Fireclay brick parameters

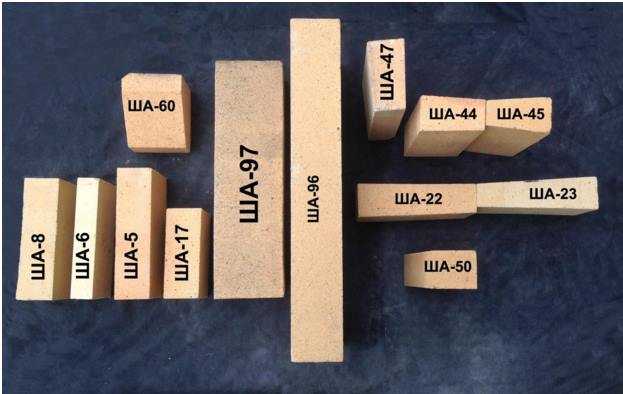

For the construction of stoves, fireplaces in the area of contact with fire, special fire-resistant bricks are used. In its production, a special type of clay is used - chamotte. Therefore, such a brick is also called fireclay. The production process is the same as building red bricks - molding, drying, kiln firing. But, due to the special properties of chamotte, the resulting building material calmly withstands prolonged contact with open fire. In everyday life, two brands of general-purpose refractory bricks are used - ША and ШБ. ША can withstand temperatures up to 1690 ° C, ШБ - up to 1650 ° C, all other parameters are identical. Therefore, they have the same field of application - it is the molding of the firebox of fireplaces and stoves.

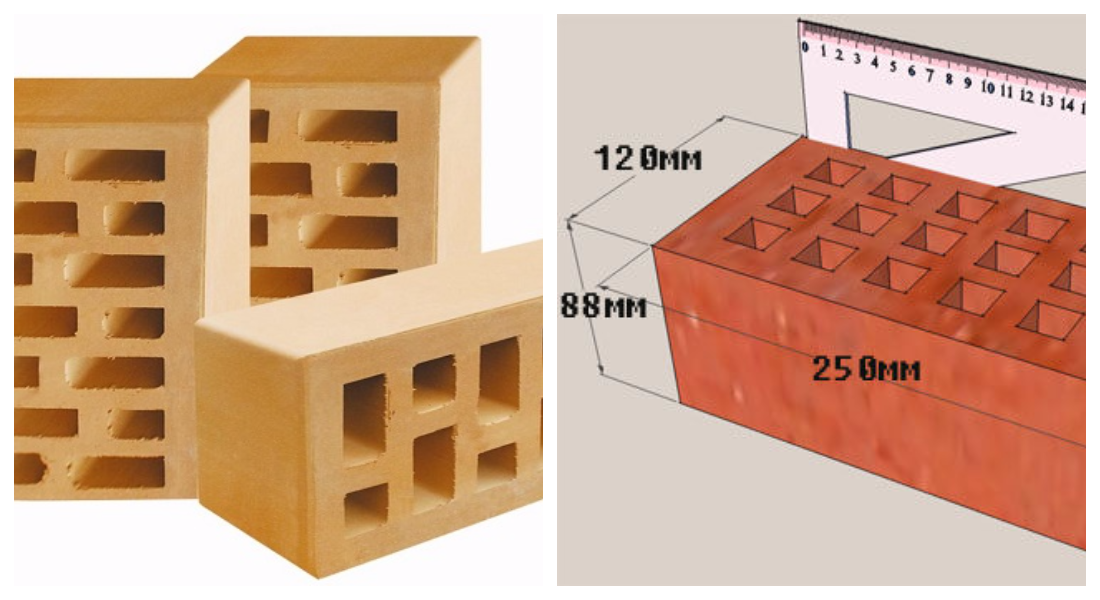

Some types of refractory bricks: the sizes may vary, but they are all standardized

The size of the refractory brick is encoded in the number after the abbreviation:

- ШБ-5, ША 5 - 230 * 114 * 65 mm;

- ШБ-6, ША 6, ША 14 - 230 * 114 * 40 mm (flask);

- ШБ-8, ША 8 - 250 * 125 * 65 mm;

- ШБ-9, ША 9 - 300 * 150-65 mm;

Most often they use ША 8 or ШБ 8. They coincide in length and thickness with the ceramic red brick, from which the rest of the furnace is placed. There is also a wedge-shaped refractory brick - for the formation of furnace arches and smooth curves in the horizontal plane.

There are two types of wedge refractory bricks:

- end - for the formation of curves in the horizontal plane

- ША, ШБ 22 - 230 * 114 * 65/55 mm;

- ША, ШБ 23 - 230 * 114 * 65/45 mm;

- ША, ШБ 48 - 250 * 124 * 65/45 mm;

Types of wedge fireclay bricks: rib and end wedge

- rib for the formation of vaults

- ША, ШБ 44 - 230 * 114 * 65/55 mm;

- ША, ШБ 45 - 230 * 114 * 65/45 mm;

- ША, ШБ 49 - 230 * 114 * 96/65 mm;

- ША, ШБ 50 - 230 * 114 * 76/65 mm;

- ША, ШБ 51 - 230 * 114 * 56/65 mm;

- ША, ШБ 52 - 345 * 150 * 125/75 mm;

- ША, ШБ 53 - 345 * 150 * 90/75 mm;

- ША, ШБ 54 - 345 * 150 * 80/75 mm;

These are not all sizes and types of fireclay bricks. You will find more in GOST 8691-73.

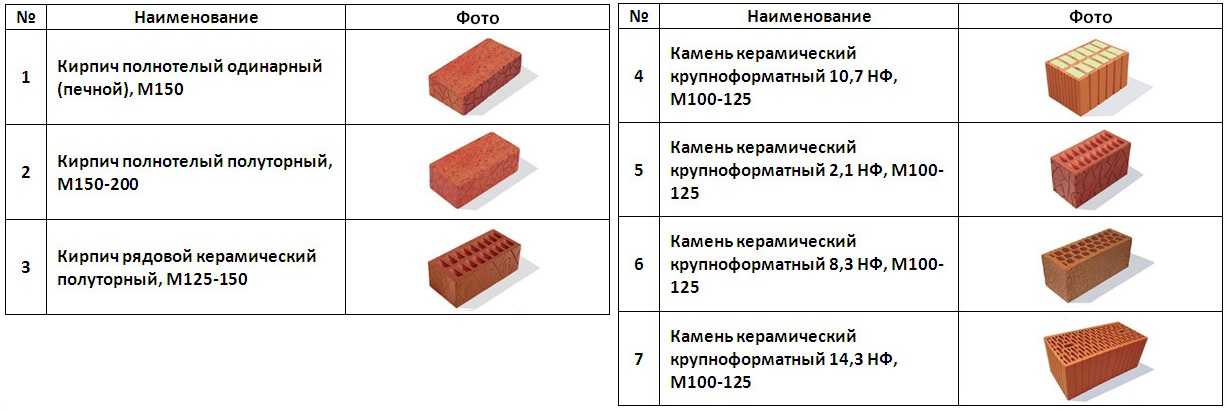

Brick types

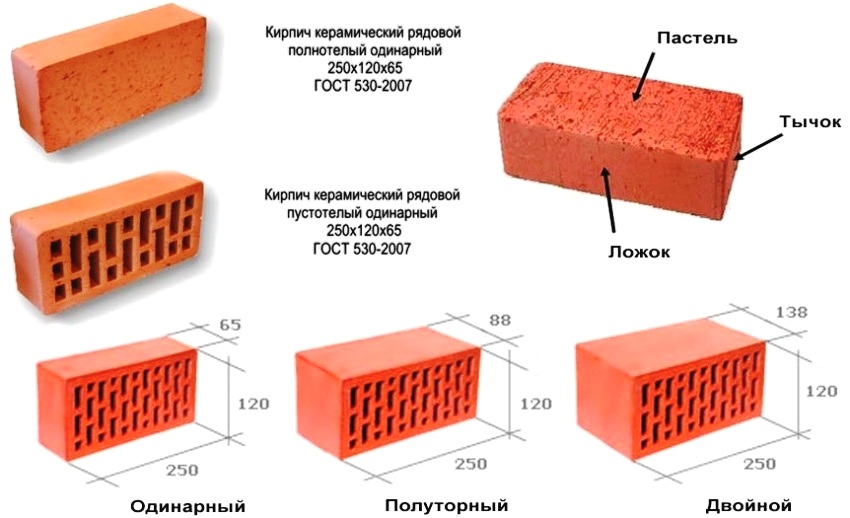

In addition to finishing the house, facing brick is used in the construction of pillars and columns of fences, fences in gardens and parks, the design of gazebos, arches and small architectural forms. Any material has unified forms, but it must necessarily have two sides with a decorative surface - a spoon and a poke. This is the "face" of the material.

There are several types of this building material:

-

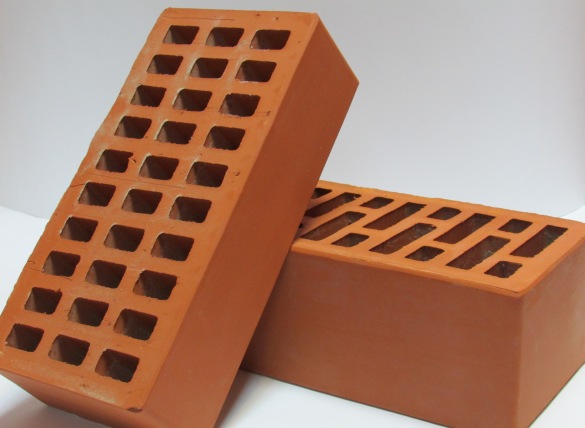

Ceramic - can be hollow or solid. The latter option, respectively, has more weight, which should be taken into account when calculating the load on the foundation.

-

Clinker - has a dense structure, which provides moisture resistance and frost resistance.

-

Hyper-pressed - it is made of clay and sand, in the section it has an expressive chip, similar to a natural stone.

-

Silicate - used less often due to low decorative qualities. However, it has a low price.

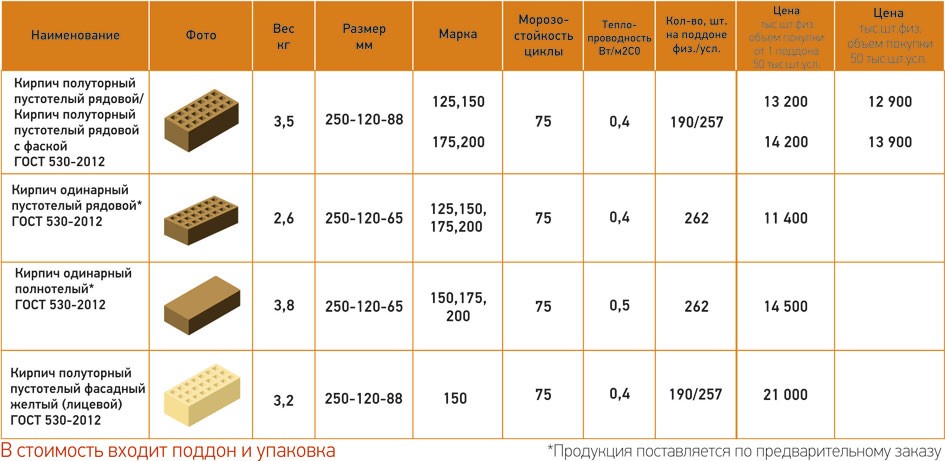

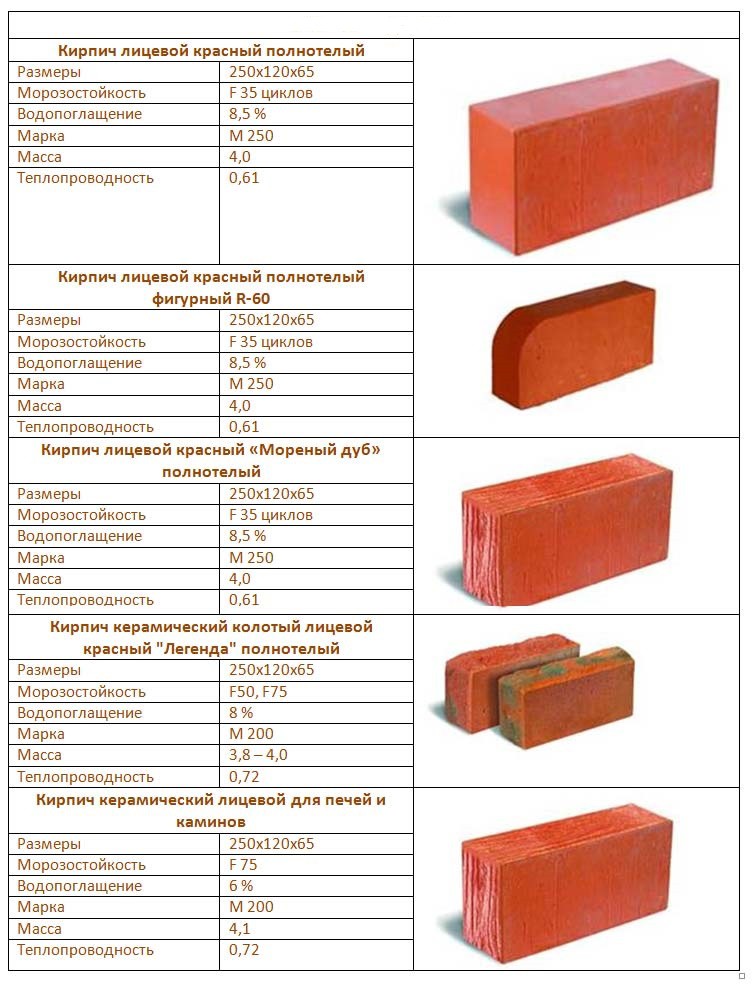

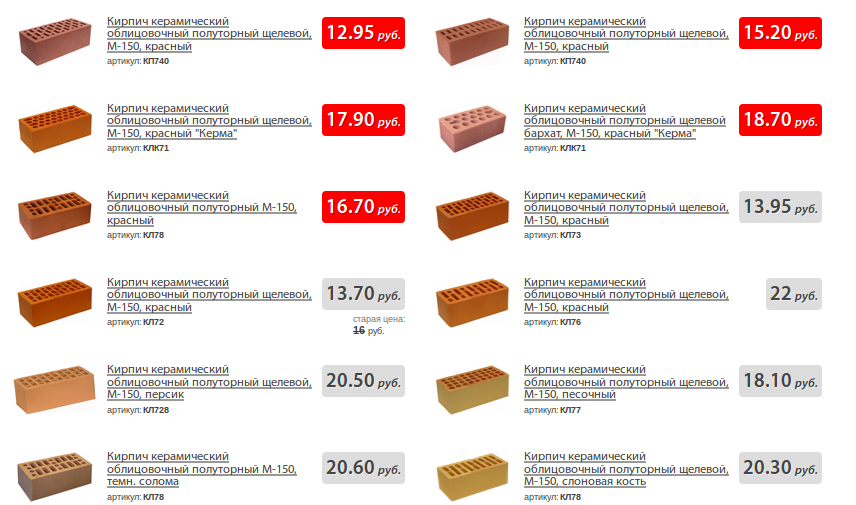

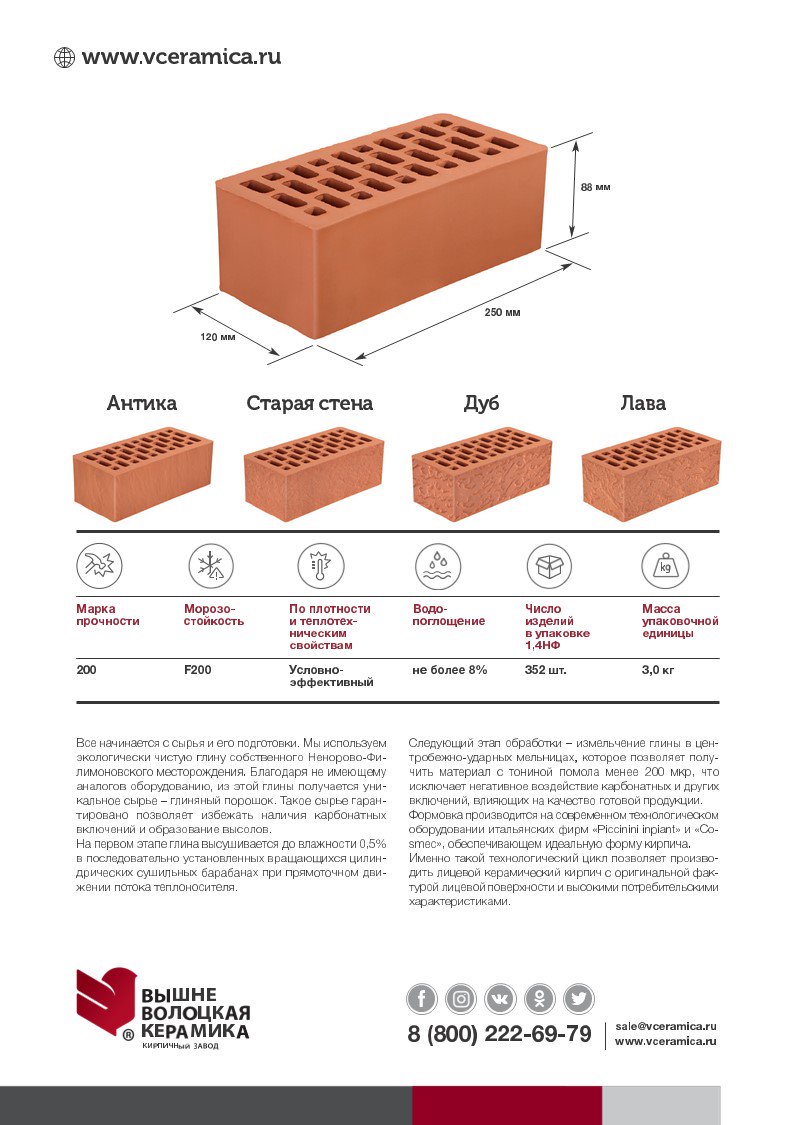

Ceramic cladding brick

Ceramic bricks are made from special brick clay, which is first formed and then fired. This facing material is considered one of the environmentally friendly and safe materials in construction, not spewing any impurities. Ceramics does not absorb moisture and is breathable.

Ceramic option

In addition, the facing brick has a standard shape and uniform color. There are no splits or cracks on the surface of the material.

Standard material sizes are: 25/12 / 6.5. The weight of the product ranges from 2.7 to 6 kg, depending on the size (single, double).

Clinker brick

Clinker facing bricks are made from special clay, from which a product is formed and fired in an oven at a temperature of 1200 ֯ C. The product is very durable due to the strong adhesion of clay particles. Color difference may appear due to pigmentation. In order to avoid strong differences in the shades of the material during manufacture, manufacturers use a standard formula. This facing material can be dense or with internal cavities.

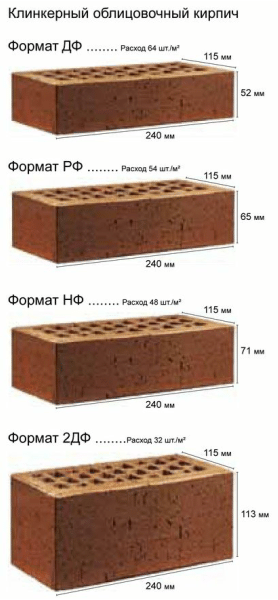

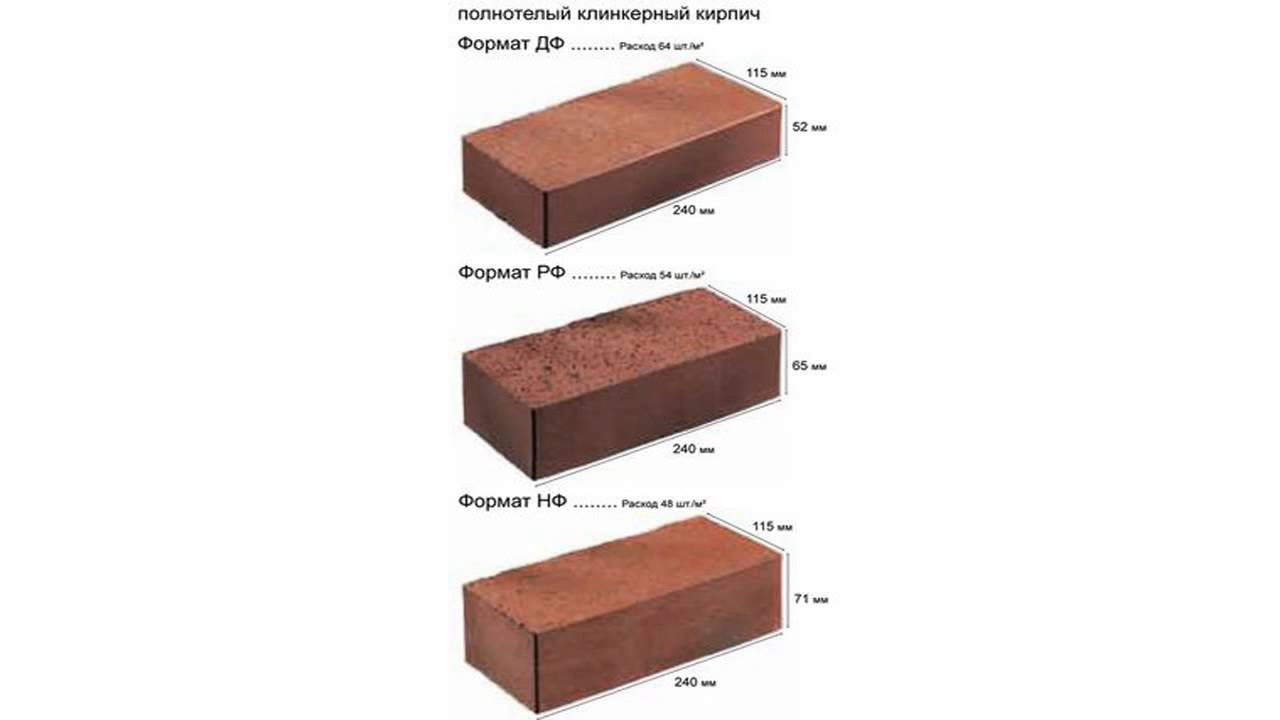

Clinker

Paths and terraces are made of such material.

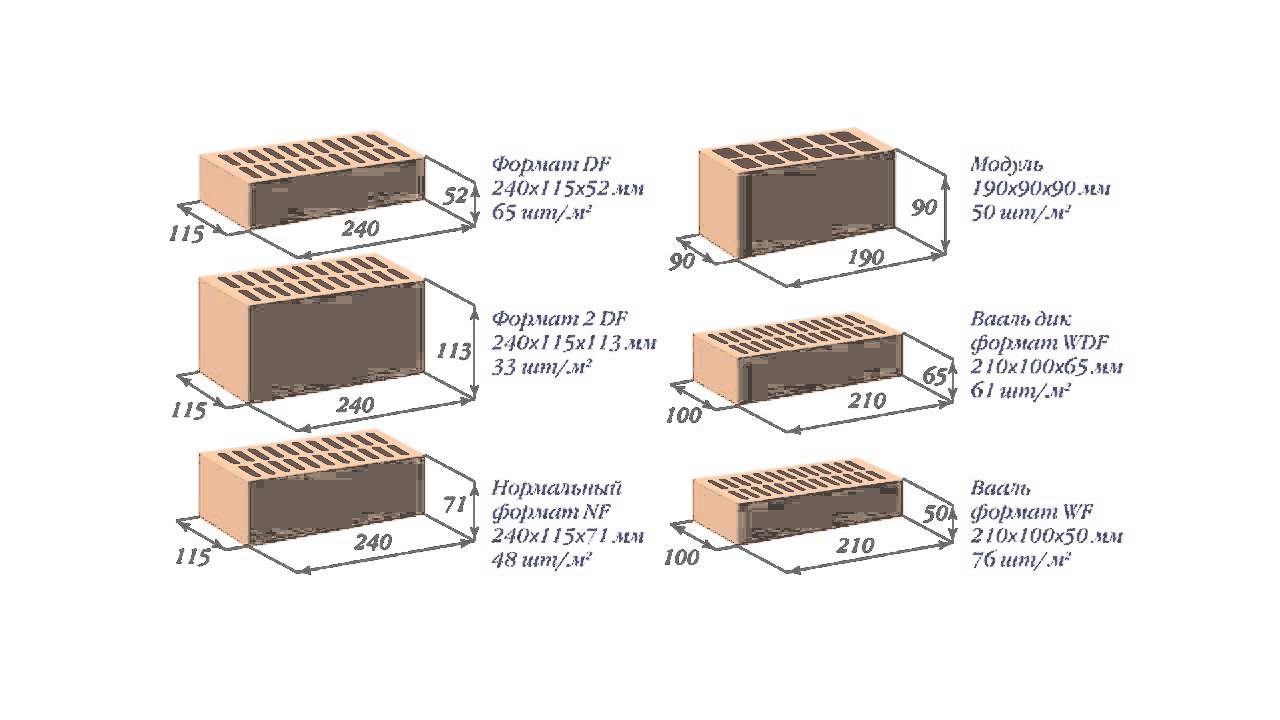

The installation of this brick is a laborious process that requires the participation of specialists. Do not install clinker bricks in hot weather, when the original wall is very hot. Moisture will have time to dry out even before it has time to penetrate into the structure of the product. The standard dimensions of the base brick are 240/115/71 mm. Weight can range from 1.6 to 6 kg, depending on the size.

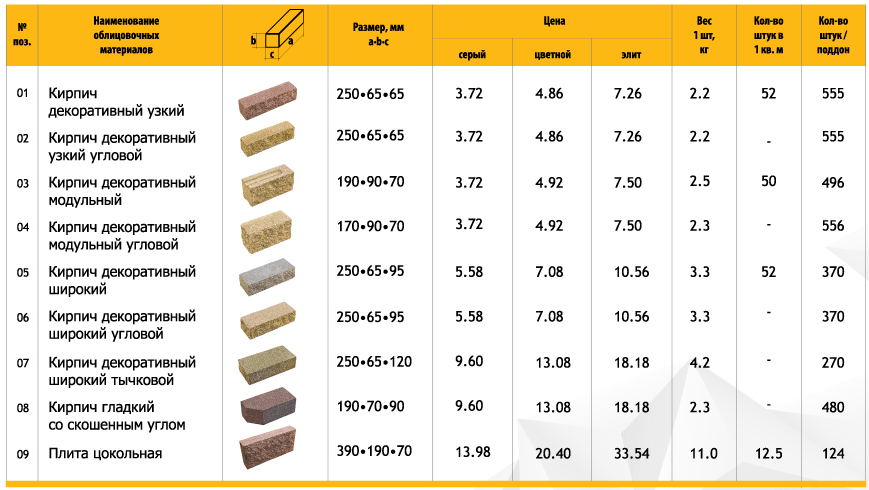

Hyper-pressed brick

Hyper-pressed facing brick is produced by semi-dry hyper-pressing from a material of natural origin (limestone, shell rock). Sometimes mechanical cleavage technology is used. As a result, a material with an unusual relief is obtained - during the manufacturing process, dyes are added to the initial material, which make it possible to obtain a material of a wide color spectrum. Such material is often used for facing the facades of not only one-story, but also multi-story buildings.

Hyperpressed

However, this material has many disadvantages and manufacturers rarely mention them, which is unfair. Indeed, when selecting the optimal material for facing the facade of a house, the applicant expects to receive comprehensive information about all the technological characteristics of the material.

The dimensions of the standard material are 250/120/65 mm, and the weight is 4.5 kg.

Silicate brick

The composition of the silicate facing material is limestone, sand, which are held together by water. If the proportion is violated, this can lead to the appearance of low-quality products, therefore manufacturers carefully control the process at all stages. To give the material strength and density, it is pressed.

Silicate

Facing silicate brick has a high geometric accuracy. It is manufactured in accordance with accepted standards, due to which it has clear corners and an even surface. This material is frost-resistant and can freeze and thaw several dozen times without loss of quality.

The size depends on the type of brick. The standard size is 250/120/65 mm. Weight ranges from 2.5 to 6 kg.

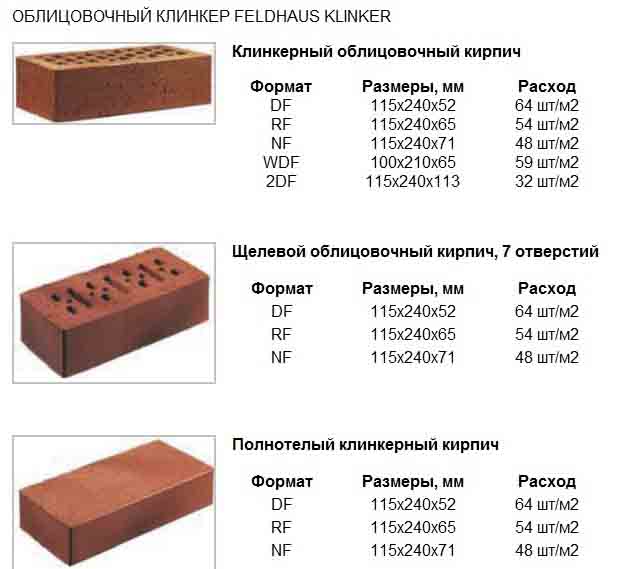

Decorative clinker facing brick: dimensions and characteristics

Clinker bricks are in many ways similar to ceramic ones. But there are certain differences between them associated with the characteristics of the feedstock and temperature regimes for firing. In order to make clinker bricks, mainly medium-melting and refractory clays are used, so that for firing, accordingly, higher temperatures are required.

Decorative facing bricks can be combined in texture and color to create a unique facade appearance

The result of using this technology is a more durable facing brick, which is characterized by a minimum level of water absorption, and excellently resists the effects of all kinds of external factors. Such characteristics make it possible to use it not only for decorating the walls of a house, but also as a facing material for the basement of the foundation, paving paths and erecting fences.

But there are also indicators by which clinker bricks are inferior to ceramic ones. For example, this applies to thermal conductivity, which in this case is slightly higher. True, this disadvantage is compensated for due to the fact that the material is characterized by a high level of resistance to cracking as a result of exposure to low temperatures.

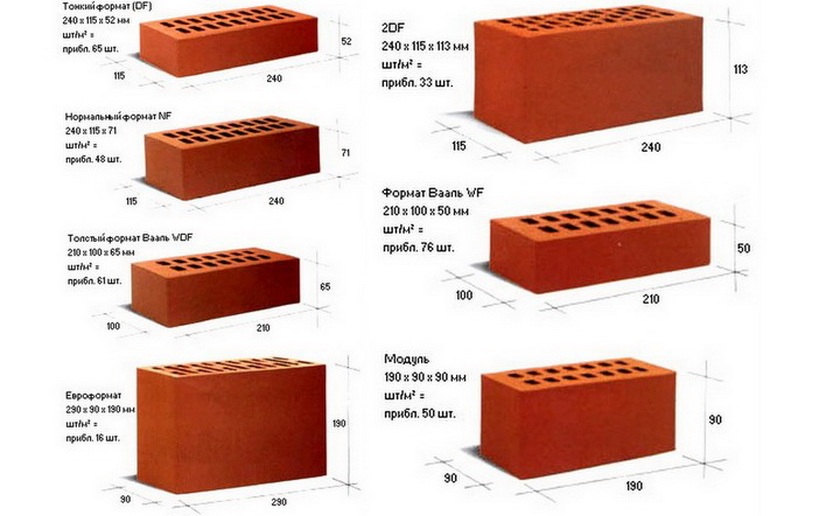

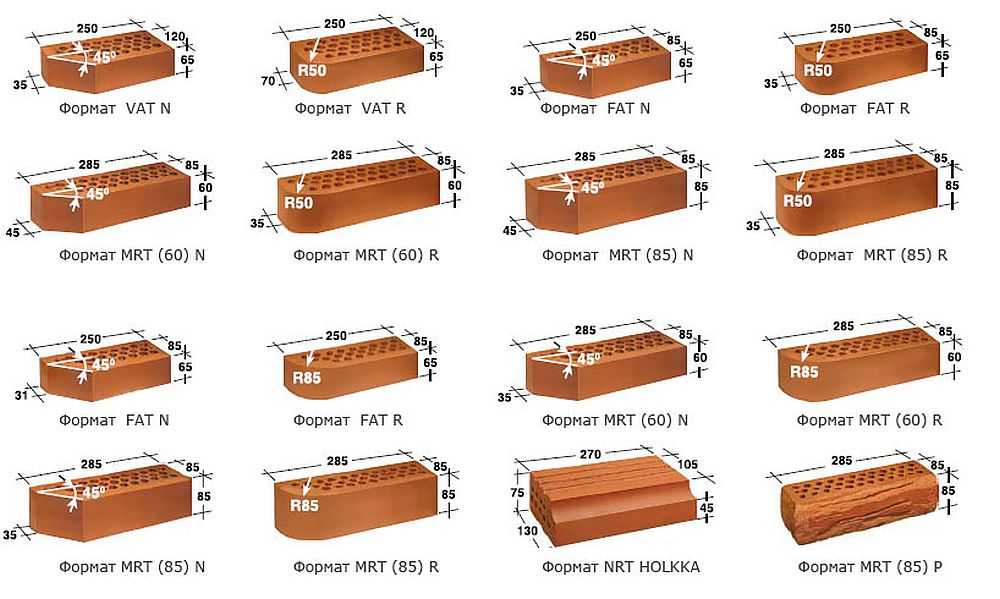

The colors and textures of clinker bricks can be so diverse that one may even come across the concept of "collections" that various manufacturers offer their customers. As for the size of clinker bricks, here you can find a wide variety of options.

The standard size of decorative bricks can have the following parameters - 250x120x65 mm, 250x90x65 mm and 250x60x65 mm. As you can see, the height of the brick can change, but the length and width of the brick remain unchanged.The only exceptions are the elongated elements, the parameters of which are 528x108x37 mm.

Dimensions of facing bricks

Classification of facing bricks

The gradation of the facade cladding is determined by the technology of its manufacture.

There are four categories of facing bricks:

- Ceramic.

- Clinker.

- Hyper-pressed (concrete).

- Silicate.

Brick in each of the listed categories is available in two versions: solid and hollow. The weight of hollow bricks is on average 25-35% less, and its resistance to heat loss is about 10-15% higher.

Ceramic cladding brick

It is produced by firing a raw mixture consisting of red low-melting clay, organic and mineral additives that regulate plasticity. In this capacity, coal dust, slag, chamotte, sawdust, ash and quartz sand are used. The initial mixture successively goes through the processes of forming, drying and firing. The main difference facing ceramic bricks from ordinary - Thorough preparation of components before molding. Therefore, there are no foreign inclusions and cracks in it.

The material obtained at the exit from the firing chamber is characterized by resistance to moisture, high strength and good energy-saving properties. Types and colors of ceramic facing bricks are varied.

On sale you can find not only ordinary, but also shaped material (for laying complex architectural elements). To expand the color gamut, manufacturers use mineral dyes (chromium oxide, finely ground iron or manganese ore), adding them to the composition of the feedstock.

Decorating the surface of ceramic bricks is performed in several ways. In addition to the smooth matte and glossy surface, there are available finishes that give this material a similarity to wild stone.

Clinker brick

The closest "relative" of ceramic bricks. The main difference between the two is the feedstock and the firing temperature. For the production of clinker, medium and refractory clays are used. Accordingly, they are fired at a higher temperature. The result is a very dense and durable facing brick with minimal water absorption. These qualities make it possible to use it not only in the decoration of the facade, but also for the cladding of the basement of the foundation, the construction of fences and the paving of paths.

The thermal conductivity of clinker stone is higher than that of ceramic. This disadvantage is compensated for by its high resistance to cracking at low temperatures.

The color palette and texture of clinker stone are extremely diverse, since each manufacturer offers its customers its own collections. The size range of this cladding is also not boring. In addition to the standard single version 250x120x65 mm, you can buy a brick of reduced thickness and height, as well as a long clinker (528x108x37 mm).

Hyper-pressed brick

Firing clay is an energy-intensive and not very cost-effective process. Therefore, many manufacturers are switching to pressed fired bricks. Its basis is granite screening, water and cement. At its core, it is an ultra-dense concrete that has been shaped into masonry bricks.

The main requirement for facade finishing is weather resistance. According to this indicator, hyper-pressed brick is perfect for finishing external walls.

In terms of strength and other quality characteristics, it is practically not inferior to clinker. Due to the texture of the surface (like a rock, torn stone) and the use of persistent dyes, this material looks great in masonry.

Facade decoration with hyper-pressed bricks looks elegant, solid and reliable

Facade decoration with hyper-pressed bricks looks elegant, solid and reliable

Silicate brick

Belongs to the category of non-firing materials. It differs from hyper-pressed brick in its raw material composition. There is no cement in it.High mechanical strength is achieved here due to the hardening of a mixture of silicate sand and hydrated lime in an autoclave installation (elevated temperature and pressure).

Nowadays, silicate facade brick as a facing material is losing its former popularity. In the struggle for a buyer, manufacturers have developed several color options for the silicate mixture. Unfortunately, they all look rather pale and cannot compete with the rich colors of ceramics and clinker.

This material behaves well in the facing of the building. Compared to clinker bricks, it absorbs moisture more strongly, but at the same time it withstands repeated soaking, freezing and thawing better than ceramics.

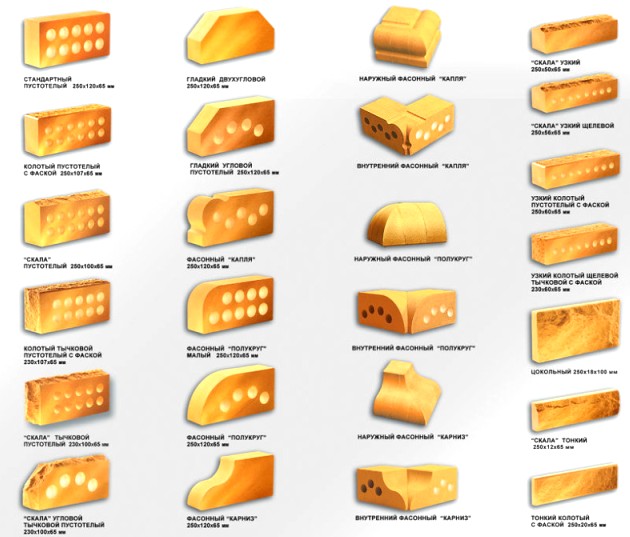

Figured (shaped) brick

Today, no one is satisfied with the straight lines of the facade, therefore, each type of facing brick is complemented by a wide range of shaped elements. Using them, you can lay out complex architectural elements without time-consuming cutting and cutting, dressing up the house in a beautiful "stone lace".

Dimensions as standard

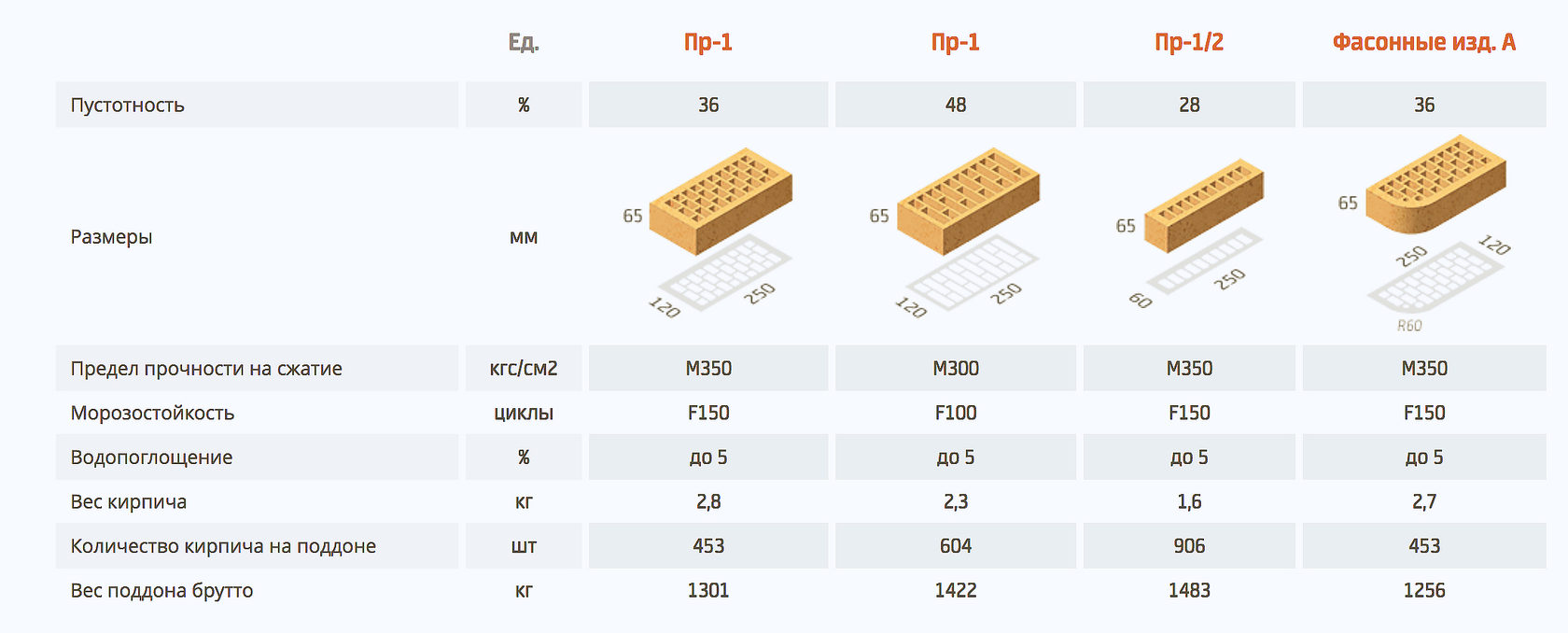

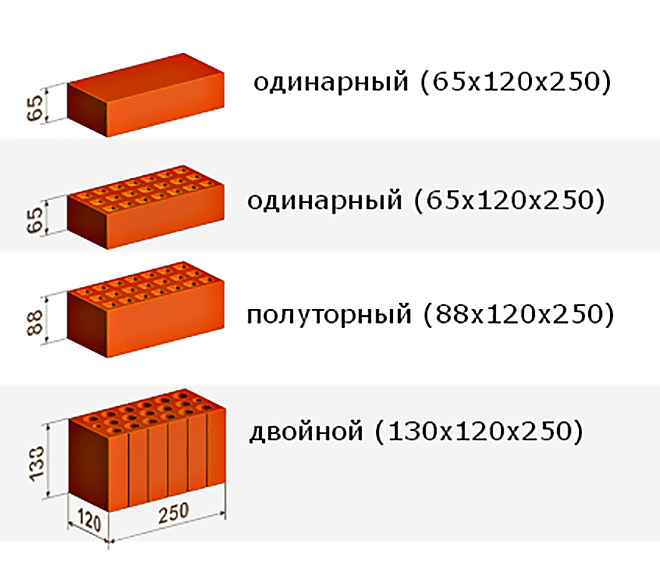

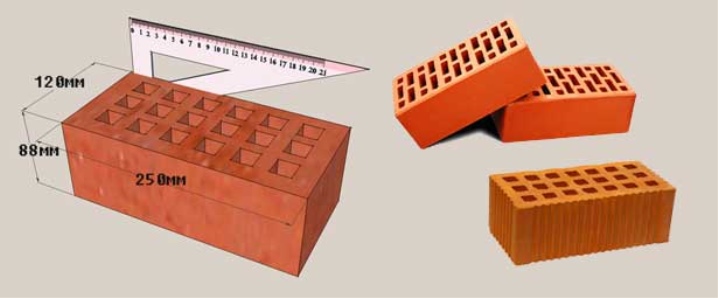

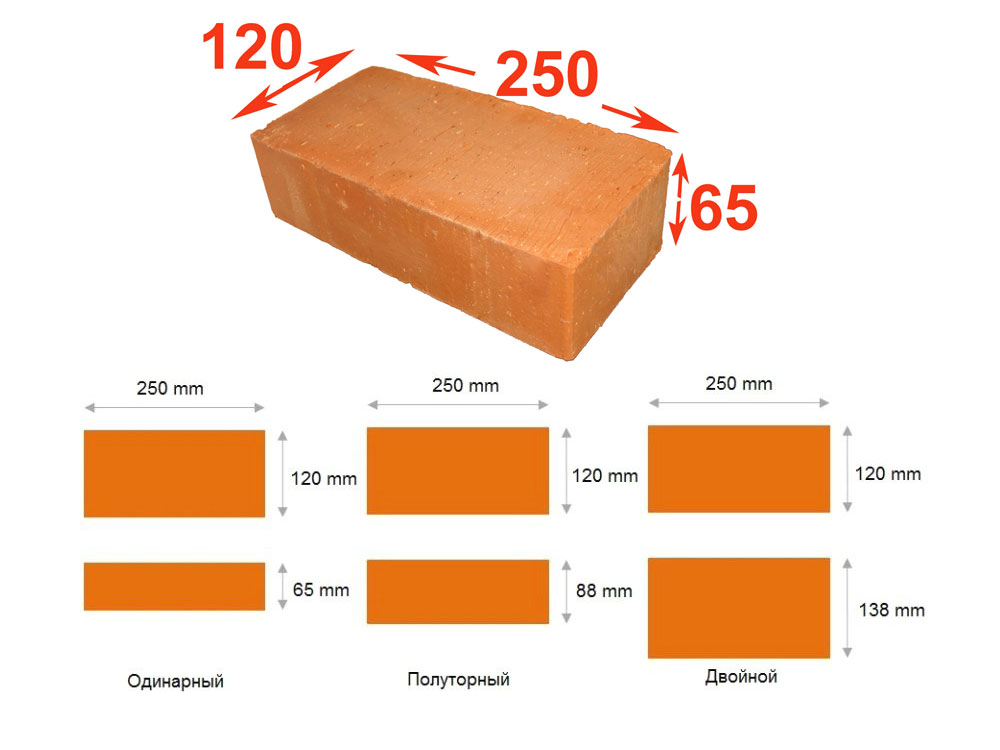

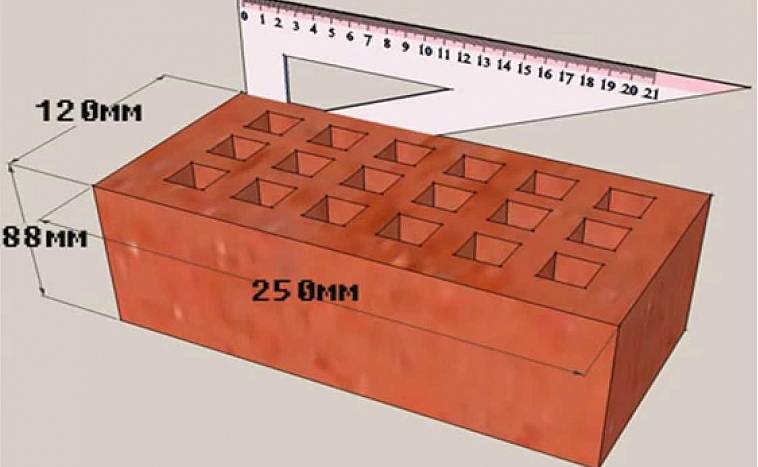

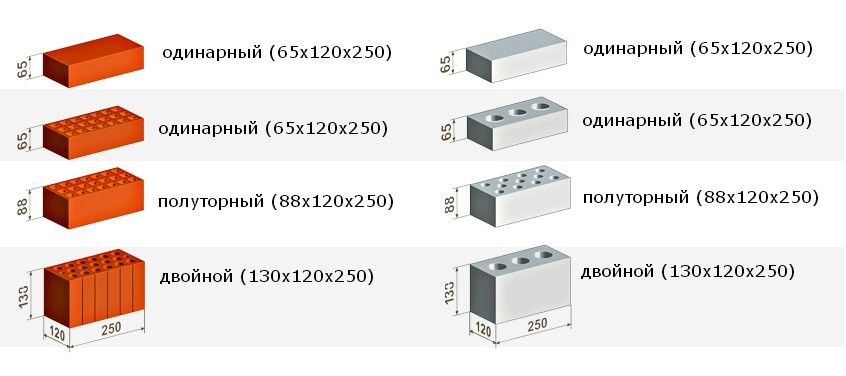

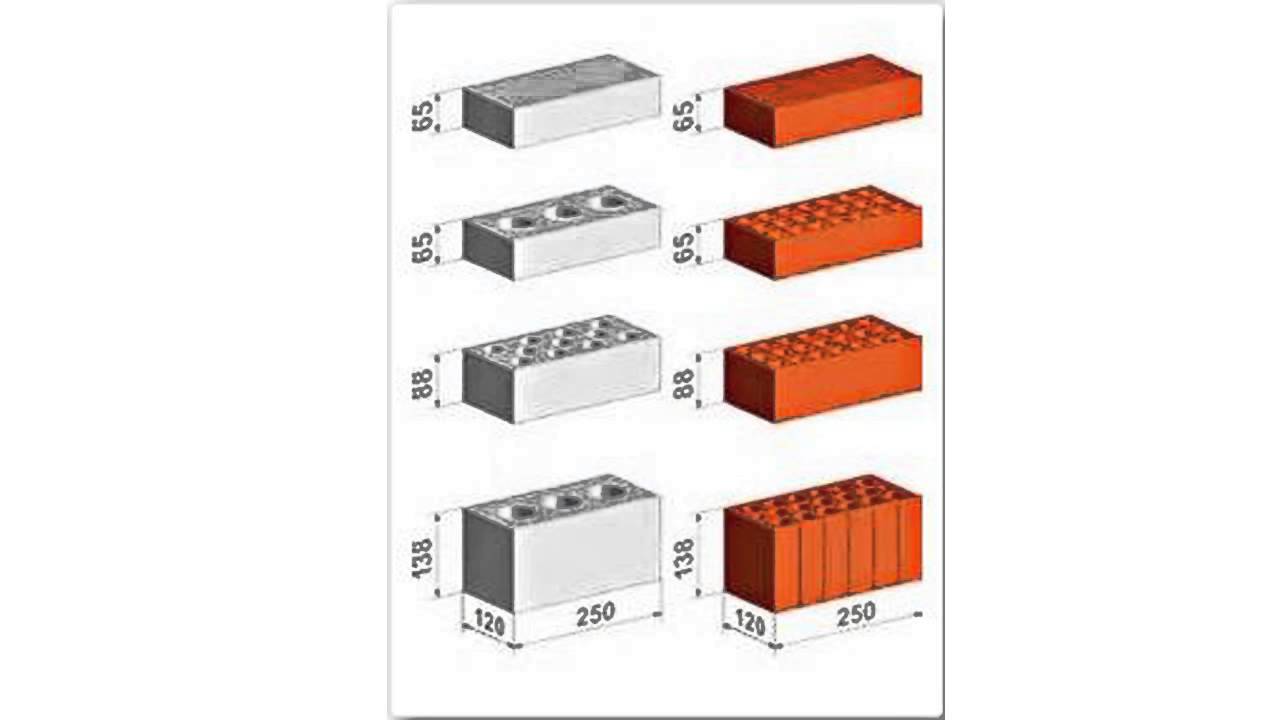

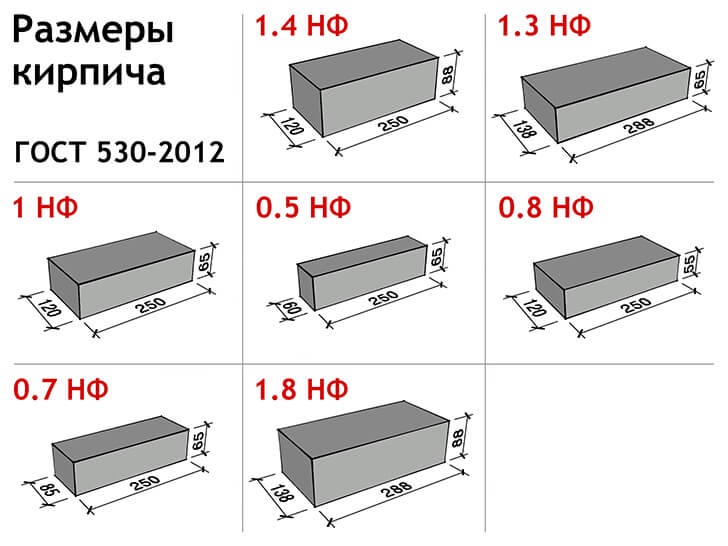

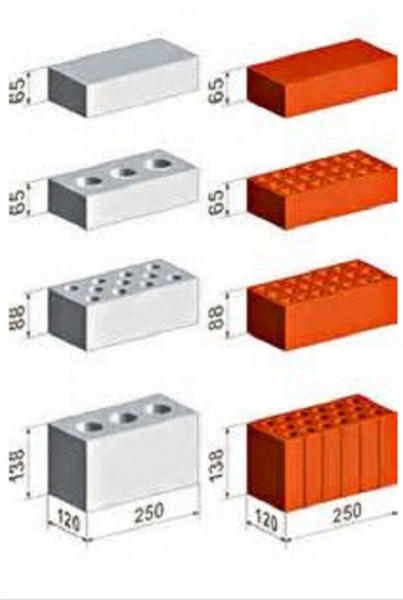

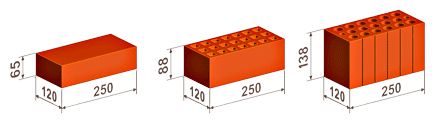

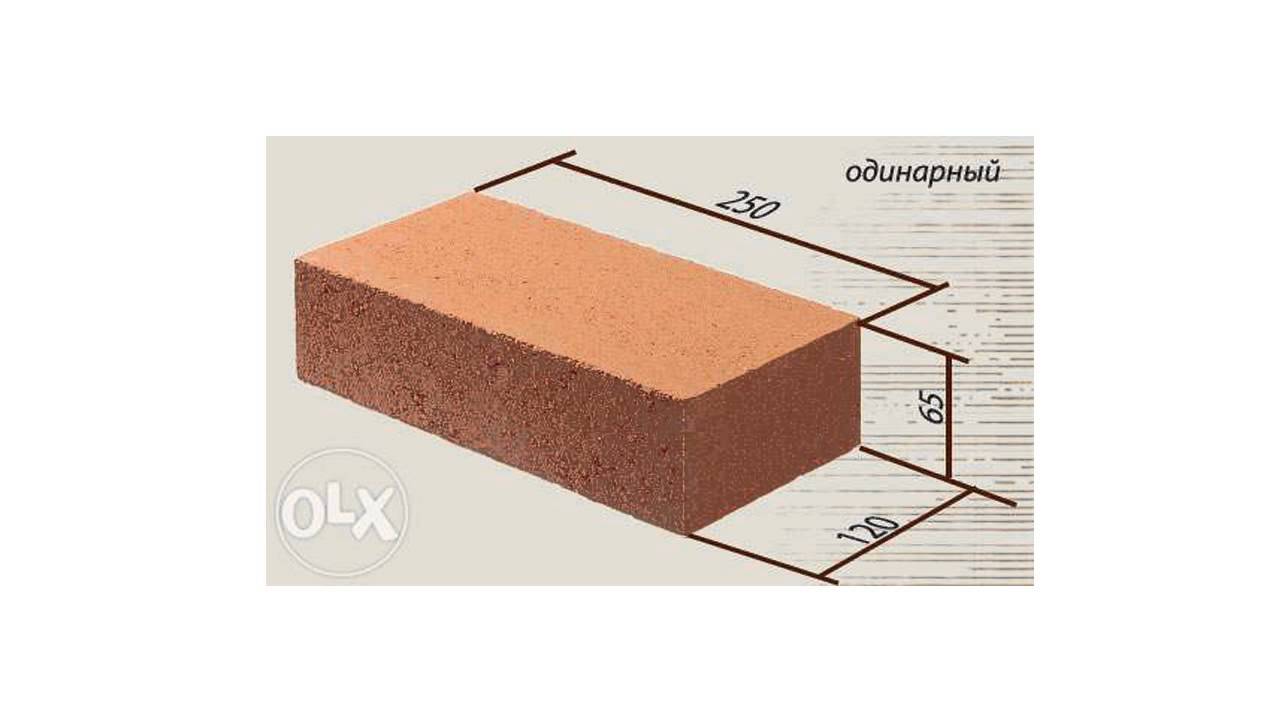

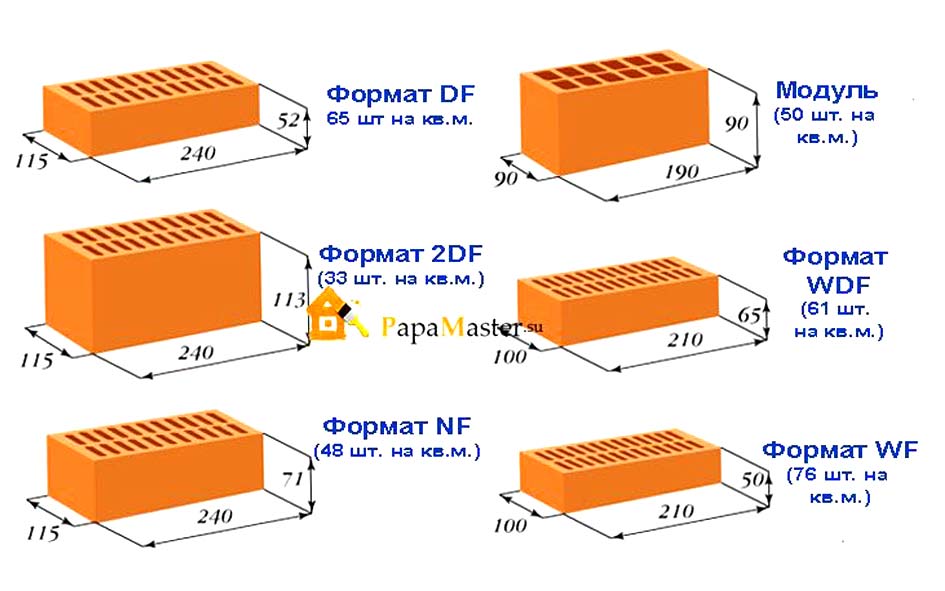

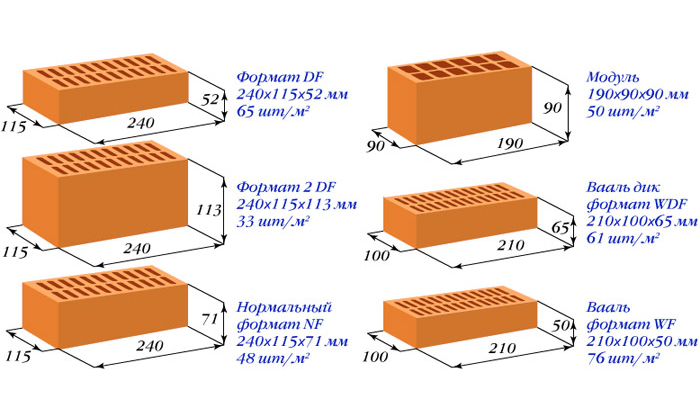

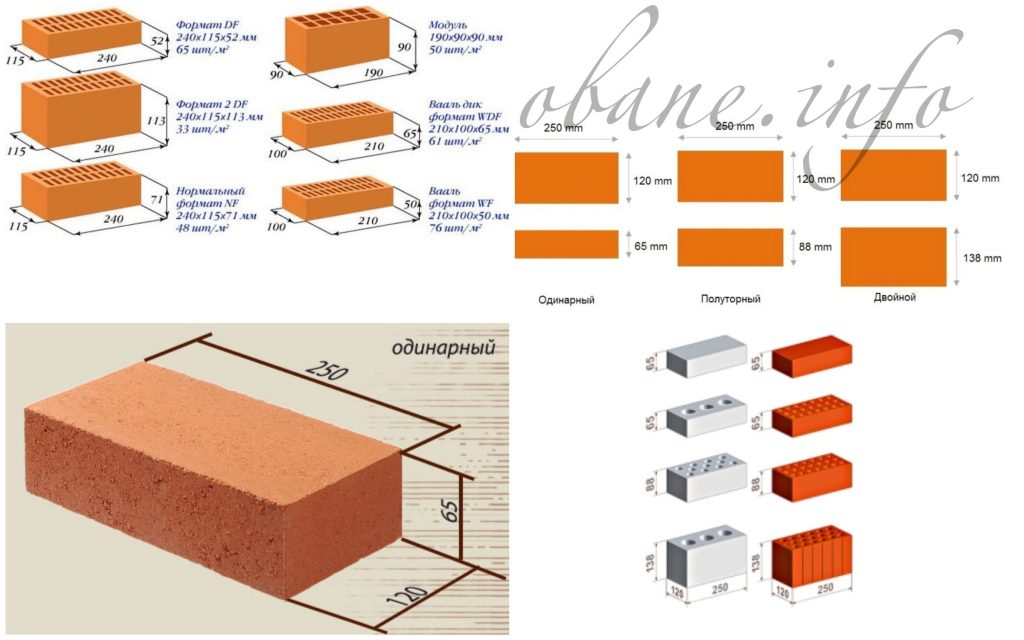

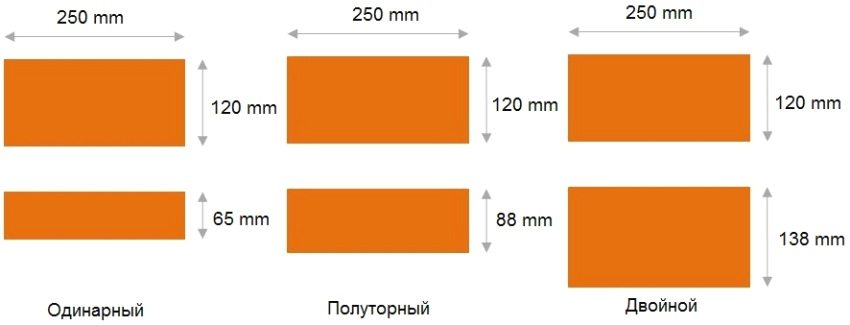

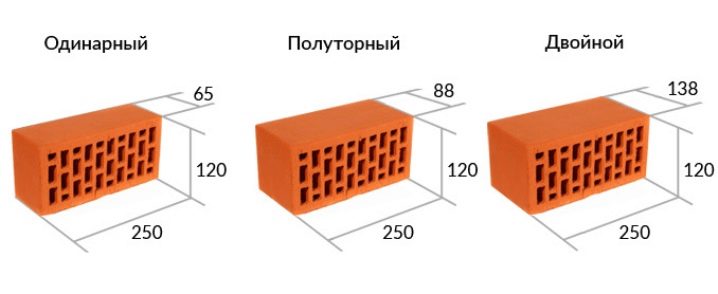

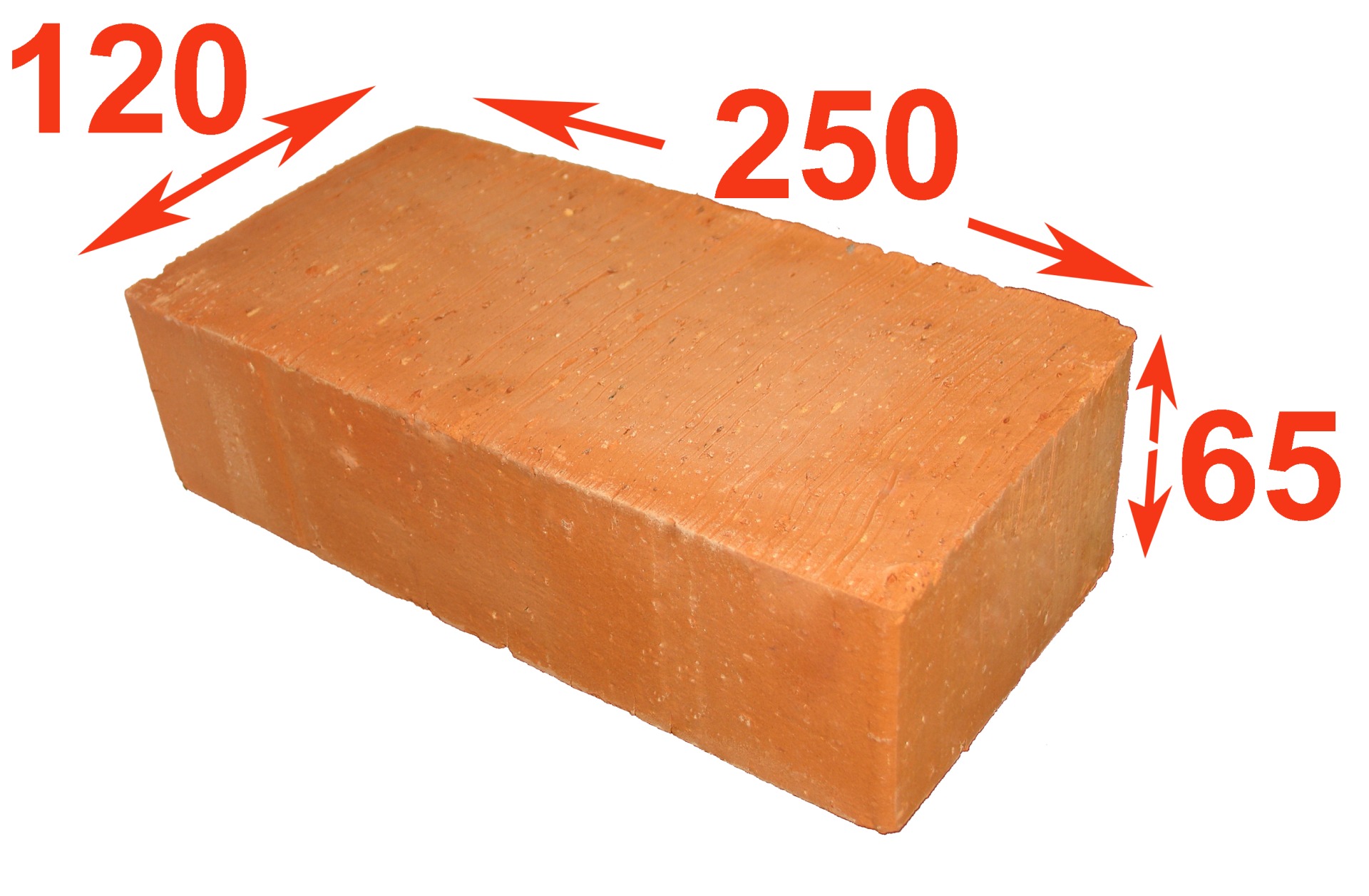

The main point in the standardization of brick sizes is the following proportions 1: 1/2: 1/4. This aspect ratio is optimal for masonry with a rotation of the transverse and longitudinal placement. In individual construction, single brick is in demand, its consumption per 1 m³ of masonry is 513 pieces.

According to state regulations available on the territory of the Russian Federation, the size of a standard single product is equal to:

- 25 centimeters in length;

- 12 centimeters wide;

- 6.5 centimeters in height.

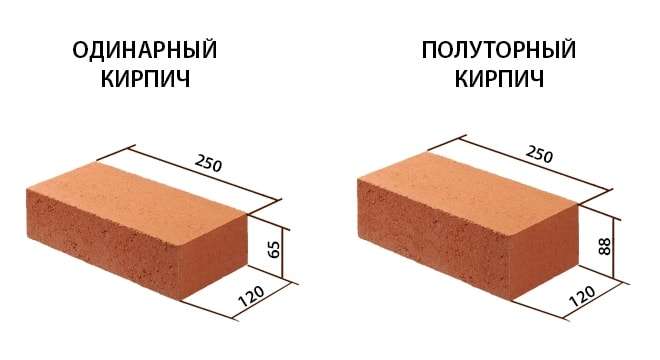

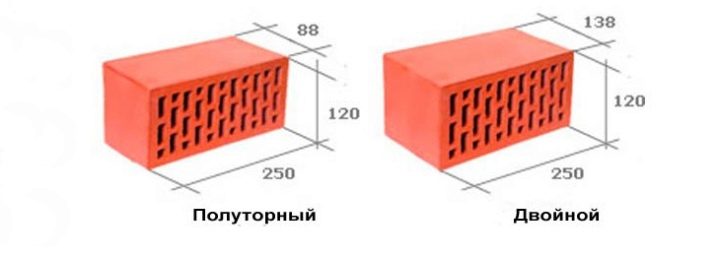

In addition to single bricks, the building materials market offers other types of standard sizes:

- one and a half;

- double.

One and a half building material began to be produced during the industrialization of the country in order to accelerate the pace of construction. The standard consumption of bricks is 318 pieces per 1 m³. A characteristic indicator of a one-and-a-half product is the added height; GOST defines the following standard product parameters:

- 25 centimeters in length;

- 12 centimeters wide;

- 8.8 centimeters in height.

The double brick, having the same 25 centimeters in length and 12 centimeters in width, has a height of 13.8 centimeters. Based on the considerable size, to reduce the weight of the product, double bricks are usually made hollow. It is widely practiced in various fields of construction. Height-added products are practiced for the construction of both civil and industrial facilities.

How many bricks are in a red brick pallet?

First of all, you need to understand the container. Brick products are delivered on pallets of two standard sizes:

- 0.52 x 1.03 m - small pallet;

- 0.77 x 1.03 m - large pallet.

With a weight of one red brick of 3.6 kg according to the table above, the maximum weight of a cubic meter of brick is 1847 kg, the total number of bricks per square meter is 513 pieces. How much does a pallet of red bricks weigh? The large pallet holds 1440 kg. And if you are wondering how many pieces of red bricks are in a pallet, then this figure is 400-420 pieces. The total amount on a pallet depends on the manufacturer and may vary up or down.

The amount of hollow is also calculated. For example, to find out how many red bricks are in 1 m3, you should divide the cube by the volume of one brick or use the tabular averaged value.

Piece by piece counting can be done by mathematical methods. To do this, it is enough to count the number of pieces in a row and the number of rows.

Layout of products on a pallet

Video: determine the weight of the pallet:

How to determine the amount of facing bricks in 1 m2 of masonry

The construction of any building begins with an estimate of the building materials that will be required for the implementation of a specific project.

The consumption of facing bricks required to form the walls depends on the linear dimensions of the brick blocks, the thickness of the seam of the cement mixture, as well as the height of the walls and the method of briquetting.

It is unlikely that it will be possible to determine the number of blocks with an accuracy of a brick, but it is quite possible to calculate the approximate number of pieces in 1m2.

Why is the consumption of blocks in m2 calculated? The answer is very simple and lies literally on the surface: this parameter allows you to understand how many briquettes are required for the construction of any building, even the most complex architecture.

Features of counting the number of bricks

To correctly calculate the consumption of bricks, you need to follow these steps:

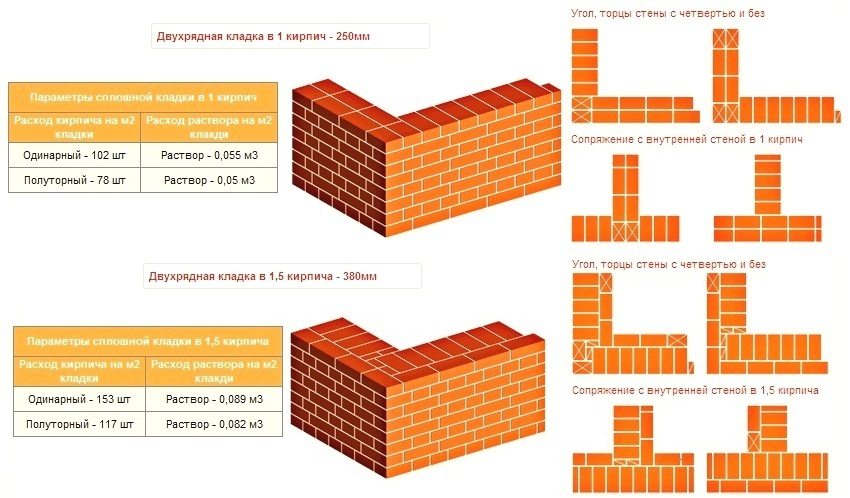

- Decide on the thickness of the masonry. The walls are formed in half a brick, which is 120 mm, a whole brick, the length of which is 250 mm, one and a half briquettes - 380 mm, two blocks - 510 mm, as well as 640 mm, which is equivalent to two and a half clinkers. The warmer the climate at the location of the building being erected, the thinner the walls can be made. For middle latitudes, a masonry of 2.5 bricks is considered ideal. Also, the thickness of the walls is directly influenced by the number of floors of the building being erected, the type of arches used, as well as the type and depth of the foundation. The higher the structure, the greater the load the walls will have to withstand, therefore, for multi-storey buildings, masonry is made of 2 or more bricks.

- Select blocks for masonry. To understand how much facing bricks are needed to form 1m2 of a wall, you need to know exactly the dimensions of the purchased briquettes. Bricks are produced in single size (250 × 120 × 65 mm), one and a half (250 × 120 × 88 mm) and double (250 × 120 × 138 mm) formats.

- Increase the dimensions of the brick spoon and poke by the thickness of the seam. As a rule, on horizontal surfaces, the cement mixture is laid out with an interlayer of 10 mm, and on vertical surfaces - 12 mm. Since two building blocks are in contact with the seam, to take into account the thickness of the seam when calculating the number of bricks in 1m2 of the wall, half of the seam value is taken, that is, the length of the spoon is increased by 6 mm, and the height of the poke is increased by 5 mm. Based on these data, the area of the spoon is calculated.

- Then 1m2 is divided by the area of the recalculated brick spoon. The resulting value is the approximate number of facing bricks that will be consumed in the formation of each m2 of a wall half a block thick.

- We divide the thickness of the walls by the recalculated width of the brick poke and we get the coefficient by which it is necessary to increase the previously obtained number of bricks.

There are several techniques for laying building blocks, but all of them are used to give the facade of a building a certain aesthetic appearance and practically do not affect the amount of bricks per m2 of the wall.

The exceptions are patterns that are specially formed from bricks when erecting the external walls of buildings.

In any case, it is the dimensions of the briquettes used that are the key parameter that determines the consumption of materials during construction work.

Important nuances

After calculating how many building blocks are needed for laying each m2 of the wall, the resulting value is increased by 5-7%. This gap is necessary to cover scrap and breakage, which is inevitable when transporting building materials.

How many blocks do you need to build a specific building? To determine the final consumption of briquettes, first calculate the total area of all walls of the object being built. To do this, the height of the walls is multiplied by their length and the dimensions of the windows and entrance doors provided for by the construction project are subtracted.

The total area value is multiplied by the number of bricks in each m2 of masonry. The target number is the number of clinkers required for the construction of this facility.

Correctly carried out calculations will allow not only to determine how much brick will be needed for the construction of a building, but also to significantly reduce the cost of purchasing building materials.