What is fireclay refractory brick? Types and characteristics

What a fireclay brick is is known to everyone who has at least once equipped a solid stove in a bathhouse or a fireplace in their home. But for beginners who are just learning these basics, it is worth taking a closer look at such an unusual material. Today we will look at the main types of furnace blocks, their properties and determine the standard sizes.

Composition and characteristics

Like traditional ceramic, refractory bricks are made from clay, not ordinary red, but yellow chamotte. Stones, 2/3 consisting of it, belong to alumina types of heat-resistant materials. They are not only able to withstand extremely high temperatures, but also resist deformation under pressure in such difficult conditions. Fireclay bricks are fired at +1300 ° C (ceramics are sintered at +1100 ° C). And in the course of its further operation, it calmly endures prolonged contact with open fire. It acquires other positive characteristics thanks to additives: graphite, crushed quartz, coke and various oxides.

Basic properties and technical characteristics of fireclay bricks made according to GOST:

- Compressive strength - 15-23 N / mm 2.

- Thermal conductivity - 0.84-1.28 W / m ° C.

- The average operating temperature is not less than +1350 ° С, although the actual indicators of refractoriness are much higher and reach +1730 ° С.

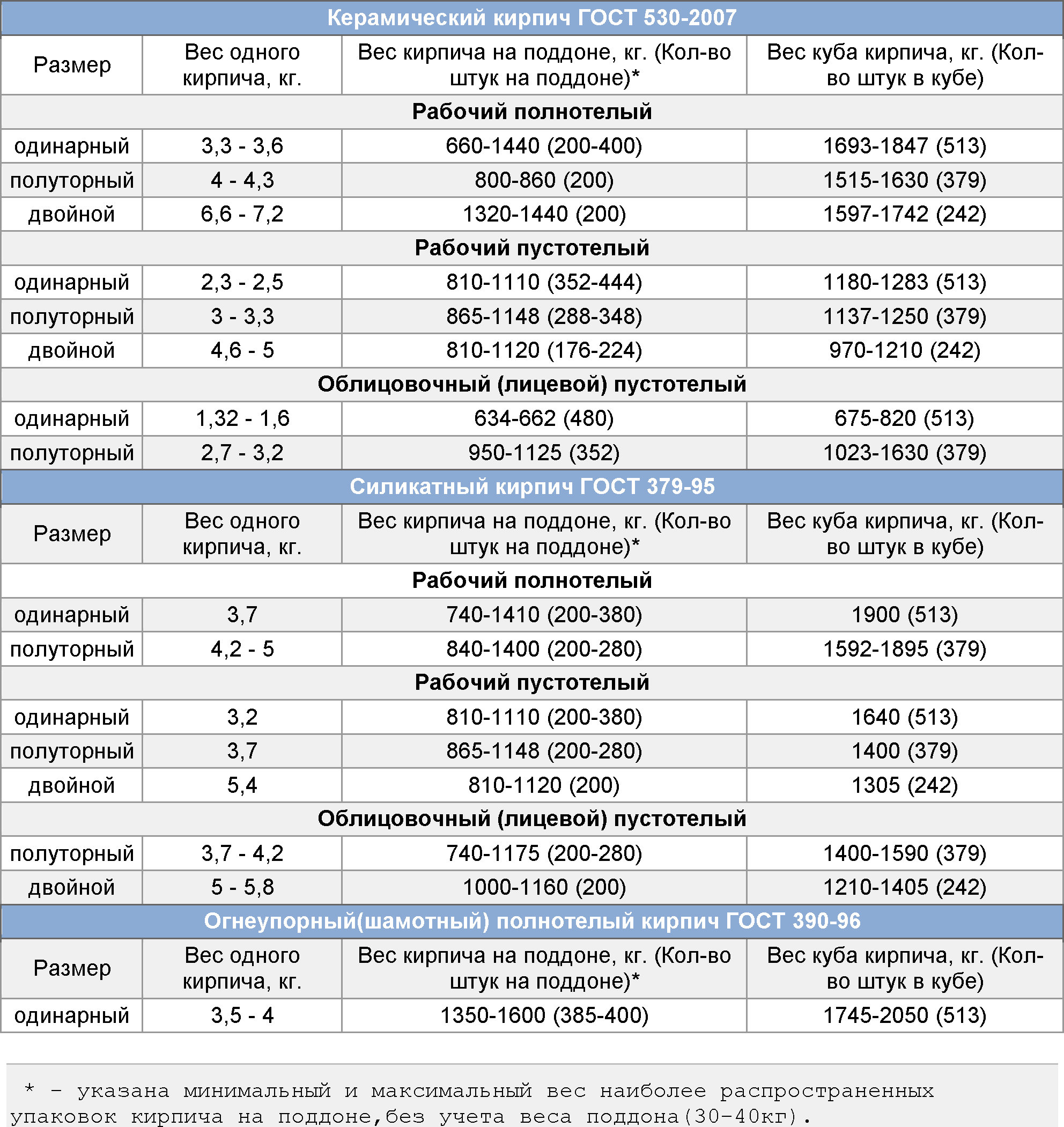

- The average weight of a single brick is 3.7 kg. Products manufactured according to TU can have a mass of 2.5-6.0 kg.

- Chemical resistance to alkalis and acids.

- Water absorption (for dense materials) - at the level of 7%.

The main component that manufacturers add to the refractory mixture is alumina. It increases the mechanical strength of the blocks and their resistance to aggressive substances. In addition, the content of Al2 O3 affects the porosity of the finished material, and hence its heat capacity. Therefore, a classification of refractories was introduced in terms of voidness, according to which fireclay bricks are divided into eight groups - with the ratio of internal pores to the total volume from 3 to 85%. But in this case, it is worth adhering to the golden mean, because stones with a small specific gravity noticeably lose in strength.

Light brick (SHL or SHLT) has a slightly different composition, since organic components such as peat or sawdust are included to obtain high voidness values. After firing, they simply burn out, leaving pores of the appropriate size in the body of the stone. The main characteristics of a refractory brick of the SHL brand:

- Density - 0.3-0.9 t / m 3.

- Compressive strength - 1.0-3.5 N / mm 2.

- Thermal conductivity - 0.2-0.7 W / mK.

- Refractoriness - +1300 ° C.

Despite their low weight, such products are capable of operating at very high temperatures, but they are mainly used only as thermal insulation for furnaces and hot units (steam pipelines, boilers). Private developers should buy lightweight refractory bricks to reduce energy costs for heating. With its help, you can reduce the heat loss of heating devices and save from 10 to 45% of fuel.

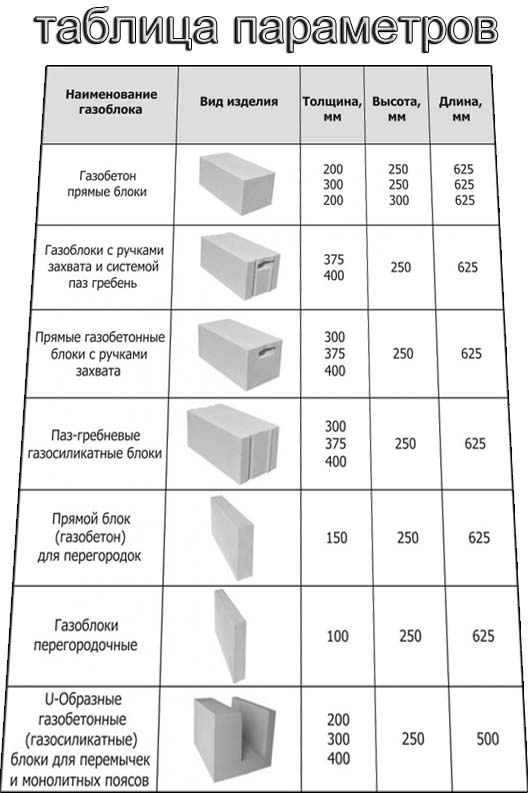

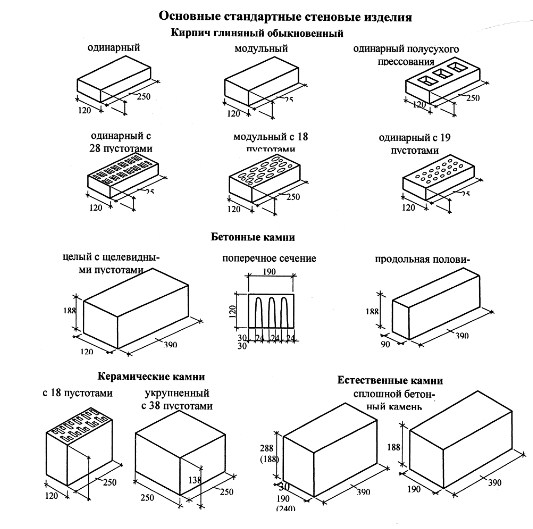

Types of brick products and their standard sizes

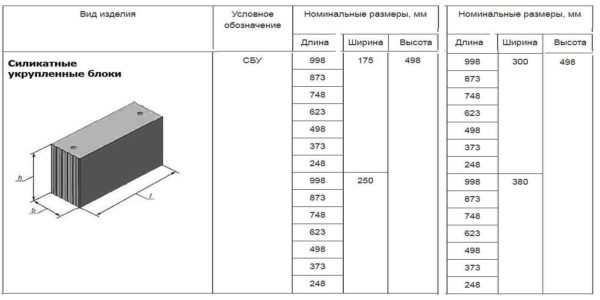

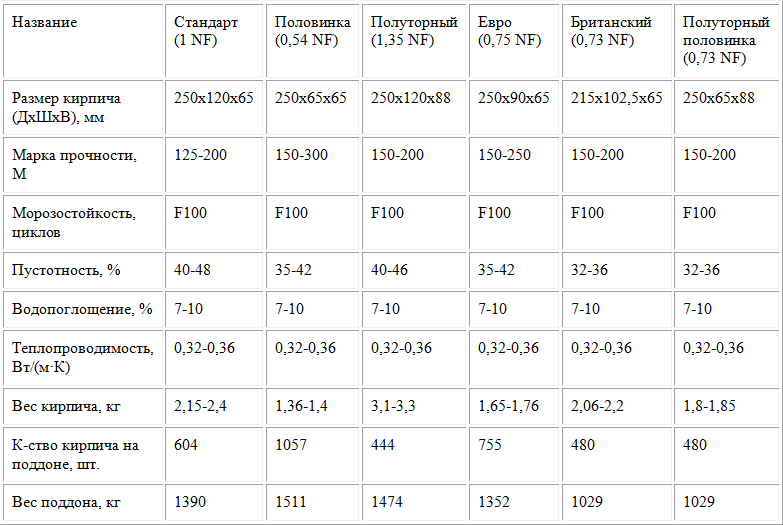

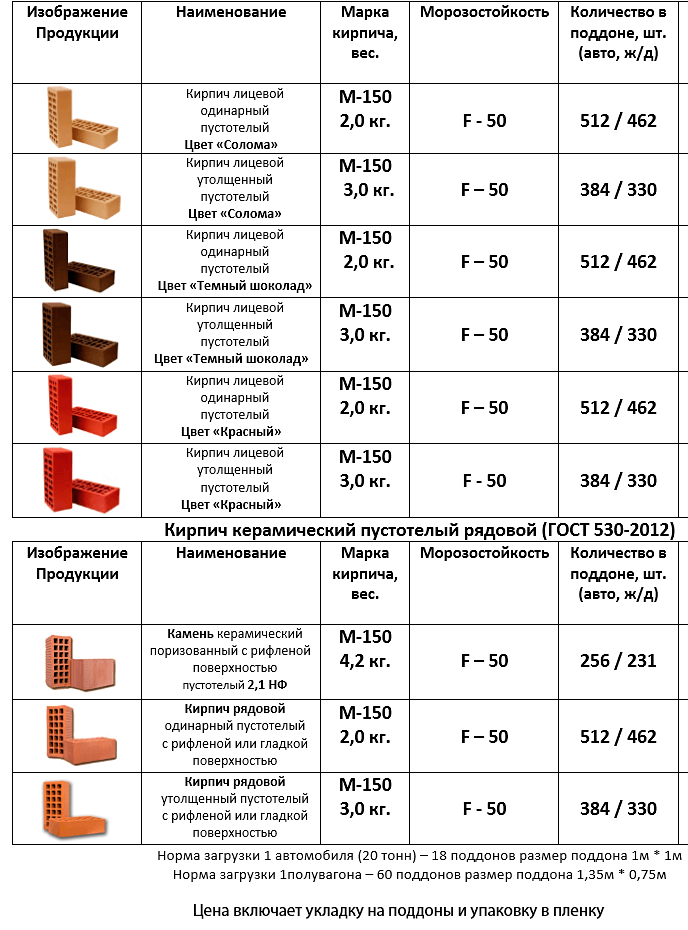

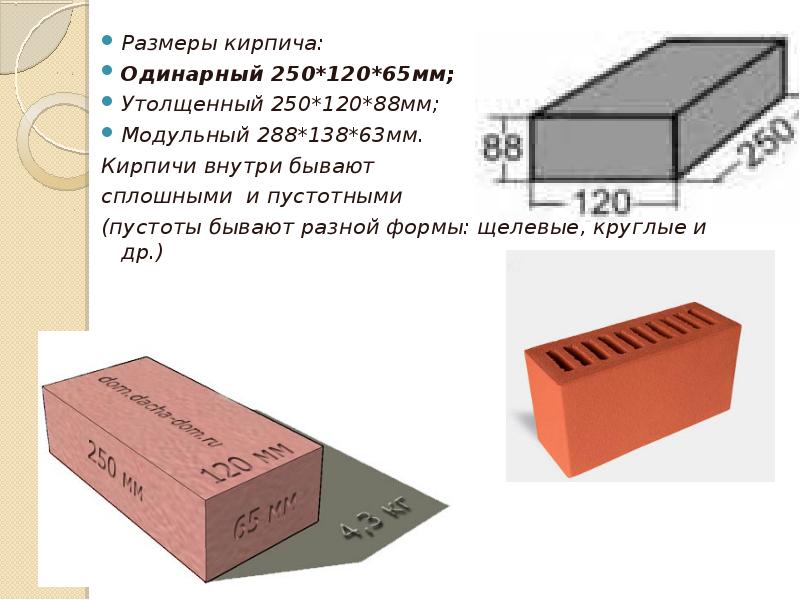

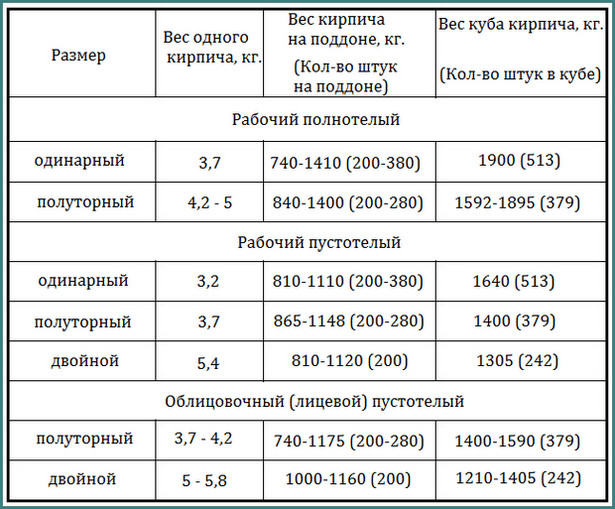

The sizes of brick products depend not only on the standard size, but also on the type of building material. The main types that are in demand in the construction of residential buildings and the construction of industrial buildings are:

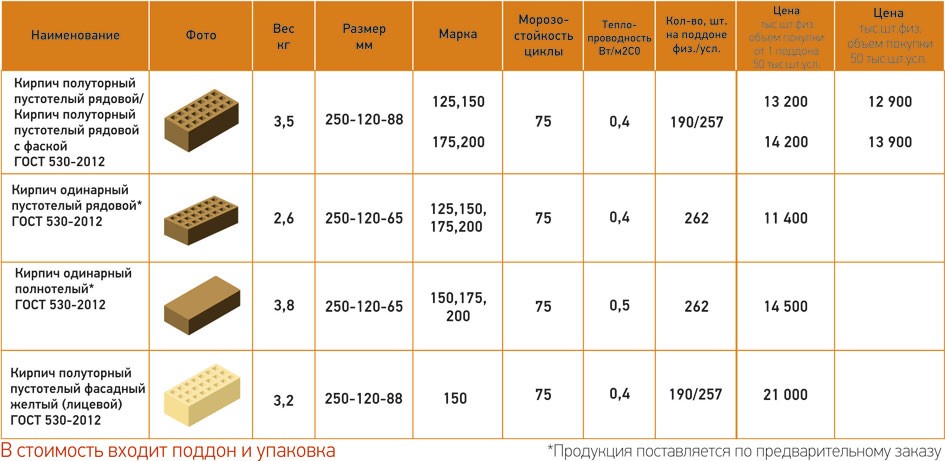

Red building blocks and their features

Red brick is a universal building material used for the construction of foundations, external enclosing structures and partitions in the house, fences.

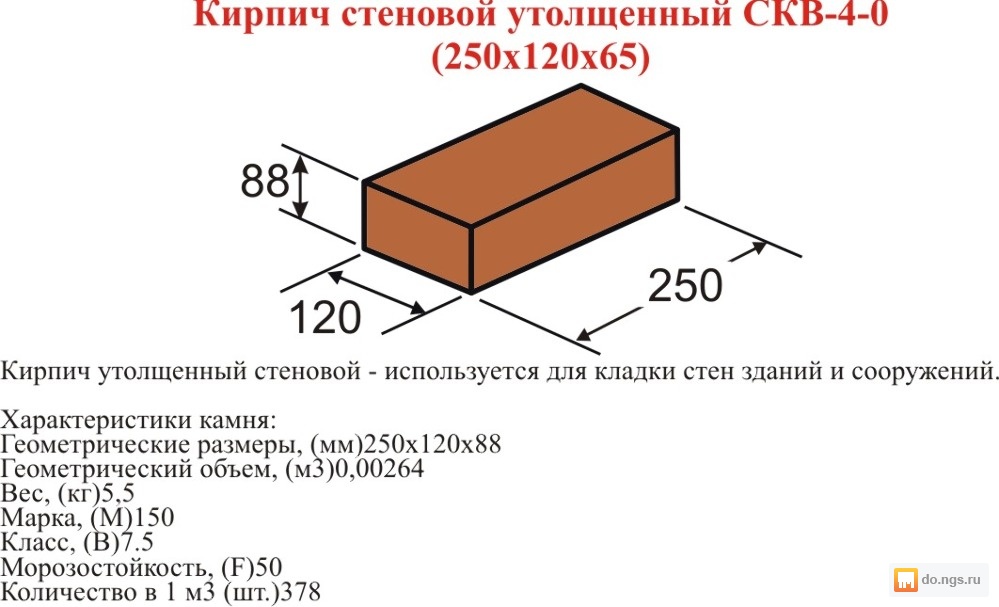

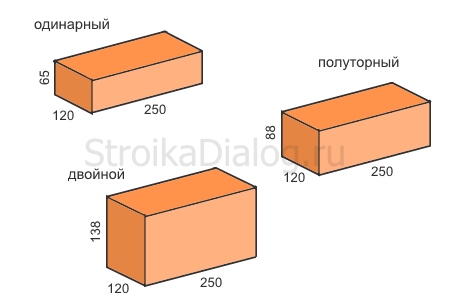

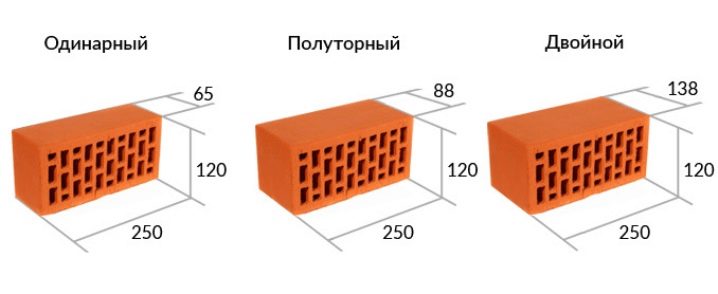

Red brick products are made on the basis of clay briquettes, which are pressed by firing.The dimensions and technical characteristics of the product are regulated by GOST 530-2007 and are (in millimeters):

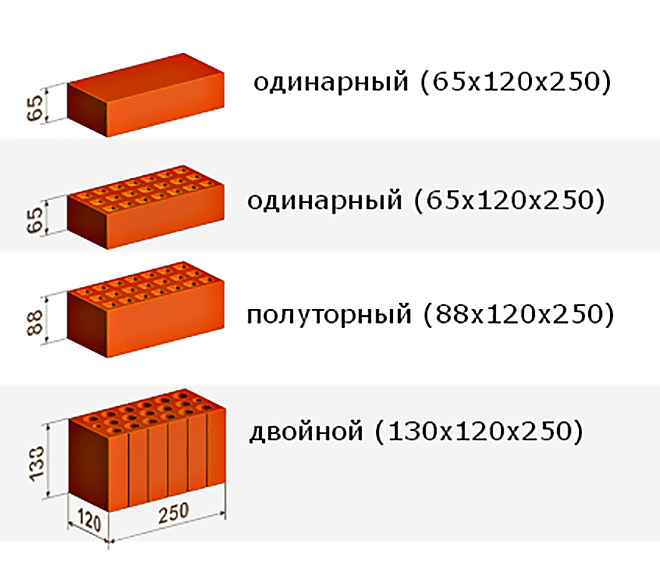

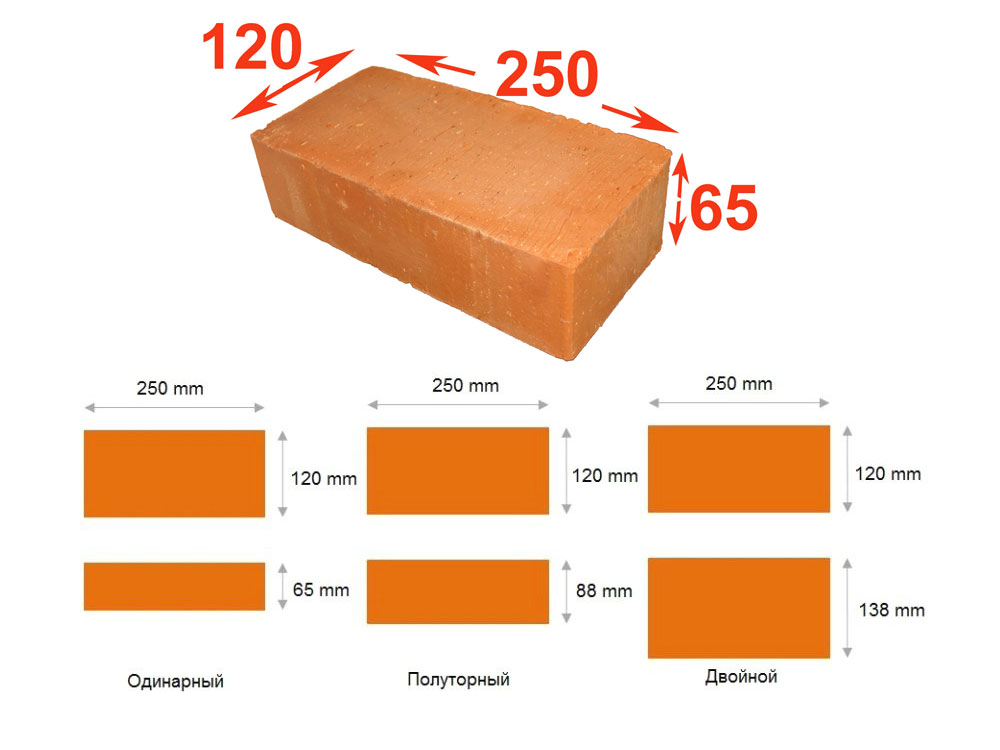

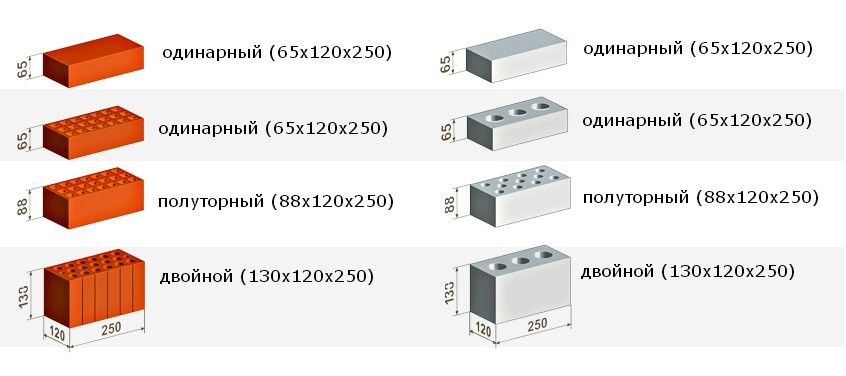

- standard format - 250x120x65;

- thickened format - 250x120x88;

- double format - 250x120x138.

In addition to the popular standard sizes GOST, there are also less popular formats:

- 0.7 NF with parameters 250x85x65 mm;

- 1.3 NF with parameters 288x138x65 mm.

Building materials of "European format" are used for decorative finishing of windows and other structural elements of the facade.

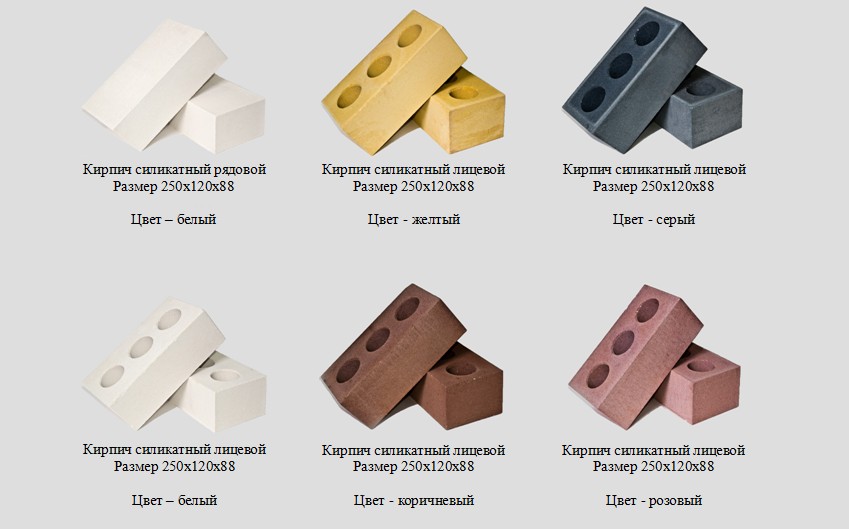

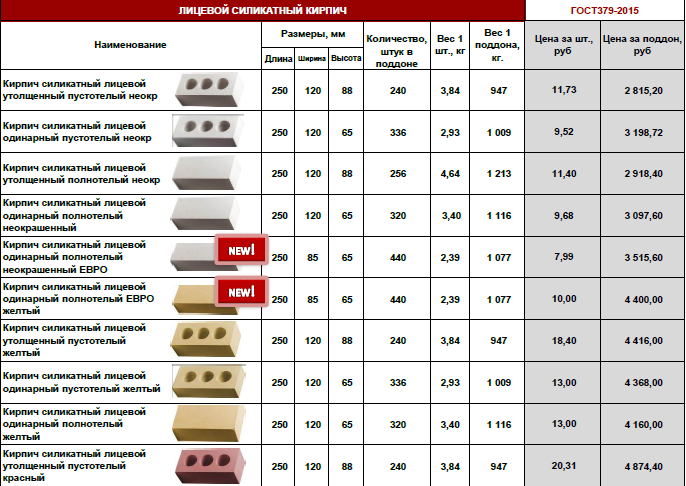

Silicate brick

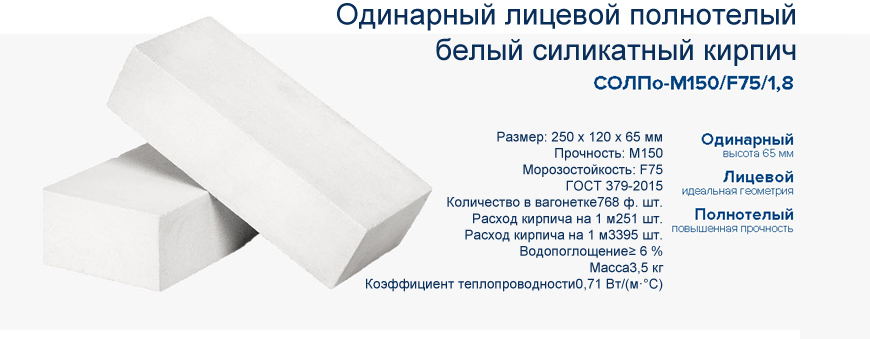

Silicate brick blocks - a building material made on the basis of silicate, intended for the construction of load-bearing external walls, partitions in the house. The modular dimensions of white brick are 250x120x65 and 250x120x88 millimeters.

There are two types of silicate building blocks:

The volumes of the voids of the silicate block, as well as the overall dimensions, are adjustable

state standards. Hollow silicate blocks are divided based on the proportion of volume, diameter and number of blind voids having a cylindrical shape.

The following types of hollow one-and-a-half silicates are distinguished:

- three hollow - the proportion of voids is 15% of the volume of the product, the diameter of blind holes is 52 mm;

- eleven are hollow - the proportion of voids in the total volume is 25%, diameter is from 27 to 32 mm;

- fourteen voids - the proportion of voids varies from 28 to 31%, the diameter can be from 27 to 32 mm.

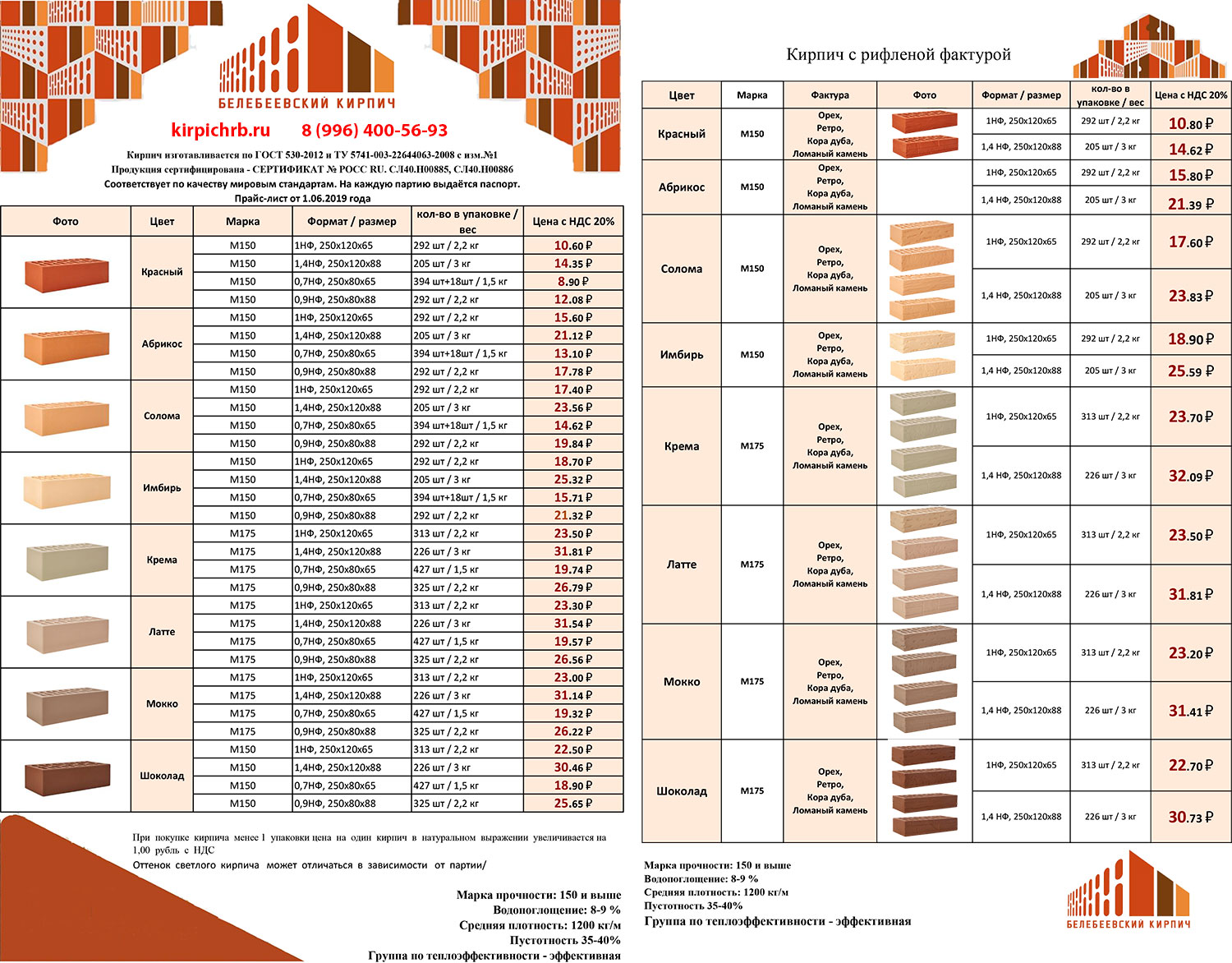

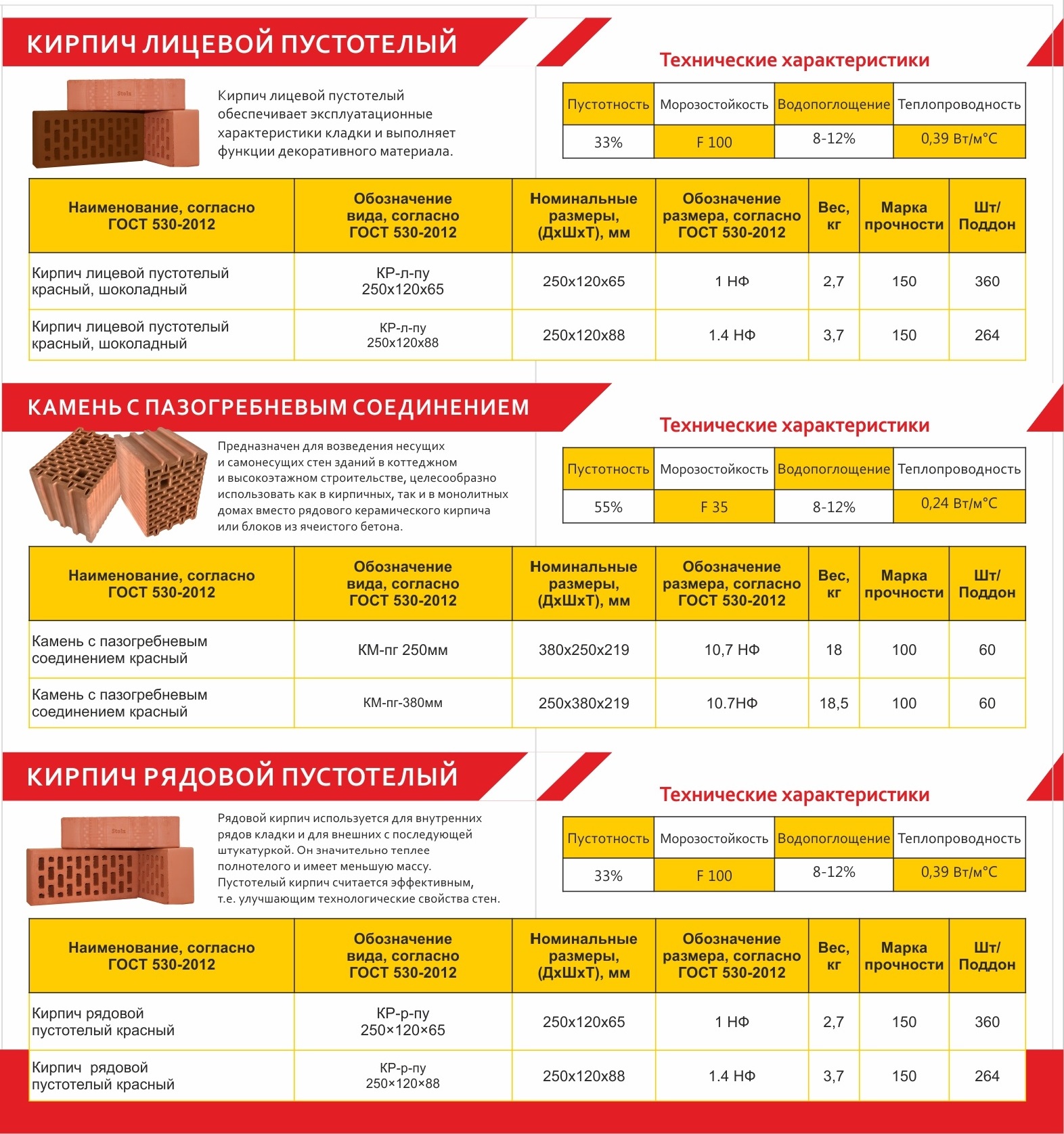

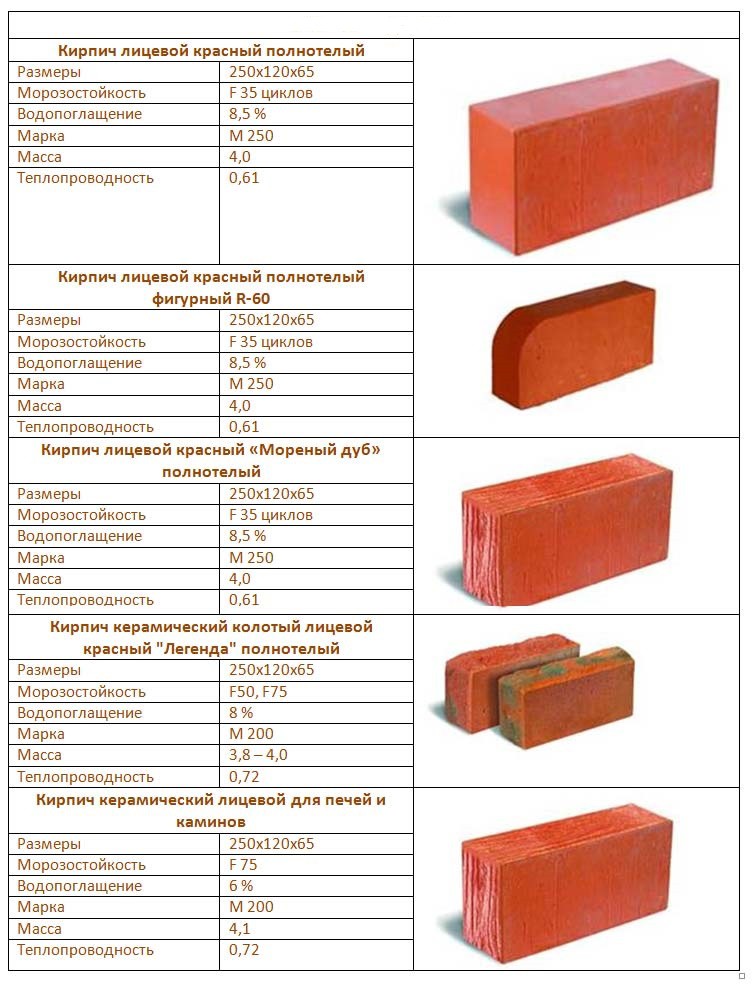

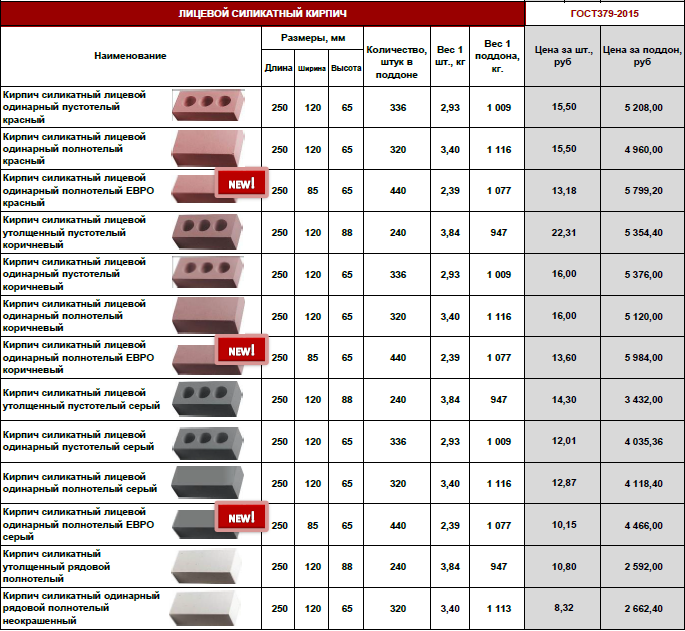

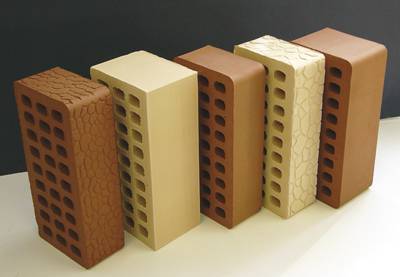

Facing brick

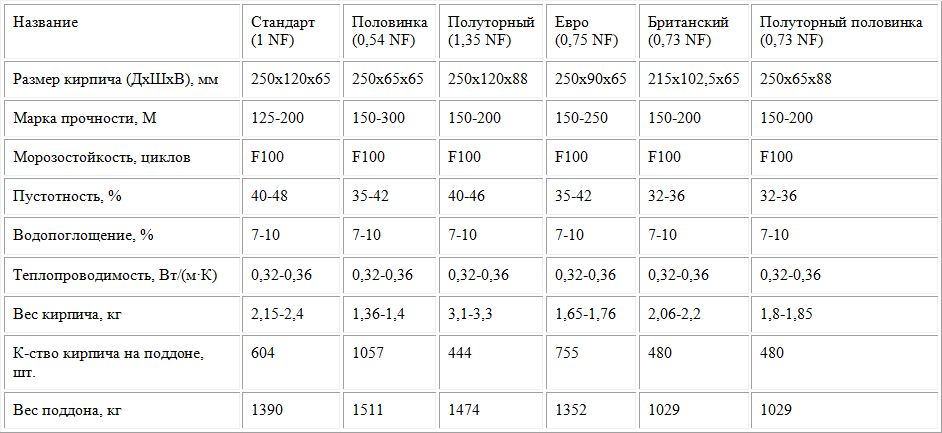

For facing the facades, a standard size facing brick is used, which corresponds to the traditional counterpart.

The construction market offers several types of facing products:

- clinker;

- ceramic;

- hyper-pressed;

- silicate.

Clinker building blocks are used for finishing facades, for erecting decorative pillars, decorating window openings, arched windows are erected using this type of material. The material is characterized by a dense, smooth structure, excellent soundproofing and frost-resistant qualities, resistant to moisture, and retains heat well. Clinker can be colored and glazed, glossy and matte. Facade windows and walls, facing with clinker blocks, retain an attractive appearance for a long time.

Ceramic facing products are able to withstand up to one hundred changes of natural seasons, the material is not afraid of sudden changes in temperature. The brick retains its original qualities and appearance for a long time.

Hyper-pressed material is made from a lime-cement mixture, by the method of semi-dry hyper pressing, followed by steam treatment. The material is used for decorative finishing of facades, with its help, windows and doors are distinguished. There are several types of facing material:

The standard dimensions of smooth and figured hyper-pressed bricks are 250x120x65 mm. Standard spoon bricks have parameters 250x85x65 mm, angular and narrow spoon bricks - 250x60x56 mm.

Silicate facing brick is an environmentally friendly frost-resistant material. Facing silicate brick strikes with a variety of color solutions, differs from its ceramic counterpart in a uniform tone of color throughout the entire area of the product. Silicate facade material is not used for cladding areas in contact with the ground.

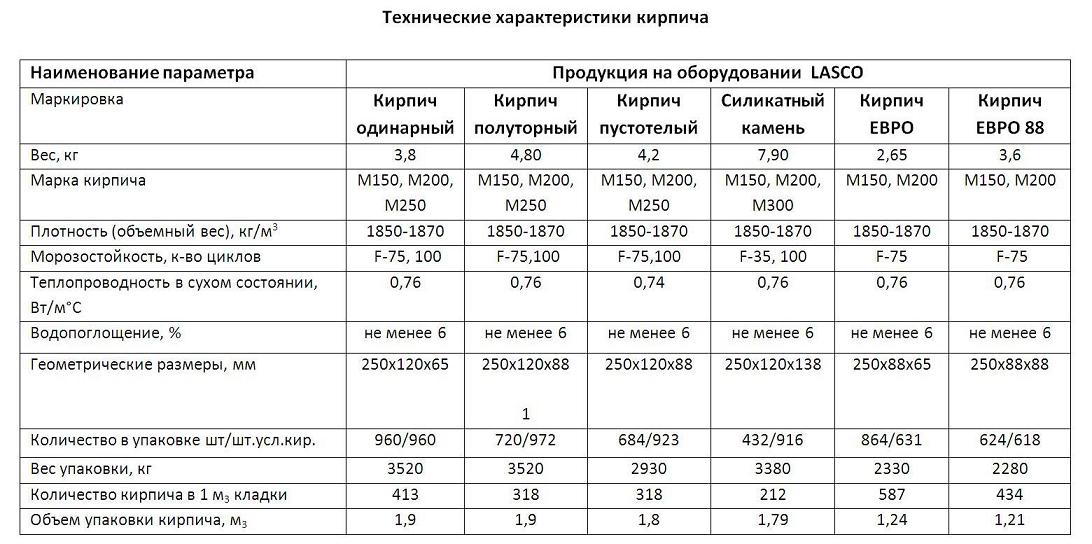

Specifications

Types of silicate bricks.

The properties of silicate bricks make it possible in many climatic zones to erect buildings of any purpose from it, from outbuildings to industrial workshops, and living quarters are built not only of various storeys, but also of all kinds of configurations.

To achieve the optimal option, buildings are erected with masonry of various types, with different wall thicknesses and using solid and hollow bricks of various sizes. To choose the best type of brick for each case, you need to take into account the technical characteristics of the product.Only in this case the service life of the building and the comfort of its use will be maximized.

Density and weight

Sizes of silicate bricks.

One of the strength indicators is the density of silicate bricks. This physical quantity is determined by the ratio of the element's weight to its volume, therefore, the fewer voids (pores) in the material, the stronger and, accordingly, the heavier the product will be. The density of bricks lies in the following ranges, measured in kg / m³:

- silicate hollow - 1135-1577;

- silicate corpulent - 1840-1933.

The weight of a silicate brick directly depends on its density, size and shape. The single hollow block will be the lightest of all silicate wall masonry products.

| Product | Weight, kg) | |

| corpulent | hollow | |

| Eurobrick | 2,1 | — |

| Single SC | 3,7 | 3,2 |

| One and a half SC | 5 | 3,9 |

| Double stone | 7,7 | 5,8 |

Silicate brick scheme.

You can find out the properties of this building material by finding out how much a silicate brick weighs: the heavier it is with the same size, the worse the characteristics of its thermal insulation. Hollow brick can be 3-, 11- and 14-hollow, that is, its internal volume can be reduced by 15, 25 and 31%, respectively. In this regard, the mass of hollow products will also differ within the range of up to 0.5 kg.

The weight of one product may fluctuate, since it depends on several indicators, including size (since tolerances are allowed for all sides) and density, which, in turn, depends on the starting material and the specifics of the manufacturing technology.

Thermal conductivity

Thermal conductivity directly depends on density and is measured in SI in complex units W / (m × K) or watt / (meter × kelvin), and is denoted by coefficients.

Diagram of a brick and its parts.

For the calculated laboratory thermal conductivity of silicate brick, the coefficients are:

- for a full-bodied product - 0.7;

- for hollow - 0.66.

For clarity, the thermal conductivity coefficient of silicate brick can be compared with other materials. So, for glass wool the coefficient will be 0.03-0.04, for glass - 1, for wood - 0.15, for water under normal conditions - 0.6.

Frost resistance

The product is not suitable for walls exposed to moisture as it absorbs moisture well. That is why it is not recommended to make parts of the building open from above (parapets) from it, since they can get very wet from precipitation, and then freeze, which will contribute to the early destruction of the structure.

Types of silicate brick masonry.

Frost resistance of silicate brick is one of the indicators of its durability and is measured in cycles. The more times it can freeze at a temperature of -18 ° C and then thaw at + 20 ° C without the formation of signs of destruction, the more durable it is considered and the higher its frost resistance, which in the marking is indicated by the letter F and the numbers 15, 25, 35 and 50. Moreover, the facing product is produced only with frost resistance 35 and 50.

All the listed figures are indicators of the number of cycles and have little to do with reality, because the tests are carried out in harsh laboratory conditions with sharp changes from minus to plus. In fact, nature rarely presents such surprises, and the durability of silicate bricks is much higher than predicted, thanks to which it is used for the construction of buildings even in regions with severe winters.

Standard type brick size - Table.

Brick is a stone of the correct form of artificial origin, which is very widely used in construction.

He has three surfaces:

- the bed is the largest;

- spoons - medium;

- butt is the smallest surface.

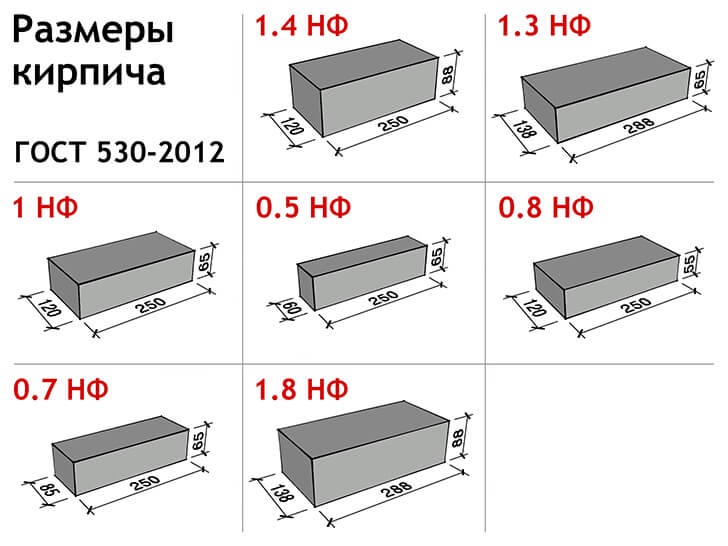

Dimensions and marking of bricks from domestic manufacturers.

In the table below, you can find out the size of the required brick block, as well as its marking, which is used in our market.

| Name | Dimension marking | Dimensions, mm. | Name marking |

| Single | 1-NF | 250x120x65 | O |

| "Euro" | 0.7-NF | 250x85x65 | E |

| Modular single | 1,3-NF | 288x138x65 | M |

| One and a half | 1,4-NF | 250x120x88 | Have |

| Thickened brick with horizontal voids | 1,4-NF | 250x120x88 | UG |

| Double brick (stone) | 2,1-NF | 250x120x140 | TO |

| 3,7-NF | 288x288x88 | ||

| 2.9-NF | 288x138x140 | ||

| 1,8-NF | 288x138x88 | ||

| 4,5-NF | 250x250x140 | ||

| 3,2-NF | 250x180x140 | ||

| Large-format stone (porous ceramic block) | 14,3-NF | 510x250x219 | QC |

| 11,2-NF | 398x250x219 | ||

| 10,7-NF | 380x250x219 | ||

| 9,3-NF | 380x255x188 | ||

| 6,8-NF | 380x250x140 | ||

| 4.9-NF | 380x180x140 | ||

| 6.0-NF | 250x250x188 | ||

| Stone with horizontal voids | 1,8-NF | 250x200x70 | KG |

Size marking of European bricks.

Foreign manufacturers have completely different standards and sizes differ from domestic ones. Therefore, for complete convenience, the following table of brick sizes is presented:

| Marking | Dimensions, mm |

| DF | 240x115x52 |

| 2DF | 240x115x113 |

| NF | 240x115x71 |

| RF | 240x115x61 |

| WDF | 210x100x65 |

| Wf | 210x100x50 |

Knowing the size is good, but you also need to know the species, and there are many of them.

Red brick size.

The standard size of a red brick product was introduced at the beginning of the 19th century, and finally established itself relatively recently, in 1927, and is 250x120x65 mm.

Often such dimensions of single ceramic bricks are called normal or basic format. It is a product of this size that is considered the most convenient for the production of wall masonry work, more precisely, for alternating the arrangement of bricks when bandaging the masonry.

The size of the silicate brick.

SC is used in many cases when high strength is required from the building.

A brick is produced with the following dimensions:

- single - 250 mm long, 120 mm wide and 65 mm thick. The weight of the product depends on its type - hollow or corpulent;

- one and a half - or thickened, with the same length and width, the thickness of the product is 88 mm;

- double - or silicate stone, has a thickness of 138 mm.

There is a whole category of SC of non-standard size and shape rather far from a parallelepiped. These products are designed to form various architectural elements: arches, rounded corners, vaults, and so on. Their dimensions are regulated by TU and annexes to GOST.

The size of the facing brick.

The usual size of decorative bricks can have the following parameters - 250x120x65 mm, 250x90x65 mm and 250x60x65 mm.

As you can see, the height can change, but the length and width of the brick remain unchanged. The only exceptions are the elongated elements, the parameters of which are 528x108x37 mm.

Dimensions of ceramic bricks.

KK is full-bodied, hollow, porous. The first modifications are made using a similar technology in various forms, into which the clay is filled. A unique technology is used in the production of porous ceramics.

The dimensions of the KK are as follows:

- single, perhaps the most common type. The standard dimensions of a single ceramic brick are 250 × 120 × 65, as you know, the dimensions of building materials are indicated in millimeters;

- the size of a one-and-a-half ceramic brick differs from a single one only in height, it is 88 millimeters, and the length and width remain unchanged.

- double, also higher than the standard, single, its height is 138 millimeters with the same length and width.

What are the markings of bricks.

Each batch of bricks is marked by the manufacturer, all information about the product is indicated on the marking in an alphanumeric code. It is not difficult to decipher the marking, it consists of: marking the name of the product, letters P - for privates, L - for obverse; size designations and designations: Po - for corpulent, Pu - for hollow; grades for strength and frost resistance; medium density class and designation of GOST.

For example: Brick KORPu 1NF / 100 / 1.4 / 50 / GOST 530-2007.

Marking of ordinary ceramic bricks, hollow, thickened, size 1.4NF, strength grade M150, average density class 1.4, frost resistance grade F50.

Or: An ordinary silicate brick of an ordinary grade of strength 150, grade of frost resistance F15 will be marked: Brick COP-150/15, GOST 379-95.

Price for one

Silicate brick, due to its low price per piece, is very popular with construction companies and individuals. The cost varies depending on the style of execution, color, type, size and region of brick production. The price between the full-bodied and the hollow version ranges from 3-6 rubles per unit.

A full-bodied brand M100 costs from 6 rubles / piece, M250 - from 12 rubles / piece. Facing starts at 8-10 rubles apiece. We must not forget that wholesale lots are always much cheaper than small deliveries. Promotions and discounts for regular customers, relevant for large construction companies, play a role in the pricing of sand-lime bricks.

Russian briquettes and their dimensions today

Domestic briquettes acquired their modern look only in the 27th year of the last century. A little later, the dimensions of a single ceramic briquette and its value in one and a half and double form appear in regulatory documents. Finally, this information is approved with the introduction of conventional units of measurement of structural parts and building materials, which, according to the latest editions of the state standard, began to be called a module.

White brick is most often sold in lots

An interesting fact remains that the word "one and a half" cannot be confirmed by mathematical calculations, because its height, in comparison with a single one, is more than 1.3 cm. This name was used most often among builders and since then it has begun to be included in state rules and regulations. This term is incriminated with the size of a silicate briquette, the size of which is 25 * 12 * 8.8 cm.

Building material began to be made from a combination of sand and lime only in the 20th century, after a significant modernization of industrial production in the field of building materials. Then they began to use the method of semi-dry pressing and burning in an autoclave. The dimensions, cost and strength indicators did not cause any complaints from users, the materials became resistant to moisture and increased temperature.

Today, any non-observance of established standards in matters of laying briquettes is allowed only when decorating rooms or supporting structures. The parameters of briquettes for facing are controlled with the utmost rigor. The boundary deviation can vary from 3-4 mm, and in the border of 2 mm in thickness. Therefore, the dimensions of the white briquette are strictly limited and comply with the norms of interstate rules.

There are a number of restrictions regarding the use of briquettes. Reduced resistance to moisture prohibits their use in homes that are exposed to increased moisture (base, basement rooms, water shafts) and maximum temperatures (capsules for the stove, chimney).

How to choose the right one?

In order for any construction of silicate bricks to be as strong and reliable as possible, not to be damaged for a long time, even at the time of choosing the building materials themselves, you need to be very careful

Experts advise to pay special attention to the following important points

- If you lightly hit a silicate brick with a metal object, then the sound should be quite sonorous. If you hear a dull echo, then this may indicate poor-quality drying of the material.

- We must not forget that the storage conditions of such a building material will certainly affect its quality and durability. If the bricks are laid out in the open, then their positive qualities will be significantly reduced, so you should not buy such a product, even if it has a tempting price.

The quality of the packaging, as well as the delivery of bricks, plays an important role. Experts recommend buying products sold in special pallets of safe height

This is due to the fact that in such a container, bricks are much more difficult to damage or destroy.

Pay attention to the integrity of the silicate bricks. They should not have major damage and large chips.

If any were noticed, it is better to refuse the purchase and look for better quality products. Otherwise, a building from this raw material may not turn out to be the most reliable and high-quality, albeit cheap.

When making a purchase, be sure to check if what you plan to purchase matches what is being shipped to you.

- By itself, this material is inexpensive, so you should not chase the record low cost. A product that is shockingly low in price may well be of poor quality. Building from such raw materials will not last long, you will have to redo the work, but with new bricks, and this is an extra expense.

- If you are looking for a suitable cladding material, then you should only select high-quality, perfect executions - they should not be the slightest defects or damage. It is advisable to give preference to beautiful textured specimens. In addition, such products may not only have a white color.

- Try to purchase such building materials in proven retail outlets known in the city of your residence.

In the next video, you will find the pros and cons of sand-lime bricks.

Let’s block ads! (Why?)