What does the expense depend on?

How much putty is needed to complete the repair, what parameters affect its consumption - this is the main question that needs to be resolved before starting work. To avoid getting into an unpleasant situation, when, shortly before the end of the work, it turns out that there is not enough material, it is necessary to calculate the required amount in advance.

Factors affecting consumption:

- the condition of the walls (the degree of roughness, the presence of cracks) and the material from which they are made;

- type of putty (front, decorative, for interior work);

- putty application technology;

- the correct preparation of the mixture;

- the next stage of repair (painting, whitewashing or wallpapering).

But first of all, the type of putty affects the consumption of the putty. Depending on the type of work, the putty is divided into three basic groups:

Start (leveling)

It is this type that is characterized by the highest consumption. Such a putty is used at the first stage of work, it is used to level the surface, seal cracks and chips. Penetrates deep into the wall, applied on top of the plaster

Universal

The second type of putty is consumed in slightly smaller quantities than the starting one. It can serve as a transitional stage from start to finish, or replace both types at once, but only if it is necessary to eliminate very minor flaws.

Finishing (decorative)

The species with the lowest consumption. It is applied as the last step before finishing finishing and is used to give the wall maximum smoothness. The finishing mixture can also be used as a first coat if only minor surface defects are to be removed.

The correct calculation of the amount of material is an important step necessary before starting finishing work. If the putty is less than required, it will be necessary to prepare a new one, and then try to dock it with the previously applied mixture. If the amount of the mixture exceeds the norm, then it will remain unclaimed, since it will no longer be possible to use it. Any mistake in the calculations delays the finishing process, postpones the completion of the repair.

Types of putty and scope

In order to choose the right putty, it is necessary to study well the characteristics and features of the operation of each type of this material. According to the scope of application, the putty is divided into several types.

- Leveling - this type is used in the initial stages of repair, with its help you can carefully level the walls or ceiling, as well as hide various surface defects. The material dries quickly and is practically impossible to sand. The leveling putty is applied to brick or concrete. If you do not apply the finishing putty, then you will not be able to glue the wallpaper on the surface or paint it.

- Finishing - it is applied in a thin layer, it prepares the surface for finishing. Due to its fine-grained structure and plasticity, walls and ceilings are smooth. The layer thickness is 0.5 cm, but it must be applied in several layers.

- Universal - it can be used for both starting and finishing. This type is suitable for any surface, guarantees a smooth finish without flaws. The material has a high level of strength and is easy to putty. But the cost of universal plaster is quite high, but even novice specialists can work with it.

Putties also differ in the level of readiness: they are dry and ready-made. The first type has a powdery composition and is sold in sachets of 5 - 25 kg. The shelf life is one year; the material must be preserved in a dry state.

The finished putty is sold on a latex and water-dispersion basis in special containers. The special substances contained in this material ensure the durability of the product.

Also, putties are distinguished according to the basic basis:

- On a gypsum basis - the composition contains gypsum, polymer additives and all kinds of fillers. This product is ideal for rooms with low humidity levels. Such a putty is safe, odorless and has an affordable cost, thermal insulation, elasticity, and fire resistance.

- Cement-based - the product is suitable for facade and interior work. The composition contains cement, sand and water. When the putty dries, the surface must be sanded. It is recommended to apply the diluted mixture within 24 hours.

- Polymer - used for coating cement, concrete, gypsum and polyurethane surfaces. Differs in high cost, but environmental friendliness and safety.

- Acrylic - designed for finishing stages, namely, for carefully leveling the surface for its future finishing. The product is resistant to damage, high quality and safety.

- Latex - It is often used for drywall, niches or arches, but it does not withstand low temperatures. Differs in plasticity and strength. It is easy to work with it on drywall even for a novice builder.

- Water-dispersive - designed for filling walls and ceilings made of concrete, brick, aerated concrete, wood, stone and other materials.

- Oil and glue - it is used on wooden and concrete surfaces to decorate walls and ceilings with paint. It has proven itself well on wet surfaces.

- Facade - designed for outdoor use, has moisture resistance, durability, fast drying speed.

- Spakryl is a special putty for skirting boards and leveling walls after plastering.

How to calculate?

On plaster

Assess the quality of the wall and the required layer thickness. Decide whether you will putty the entire wall or only defects and damaged parts, estimate the treatment area.

If the wall is perfectly smooth, it is enough to apply 1 mm of starting putty (1 kg / m2) and 0.5 mm of finishing (0.6 kg / m2).

Increasing the layer thickness increases the consumption proportionally: for a 10 mm layer of starting putty, 10 kg / m2 will be required.

Keep in mind that re-filling is often required! The second layer is usually thinner than the first (up to 3 mm), but it must also be included in the calculation. The consumption of the finishing putty varies slightly, up to 1-1.2 kg per m2.

Example: a relatively flat wall 2.6 mx 3 m = 7.8 m2 with small cracks and minor defects. The estimated layer of the starting filler is 3 mm (3 kg per m2). The required amount of dry mix: 7.8 * 3 = 23.4 kg. The finishing putty will require approximately 8 kg.

But it must be borne in mind that different sections of the wall may require a different amount of putty!

On drywall

Despite the perfectly smooth surface of a single sheet, there will always be joints between the sheets that need to be repaired. You also need to hide the caps of the screws with which the sheets are attached. Therefore, it will not be possible to limit ourselves only to the finishing putty.

It usually goes up to a kilogram of the mixture per square meter. The choice of material depends on the conditions in the room: for wet rooms, a cement putty is recommended (~ 1.1 kg per m2), for dry rooms - gypsum (1 kg / m2) or polymer mixtures (0.5 kg / m2).

On a smooth concrete wall

Smooth concrete walls must be treated with a primer before puttingtying and only then a layer of putty should be applied (no more than 6 mm for the first layer and no more than 3 mm for the second). Wooden surfaces can also be putty, but the layer of putty should be minimal, no more than 2-3 mm.

Please note: no matter how carefully you work, some of the solution will remain on the buckets, on the tools, on the floor.The inept handling of mixtures can also significantly increase the consumption, sometimes the composition freezes before you have time to use it, or you have to redo individual sections

These inevitable losses can be up to 10% of the total, so it is better to have some supply of materials.

The inept handling of mixtures can also significantly increase the consumption, sometimes the composition freezes before you have time to use it, or you have to redo individual sections. These inevitable losses can be up to 10% of the total, so it is better to have some inventory of materials.

This video tells you how to correctly calculate the consumption of putty.

Expert advice

Experts advise adhering to the following rules:

The consumption of the building mixture depends on its quality. You need to look at the expiration date, follow the storage rules indicated on the label. After opening, dry mixtures must be tightly packed, stored in dark dry rooms. Ready-made mixtures cannot be opened in advance, as they dry out quickly and become unusable as early as 4 days.

Advice

Pre-leveling of the surface with plaster can reduce the consumption of the mixture used.

It doesn't matter what layer the finishing will be done. The main thing is to make the surface even, smooth, so that later you will spend less of the mixture.

Consider the type of room

Wet rooms are better putty with cement compounds... They will be spent less, more economically. In this case, the thickness of the layer does not differ much from the previously calculated one.

The consumption of the putty strongly depends on the correct dilution of the dry mixture. With incorrectly selected proportions of water and dry residue, the consumption can greatly increase. It is much more profitable to take ready-made mixtures in this regard. There are less chances to spend a large volume despite a small spatial coverage.

Masters recommend using the Shitrok mixture. Experts like it for its economy. Its costs with a thickness of 1 mm will be equal to 0.5 kg / m2. Finishers appreciate its ease of use, quick drying, no asbestos and no cracks upon drying.

The calculation of the putty can be done independently according to the instructions on the label. You can use special calculators, where the necessary indicators are hammered in and an exact answer is obtained. A 10% margin of the obtained value is required in order not to be left without a working mixture in case of unforeseen expenses.

Example

Let's say you need to process four walls with a height of 2.7 m. Of a room whose dimensions are 4.5 by 5.3 meters. To do this, you are going to use the Fugenfüller universal composition, gypsum type. The layer thickness on average will be 4.5 mm.

We multiply the figure 0.9 by 4.5 (coating thickness) - we get 4.05 kg. We calculate the area of the room - we multiply separately both size indicators by the height, we add both numbers, the result is 52, 92. Now we multiply this value by 4.05 - 214.326 kg. This is the required size.

It remains only to calculate how many bags are needed - for example, if the weight of one is 25 kg, then dividing the sum of 214.326 by this number will result in 9 bags.

First you need to figure out what kind of putty consumption for the wall needs to be calculated. If the exterior walls are to be finished with putty, then the material consumption will be greater than during internal work.

For example, Vetonit putty is used to decorate rooms with an increased level of importance, and is applied in a middle layer. The glue putty is applied in the same layer, because it involves the application of a special glue paint, which is thick in structure and adds extra volume to the surface

Gypsum and finishing types of putty are designed to be applied on the surface with a thin layer, their consumption will be significantly less than that of other types of material.

The approximate consumption of putty per 1m2, according to the material, is given below.

- Vetonit putty, its consumption per 1m2 is 1kg 200gr;

- Glue putty is applied to the walls at a consumption of up to 500g per 1m2;

- Finishing putty in consumption for walls per 1m2 is 450g;

- Gypsum plaster is applied to the walls at a consumption of 900g per 1m2.

Before proceeding with the decoration of the walls outside and inside, it is necessary to take into account the material on which the putty is applied. The starting external putty is applied to the cinder block, brick, wood (with a grid) and closes significant flaws and irregularities in the walls.

How much putty needs to be applied to the walls and in how many layers depends directly on the walls of the building. Outside the brick and cinder block building, the first, rough layer is applied using a starter filler. Starting putty can be applied up to 2-3 layers. Then the starting layer of the putty is covered with the finishing putty once or twice, depending on the type of putty.

It turns out that the first layer of such putty serves as a start, and the second layer of putty completes the wall decoration and serves as the finish. Acrylic and silicone putty is applied in one layer, it is quite convenient to use, in the sense that the required volume can be laid out in one layer.

In order to purchase the required amount of putty for repairs, you need to know the exact area of the room along the perimeter and height of the walls. Consumption can be made manually, knowing the following data: the sum of the length of all walls in the room, the height of the walls, the length and height of the wall above and below the door. The width and length of the walls, the thickness of the application of the material, taking into account the irregularities, are taken into account.

Calculation by the formula:

- The material consumption rate per 1m2 is multiplied by the thickness of the irregularities, which we took into account in the calculations;

- Add up the length of all walls in the room;

- The length of the wall above the doorway should be multiplied by the height of this section, the indicator should be added to the sum of the height of the walls;

- Add the amount of action 2 to action 1. Multiply the resulting amount by the number of action 3.

Putty consumption rates

The manufacturer provides information on optimal rates. Typically, the consumption is indicated based on a layer of 1 cm thick for starting putties and 1 mm for finishing.

The starter putty is applied to the previously plastered wall, on which there are no significant defects. The thickness of each layer should not exceed 10 mm, and the total thickness should not exceed 30 mm, otherwise the coating may crack and peel off.

For a smooth wall, a 1 mm thick layer is enough - then 0.8-0.9 kg / m2 will be required, but if the cracks and irregularities are significant (up to 10 mm), the consumption can increase tenfold.

As an example, consider the starting putty Knauf HP Start. Recommended consumption for a layer thickness of 10 mm - up to 10 kg / m2. A standard bag of 30 kg is thus enough for 3-3.5 m2 of surface. The surface is quite grainy (grain size up to 1.3 mm) and dries up to 7 days. After that, you can proceed to the final processing.

The finishing putty is a homogenized mixture with a very fine structure (up to 0.3 mm), intended for the final leveling of walls.

It is applied in a thin layer so that it does not float when wet and does not crack as it dries. The optimum layer thickness is 0.5-1 mm.

Consumption for putties from different companies is almost the same. For example, for Vetonit Finish plus putty with a layer thickness of 1 mm, the recommended consumption is approximately 1.2 kg / m2, a 25 kg bag should be enough for 20-25 m2.

Ready putty - the so-called putty smooth surface. It is used for leveling ceilings, relatively smooth walls or minor damage to the joinery. The additives included in its composition (plasticizers and vinyl substances) significantly improve the surface quality.

These mixtures have a number of advantages over dry formulations:

- immediately ready to go;

- dry faster;

- do not crack after drying.

One of the most economical is the Sheetrock mixture: with a layer thickness of 1 mm, it only needs 0.5 kg / m2.Consumption of other putties (Knauf, Pufas) can range from 1.5 to 1.7 kg / m2.

Use of popular brands

Doing renovation work for the first time, you will surely face the problem of choosing a high-quality putty. It is best to opt for the products of well-known companies with a good reputation. Of course, the cost of such putties is higher, but they mix well, are easily applied to the surface and do not crack over time.

- The Ceresit brand is in demand; its assortment includes various types of putties for both starting and finishing. For example, Ceresit CT29 is used to work with brick, concrete, cement surfaces. You can apply the mixture an hour after mixing, and it dries up in 15 hours. Ceresit CT 225 is intended for finishing, resulting in a smooth and durable surface.

- Putties "Prospectors" and "Hercules" are materials that are appropriate for use in rooms with high levels of humidity. The mixture can be applied even to damp walls, they are durable, reliable and durable. "Prospectors" are supplied in sturdy 5 and 20 kg bags. Such a putty is made on the basis of white cement.

- Latex putty "Tex" is very popular among craftsmen. Regardless of the layer thickness, the mixture has strength and long service life. The material is elastic, does not leave unnecessary marks after pulling the trowel along the wall or ceiling. A large selection of color shades allows you to please every customer.

- Worthy of attention is the EK putty, which is used to eliminate defects on foam concrete, cement and gypsum surfaces. The mixture is used for sealing joints, it is applied in a thin layer, thereby preparing the walls or ceiling for painting or wallpapering. The product is easy to use, after drying it creates a high level of strength.

- The Knauf company offers a wide range of putty mixtures: ready-made and dry products, gypsum, cement, finishing, starting, water-resistant, etc. After application, the mixture makes the surface even and smooth.

- Putties "Vetonit" have earned a huge number of positive reviews, thanks to a wide range of types and excellent characteristics. Mixes of this brand can be used in various conditions. The price range allows you to please every customer.

- "Scanmix" is a cement-based putty for outdoor use, therefore it has increased moisture resistance. In addition, this mixture is resistant to low temperatures. Also, the product is environmentally friendly, it is safe for both the environment and human health.

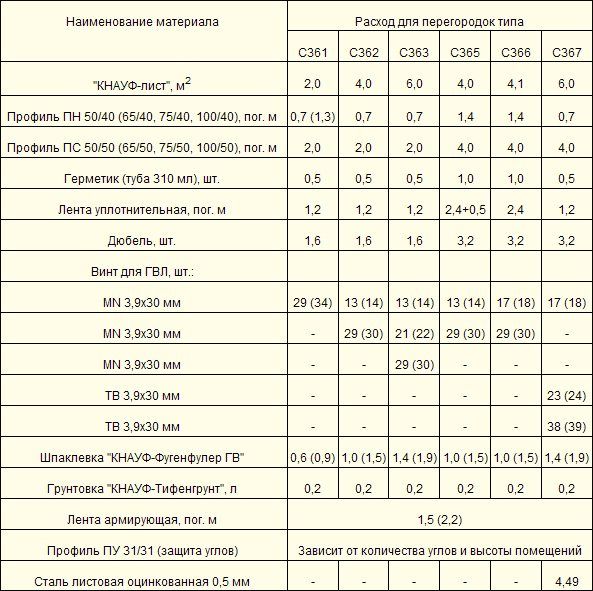

Knauf classification

Plasterboard classification and standard sheet sizes according to Knauf.

- GKL. It is a rectangular “piece of gypsum, pasted over with cardboard on 4 sides.

- GKLV. Moisture-resistant plasterboard, intended for use in rooms with high humidity. The cardboard used in the production is processed to reduce the possibility of the formation of mold, fungi and other similar microorganisms. To be able to distinguish the moisture-resistant material from the usual one, green cardboard is used for pasting the gypsum board.

- GKLO. This drywall has increased resistance to high temperatures. It is used where there are high fire safety requirements.

- GKLVO. The material is fire-resistant and at the same time has increased resistance to moisture penetration.

- GVL. Gypsum fiber sheet, which is a compressed non-combustible mixture of crushed paper and gypsum.

- GVLV. Drywall with increased resistance to moisture.

The first four types of gypsum plasterboard sheets are actively used in construction for the construction of frame partitions, wall cladding, and ceiling filing. GKLV can also be used as additional insulation.The last two types of drywall from the above list are used:

- in basements where the humidity exceeds 70% (for arranging the floor, walls, followed by laying tiles);

- in plumbing rooms;

- in utility rooms, storerooms;

- in attics and attic rooms;

- in ordinary living quarters.

When calculating the need for drywall, it is necessary to take into account its standard dimensions and the height of the room in which the gypsum board is supposed to be installed. Knauf produces standard sheets:

- width 1.2; 0.5 m;

- length 2.5 m;

- thickness 16, 14, 12, 10 mm.

Putty consumption on different surfaces

The leveling process can be carried out on two types of surfaces: on sheets of drywall or plaster. For each of the above options, there is its own amount required to achieve evenness per 1 m2.

On plaster

A parameter such as consumption depends on various factors: air temperature, composition used and humidity level. There are consumption indicators for standard rooms. They are set by standards, and when a manufacturer produces low-quality products, it takes full responsibility for this.

The putty is a versatile material, so it is impossible to accurately determine the required amount per 1 m2. It can be used in all types of filling. When puttingtying on a plastered surface per 1 m2, you need 1.5 kg of material. But it should be understood that the versatility of the product in question suggests that it can be used for all types of work.

On drywall

If you decide to apply the material on a drywall wall, then the consumption depends on the area to be treated. In addition, when certain defects are present on the wall, the amount of putty will increase. Knowing the standard size of a drywall sheet, it will be easier to make calculations.

Each type of material under consideration has its own proportion:

- When the surface of the wall is primed, the approximate amount of material will be 1.1 per 1m2. This calculation is typical for cement-based mixtures.

- If the wall is being treated with a gypsum composition, then its consumption per 1 m2 will be 1 kg.

- The glue-based material today belongs to the most budgetary options, since 0.5 kg of material is required per 1 m2.

When you use an already dried composition during work, you get an uneven surface with a certain roughness. In the future, the applied putty will fall off, as a result of which finishing activities will have to be carried out again. The application of the finishing material to the drywall surface is not yet the final stage of finishing. After that, you should definitely apply a primer solution and make a final finish using wallpaper or paint. Pl the link you can find information on wood putty for interior work. Also read what kind of putty to choose for the walls under the wallpaper.

How to calculate?

To calculate the exact amount of material that will be used in the process of repair work, the following should be done:

- find out the exact area of the room;

- measure the height and the sum of the lengths of the walls;

- calculate the thickness of the walls, taking into account all surface defects;

- determine the thickness and number of putty layers (taking into account surface defects).

It is important to remember that the amount of mixture used also depends on other less important factors. It often happens that a fairly large amount of unclaimed material remains in the process of working on tools, the composition hardens earlier than it is used

It also happens the other way around: you have to redo some areas in the process, which will require an additional mixture. In general, the inevitable losses can reach up to 10% of the total amount of material, so it is worth considering this point when preparing the mixture.In addition, the consumption rates of the putty depend on the basis of the mixture used.

The basis can be:

- cement;

- plaster;

- glue.

Plaster

Before starting work, you need to figure out how plaster differs from putty.

Both are used in decoration and serve for leveling, but there are important differences between them:

- Plaster, unlike putty, is used in much larger volumes. With the help of putty, as a rule, only small defects are masked, while plaster evens out damaged areas of a larger scale.

- The price of putty is significantly higher than the price of plaster due to differences in composition.

To calculate the required amount of putty for a plastered surface, it is necessary to take into account climatic indicators and carry out work only in the range specified by the manufacturer.

Taking into account all the recommendations given by the manufacturer, per sq. m of area usually requires one and a half kilograms of putty. However, the thickness of the applied layer and the quality of the wall, as well as the area of the filling, should be taken into account.

For walls without significant defects, it is sufficient to apply a layer of 1 mm (the calculation is equal to a kilogram per 1 m2) of the starting putty and 0.5 mm (0.6 kg / m2) of the finishing coat. Increasing the layer thickness results in a proportional increase in consumption. Do not forget about re-filling, which is better to include in the calculation even before starting work. Consumption is approximately equal to one kilogram per square meter.

Drywall

Currently, drywall is one of the most common options for decorating a room. There is an opinion that it is not necessary to putty the coating in the presence of drywall, because it already has a flat surface. However, this opinion is erroneous. You should definitely use a finishing putty to prevent paint or glue from absorbing into the drywall.

The exact consumption is directly related to the surface area to be treated. There is a little trick that allows you to reduce the amount of the mixture: before filling, drywall sheets must be treated with a primer.

The amount of material for work depends on the composition.

The consumption table looks like this:

- When mixing cement-based putty, the calculation is 1.2 kg per square meter.

- A polymer-based mixture is consumed less than others - only 0.6 kg per 1 m2, but this type of composition is the most expensive.

- Gypsum mix is the most economical option. Consumption is 1 kg per 1 m2.

Drywall is quite simple to work with. If the sheets were initially installed correctly, then careful alignment can be dispensed with. Before the finishing coat, it will be necessary to properly seal the fastening joints and the caps of the self-tapping screws.

Other surfaces

When working on other types of surface, the walls should be covered with a layer of primer. In general, the amount of putty on concrete is only slightly at odds with the costs for the above types of surfaces. For a smooth concrete wall, the first layer is not thicker than 5 mm, and the second one is not exceeding 3 mm in thickness. Taking into account the thickness of the layer, the calculation of the consumption per square meter is made.

You can also putty on wooden surfaces. But the layer of the applied material should not exceed 2 mm.

Types of mixtures

The modern construction market is represented by a variety of putty mixtures. There are many different classifications, but the main one is the differentiation of the types of putty according to the degree of readiness for use. According to this parameter, the putty is divided into two types:

Dry

This type of putty mixture has a lot of advantages and is a fairly popular solution for finishing work. The price for it is much lower than for the finished putty, it is stored longer and is more convenient to transport. It is not difficult to prepare a dry powder for application, the consumption of the prepared material will be small.However, it is necessary to strictly observe the proportions when preparing the solution, and also knead a new solution every half hour, since the old one will dry out by that time.

Finished

Such a putty will cost the buyer a little more, but it will significantly save time when mixing. In addition, when working with a ready-made mixture, there is no need to try to guess the ideal proportions. The disadvantages of this type of mixture are that the consumption of the finished material increases, and the shelf life, on the contrary, becomes shorter.

The types of putty also differ in their interaction with the type of surface to be treated.

In addition to the main varieties, which will be discussed below, mixtures are divided into the following groups:

- The adhesive mixture is used for painting work. It is flexible, dries quickly and can last for a very long time. However, it is not suitable for use in outdoor work, it is not resistant to moisture and mechanical damage.

- Latex putty is suitable for all types of surfaces. The cost is higher than that of glue, but this is offset by better technical characteristics. Easy to apply, does not crumble under the influence of stress. The disadvantage is low resistance to temperature fluctuations.

- Tex putty is in high demand due to the possibility of applying to almost any surface, as well as a variety of colors. Possesses high stability, only poorly tolerates sub-zero temperatures.

- Water-dispersion mixture is the most economical type, while having good performance characteristics. The disadvantage is the complexity of storage - it is advisable to do this in an airtight container.

- Facade type of putty is used for finishing the outside of the house. This mixture is characterized by high resistance to temperature effects, insensitivity to moisture, low cost. Minus - after finishing, it may start to crack.

The types of mixtures can also be distinguished from each other depending on the manufacturer. Despite the huge number of different brands, several quality products stand out that can definitely be used in the renovation process:

Putty "Vetonit" is a high-quality mixture for plastering walls before finishing. "Vetonit" is used only in dry rooms, for one square meter you will need a little less than one and a half kilograms of the mixture. If the material is laid in a layer 1 mm thick, when using a putty for wallpaper / painting, the consumption will be equal to one and a half kilograms per square meter. meter of surface.

Rate per square meter

Starting material

The starting material is used one that contains gypsum. And they use it when leveling the walls inside the house. If putties are applied on a flat surface, then the material consumption will be 0.8-1 kg per m3. It is worth taking into account the consumption per 1 m2 of deep penetration primer if you use this material.

If the starter putty is spread over a surface with multiple flaws, the reported value may increase up to 8 kg / m3. The thickness of the applied layer should not exceed 1 cm. Moreover, the thickness of the layer, which is applied at one time, should not have a value exceeding 5-10 mm. This figure also affects how much the plaster dries.

This is extremely important, because it is necessary for the composition to get stronger and acquire the required strength indicators.

Finishing material

The amount of material in question for processing one square meter will be 1.2 kg. But to say that this indicator is accurate will not work. The reason is that a very smooth surface must be obtained with the finishing putty, especially if paint is then applied to it. And sometimes it happens that in order to achieve the required evenness, the finishing putty is consumed in a double amount.

But most often this happens to a person who does not yet have certain skills and experience.As a rule, with a person experienced in this matter, the consumption of finishing putty will be minimal.

When working with the finishing putty, you need to be especially careful and scrupulous.

It is so important here to achieve a perfectly flat surface on which the applied paint would look spectacular and beautiful. You may also need information on how to apply the finishing putty.

Gypsum plaster

It has been repeatedly noted that today gypsum putty is in the popularity rating. It is she who can boast of excellent quality indicators and easy application.

To process 1 m2 of surface, you need to stock up on 0.4-0.5 kg of gypsum material. Taking into account the presented standards, all calculations must be performed.

Calculation of the total mass of 1m2 plasterboard partitions

It is usually produced not only in order to find out the estimated consumption of material, but also to find out the level of load that the structure will create. The approximate calculation given below is valid for standard GKL sheets having a thickness of 12.5 mm and used for sheathing a partition with a metal frame.

An example of calculating materials for partitions.

- The weight of the 1st “square of the partition up to 5 m high, the frame of which is sheathed on both sides with only one layer of gypsum board, is about 25 kg. When arranging partitions of greater height, a thicker profile is used, therefore the weight of 1 sq. m will be higher.

- If a partition with a single frame is sheathed with two layers of drywall, then the weight of 1 square meter with a height of up to 6.5 m will be approximately 45 kg.

- When constructing a double frame and sheathing gypsum board in 2 layers, weight 1 sq. m increases to 48 kg.

- If it is supposed to build a double frame with space for laying communications, then the mass of 1 sq. m will be 49 kg (with a height of up to 6 m).

When constructing a frame made of wood, the mass is 1 sq. m decreases. But when using wooden blocks, the height of the partition usually does not exceed 4 meters. When constructing a structure with one layer of drywall, fixed on both sides, the mass is 1 sq. m will be less than 30 kg. If the frame is sheathed with two layers of plasterboard, then the weight of the 1st “square will be 50.5 kg. Knowing the total mass of the partitions, it is possible to calculate the load on the floor, which is important, for example, when arranging an attic. When preparing drywall for further finishing, any homeowner will be forced to calculate the consumption of other materials, in particular, primers, putties. They are the main finishing material when using drywall.