Bricklaying joints

It is advisable to join brickwork only if the brick walls will not be plastered or finished with another type of finish that will completely cover the brick surface.

Often, jointing of brickwork is necessary when the brick wall will be painted or varnished.

Bricklaying tool

Joints are sewn with a special jointing tool, which can be convex or concave. In the process of sewing joints with your own hands, it turns out, to achieve not only clear shapes and sizes, but also strengthening, giving the brick seams more strength.

Given the fact that the surface of the walls must be prepared in a certain way to join the brickwork, this process will also require a brush with a hard bristle and a roller for painting the walls.

Joint mortar

Do-it-yourself brickwork jointing technology will be discussed below. Now it is worth talking about the solution that is used for joining, since it can be either dry or ready-made, diluted with water or other means.

If it is necessary to make a mortar for jointing brickwork, which is presented in a dry form, then it is better for these purposes to use an electric drill with a mixer nozzle put on. The proportions of water and dry mixture of the grouting mortar must be observed as recommended by the manufacturer.

Brickwork joining technology

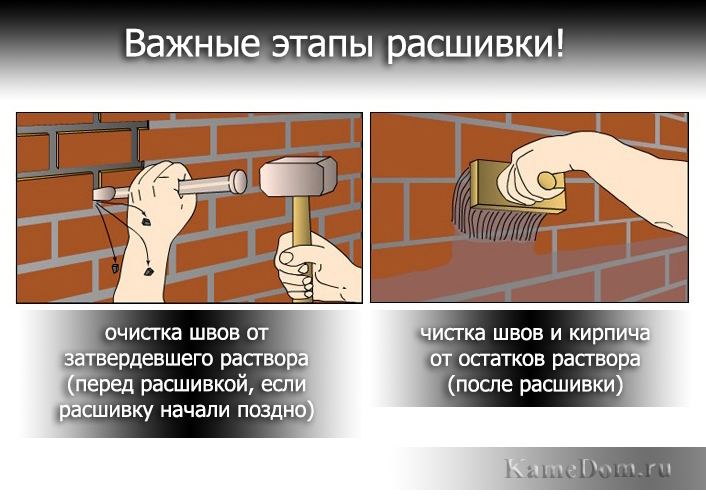

As mentioned above, jointing brickwork requires special surface preparation. To do this, you first need to deepen the existing brick joints. To do this, use a puncher or other convenient tools to remove the old mortar between the bricks.

In this case, it is necessary to act carefully so as not to severely destroy the seams and not damage the brick surface itself. It is enough to choose an old solution to a depth of 1-1.5 centimeters.

Then, using a brush with a hard bristle, clean the brick joints from the chipped mortar and accumulation of dust. Further, using a roller and ordinary water, the grooves between the brick joints are abundantly moistened with plain water.

Only after all the above preparatory work, you can make a mortar for jointing brickwork and start applying it to the seams.

What to consider when doing this:

- The prepared solution is rubbed into the brick joints with a tool, and its excess, if any, is immediately removed with a trowel.

- The mortar for grouting brickwork must be pressed in, not rubbed in, this is the only way to remove excess air from it.

- Horizontal jointing of brickwork is done with an oblong tool, and vertical jointing, on the contrary, is narrow and short.

- By standards, the thickness of horizontal brick joints should be in the range of 12-15 mm, and vertical 8-15 mm.

The jointing of brickwork is actually not difficult. The most time-consuming work here is precisely related to the correct preparation of the joints between the bricks.

Nevertheless, there are many videos on this topic on the Internet, and if you first prepare properly, then jointing the seams will not cause much difficulty.

Joining technology during construction

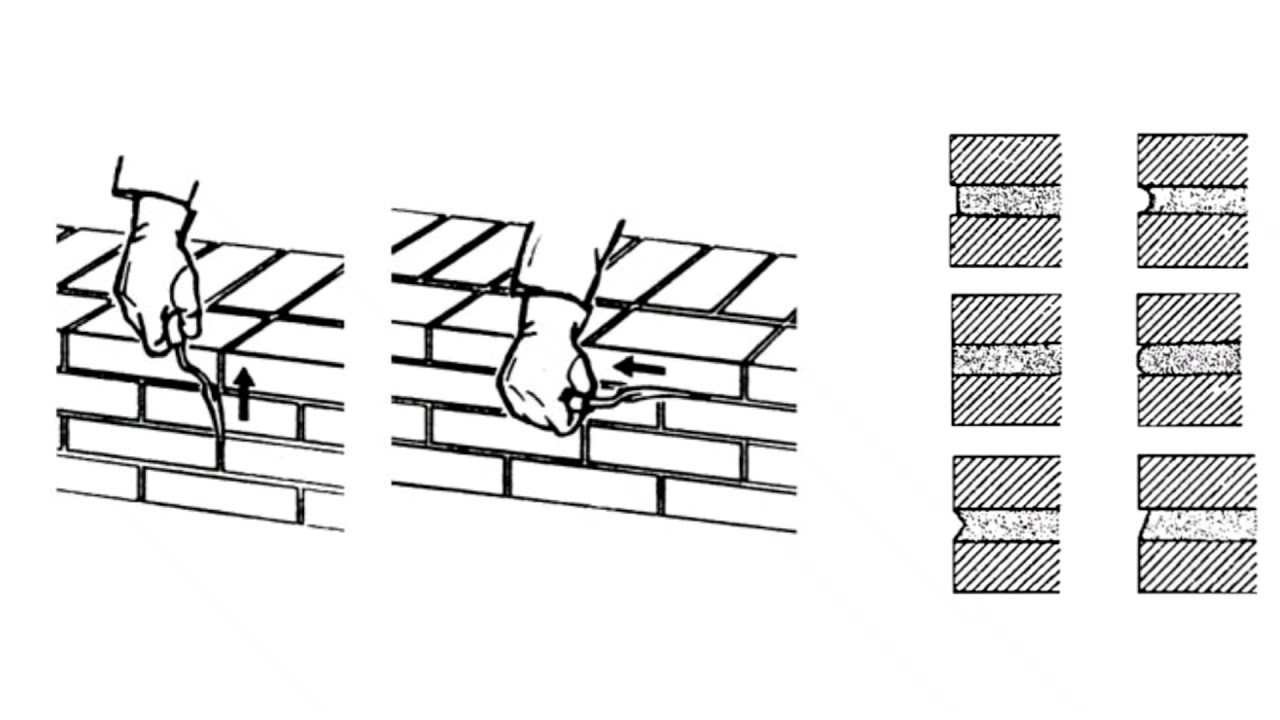

In this case, the seams are finished immediately after laying several brick lines. The starting point for work is the beginning of the hardening of the composition. The composition itself must retain its own elasticity.

Here it is important to perform the following sequence:

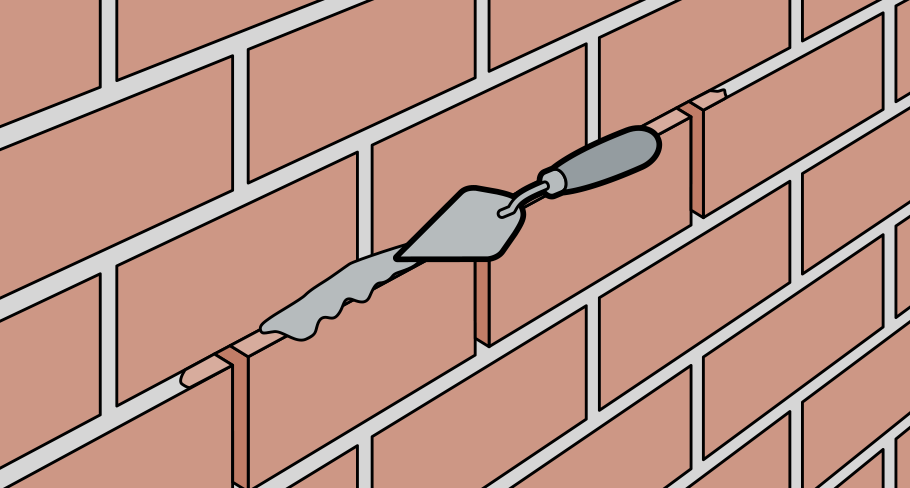

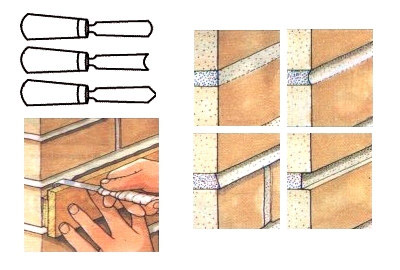

- When laying this material, the entire composition that has protruded outward is cut off along with the laid masonry. Such trimming significantly increases the rate of joining. An example of this is shown in the figure below:

- The wall surface is carefully cleaned. The tool for work is a hard, fluffy brush.

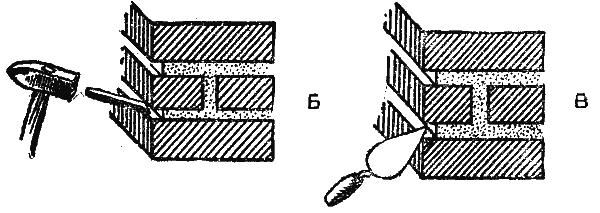

- Joining of vertical seams. The tool moves from top to bottom, pressed into the masonry. Air is removed from the composition by pressure. The density and strength of the composition is developing. Short seams must be sewn upright.

- To give evenness to the seams in a horizontal position, a wooden strip is attached to their underside. You should lean on it and guide it along the masonry line. Equal pressure here will create a pleasant aesthetic cladding.

- Grouting in a vertical position. Then - in a horizontal position. Surface movement for work: from top to bottom.

- When the composition is completely seized, the details of the jointing mixture are removed from the wall. A broom or brush is used here.

Placing the seams of internal walls

If the room needs a grouting material for brick joints, for example, between gypsum tiles or decorative stone, it is necessary to select the color scheme of the grout to match the main tone of the interior. Alternatively, you can choose a color in the same shade as the tile. If, for example, there is only one wall in the interior, reserved for tiled masonry, you can choose a grout of the same shade with the walls. If this is a floor, then it is necessary to choose a tone so that the walls do not merge with it. Thanks to grouting, you can quickly, without any problems and significant costs, update and refresh the color of the inter-tile space.

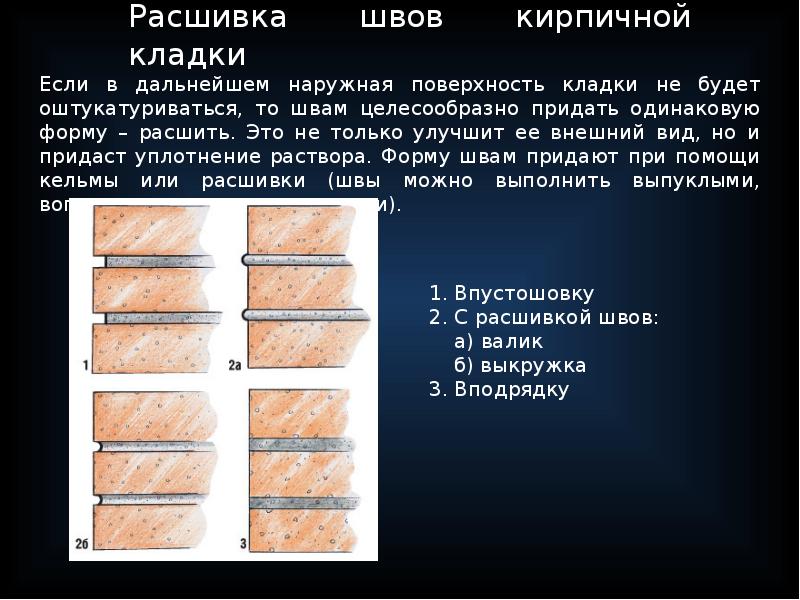

Joining types

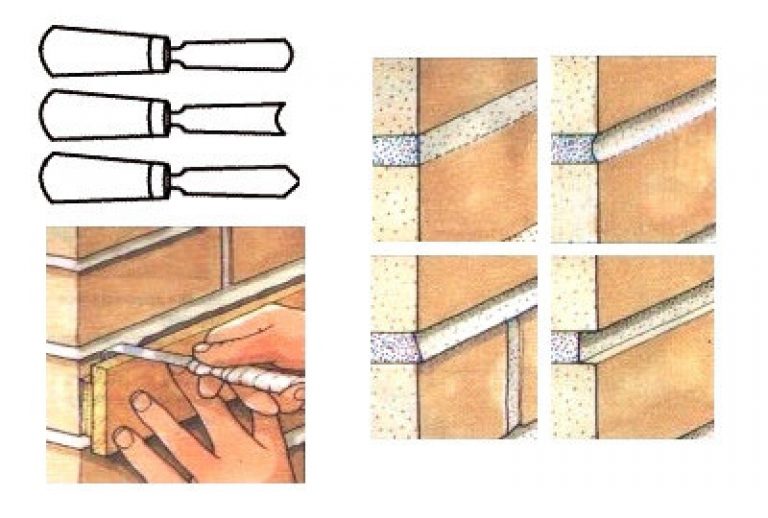

The jointing tool gives the seams a clear pattern. The size of its edge can be of several types:

- Recessed rectangular shape.

- Convex oval.

- Rectangular undercut with bricks.

- Concave oval.

- Triangular concave.

- Triangular convex.

- Single cut concave.

The recessed rectangular shape provides for the removal of mortar from the joints to a depth of 6 mm. Then they are filled with a new mixture and smoothed with a rectangular trowel. If the brick structure is subject to high humidity, then it is better to refuse this type of jointing.

Rectangular jointing is also used for undercutting with two bricks. To do this, the solution is simply carefully removed from the seam, without deepening.

A concave oval is made by removing excess mortar from the seam, then filling it with a new mixture and processing with a special jointing. The convex oval is made using a similar technology.

Triangular and single-cut joints differ from the previous ones in that they make a cut on the mortar at an acute angle.

Technological process

How to make brickwork for joining? When is it allowed to start such work?

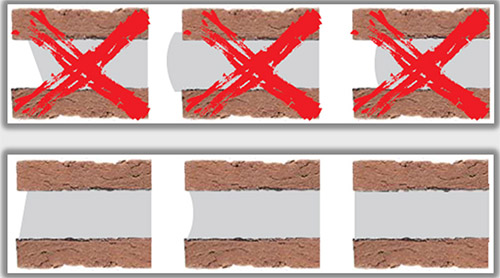

If you decide to use the technology of laying facing bricks with the simultaneous design of the seam areas for joining, then the excess mortar mixture is removed with a trowel so that a common level with the plane of the wall is ensured.

As soon as the mortar mass begins to set, it is given the required shape using a joining template. The solution between the brick rows is pressed inward by about three millimeters, well compacting the mass. This improves the quality of not only the masonry, but the entire wall as a whole.

With regard to the time when it is best to start such a procedure, the following points are observed, which are the most significant:

- monitor the consistency of the solution and the degree of its plasticity;

- control natural factors - the temperature regime of the air and the percentage of humidity in it;

- high-speed mode of work of the master performing the laying of brick stone.

Masonry with simultaneous joining

A similar procedure is started by preparing several rows of masonry, the solution in which begins to gradually harden.

It is necessary to act in a certain sequence:

- the brick stone is laid on a sufficient thickness of the mortar layer, slightly pressed. The mixture outside the joint is removed flush with the brick surface;

- the mortar that has seized, but did not have time to harden, is smoothed with a jointing or a piece of a simple hose, compacting and pressing the mass into the seam;

- if the joining will be performed a little later, then it is recommended to leave a little free space in the joints so that there is room for the jointing mortar.

Joining after masonry

Making bricks for joining is possible on long-erected walls. To do this, you will have to remove a certain amount of old masonry mortar. The formed cracks are moistened, a new solution is laid in them, which is embroidered in a known manner.

It is recommended not to prepare the mixture yourself, but to purchase ready-made formulations in a dry form, which remains to be diluted with water. Such materials, after completing the jointing procedure, perfectly retain their shape.

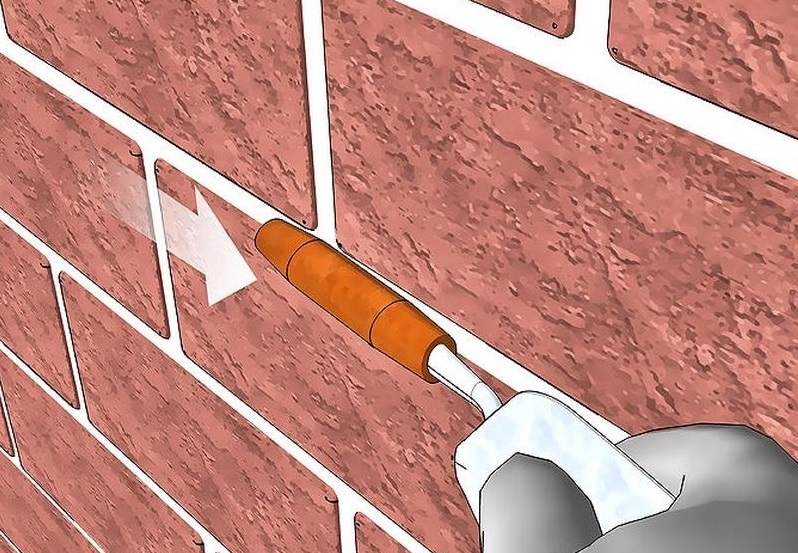

Masonry using a rod

This technique is based on the use of a round or rectangular steel rod, which is laid along the entire length of the bottom row on both sides. Then it remains only to fill the free space between the metal elements with a mortar mixture, lay out the brick stone in a row, adjusting it in place with a wooden mallet.

Carrying out such work implies a large supply of metal rods of the same section, since the laid steel elements should be removed after a certain number of brick rows have been removed from above. The rods are carefully pulled out, after which they are immediately washed with water from traces of the mortar mixture.

The advantage of this method of joining is that after removing the rod, an attractive and even joint remains, uniformly filled with sand-cement mortar. It does not have to be additionally modified, even cleaning with a metal bristle brush is not required

True, the performer of the work will need special attention on the layout of the first row - it should turn out to be ideal, displayed strictly in a line. The check is carried out at the building level

By expanding seams with a metal rod, you get the following benefits:

- masonry seams are perfectly flat;

- if all work is done carefully, then the front surface of the brickwork retains its cleanliness. This is especially true for expensive facing stone, the surface of which is difficult to clean from dried mortar particles;

- the need for the formation of seam areas completely disappears - all the work is performed by a metal rod.

By the way, many people prefer to use round steel elements, because square shapes do not always make it possible to maintain the general level for brick stone and mortar. This type of joint requires additional filling with jointing compound.

Trowel technique

To carry out the last stage of laying the cladding elements, it is necessary to prepare tools and materials:

- putty knife;

- bag;

- gun;

- mixture;

- gloves;

- container with water.

Important

Not every job can be done with a syringe, so an ordinary, narrow spatula and a bag that is filled with grout may be required.

Additional tool:

- mixer;

- trowel;

- level;

- container for the solution (if it was in the bag).

- First you need to prepare the surface. It is cleaned of excess glue and dust solution. They wait for it to dry (10–20 minutes), prepare for grouting.

- The composition is laid neatly into the seams, compacted. Excess when applied is removed immediately, while not hardened.

It is important to choose the right mix for the cladding. Dilute it according to the instructions that manufacturers have on the packaging

If the composition is purchased dry, a small amount must be diluted. It will be convenient to work this way, and a large volume may begin to dry out. And stale (if you cook a lot and leave the next day) will lose its properties, worsen the waterproofing of the seams and crack.

When all the factors of the grouting process are taken into account, and the composition is selected in accordance with the lining, then you can rub it in the following ways:

- Inside - the solution is tamped under the stone, without leaving it outside, if necessary, additional indentations are made. The seam becomes concave and the stone appears to protrude outward.

- Flush - performed with a semi-dry mixture, you can rub it in with your hands (but with gloves). After rubbing, wipe the surface with a rag or hard cloth to get rid of excess.

- Convex - the composition is rubbed with a special spatula, which is carried along the seam, then, on the contrary, it protrudes outward. It is worth practicing for this method, as it requires certain skills.

- Beveling is a method that does not require skill. It is necessary to move the trowel along the seam, and then immediately remove part of the mortar, making indentations up to 4 mm at an angle.

- The triangular method is a complex and beautiful grouting method used more indoors. For mashing, you will need to remove a certain amount of mortar between the bricks, the remaining composition is placed in a triangle. This requires skill and skill from the master.

With a syringe gun

The method is used in the following cases:

- outdoor cladding;

- a large amount of work;

- when processing a porous or sandy surface.

Grouting with a gun allows you to apply an exact strip of the seam along the entire length of the decorative elements, while eliminating the occurrence of voids, interruptions, bubbles.

The tile or stone remains clean after work, material loss is minimized and the grouting speed is high.

- The finished composition is put into the gun with a trowel or spatula.

- Then, by neat straight extrusion from the tool, vertical seams are filled from top to bottom, and horizontal seams - from left to right.

If there is no special gun, then you can buy a disposable grout. It looks like a syringe tube, it has a seal, and the solution inside does not need to be prepared and diluted.

Spatula

Attention

The rubber spatula is the most common tool in the job. A thin strip of grouting material is collected on it, and then laid between stones or tiles at the desired angle

The solution must be put with effort into the gap, then walk along the seam, removing the excess.

The force must be sufficient to rub the tool plate with the plate so that it fills the entire seam cavity and ensures that the tile lining is tight. Cement and epoxy grouts can be applied with a trowel.

From individual publications of experts on our website, you can find out what types of decorative stone exist and are used for wall decoration, as well as read how to beautifully and correctly decorate with such materials Khrushchev, balconies, arches, kitchens and hallways, as well as doorways in various apartments ...

Precautionary measures

When performing jointing work, you must follow the safety rules:

- use personal protective equipment: hard hat, goggles or face shield, gloves, heavy clothing, steel toe cap and heavy-soled shoes, respirator;

- follow the rules for working at height;

- do not hang on the wall and do not lean on fresh masonry;

- do not work from random supports, use only inventory scaffolding, ladders and meanness;

- do not leave tools and materials on the scaffolding unattended;

- before using electrical appliances, make sure that they are in good working order and that the insulation is intact.

Personal protective equipment will be required for jointing.

Personal protective equipment will be required for jointing.

Compliance with these requirements will save health and life.

Brick laying for joining the nuances of the process

Before proceeding to the direct solution of the question of how to lay a brick under the jointing, first we will deal with the question of what it is all about. According to many people, jointing is a special tool that creates a beautiful face seam. But many people forget that jointing is a kind of template that allows you to maintain an equal distance between individual bricks. In most cases, this tool is half or most of the brick length, making it easy to use to level masonry.

The jointing is either a thick plate with a curved handle, or a tube cut in half lengthwise. The latter option was actively used by bricklayers before, and today flat joining has become widespread, which make the seam more accurate.

Brick laying for joining photo

So, we figured out the joining, now it's time to clarify the situation with the question of how the laying under the joining is done? In principle, there is nothing difficult here, especially if you clearly lay out the first, fundamental row in the level. Let's start with him.

There are several ways to lay out the first row in compliance with the horizon, but in most cases, experts use only one. Lighthouse bricks are installed at the corners or edges of the wall - their uniform level can be checked hydraulically or with a laser. A thread is pulled between these bricks, relative to which the first row is laid out.

Here you need to pay attention to the tension of the thread, since at long distances it can sag - it may be necessary to install an intermediate lighthouse brick. If the distances are small, then the first row can also be laid using an ordinary rack level. Now the second row and all subsequent

This is where the fun begins - you have to learn how to apply the solution in a certain amount. This is where the jointing is needed, which can be used as some kind of template. On the previous row, a mortar is applied with a slide, the height of which is two times greater than the width of the jointing. Then the brick is set with a hammer, and the joint gap between it and the previous row is controlled by jointing. It is simply inserted into the seam, and the brick is lowered all the way. It should be understood that such control will have to be carried out on all sides of each brick.

Now the second row and all subsequent ones. This is where the fun begins - you have to learn how to apply the solution in a certain amount. This is where the jointing is needed, which can be used as some kind of template. On the previous row, a mortar is applied with a slide, the height of which is two times greater than the width of the jointing. Then the brick is set with a hammer, and the joint gap between it and the previous row is controlled by joining. It is simply inserted into the seam, and the brick is lowered all the way. It should be understood that such control will have to be carried out on all sides of each brick.

How to lay a brick under the joining of a photo

In this way, each brick of the front masonry is laid. This, of course, may seem difficult, but, believe me, after a few unsuccessful attempts at most, everything will turn out in the best possible way. As the solution dries, it is additionally necessary to cultivate the seams - the jointing is again driven into the seam, and with its help, the solution in it is smoothed with a longitudinal movement. Here she works as a spatula. Do not forget that this tool needs to be moistened with water more often, then the solution will not adhere to the metal, and the seam itself will remain smooth. And yet, in this way, the seams can be given any color. This process is more similar to grouting tiles, only it is done much more carefully. Excess mortar or grout after drying is removed with a special brush with wire bristles.

Brickwork for joining photo

Homemade device for getting even masonry

To improve the quality of masonry work and speed it up, you can make a special masonry template

To improve the quality of masonry work and speed it up, you can make a special masonry template. Outwardly, this product resembles a wide container without a bottom. With this device, you can easily apply a perfectly even layer of mortar. As a result, the masonry process itself will be much easier.

The following characteristics of the masonry depend on the evenness of the application of the solution:

- If you lay the stone on a very thin layer of mortar, then the adhesion of the bricks will not be strong enough.

- Too thick layer of masonry mortar will lead to overspending and getting ugly uneven masonry.

- If the mortar is applied in an uneven layer, then the outside of the masonry will look sloppy due to the curved rows.

You can avoid all these disadvantages of incorrect application of the solution using a template. Outwardly, this is not just a container without a bottom, but a product with restrictions on the sides, which allow it to be firmly held on the wall. The dimensions of the template can be very different and depend on the masonry performed and the stones used.

The mortar can be put into the elongated hole in the central part of the fixture.

The template is placed on top of a row of bricks. The mortar can be put into the elongated hole in the central part of the fixture. As a result, thanks to the limiting parts of the template, the mortar layer comes out perfectly even in width and height. Moreover, the seam height will be exactly the same as specified by the dimensions of the template. After filling the niche with a solution, the template can be moved to a new place.

The template allows you to replace two tools used at once when making a masonry mortar - this is a building level and a cord. At the same time, during the construction of one building, several types of templates can be used:

- When executing the main walls of the building, templates with the specified basic parameters of the walls are used.

- To perform the facing brick layer, a different template is used with the parameters of the facing stone.

Making a template

Such a device for quickly laying bricks is easy to do with your own hands.

Such a device for quickly laying bricks is easy to do with your own hands. It's over, you can buy the finished product in the store. Usually on it you can adjust all dimensions (seam height and seam width). But if you want to save money, you can make a template yourself.

First you need to decide on the basic geometric dimensions of the masonry joint (width and height). Here a lot depends on the stone used. Depending on the masonry technology and the material used, the dimensions of the template niche are determined.

To work you will need the following materials and tools:

- a plastic box of a suitable size or a sheet of chipboard (plywood) and strips of a suitable thickness;

- pencil, level and ruler;

- drill (hand or electric);

- fasteners (screws, nuts, screws);

- steel corners;

- screwdriver;

- screwdriver;

- hammer.

If you managed to find a plastic box of a suitable size, then the template is much easier to make from it.

Moreover, the plastic is quite strong and lightweight, which is important when performing masonry work. If you did not find the box, then you can construct a structure of the required size from chipboard sheets or plywood and slats

First, you need to make a regular box without a bottom slightly larger than the width of the brickwork.

The whole structure includes the following components:

- Frame with two longitudinal wooden sides. The distance between these wooden planks should be equal to the thickness of the wall. Thanks to the protruding lower parts of the planks, it is convenient to align stones when laying, as these planks go into the lower row.This makes it much easier to maintain the verticality of the wall without a plumb line and level.

- Carrying handles. The handles make the tool easier to use.

- Crossbars. They are usually made of strip steel. This element allows you to control the linearity of the masonry.

The second name of such a template is a dispenser, since it can be used to accurately dose the amount of applied solution.

The second name of such a template is a dispenser, since it can be used to accurately dose the amount of solution applied. Above, we described the device and the principle of using a horizontal dispenser. It is suitable for horizontal seams.

To form a correct and even vertical seam, a vertical dispenser is used. The principle of using an end dispenser is similar to that of a horizontal template. The only difference is that, due to the small amount of solution, it is applied using a hand trowel.

Tools for the job

Thanks to the jointing, the brick wall takes on a noble and beautiful appearance.

- Convex or concave jointing - this tool is designed to fill the joints of brickwork at home and remove mortar residues from them. Depending on the required thickness and shape of the joints, the cross-sectional profile and the size of the jointing are selected. If desired, you can make it yourself by bending a strip of metal and wrapping the intended place for the handle with electrical tape. You can use an old knife by pre-heating it on the burner and bending it.

- Falcon is a tool that is a 40 × 40 cm shield with a handle. It can be made of both metal (it is more durable) and wood. Used as a grout tray.

- The masonry trowel is a steel trowel, sanded on both sides, with a wooden handle. It is used for leveling, cutting mortar from brickwork at home and for filling vertical joints. This tool can be used to bandage the seams of brickwork.

- The mortar shovel is used to supply mortar, to spread it on the wall of a brick house, to stir the mortar in a bricklayer's box or bucket.

- The bricklayer's box is used to receive and supply mortar to the bricklayer's workplace.

- The mop is used to form seams when laying ventilation ducts at home, to clean them from protruding surpluses, to fill them more completely and smooth out the mortar between the masonry bricks.

Instruments

Sewing seams can be done either with ready-made devices purchased in the store or with homemade ones. Moreover, some master masons make their own hand tools of various configurations in order to obtain irregular seams.

But the use of joints alone is not enough. Depending on the condition of your brick wall, you may need:

- Sharpened chisel and hammer or hammer to remove old mortar from the joint.

- Drill with mixer attachment for grout preparation. If the volume of work is large, it makes sense to use a concrete mixer.

- Triangular trowel and falcon - for gentle application of the mixture and removal of excess from the masonry.

- Stiff brush and brushes - will easily clean the surface of stones when grouting and grouting are finished.

- A soft flute brush or roller is needed to wet the surfaces.

- A wooden lath about a meter long - it is convenient to support the tool on it when joining horizontal seams.

Also, do not forget that to prepare the grout, you will need a special container - deep, but not wide, so that the solution does not set in it so quickly.

Really working legal way to save money. Everyone needs to know this!

Grouting brickwork

This procedure may be required if you need to restore the properties of old walls or make a jointing of the same color. Indeed, often the mixture in different parts of the masonry differs markedly in shade.First of all, it is necessary to cut the surface of the dry mortar to a depth of 1-1.5 cm (with a hammer and chisel) and remove its remnants. Cleaning is carried out not only at the seams, but also throughout the masonry - the brick wall must be completely cleaned of dirt and dust before grouting. To simplify the task, you can use a compressor unit to blow out even the smallest chipped particles from the cracks and ensure the best adhesion of the fresh joint.

Also, a reliable and well-sharpened tool is needed to accurately prepare for joining. Only with its help can excess mortar be removed so that the brickwork does not suffer. After that, you need to moisten the seams with water and get to work. Do not moisten the entire surface at once - limit yourself to a small area that you will be working on in the next hour.

Brick grout is sold ready-made or dry. It can come with the addition of pigments and plasticizing additives. But the main thing in any selected composition for seams is its basis. Today, there are two options for embroidering walls:

- cement (Quick-Mix, Mixonite);

- epoxy resin (Litokol Litochrom, Mapei).

But you can make an inexpensive mixture yourself. The simplest grout for masonry consists of two parts of lime and cement, taken equally, and 10 hours of fine sand. Such a solution has a pot life of about 90-120 minutes, so it is not worth kneading a large volume for joining immediately.

Another recipe: for one part of the cement, they take the same amount of ground volcanic track and 5 hours of sand as an aggregate. This grout should be used if the brick wall "pleases" the eye with efflorescence and whitish smudges from the seams. A purchased or independently prepared jointing solution is stirred to the consistency of liquid sour cream: it should not spread, but should be kept on an inverted trowel in a lump.

Having prepared the grout according to the instructions on the package, you can proceed to the vertical seams. The composition should be soft and plastic, so that it is easier to work with it, but at the same time not liquid, otherwise the solution will not keep its shape and will simply flow over the masonry. After all the preparations, the jointing is performed using the following technology:

1. Apply the ready-made grout with a trowel - a little more than needed to fill the joint. In order not to stain the bricks of the lower row, you can substitute a plaster falcon.

2. Remove excess mixture with an edge and smooth the surface with a suitable hand tool. Each seam is pressed with force so that there are no voids between the old grout and the grout.

3. After filling in, the actual jointing takes place, that is, giving them a shape. To work in horizontal rows, it is more convenient to use a straight rail - under it, as under a ruler, it will turn out to draw a straight line.

When the jointing of the brickwork is completed, the front side of it is cleaned of traces of mortar with a stiff brush. Then you need to give the mixture to finally gain strength, not allowing the seams to dry out, or vice versa - get wet in the rain.

List of sources

- .

- .

- .