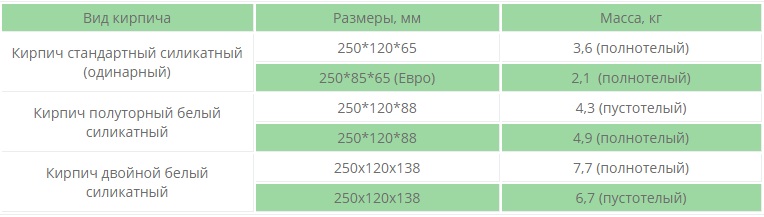

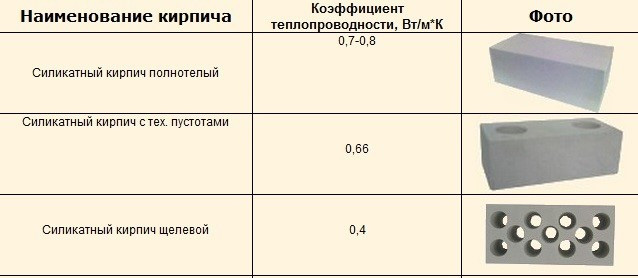

Silicate brick

In construction, this material is also popular and is considered the heaviest.

The material is distinguished by good soundproofing qualities, a long operating period, exceeding the service life of the red analogue. It is divided into working and facing stone.

The mass of brickwork in 1 m3 is influenced by the structural structure of the material:

- an ordinary brick weighs 3.7 kg;

- having voids - 3.2 kg.

It is quite natural that the parameters of one cubic meter of masonry are also different.

The first production of silicate material began in the nineteenth century. Brick is made from:

- sand, cleaned of impurities and corresponding to certain characteristics;

- quicklime;

- specially prepared industrial water;

- additives and additives that increase the value of the strength of the material.

Especially popular today is a double silicate brick, which has improved characteristics. It is produced as follows:

- all ingredients are mixed in certain proportions established by the technological documentation;

- the composition is molded, sent to autoclaves for firing;

- the products are subjected to high pressure in order to achieve the desired compaction of the brick material.

Cement mortar

The consumption of mortar material depends on numerous parameters - the dimensions of the brick, the width of the seam row, etc.

Wide seam areas increase the consumption of the mortar mixture. In addition, the weight of the solution is influenced by the brand of cement material and its volume required to prepare the mixture. As a rule, up to 0.3 m3 of mortar is required for laying one cubic meter of masonry, which will be approximately five hundred kilograms.

What is the weight of a brick in 1 m3

- Ceramic red

- Silicate brick

Brick is a building material obtained by firing mineral raw materials. Depending on what is the basis - clay or lime - the output will be ceramic (red) or silicate (white). Each of these types has its own parameters. Accordingly, in 1 m 3 there will be a different number of units, and this cube will have different mass.

The weight of a brick is influenced by the material from which it was made.

The weight of the finished product depends on several parameters - in addition to the composition, production technology plays an important role. Moreover, during manufacture, as a rule, minor deviations occur. They can be expressed in a change in both the processing mode and the raw materials used. Therefore, the weight of a brick, as well as 1 m 3, cannot be an absolutely accurate value. Each type has its own tolerances.

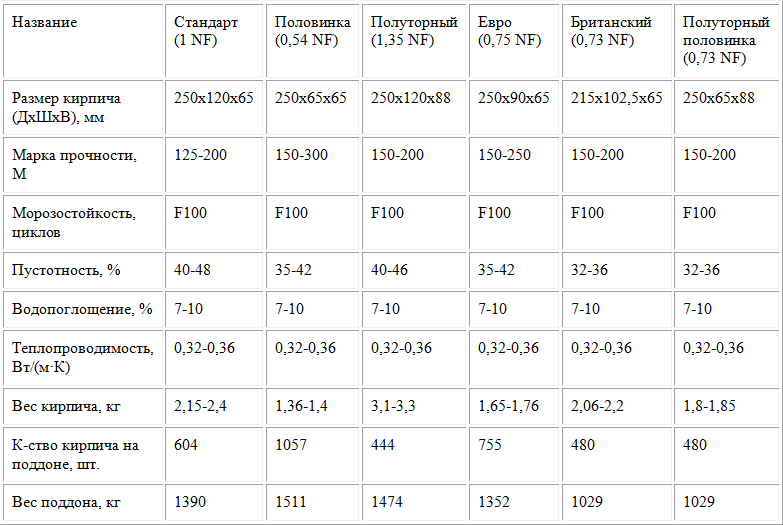

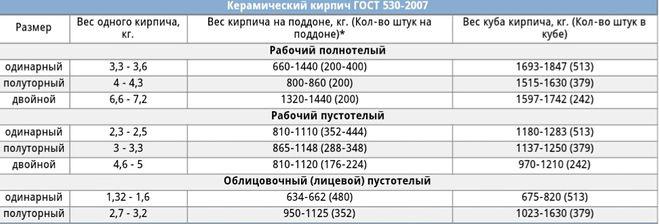

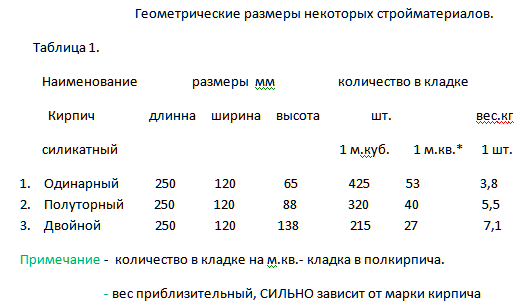

Dimensions and weight according to GOST

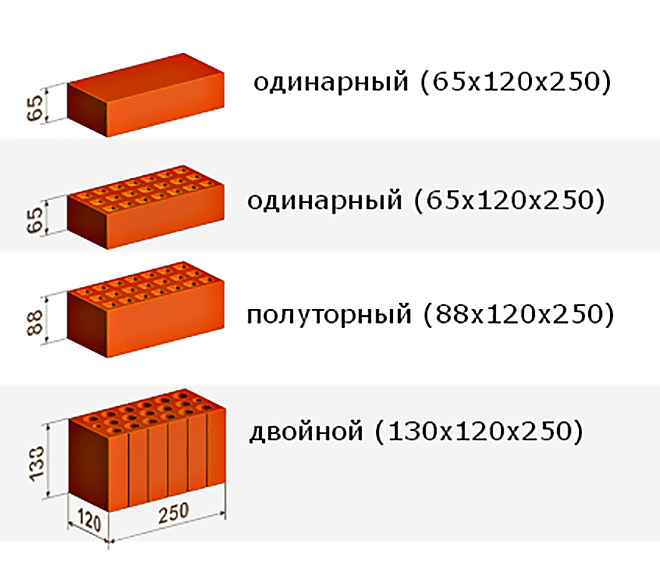

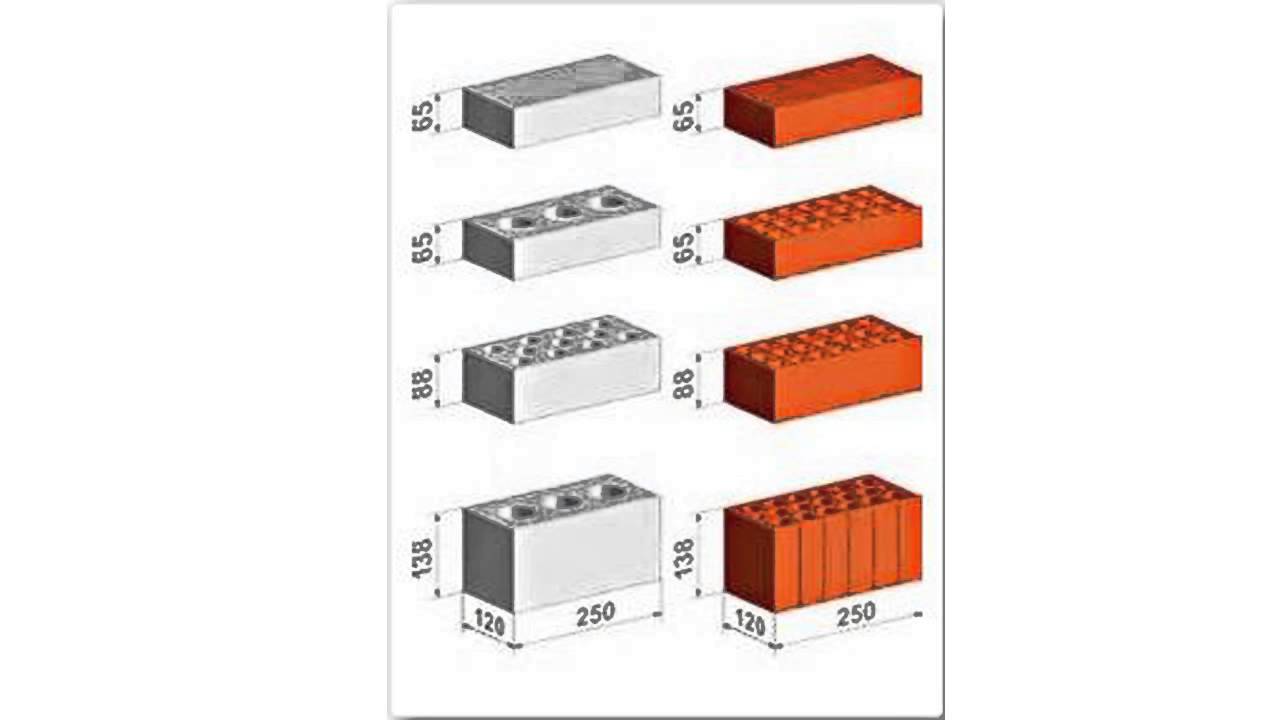

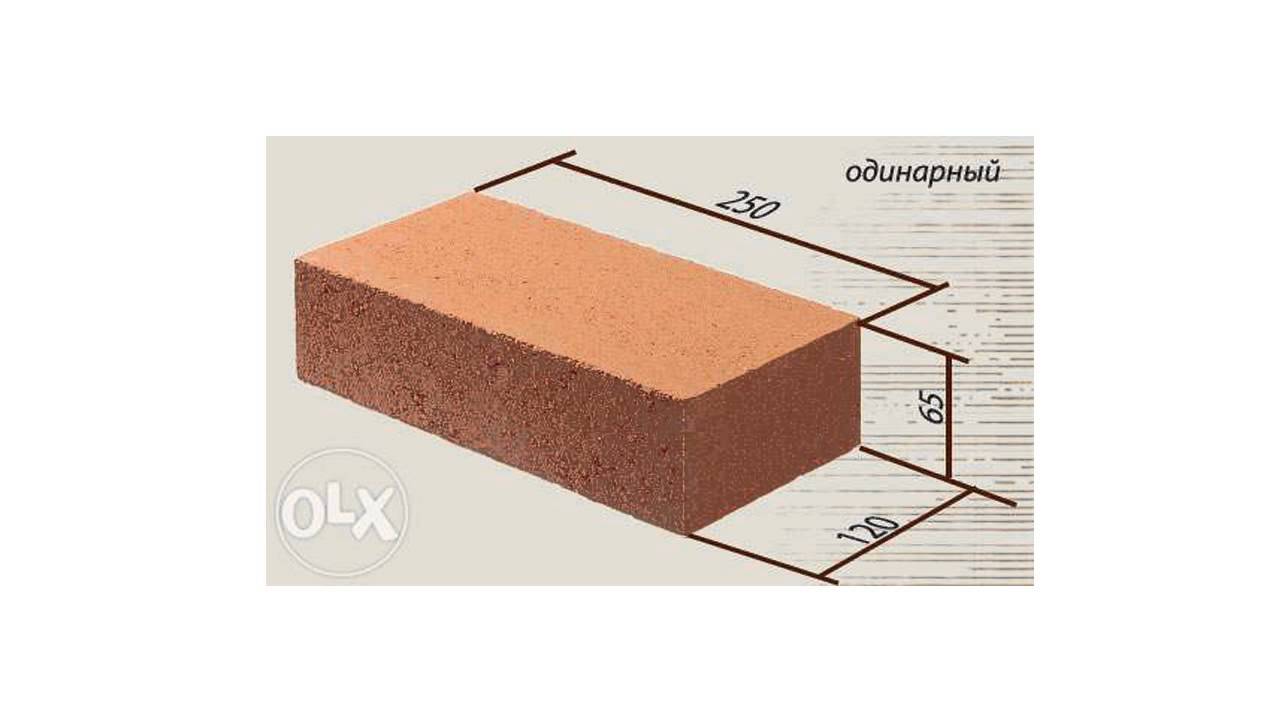

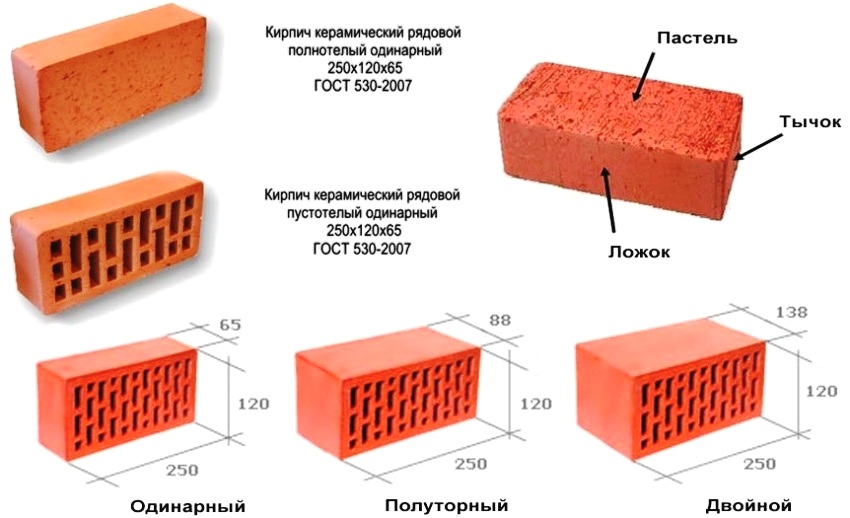

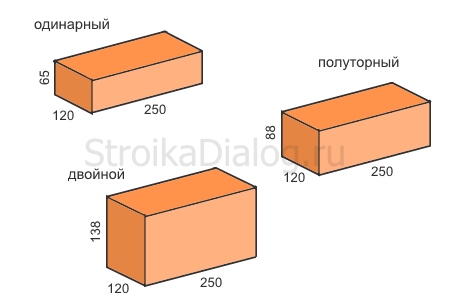

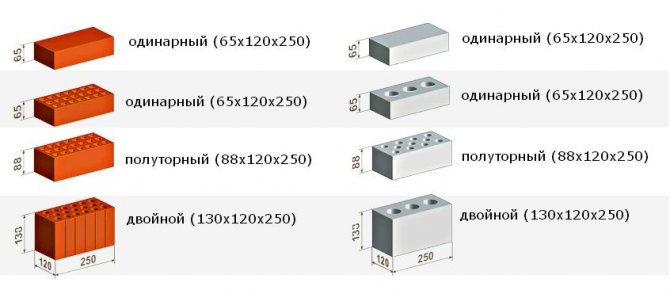

Standard sizes for single, one and a half and double products:

When designing buildings and structures, all characteristics are taken into account, including the overall dimensions and weight of red brick.

Manufacturing products according to uniform dimensions allows the designer to easily select elements of a certain format for construction or cladding, and knowing their approximate weight - correctly calculate the loads of the structure being erected on the foundation.

It will be possible to purchase the material from any manufacturer and at any time after the preparation of the project.

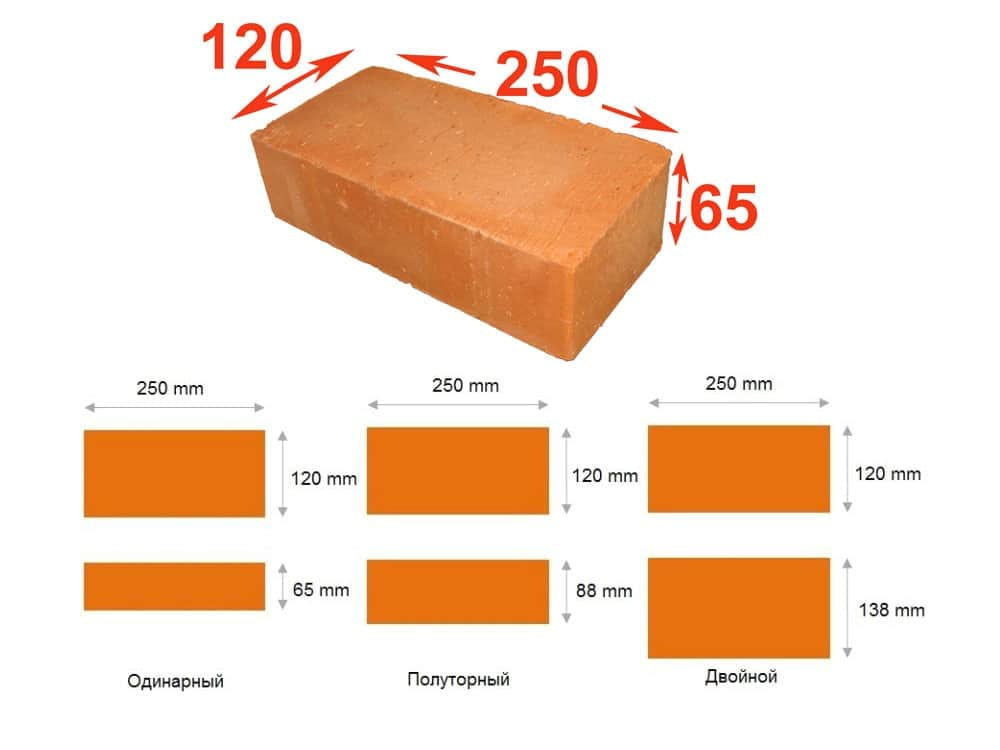

Standard sizes of red brick in normal (regular) 1NF format:

- length - 250 mm;

- width - 120 mm;

- height - 65 mm.

It is the dimensions of single elements provided for by GOST that are a kind of starting point - i.e. a material with other parameters will have a different marking instead of 1NF, where the number denotes its proportions of the ratio with a single one.

So, the size of a one-and-a-half red brick will already be 250 × 120 × 88 mm, and will be designated as 1.4 NF. Products of these formats are produced as ordinary and facing.

The list of sizes of facing red bricks can be supplemented with euro format products (0.7NF, 250 × 85 × 65 mm), and ordinary ones - with double elements (2.1 NF, 250 × 120 × 138 mm).

Dimensions of red brick euro format

Thin face material (euros) will help reduce the financial costs of facing, and a large stone (double) will significantly speed up the process of building a house.

Many are often interested in the question of how thick the red brick is. For materials of basic formats (single, one and a half and double) it is standard - 120 mm.

The exception is euro size elements, the width of which is reduced to 85 mm.

Deviations from standard dimensions

According to GOST, the maximum permissible deviations from standard sizes on one element (regardless of the format) are:

- in length ± 4 mm;

- in width ± 3;

- in thickness ± 2 mm for front and ± 3 for ordinary material.

Standard red brick weight

The GOST does not reflect information on how much a single or red brick of other dimensions weighs - the standard indicates only material classes in terms of average specific gravity.

Depending on the class of average density, the products are divided into several groups according to thermal characteristics:

- 2.0 and 2.4 - ineffective (normal);

- 1.4 - conditionally effective;

- 1.2 - effective; 1.0 - increased efficiency;

- 0.7 and 0.8 - high efficiency.

Before proceeding directly to the question of how much 1 standard red brick weighs, you need to consider its types depending on the structure.

The material is available in several options:

Hollow (slotted)

With the amount of voids up to 45%. It is much lighter than corpulent, but less durable.

Corpulent - the number of voids is no more than 13% of the total volume of red brick. It differs in a larger mass, but the strength characteristics of the elements are an order of magnitude higher.

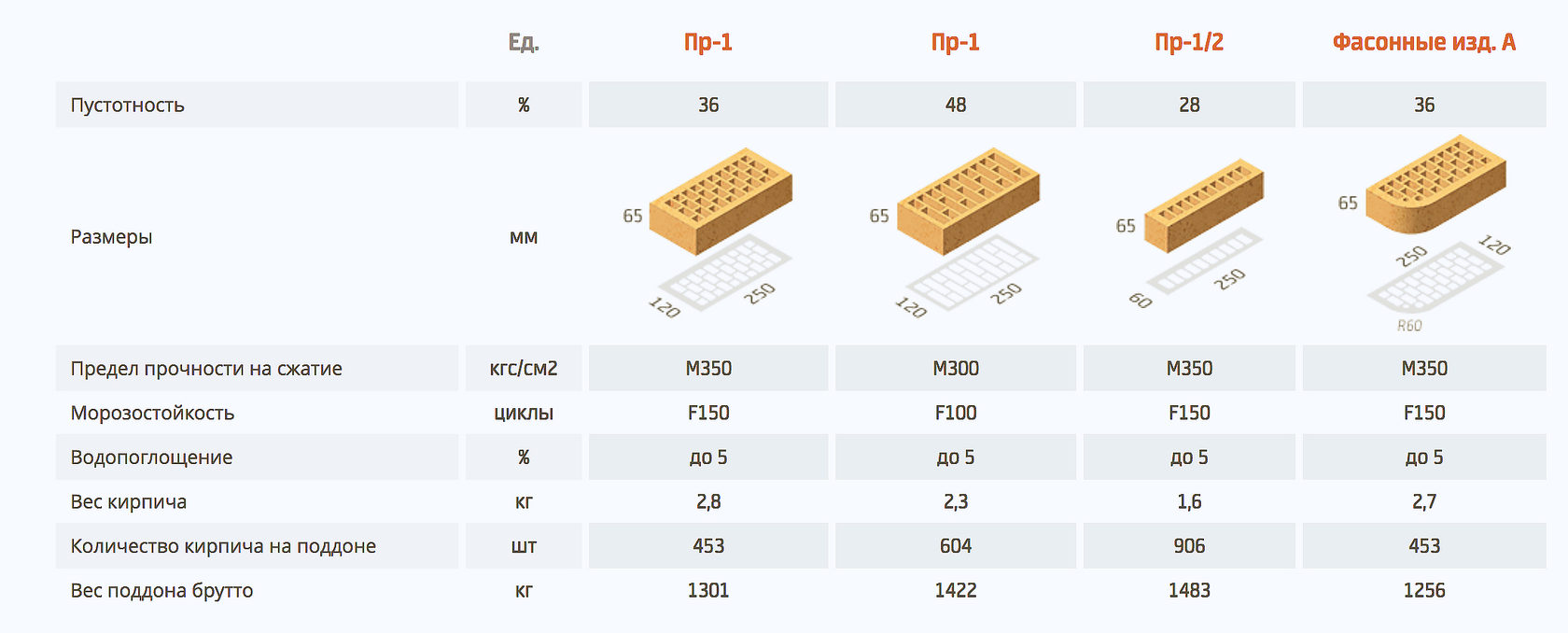

Table 1. Weight (weight) of red bricks of single (250 × 120 × 65 mm), one and a half (250 × 120 × 88 mm), double (250 × 120 × 138 mm) and euro (250 × 85 × 65 mm) formats:

The weight of a red facing brick does not differ from the weight of an ordinary hollow brick. The only thing worth noting is that cladding products are produced only 0.7NF, 1NF and 1.4NF, and there are no double formats for finishing work.

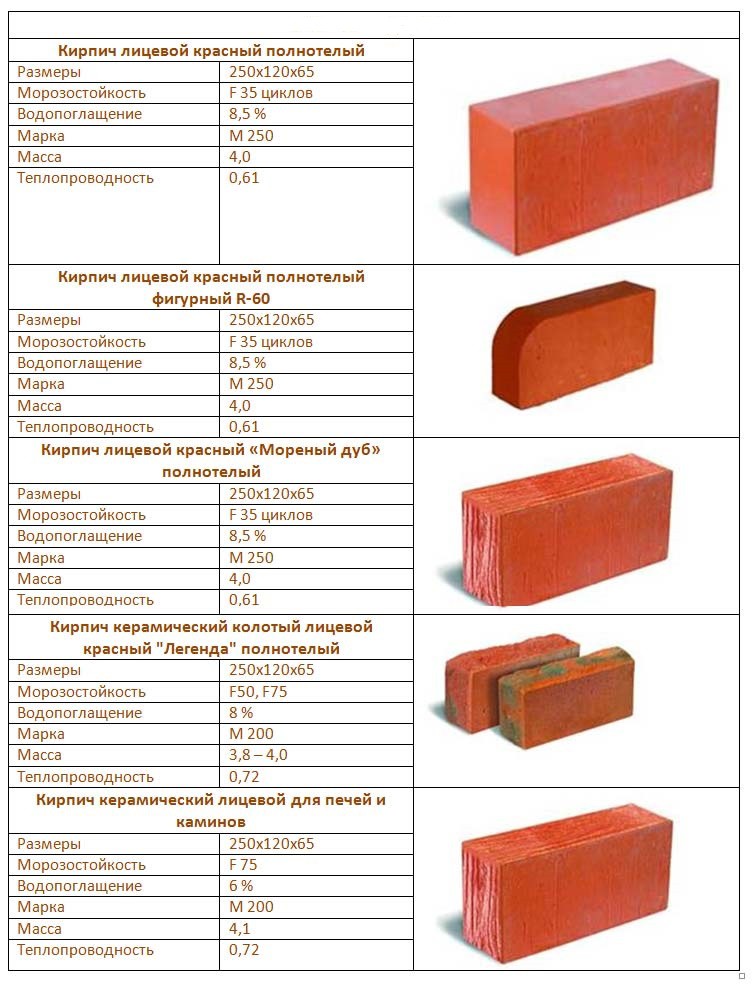

How much does an oven red brick weigh?

Kiln brick

Interested in the weight of red oven bricks, many consumers do not know its main purpose - this is a brick with increased characteristics, but not refractory.

Note! A material made of ordinary clay is intended for laying the body of the stove and chimney. If you need elements for laying out the internal heated surfaces of the furnace, then for this, special refractory products made from special types of clay are used.

If you need elements for laying out the internal heated surfaces of the furnace, then for this, special refractory products are used, made of special types of clay.

Standard kiln material also has a fairly high heat resistance and increased density compared to traditional building or cladding products.

In this regard, to the question of how much a red brick weighs for a stove, one can unequivocally answer that it is heavier than the usual corpulent one and its mass is in the range of 3.7-4.2 kg.

Recommendations

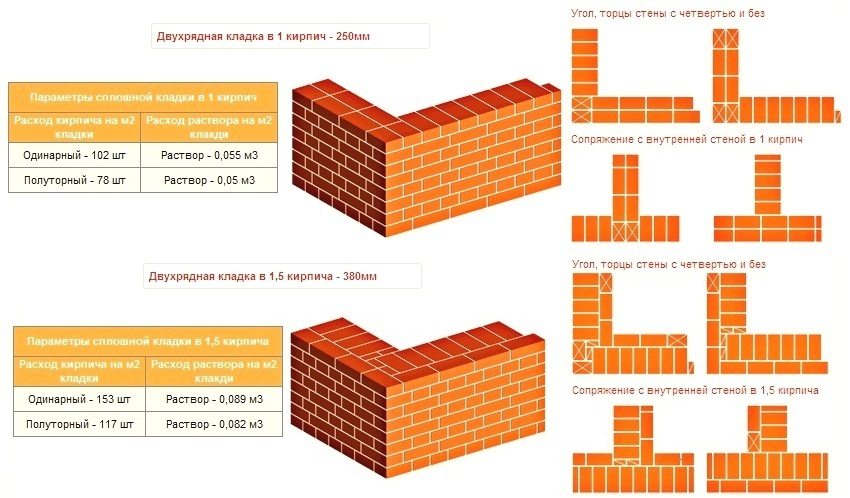

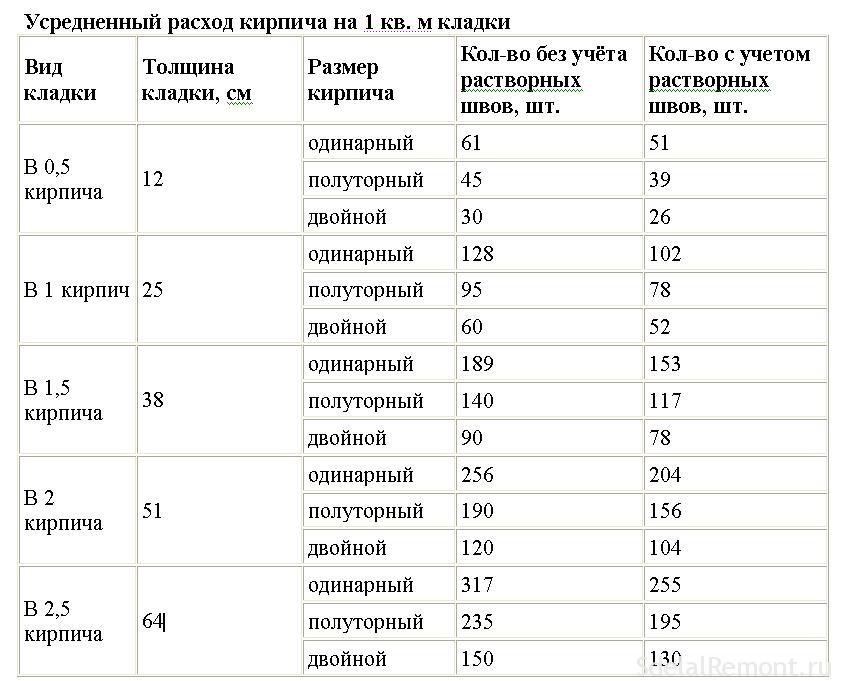

During the construction of walls, they perform not only the calculation of bricks in a cubic meter, but also in squares. Like the calculation in m3, this indicator is influenced by the dimensions of the products and the way they are laid, as well as the preferred seam thickness.

When planning a construction site, do not forget that material damage is possible. Therefore, it is necessary not only to determine the exact number of bricks in 1m3, but also add about 5% to the figure obtained after the calculations.

For a square meter, the walls are determined as follows:

- To determine the area of an individual element: multiply 25 by 6.5 and get 162.5 cm2.

- Since one square meter contains 10,000 cm2, further calculations are carried out as follows: 10,000 is divided by 162.5, which gives 61.5 pieces of bricks.

If one-and-a-half products are preferable, then to determine their number, 25 is multiplied by 8.8 and 220 cm2 is obtained. After that, 10,000 is divided by 220 and 25 bricks are obtained. The number of double stones is determined in the same way.

Using this method, products of unusual sizes are also counted, but using the parameters of the sidewall of a brick, and divide the square meter by the resulting number.

To account for the seam, add 10-12 mm.

Since the material can be laid in different ways, the wall thickness in each structure is different. This can also affect the consumption rates for 1m3 of inserts.

If the volume of construction is small, then this fact may not be taken into account.

But for large-scale construction, you need to pay attention to any little thing, since due to the wrong approach to work, you will have to re-purchase material and stop the entire process of building buildings

Consumption rate for 1m3 of the insert may vary. To determine the indicator, the total wall area is determined.

Before construction, you first need to find out how many bricks are in 1m3 of the bed, a calculator will help with this. This data will help you buy as much stone as you need and avoid work downtime.

It is important to take into account the number of bricks in 1m3 of the lining, taking into account the mortar, since this indicator will affect the total amount of products

In the absence of additional time to determine how much ordinary brick is in a cube, you can use special tables. They contain data for which you can navigate during the calculation the amount of materials intended for the construction of the building.

It is important to remember that each building has its own architectural features. It also depends on them whether less or more bricks are needed.

Therefore, even if super-accurate calculations are made, it is better to buy a little extra material. Indeed, in the process of work, various difficulties may arise, for example, scrap bricks. Other items of expenditure are also appearing.

If you correctly determine how much stone is needed, you can find out if the financial security is in line with the plan. Otherwise, if a lack of funds is discovered already at the stage of building a house, then you will have to change the project, stop the construction until better times, and this can be significantly delayed.

Through costing, you can prevent additional costs from occurring. You don't have to buy a brick again, pay for its delivery to the site. It is advisable to take products in batches so that they do not differ in color. If there is too much material, it will clutter up the space, which will cause inconvenience during work.

If you approach the process with all responsibility, make the correct calculations, then the construction will be completed as soon as possible, there will be no downtime and delays.

Calculation examples

Recently, many land owners prefer to engage in the construction of houses and outbuildings on their own. Of course, this process is considered complex and requires certain knowledge, but if you draw up a project correctly and calculate the consumption of bricks, then in the end you will be able to build a beautiful and durable building. The following examples will help beginners in calculating building materials.

The consumption of red solid bricks for the construction of a two-story house is 10 × 10 m. First of all, you need to know the entire length of the outer ceilings. Since the building will have 4 walls, the total length will be 40 m. With a ceiling height of 3.1 m, the area of the outer walls of the two floors will be 248 m2 (s = 40 × 6.2). From the resulting indicator, you will have to subtract individual areas that are distant under door and window openings, since they will not be lined with bricks. Thus, it turns out that the area of the walls of the future house will be 210 m2 (248 m2-38 m2).

For the construction of multi-storey buildings, it is recommended to make walls at least 68 cm thick, so the masonry will be made in 2.5 rows. First, the laying is carried out with ordinary single bricks in two rows, then facing with facing bricks is made in one row. The calculation of blocks in this case looks like this: 21 × 210 = 10710 units. In this case, a single ordinary brick for floors will be needed: 204 × 210 = 42840 pcs. The weight of the building material is calculated by multiplying the mass of one block by the total amount

In this case, it is important to take into account the brand of brick and its features.

Consumption of solid red brick for laying a wall is 5 × 3 m. In this case, the surface area that needs to be laid out will be 15 m2. Since for the construction of 1 m2, you need to use 51 pieces. blocks, then this number is multiplied by the area of 15 m2. As a result, it turns out that 765 bricks are required for the construction of a 5 × 3 m floor. Since it is necessary to take into account mortar joints during construction, the resulting indicator will increase by about 10% /, and the consumption of blocks will be 842 pieces.

Since up to 275 units of red solid bricks are placed on one pallet, and its weight is 1200 kg, it is easy to calculate the required number of pallets and their cost. In this case, to build a wall, you will need to purchase at least 3 pallets.

For an overview of the characteristics of the red full-bodied Votkinsk brick M 100, see below.

Brick sizes, determined by GOST.

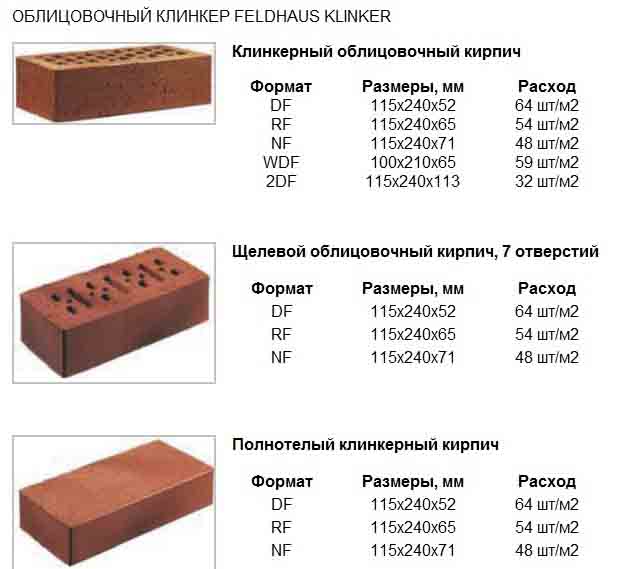

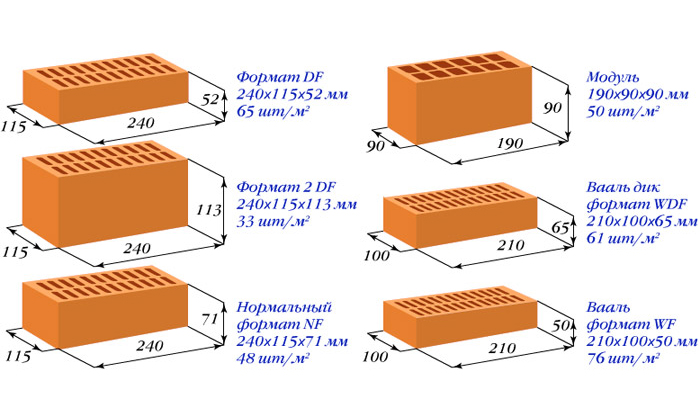

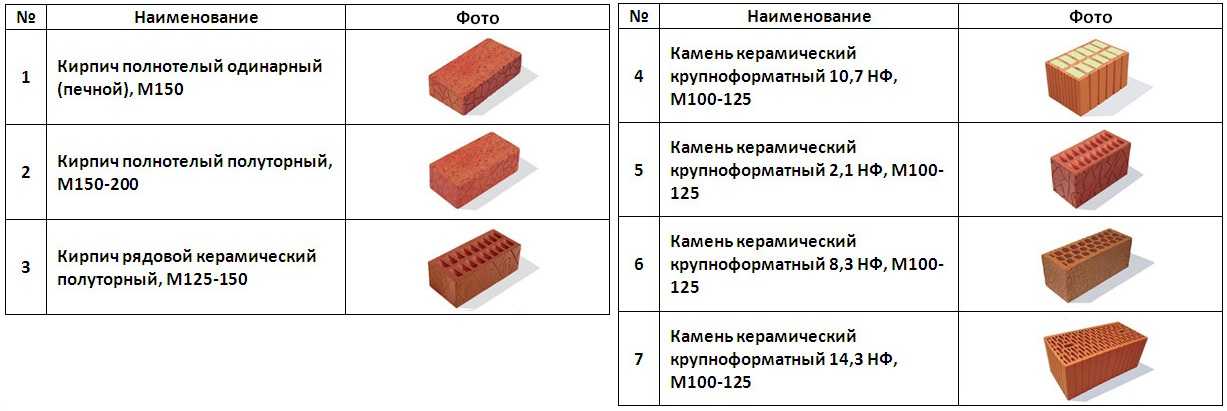

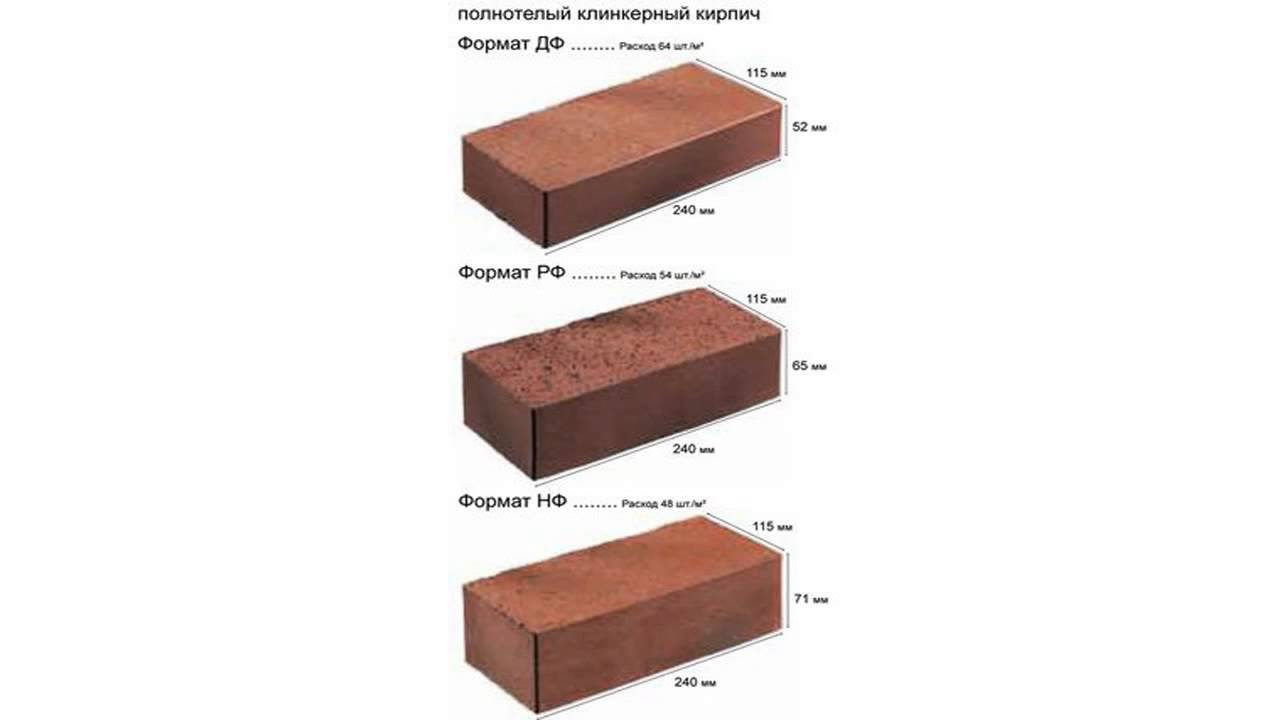

The main GOST, which determines the size of bricks, is GOST 530-2012 "Ceramic bricks and stones". With the increase in regulations and stricter requirements for the construction of houses and other structures, the range of brick sizes has expanded. There are the following main types of bricks:

1. Single (250x120x65 mm). Designation for European marking - RF;

2. Double (250x120x138 mm);

3. One and a half (250x120x88 mm);

4. Modular (280x130x80 mm);

5. Euro brick (250x85x65 mm).

In terms of shape, bricks are divided into:

• corpulent;

• hollow (slotted);

In addition to the overall dimensions of the brick, there are certain permissions for deviations from the norm (defects). The size of the deviations depends on the type of building material - building or facing. Stricter measures are imposed on facing materials, because the appearance of the building depends on its properties and characteristics.

For solid bricks, it is allowed:

1) The presence of dullness and chips of ribs and corners (no more than two) and no more than 1.5 cm in length along the rib;

2) Curvature of edges and edges no more than 0.3 cm;

3) On the lateral longitudinal edges, the presence of a crack up to 3 cm long across the width of the brick is allowed.

For hollow bricks, it is allowed:

1) No more than two bumps at corners or edges 1-1.5 cm long, provided that they do not reach the voids;

2) Full thickness cracks in the bed. In width, they can reach the first row of voids;

3) One crack on the butt and spoon edges.

For facing bricks, it is prohibited:

1) Chipped corners, the depth of which exceeds 1.5 cm;

2) The presence of cracks;

3) Chipped ribs, the width of which is more than 0.3 cm, and the length exceeds 1.5 cm.

A facing material is considered the most suitable for work, in which:

1) No more than 1 bit of corners up to 1.5 cm deep;

2) Separation of handwriting, which in total does not exceed the length of 4 cm;

3) No more than 1 chipped ribs, not exceeding 3 cm in depth, and not more than 1.5 cm in length.

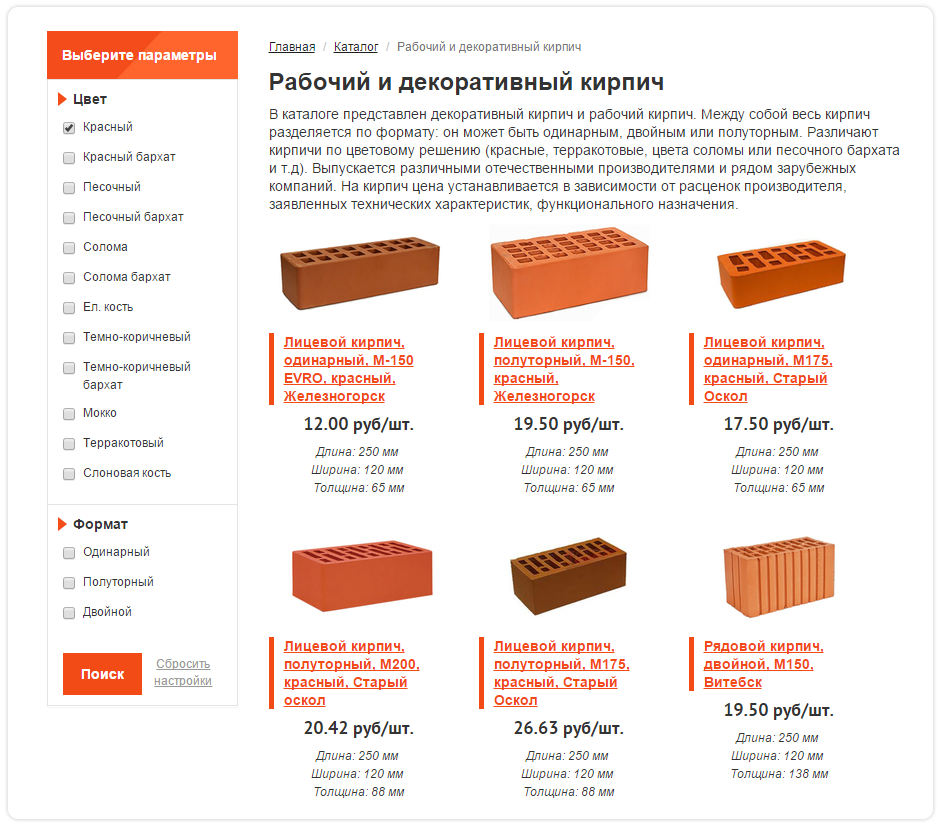

Modern architecture projects allow the use of bricks of various shapes and colors. The choice of building materials today is very diverse. There is an opportunity, without harm to the reliability and strength of the structure, to connect in the masonry variants of bricks of different texture, for example, artificially aged, variegated.

In order to reduce the weight of the structure, bricks of one and a half and double sizes are often made hollow. Large-scale porous blocks have become widespread in modern construction. The use of ceramic bricks simplifies and speeds up the construction process, while allowing to reduce the consumption of masonry composition, since this type of brick is lighter and warmer than usual.

Weight measurement

In terms of its severity, silicate is similar to fireclay brick. Some manufacturers may add iron oxide to the raw materials for brick making, as a result of which the product will look like ordinary red brick. But when choosing, you need to be careful, since this type of stones cannot be used to decorate fireplaces or stoves. With intense heating, they will crumble and turn into powder.

It is also important to know the weight of the brick, which is determined by the type of product. Depending on the use, silicate can be as follows

Ordinary. It is used for simple masonry and has rough sides. The presence of small chips on the surface is allowed.

The weight of any body can be calculated in a certain form and perform such work yourself

Also, when calculating, it is important to take into account the presence of voids in the product and its moisture content, which affects the weight characteristics. The specific gravity of standard silicate is 1300-1900 kg per cubic meter

Correctly made preliminary calculations will make it possible to find out how much weight will affect the basement and provide a reliable foundation that will withstand all loads and at the same time will not allow the walls to crack during construction.Also, the manufacturer must always indicate the specific gravity of the finished product, which simplifies the calculations.

The strength of the stone is determined by the brand, which must also be taken into account when choosing. For example, grade M75 is used for the construction of structures with a height of no more than one floor. It is also assumed the possibility of constructing load-bearing walls from them with a small load. The M100 brand is suitable for constructions of objects with two or three floors. For tall buildings, a brick with a strength of M200 is used.

Any silicate brick is distinguished by fire safety, which is ensured by the absence of flammable components in it. Walls made of this material should, in any case, be additionally finished with insulation. A disadvantage of silicate is a high rate of water absorption.

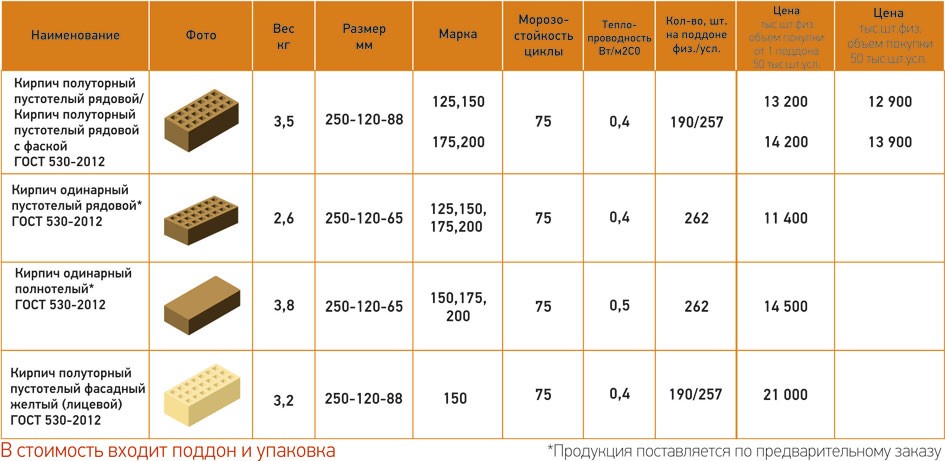

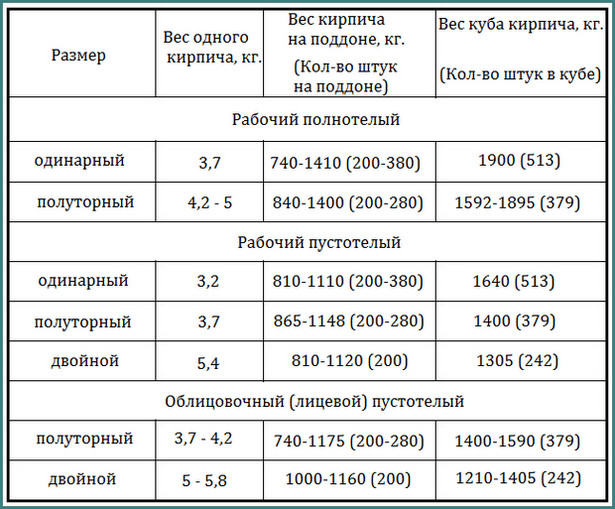

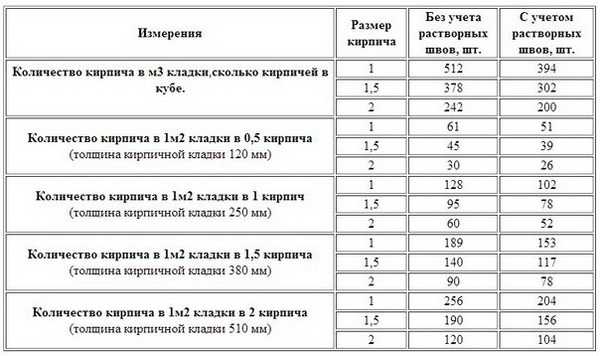

To know the weight of 1 cube of brick in the masonry, you must initially determine the number of products in it. Experts note that in the cube of masonry there are 414 single pieces, and thickened - 314. This amount is approximately, since it all depends on the thickness of the seams and the type of masonry. For example, the average joint width is one and a half cm, and therefore this value must be added when calculating the number of bricks in one cubic meter of masonry. All the data on which the calculations are made apply only to products manufactured in accordance with GOST.

- The formula for calculating the number of bricks in a cube of masonry: 100x100x 65 (88, 206).

- The formula for calculating the weight in a cube of masonry: 414 pcs. x 3-4 kg.

The bricks to the site are usually delivered in stacked pallets containing one cube of brick. This allows developers to navigate the calculations and order the required number of products. The sizes of silicate are standardized so that it is convenient to calculate their volume and number of units.

These bricks can be used for load-bearing foundations, columns, pillars and other objects, and therefore, before buying, you need to decide on the type of masonry that will be used. The choice of the product in terms of thickness and other parameters depends on this. For example, a single brick is usually used for the construction of load-bearing walls in structures. To fill the voids, you can use one and a half bricks.

Also, when choosing this material, it is necessary to take into account the ability to absorb water by it, which reduces characteristics and reduces resistance to low temperatures. Therefore, it is not recommended to use such products without additional waterproofing in basements or other places where high humidity is observed. It must be remembered that silicate does not tolerate high temperatures well, and therefore it is not recommended to use it near heating devices.

Volume and specific gravity of silicate brick

The first characteristic directly depends on the degree of voidness of the product and the density of the material. It is defined as follows: the mass of a brick is divided by the product of its geometric dimensions. The lightest are facing hollow products: 1200 kg / m3 (double); 1400 kg / m3 (one and a half). In working blocks with voids, the volumetric weight ranges from 1300 to 1640 kg / m3. The heaviest are solid ordinary bricks: a single cube weighs 1900 kg, and a one-and-a-half cube weighs an average of 1700 kg. By multiplying the volumetric weight by the cubic capacity of the masonry, the load on the foundation of the structure is determined.

The specific gravity depends on the porosity of the product, the quality of the raw material. To calculate the value, you first need to find the net volume - subtract the volume of voids from the total, and then divide the mass of the brick by the resulting number. The standard specific gravity for silicate blocks is 2000 - 2400 kg / m3. A decrease in the actual value, in comparison with the norm, leads to a deterioration in the strength characteristics.

Scope and features of solid silicate brick

Solid silicate blocks (ordinary brick, corpulent) differ in the minimum proportion of technological pores - no more than 13%. The corpulent is used for the following types of construction:

- external and internal load-bearing walls;

- partitions;

- columns;

- one-story and multi-story houses;

- country cottages;

- outbuildings.

The weight of a single sand-lime brick without voids is 3.7 kg (it is 10 - 30% denser than a hollow brick). To speed up the masonry, blocks are used in which the thickness is increased by 1.5 times. The weight of one-and-a-half silicate bricks is from 4.2 to 5 kg.

The advantage of an ordinary block is its increased strength, but a small number of voids also increases thermal conductivity - therefore, a wall from a corpulent body turns out to be cold. On the other hand, the frost resistance of a dense product is higher (up to 50 cycles), therefore, it is preferable for the northern regions.

Scope and features of hollow silicate brick

The volumetric weight of brick products is reduced by creating slot-like holes - they are through or deaf and have the shape of a circle, oval or square. The voids are small: due to this, the solution practically does not get into the holes, and they become a heat-insulating barrier. The advantages of hollow bricks:

- low thermal conductivity;

- reducing the load on the foundation;

- the ability to reduce the number of rows of masonry and wall thickness;

- solution saving - up to 10 - 15%.

Working bricks with voids are used for the construction of houses of various storeys, for laying internal partitions, and facing bricks for decorating facades. The weight of 1 silicate brick depends on the degree of voidness and dimensions - this is shown in the table.

Hollow brick weight

As you can see from the table, the weight of sand-lime brick 250 x 120 x 88 deviates from the average within half a kilogram. This is due to the fact that according to GOST 379-95, 3 types of one-and-a-half blocks are produced according to the degree of voidness:

- 28 - 31% - have 14 holes with a diameter of 30 - 32 mm;

- 22 - 25% - 11 voids with a diameter of 27 - 32 mm;

- 15% - 3 cells, the diameter of which is 52 mm.

What you need to know when buying sand-lime bricks

- Typically, brick blocks are dispensed on pallets, which hold from 200 to 380 bricks. By multiplying the weight of one product by their number in the package, it is easy to find the total weight;

- To select a delivery vehicle, you need to know the weight of the pallets. Depending on the material, the container weighs from 18 to 40 kg - this is a significant addition if the machine has a small carrying capacity;

- The above information on weight applies only to GOST products. But not all brick factories adhere to technological regulations. When purchasing products from a small manufacturer that does not have a certificate, it is worth weighing the brick and making sure that it does not differ too much from the standard and calculate the total weight;

When determining the load on the foundation, it is taken into account that the mortar is also included in the masonry. Depending on the thickness of the seam, its share can be significant

When calculating the weight of the wall, this should be remembered;

For special accuracy of calculations, attention is also paid to the method of masonry - in the process, different types of bricks are sometimes used.

For different types of silicate bricks, the weight is significantly different, therefore, it is necessary to build from it only after a full calculation, having weighed all the pros and cons.

- Foam block production at home: is it profitable?

- Making an opening in a concrete wall

- How to close up a crack in the wall: classification of destruction and methods of their elimination

One Comment to “The weight of sand-lime brick: Compliance with the standard is the guarantee of quality”

Brick packing options

Before calculating how many bricks are on a pallet, let us briefly return to the issue of bulk transportation, since many are interested in whether this can be done or not. We will not invent anything about this, but turn to the current standards - they have a chapter: "Transportation and storage".

GOST 530, which regulates the manufacture of ceramic products, clearly states that loading and unloading cannot be carried out in bulk.

Extract from GOST 530 * 2012

In GOST 379, according to which silicate brick is made, its transportation in bulk is permissible, but only if the customer agrees to this.

Extract from GOST 379 * 2015

As you can see, some relaxation is made for sand-lime bricks, but in general terms the requirements are the same - the brick must be transported in pallets. They, of course, cost money, which is why some customers tend to do without them, using a good old dump truck for transportation.

If the client does not mind, sand-lime bricks can be loaded into a dump truck

For ceramic bricks, the maximum is transportation by onboard vehicle with do-it-yourself unloading

But the best thing is loading pallets with a manipulator

For those who need to transport clay products and at the same time save on pallets, there is only one way out: to fold the bricks manually on the flatbed truck, as shown in the photo. But in this case, you will have to sweat a lot, first when laying, and then when unloading.

For most sane people, such a game is not worth the candle. They adhere to the golden mean, and transport the brick to the site as it should be according to the standard. It remains only to decide how many bricks are in one pallet, and what they are.