Figured cutting

It is even more difficult to obtain curved surfaces of a given configuration at home, and you will have to additionally spend money on purchasing a router that will help you get rid of chips and notches formed when you cut chipboard.

The price of a manual router can fluctuate significantly, depending on the manufacturer, power, and the availability of additional functions. If you do not plan to manufacture furniture professionally, then it is advisable to purchase an inexpensive model.

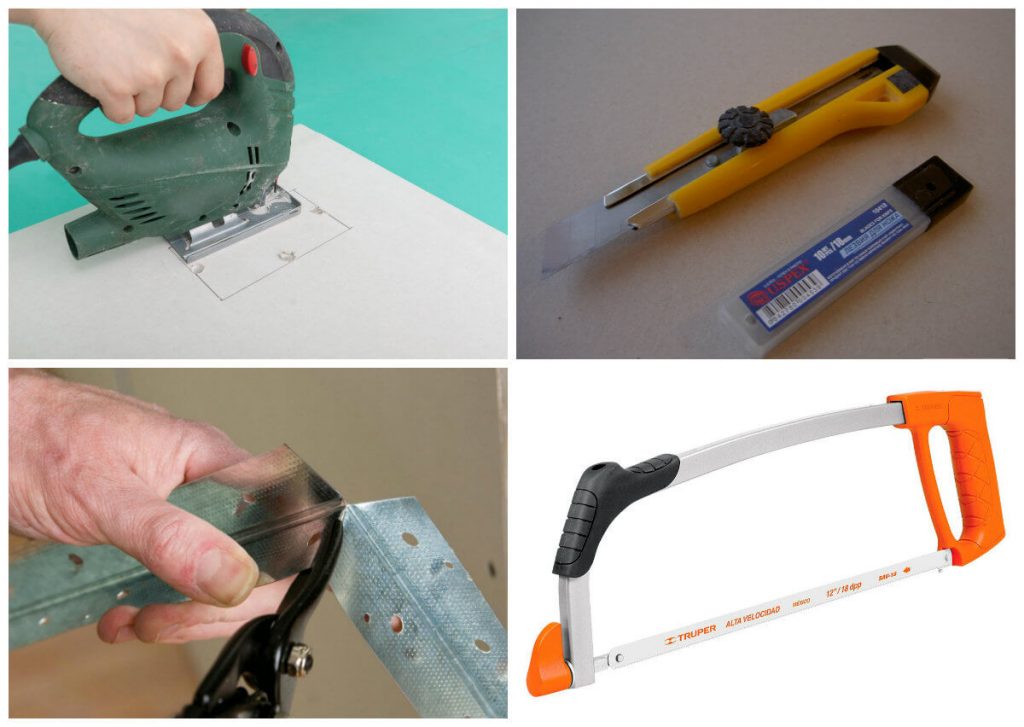

To cut chipboard, you need to follow these steps:

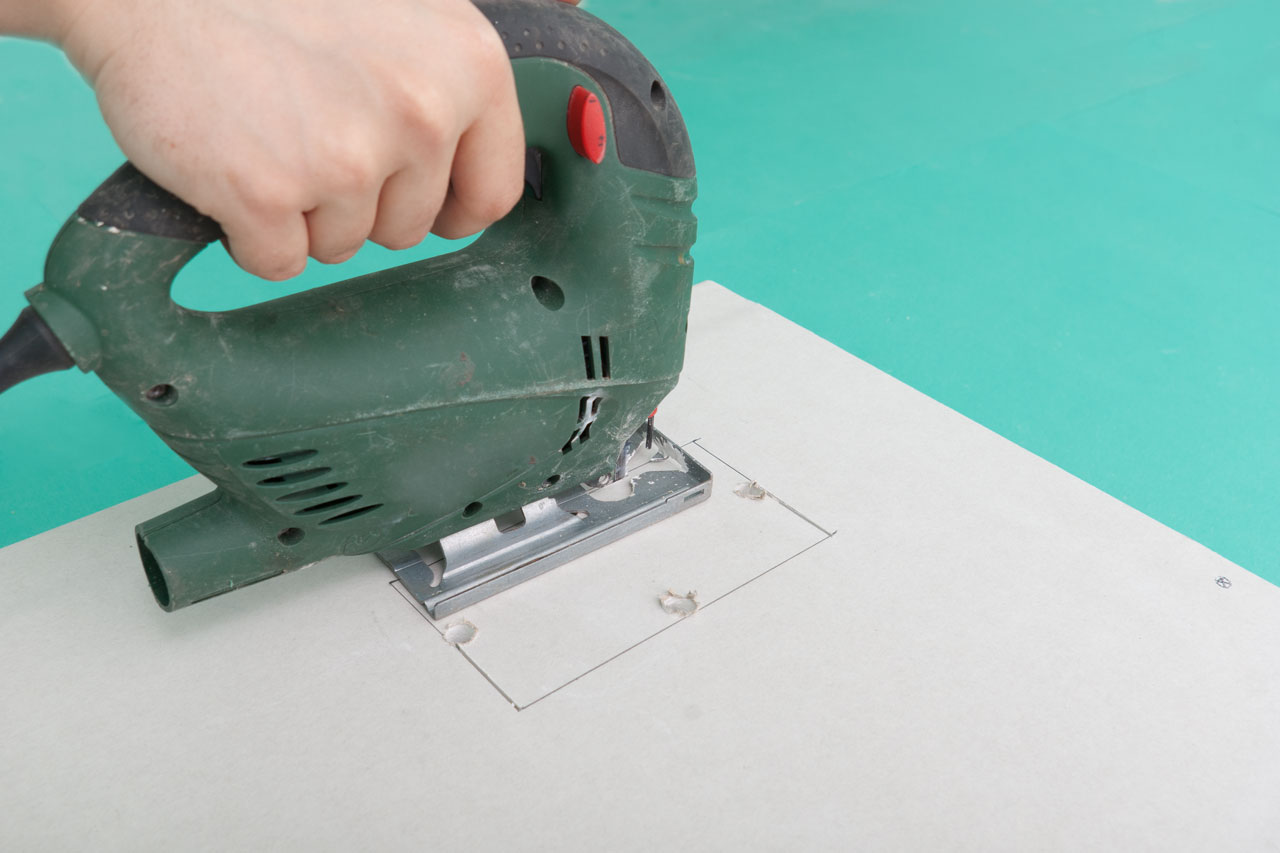

- having marked out the contours of the necessary part on a chipboard sheet, we cut it out with an electric jigsaw, trying to cut backing only a couple of millimeters from the intended cutting line;

- we make templates of the design radius from fiberboard or plywood and carefully grind the ends with sandpaper;

- attaching the template to the part to be trimmed, clamp it with clamps and process it with a manual copying cutter with a bearing, removing excess material exactly to the intended line.

In this case, it does not matter which cutter (with two or four knives used). The only condition is that the knives must grasp the cut thickness being processed along the entire height. After processing, it remains only to stick the edge on the part. How to do it - look at the video:

What to look for when choosing a circular saw?

Medium and small circular saws are highly regarded for their portability. They are preferred for use at remote sites. Large saws are stationary. These large and powerful units are simply irreplaceable in the process of building construction.

All saws can be divided into four categories depending on the characteristics of the future use. These are saws for cross-cutting wood, for longitudinal cutting of wood, for cutting non-ferrous metals, as well as for cutting laminated chipboard. When choosing a circular saw, you need to take into account the fact that not all models have a plunge function. For example, if the rip cut should be done from the middle of the board, this function is indispensable. The plunge-cut saws offer increased performance and maneuverability.

The ease of gripping the front handle is also an important criterion when choosing a circular saw. The degree of controllability of the tool depends on it. The preferred option would be a ball-shaped handle, which allows the saw to be locked in any desired position.

When buying a saw, the cost of the tool is considered an important criterion. Usually the price rises if the circular saw allows you to adjust the number of revolutions or turn on the on-line cooling mode. Before purchasing a tool, you need to decide on the necessary additional functions so as not to overpay for unnecessary "bells and whistles".

Sawing panels from chipboard and other materials

This is especially important when sawing slabs with a double-sided finish. Cutting fiberboard can be done at home using an electric or manual jigsaw

Of course, the file must be sharp, with a fine tooth; on a jigsaw, it is necessary set maximum speed... Install the fiberboard horizontally on a support that should not interfere with sawing (between two tables or chairs, for example), secure, if necessary, with clamps

Sawing fiberboard can be done at home using an electric or manual jigsaw. Of course, the file must be sharp, with a fine tooth; the maximum speed must be set on the jigsaw.Install the fiberboard horizontally on a support that should not interfere with sawing (between two tables or chairs, for example), secure, if necessary, with clamps.

The electric jigsaw should be held with both hands, pressing firmly to the surface, moving smoothly, strictly along the line of the marking, without jerking or pressing.

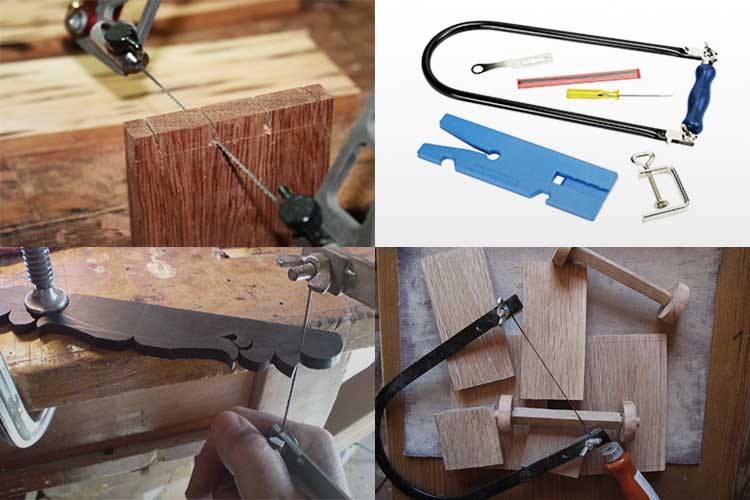

The same applies to working with a hand jigsaw.

In the case when it is necessary to cut a lot of sheets of material, it is more convenient to contact a specialized company. This will save you time and effort.

How to cut chipboard with a jigsaw without chips

Such work should be done delicately, since there is a high probability of deformation of the material. Fillers such as sand are used for cutting. Actions can be carried out using a grinder, a special machine.

Summing up, we emphasize

that cutting metal pipes is a complicated process, but everyone can enhance it. With the advice of a professional, you can easily cut pipes in a variety of sizes and materials. Also remember to file or sandpaper the edges of the pipes after cutting. And the most important thing to remember when starting such actions is safety precautions. Wear a special suit (casing), mask or goggles when getting started. Hands should also be reliably protected from sparks, so use thick gloves.

Find the right drive

The cleaner you want to cut, the more teeth should be on the disc. As long as the disc is new and sharp, then, in principle, any of the four shown in the photo on the right will do.

For clean cutting of plywood, a 140-tooth blade is good for everyone, but its disadvantage is that its teeth become blunt much faster than those with refractory tips, especially when sawing chipboard sheets. It is better to keep such a blade in stock for critical work or when you need to make a very accurate and thin cut, and not use it for everyday work.

The most convenient, however, as well as the most expensive disc with 56 teeth or the so-called disc for laminate flooring. Well, for household work and for all occasions, for example, for country crafts, a disk with 40 teeth is quite suitable.

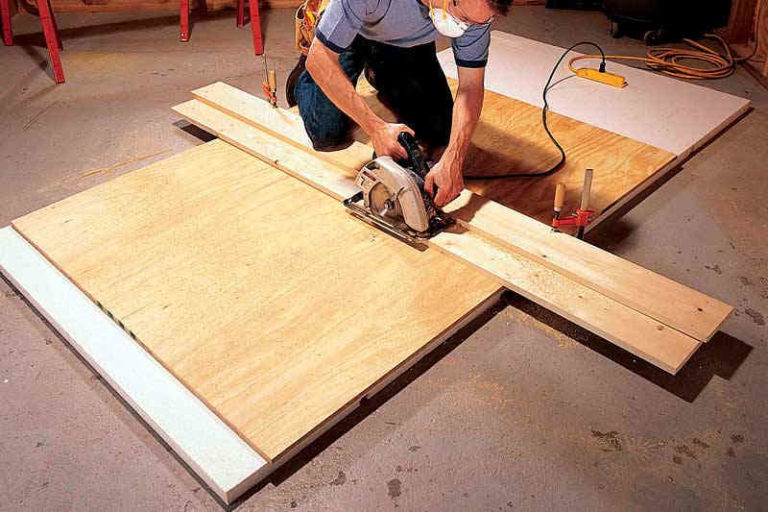

DIY plywood cut

Sawing technology:

All procedures are carried out according to drawings, which are drawn up in advance. This will avoid mistakes.

The marked plate is placed on the prepared place.

It is important to ensure free passage of the blade or saw and a rigid, stable placement of the resulting fragments.

The set stop is fixed with clamps.

Based on the most comfortable position, the largest possible cut is made. It is important to ensure that the parts - especially the part to be machined - do not sag or pinch the tool.

Whenever possible, cutting is carried out without interruption.

True shape cutting is performed in a single section or in fragments, the excess is removed gradually.

Masking tape glued to the cutting line can prevent the appearance of small chips along the edge, but if the disc is selected correctly, then such manipulations can be dispensed with.

Masking tape glued to the cutting line can prevent the appearance of small chips along the edge, but if the disc is selected correctly, then such manipulations can be dispensed with.

For complete safety, it is recommended to work in goggles, a mask and a respirator

All processes are carried out carefully, upon completion, the device is disconnected from the power

Jigsaw option

As already mentioned, what the fiberboard is cut with depends primarily on the size of the sheet. With a jigsaw, it will be easy to cut (saw) sheets of any size. To do this, we need the jigsaw itself and a file with fine teeth. It is advisable to focus on a metal file. Her teeth are small and not too far apart, which means that the edge of the cut hardboard will not be strongly split into a "fringe".

We install the stove on a flat surface.This is a prerequisite, because if there is no tight adhesion between the surface and the plate, the cut will turn out to be clumsy, since the plate will vibrate during the operation of the electric tool, and there can be no question of any even cutting in this case. At the same time, the fiberboard should be pressed to the surface. Then the seam will be even, and there will be no burrs, just as there will be no spreading of the edges to the "fringe".

After the cut is completed and the desired part (workpiece) is cut, its edges are cleaned with a file or sandpaper. All is ready.

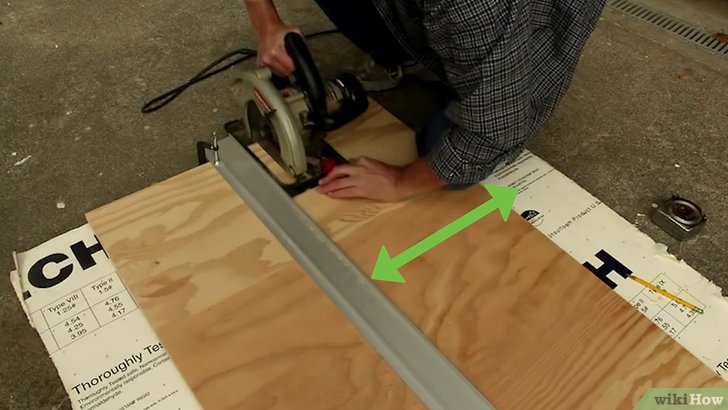

Reception 1. Cut along the guide

We install a guide (tire) on the workpiece, set the cutting depth and perform the cut. As you can see for yourself, even on the outside of our chipboard blank there are no chips, no explosions. The cut itself is even without signs of scoring or side waves. Why such difference?

What is the merit of the guide?

When we saw with a disc, we inevitably wiggle the saw, the so-called "iron movement" is obtained. That is, when we move our hand, we all the time move the saw to the right, to the left. The guide, which has a rigid edging, avoids this.

Accordingly, when we guide the saw along the guide, it does not move and the saw blade itself works smoothly, without changing its position. It turns out a perfect line parallel to the guide.

What if there is no hand-held circular saw and guide?

You need to make the guide yourself. We find an ordinary profile, you can take the rule, any even rail, the main thing is that its geometry is even.

We measure the distance from the saw blade to the edge of your chipboard workpiece. We attach the guide to the workpiece with any clamp and start cutting.

The main thing in the process is to constantly press the saw against the guide. That is, your hand should always guide the saw towards the homemade tire.

After cutting, you will get an almost perfect cut, the cutting line is barely visible. We made a very high quality cut, the cut itself is clean, no side marks are visible on it. Except for a small pile on the back of the workpiece.

Where did this pile come from, because we worked with a guide (tire)?

There is a special plastic protective tape on the purchased cutting bar. This tape prevents the pile from rising and the saw cuts it. In this case, we did not have this tape, so we got this pile on the surface.

What to do with the pile in this case?

There are two options:

1. Take ordinary masking tape. It is glued to the place where it was cut, marking is made on it and sawn together with masking tape. The scotch tape keeps the root in place and when we cut it, we get everything clean.

2. Just drive the saw blade more slowly. That is, if you do the same with a slower feed, then there will be much less chips.

Cutting panels at home

You can also cut with a jigsaw

It is quite possible to cut a sheet of chipboard or chipboard by hand. True, in this case you are unlikely to be able to avoid the appearance of chips and burrs, but you can try to reduce their number and size.

There are several rules that should be followed when cutting chipboard panels:

- cutting sheets must be done on a flat, hard surface. Two large tables can be adapted for sawing large panels (their height must be the same!);

- in order to exclude the appearance of chips, stick adhesive tape or good masking tape along the cutting line, which will hold the edges of the laminated layer;

- For sawing with a hand saw, select a blade with a fine tooth. Saw teeth should be well sharpened. You need to drive the saw with slight pressure, at an acute angle to the surface, constantly monitoring its position;

- for cutting chipboard and chipboard boards with a jigsaw, the saw line should be scratched or even cut through. It is best to use a sharp knife to cut through the durable layer of the laminate;

- install a file with a small reverse tooth;

- select the maximum speed of the jigsaw, turn off the "pendulum";

- fix a flat rail along the saw cut line and move the jigsaw strictly along it;

- the jigsaw should be firmly pressed against the surface to be sawn.

All these recommendations help to properly saw and cut the chipboard, but chips, nevertheless, cannot be completely avoided.

Therefore, if it is so important to get a perfectly smooth, even cut line, without chips and saw marks, you should contact specialized workshops, where they will cut out any shape from a chipboard sheet for a reasonable fee.

Precision and quality

Precise cutting is the key to success

Panel saws for sawing laminated chipboard and chipboard have a high cut quality, which allows you to reduce the subsequent costs of processing sections (grinding, removing chips and burrs, and so on). That is why on such machines it is possible to cut any complexity and configuration, which means almost inexhaustible possibilities in the production of furniture. Fancy children's furniture, comfortable tabletops of computer tables, curly through carved decorations in the doors of kitchen facades - all this is possible when using machine tools.

There are two types of panel cutting machines:

- vertical, representing a strong rigid vibration-resistant welded frame (frame), installed vertically with a backward deflection of 50 °, with guides located above and below, along which the saw beam moves. It is a bracket for the saw unit, which moves up and down along the beam, and also rotates 90 °, which allows you to make both vertical and horizontal cuts. The precision of the cut is amazing. For sawing laminated chipboard, as well as hard, corrugated or porous boards, a special scoring unit is used. The saw rotation frequency reaches 15 thousand revolutions per minute;

- horizontal, consisting of a table for a plate, carriages for moving the saw along the sawing mechanism and the sawing mechanism itself, consisting of one or two cutting units. The cutting units themselves are equipped with a main saw and a scoring saw. The principle of operation is simple: the main saw deeply cuts the chipboard, and the scoring saw accurately and precisely cuts the bottom edge (veneer or laminated surface). The saw unit can also be tilted up to 45 °.

The miter saw is a "domesticated" and heavily scaled-down copy of a horizontal saw. It will not be possible to cut a wide sheet of chipboard or chipboard on it, but it will quite cope with small details.

Choosing the right tool

Several recommendations from experienced professionals will help you choose the right tool for the job.

For cutting at home, a household or semi-professional D-shaped jigsaw, which is operated with one hand, is sufficient. The more power, the heavier the jigsaw, and it will be more difficult for them to cut smoothly.

The stepped speed controller, electronic stabilizer and pendulum stroke make the cutting process much easier. The presence of a plastic pad on the sole will allow you to securely attach the machine to the cutting blade. Built-in airflow and lighting are useful features.

It is worth paying attention to the fastening of the canvas. Some models have a restriction that prevents the use of any file

Sawing boards with a jigsaw is not recommended, for this there are circular saws and hacksaws. Although a powerful tool can cope with the task, it is unlikely that it will be possible to achieve a perfectly straight cut.

Each jigsaw model is different in shape, so before purchasing it is worth holding the tool in your hand, and, if possible, testing it directly in the store.

Tools and materials

If possible, it is best to cut the chipboard with a hand milling cutter, using homemade guides. This method is not very convenient when cutting large sheets, because when working with this tool, a table is required.In addition, with this method, the cutters have to be changed frequently. But as a result, you will get cleanly processed, "chamfered" edges.

The electric jigsaw is the most popular tool for sawing chipboard

The electric jigsaw is the most popular tool for sawing chipboard

Some craftsmen use a jigsaw in their work, however, in the absence of skill, it is difficult to cut exactly, and chips can form.

You can try to install a bimetallic blade with teeth pointed inward, intended for a laminate, on a jigsaw. Cutting with a jigsaw should be increased by increasing the speed, with a small feed, so that breaks do not form.

If such methods do not suit you, then for cutting chipboard at home, we will prepare for work:

- a hacksaw with fine teeth (one that is best suited for metal work). In this case, the teeth should be divorced by 1/2 of the blade thickness and be hardened;

- paper adhesive tape;

- file for rough processing of the cut line;

- sandpaper for finishing the cut line.

Rough floor finish

Sub-floors are mounted from hardboard quite often, this material is especially suitable for leveling old plank floors, if work on their dismantling is not expected. In addition to obtaining a perfectly flat surface as a result, the fiberboard layer will serve as a good heat insulator, which is especially important for residents of private houses or ground floor apartments in old high-rise buildings.

For subfloor laying, non-refined fiberboard with increased hardness or soft fiberboard is used as a soundproofing pad. Despite the abundance of hydrophobic additives in the production of modern fiberboards, experts advise to further process them before laying. Good results are obtained by impregnation with hot drying oil in 2-3 layers. After complete drying, the sheets can be stacked.

Fiberboard floor, ready for further processing

Fiberboard floor, ready for further processing

If the old subfloor is fairly flat, the hardboard is laid directly on top of it. With significant level differences (more than 10 mm), you will have to level the old floor or lay logs. In any case, the surface for laying fiberboard is pre-treated with an antiseptic primer.

We cut hardboard

Many modern enterprises selling building materials offer their customers sawing fiberboard according to individual sizes upon purchase. Special high-precision equipment is a guarantee that the work on cutting the material and processing the edges will be done efficiently, without chips. In this case, your main task will be to accurately make all measurements. If you are so unlucky, you will have to cut the hardboard yourself at home.

In principle, a hand saw with a fine tooth is also suitable for this job. After all, the small irregularities formed at the cutting site do not matter for laying the material as a subfloor. With a significant amount of work, cutting fiberboard is much faster and easier using the following devices:

Jigsaw

Jigsaw

- jigsaw or circular saw, preferably with a laser guide;

- saw blades of a special brand, suitable for cutting hardboard;

- trestles with a slope of 20-25% from the vertical, allowing you to fix a sheet of large-format fiberboard;

- metal ruler

- marker.

If you have to cut fiberboard for the first time, so as not to spoil the material, first practice on a small piece, setting the jigsaw file to the right of the marking line. Beforehand, be sure to familiarize yourself with the techniques of experienced craftsmen, for example, by watching thematic videos, one of which is presented below:

How to lay fiberboard?

If, after laying the fiberboard, it is planned to lay linoleum, the hardboard is laid with the wrong side down. In other cases, the corrugated surface will provide better adhesion of the fiberboard to the finishing materials, so it is turned up.

Installation usually begins from the corner opposite the front door.Fiberboard is fixed using special staples, nails or screws, or glued with mastics. Before nailing or gluing, they try to fit the sheets to each other with a minimum gap to make it easier to putty the seams.

By the way, sealing the cracks near the walls is not necessary, on the contrary, be sure to leave technological gaps that will allow the fibreboard to “play” without deformation when expanding with temperature fluctuations.

Cutting fiberboard when bypassing the heating pipe is easiest with an ordinary knife. More accurately, such work can be done according to a specially created template made of thick cardboard, using a jigsaw.

After fiberboard flooring, if you plan to finish the floor with linoleum or paint, it is necessary to seal the joints. In addition to having high adhesion properties, the mass with which we will putty the fiberboard must certainly be plastic, since fiberboard floors are somewhat springy and are able to change their linear dimensions. If you putty the floors with a hard and monolithic putty, then it can either bend and deform the fiberboard sheet, or tear itself at the junction of the seams.

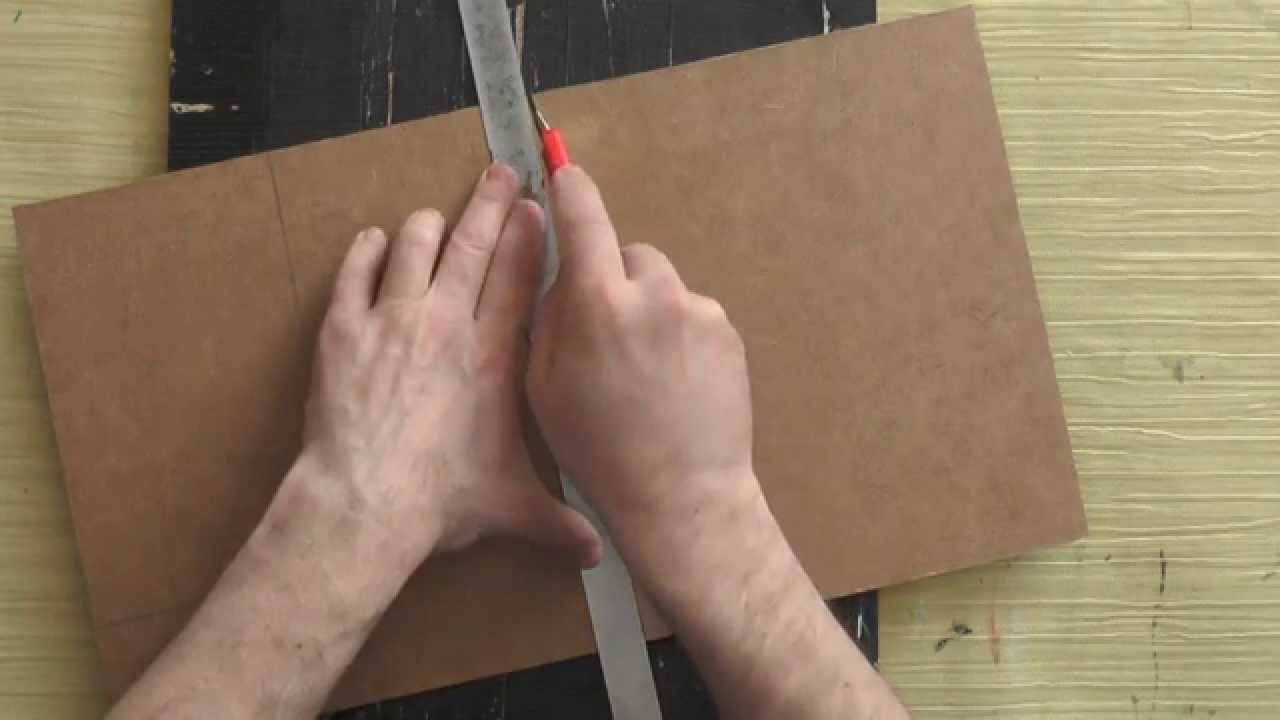

Marking the cutting line

To cut the material evenly with a jigsaw, it is necessary to correctly mark the cutting line and securely fix the workpiece to the surface. If you have to work with a long blade, it is worth using a flat rail as a guide and two clamps for fixing it and the working material. It is necessary to act in a certain sequence.

First, you need to make the markings on the chipboard using a ruler. For this, the required distance is measured on both sides, the marks are connected, forming a cut line. To make a curly line, it is advisable to draw it on paper, and then transfer it to a tree using a carbon copy, having previously sanded the surface.

To cut a circle with a jigsaw, markings are applied with a construction pencil or a black marker on the surface according to a pre-made stencil made of thick paper or cardboard. In this case, cutting the material begins with drilling a hole in the center. The blade should move from the center to the scribe line and then along the perimeter of the circle.

In order to avoid chips on the finished surface, the file during operation is not carried out along the mark, but near it. The laser guide on the jigsaw will help to cut exactly.

Pipe cutting at an angle of 45 and 90 degrees

If you need to cut the pipe at an angle of 45 degrees, which is more often required when laying water, heating pipes. Steel, cast iron pipes that are cylindrical in shape are often used. In installation work, rectangular or shaped pipes are used. However, you should correctly cut the pipe with a grinder, so that you can easily connect it later. Therefore, you should carefully mark the pipe.

Some craftsmen try to mark the place of the cut using a tape measure, but we warn you that the result is likely to be negative. And for a positive result, consider the following professional recommendation.

Take a sheet of paper or cardboard, preferably A4, fold it diagonally and wrap it around the pipe where you plan to cut it evenly. The edges of the paper must be in perfect alignment with each other. And the side of the paper that is closer to the end of the pipe was perpendicular to the axis. Then mark the cutting line in a circle.

If you need to cut exactly at an angle of 90 degrees, then solve the problem quickly using paper or masking tape again. Wrap around the pipe so the ends match. Make even lines and saw off.

How to cut a profile pipe straight?

Masters advise using a square when cutting a profile pipe. To do this, apply the square in turn to the sides, and turn and mark with smooth movements. After action, fix the pipe and cut. Prepare yourself a template that will come in handy in the future and save time. It is better to perform the action with a grinder, so the cut will be smoother.

How to cut a cast iron pipe?

V work with cast iron pipe, keep in mind that this is a fragile material. Therefore, let us point out a method with which it will be possible to cut such a metal without damage.

Before starting work, make notes for the cut, as with steel pipes. Place a piece of wood for support. Work the grinder around the circumference of the pipe, making small cuts. Then take the chisels, insert into the groove and hit hard with a hammer. Note that bakelite-based cut-off wheels are used to cut cast iron pipes.

If you don't have a grinder at hand to cut a cast-iron sewer pipe or other purposes, use a metal hacksaw, chisels or special pipe cutters.

How to cut a gas pipe?

Cutting a gas pipe is dangerous, so it is best to entrust it to professionals. But if you are confident in your strength, then take a grinder, welding, hacksaw, gas welding to cut the metal.

Pruning instruction:

- Shut off the gas riser before work. Then release the rest of the gas from the pipe. To do this, light the gas in the burners and wait for it to go out.

- After the actions taken, cut. Using the welding method, the metal base burns out when exposed to high temperature. The result is fast and effective. But remember that cutting or rooting gas pipes again takes experience.

Methods for cutting large diameter pipes

There are a number of reliable tools available for cutting large diameter pipes such as sewers. Next, we will consider some of them in detail:

The grinder is an inexpensive and affordable option, but it is considered not the safest when working with such materials. Once you decide to use this method, then be careful and use protective equipment.

A roller machine (pipe cutter) is such a tool adapted for such manipulations. The device is attached and material removal begins. Clamping force is mechanically adjustable

It is important to note that the models of the machine differ in shape, so consider the ratio of dimensions to the pipe before use.

Flame cutting is the most popular option for cutting larger diameter pipes, sheet metal. The cut occurs due to the action of a high intensity flame, the metal melts and leaves the cut zone with a gas flow

This method is convenient and effective.

How to cut the pipe lengthwise correctly?

A quick way to cut a pipe lengthwise using a grinder:

Pay the main attention to the markup.

Use for such a case the painter's thread, which has found widespread use when marking walls.

Before starting work, fix the pipe and with small movements, carefully saw the pipe.

Better not to rush, but delicately and slowly process the parts of the pipe, so the cutting disc does not jump off the marking lines. Remember safety ... How to cut thin-walled pipes?

How to cut thin-walled pipes?

Thin-walled pipes are made of non-ferrous metals: aluminum, copper.