Reliable concrete contact manufacturers

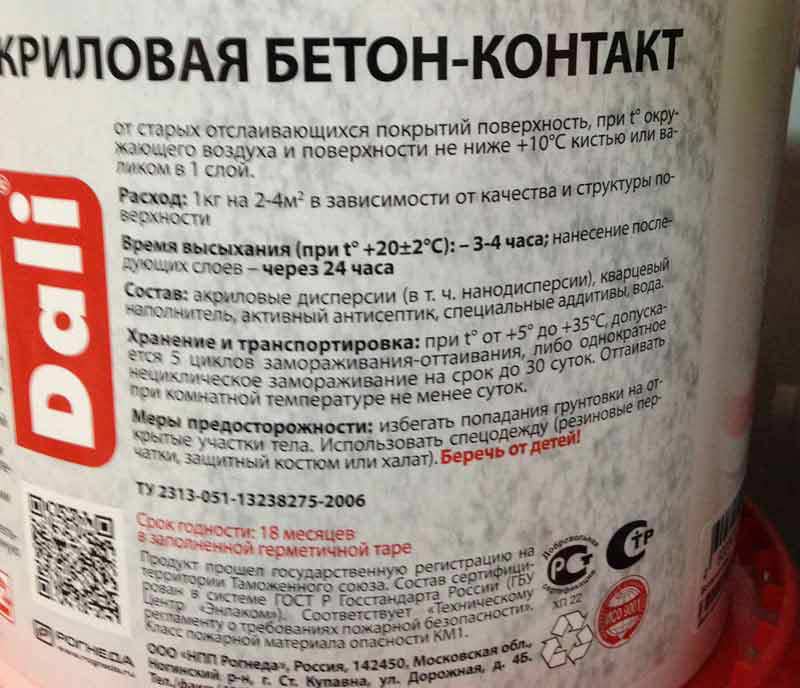

There are firms on the building materials market that have long established themselves. Primers from these manufacturers differ in composition, purpose and price. The cost is quite affordable: for 5 kg you will have to pay only 300-600 rubles.

Axton

This company produces a wide range of mixtures. The first representative is a high quality dry primer. It is used to treat any surface. Before use, add the required amount of water to the concrete contact and stir. The advantages of this material are a high drying rate: at room temperature, the composition sets in 2 hours. The declared consumption is low (300 g per 1 m2), but in fact it turns out to be more.

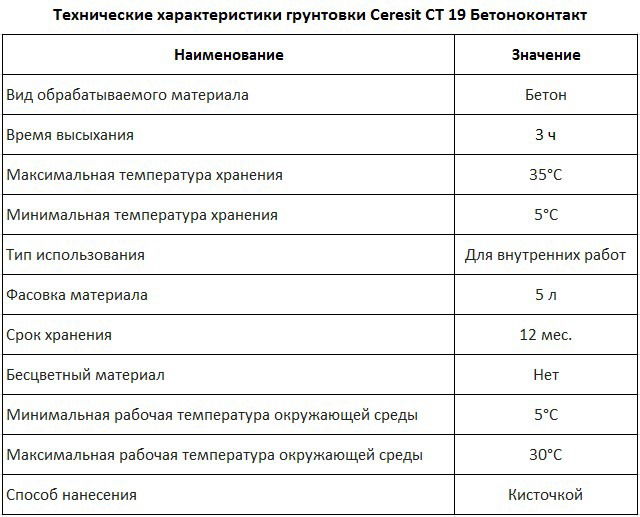

Ceresit

This water-dispersive primer differs from others in that it is better to apply it with a brush; it is not recommended to use a roller. Smooth surfaces are covered with it, in the composition of this concrete contact there is fine-grained quartz sand. The primer must not be diluted with water: high humidity and liquid that gets on the treated substrate will lead to loss of material properties. It is used only for indoor work.

Knauf

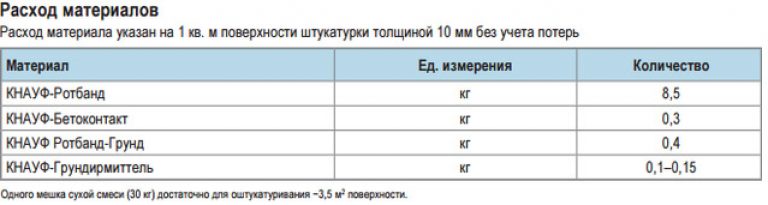

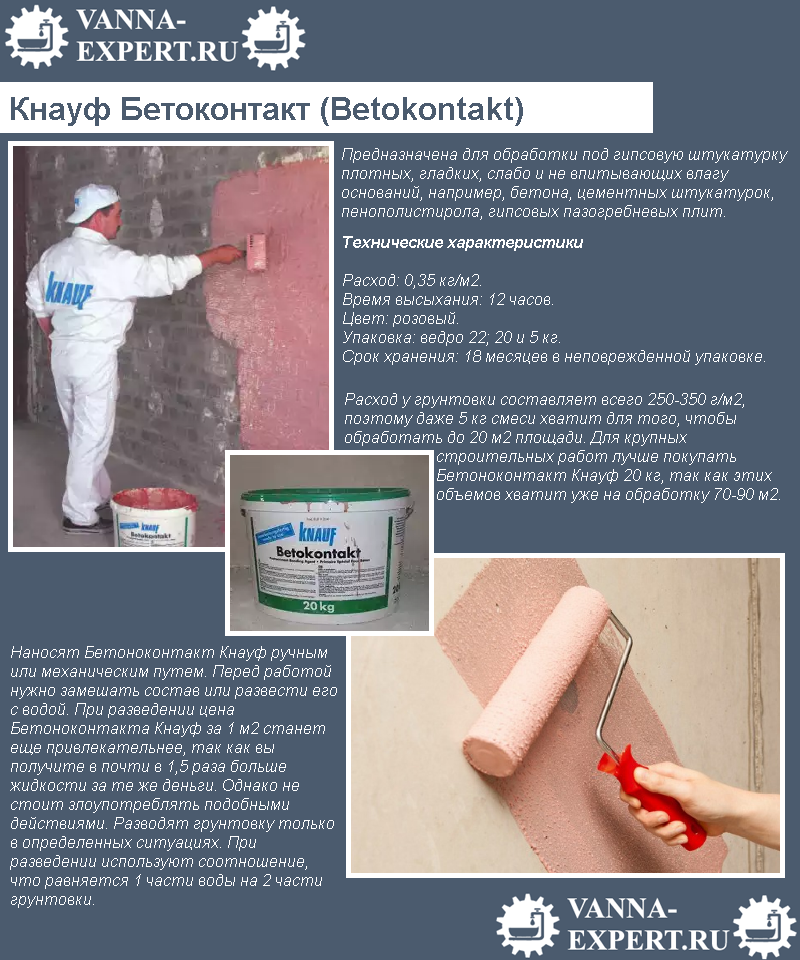

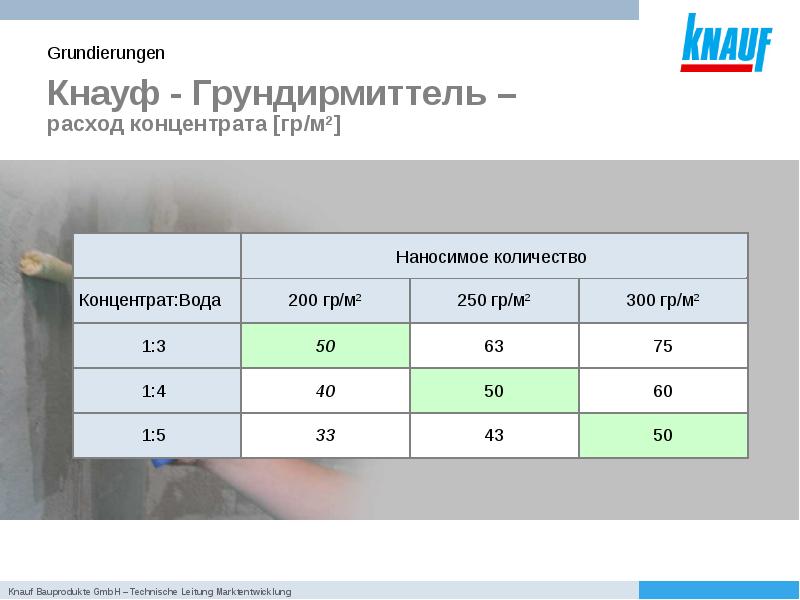

The most famous brand of the domestic construction market. The main components of this material also include fine sand fractions. It is generally accepted that this primer has the best characteristics among other competitors. They make it possible to obtain perfect adhesion to glossy surfaces such as glass. The first layer dries in an hour under normal conditions, while the final setting takes about 4 hours. Consumption - about 350 g per 1 m2.

Prospectors

This primer is a domestic manufacturer, but the place of "birth" does not detract from its merits. The primer mixture is made on the basis of latex. Concrete contact is used for surfaces that do not absorb moisture well - concrete tiles. Due to the low price and low consumption (200 g / m2), the composition is often used when arranging a self-leveling floor. The product does not require thorough stirring: the contents of the jar are simply shaken.

Optimist

Almost the only company that produces not only a decent primer for the treatment of indoor surfaces, but also a high-quality concrete contact, intended for outdoor use. These compounds are ideal for preparing substrates before applying gypsum, polymer material, before facing with cement boards. The minimum drying time of the primer is 3 hours, the maximum is 4. Material consumption - 300 g / m2.

Information about concrete contact: consumption, features of surface preparation and its application - a necessary topic, but not difficult. Already convinced of this is the one who became closely acquainted with the universal material. For example, the master from this video:

Description of the tool

The primer is intended to treat the top layer of the walls (ceiling / floor) in order to increase the adhesion of the materials. With the help of a primer, an even layer is created on which paint, glue, etc. are evenly applied. At the same time, the consumption of the same paint will decrease, that is, the primer saves building materials and improves the final result.

Due to the penetration of the product deep into the pores, a protective durable layer is created that prevents the formation of corrosion, mold and mildew. Hiding small cracks and imperfections tightly, Knauf Primer Mix contributes to a smoother finish. But with all the density of the primer layer, the surface "breathes".

Properties of Tiefengrund

This mixture does not have a specific odor - a clear advantage for the application procedure. Does not emit harmful substances into the air, which makes it harmless to the human body.The Tiefengrund mixture is used for a wide range of surfaces: plaster, brick, concrete and others.

Surface preparation before application

The application of Knauf Betokontakt primer does not require professional training, which allows it to be used at home. Surface treatment is allowed in two ways: classical, carried out with brushes, rollers or a spatula, and mechanized.

First, it is necessary to thoroughly clean the base from dust, dirt, foreign small particles. At the same time, it is not necessary to remove the old coating, if it is well preserved, does not crack or crumble. Then the surface is degreased, inspected. Deep cracks and gaps are pre-cemented and left to dry for 24 hours. After that, the surfaces are primed. It is worth noting that the soil penetrates into the layers of the concrete base by several centimeters, strengthening it.

Buyers respond positively to Knauf Betokontakt primer mix, highly appreciate its quality, convenience and ease of application, economy and quick drying.

Knauf is a time-tested brand. This modern construction primer is popular with many professionals. Knauf Betokontakt guarantees quality and durability, it saves you money and time.

For more information about the types of primers and the intricacies of priming various surfaces, see the next video.

Primer concrete contact: features and consumption per 1m2

A primer is a unique solution that is used to prepare a specific surface for finishing, such as painting. The use of such a building mixture allows you to level the surface, get rid of any defects on the wall and eliminate small cracks.

One of the most popular types of primer is concrete contact, the use of which greatly simplifies further finishing work.

Main characteristics and properties

Concrete contact is an acrylic-based building mixture that also includes cement, sand and special additives. This mixture is actively used to increase the adhesion of a surface that does not absorb moisture well, before plastering, laying tiles and other finishing work.

Among its main advantages are the following:

- high drying speed. Further finishing work can be started a few hours after applying the primer;

- moisture resistance. During the drying process, a special film is formed that does not allow water to pass through;

- durability. According to the manufacturer, the concrete contact primer has not lost its qualities for 80 years.

Thanks to its unsurpassed properties, concrete contact has been able to establish itself as a unique material that is durable, does not need a lot of time to dry and does not allow moisture to pass through. It is these properties that allow you not to worry about the quality of the repair done.

How to determine the consumption of concrete contact?

Consumption of concrete contact per 1m2 depends on many factors, among which the first place is occupied by the features of the treated surface

What matters is not the type of surface itself, but the porosity. It determines how much of the primer will be absorbed, which has a direct effect on its consumption per m2

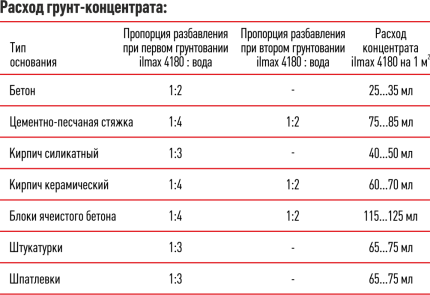

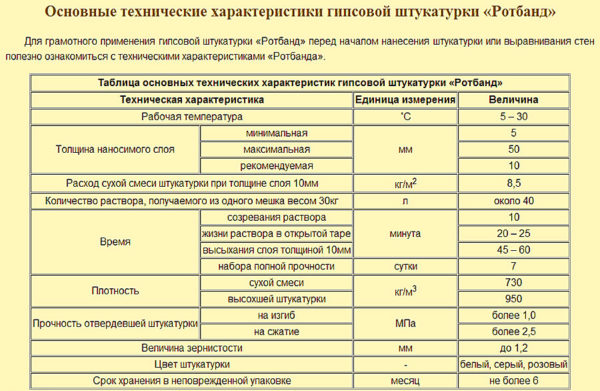

Primer consumption table concrete contact from different manufacturers

Depending on the porosity, the following types of surfaces are distinguished:

- Porous surfaces, which include brick or sand concrete. The primer is absorbed quite intensively, which leads to the consumption of concrete contact up to 0.5 kg per m2. If the porosity is too high, then you will first need to treat the surface with special solutions.

- Surfaces with medium porosity. These include concrete, concrete tiles. Consumption of concrete contact is about 0.3 kg per m2.

- Low-porous surfaces, for which the consumption of the primer is minimal - 0.1-0.2 kg per m2.

Is it possible to reduce the consumption of primer?

Most people wonder if it is possible to reduce the consumption of concrete contact primer. The answer is definitely no. First of all, this building mixture is notable for its affordable price, so there is no point in saving on it. In addition, this can lead to a decrease in the strength of the material, which over time will begin to crack or flake off.

It should be remembered that the quality of the primer and the work done to apply it has a direct impact on future finishing work and the quality of the entire repair in general. If you reduce the amount of concrete contact primer per m2, the surface will lose its adhesion properties. In the future, this may cause the coating to separate from the base.

Reduced primer consumption may result in loss of surface adhesion.

The primer plays an important role in the process of ensuring the waterproofing of the surface, which can be disturbed when the amount of mortar per m2 decreases.

Do not forget about an important feature of some finishing materials, which is that some coatings can dry out. The fact is that gypsum or Portland cement is present in their composition, and drying out becomes a natural reaction to a decrease in the amount of water.

Thus, the use of concrete contact is essential for the future of the entire renovation.

All the nuances of using this building mixture should be taken into account. The level of concrete contact consumption per m2 depends on the type of substrate and its porosity

It is not worth saving when using a primer, as this can negate all further finishing work.

It is interesting: DIY repair of a small kitchen in Khrushchev

Consumption of concrete contact: how much does it take for 1 m2?

For most people, the word "repair" is unlikely to cause at least some positive emotions. Usually this process is associated with huge expenditures: effort, money and time.

One of those tasks that sometimes cause torment even for people with repair experience, albeit not professionals, is the need to increase the adhesion of certain materials. This is where the concrete contact primer will help.

Concrete contact is a special type of primer that can turn absolutely any surface from perfectly smooth to as rough as necessary.

It consists of a very strong adhesive, as well as acrylic and quartz sand. Apply concrete contact for external and internal work. The main manufacturers of this material include Knauf, Prospectors, Master.

Advantages:

- The main positive side of using this primer is that you do not have to remove old coatings from where you want to apply it before applying it.

- You can not use a reinforcing mesh during plastering work, and using a concrete contact on the plaster will increase its strength, since the solution penetrates into the plaster coating and holds it together. This means that after using the concrete contact you can, for example, drill or perform other similar work without fear of significant damage to the finish.

- When working with this substance, you may not use special protective equipment, because it is an environmentally friendly substance that does not contain any solvents or other harmful substances that can harm your health.

- Walls treated with concrete contact will not stop "breathing", and mold and other types of fungi will never appear on them.

You may find it useful to know how to prime the walls under the wallpaper. Read this article.

Disadvantages:

- You cannot store this material in the cold because it will lose its properties.

- If applied incorrectly, it will not fulfill its basic properties.

to the content

Consumption rates

Despite the fact that the name of this material contains the word "concrete", concrete contact can be used on completely different surfaces.

Accordingly, the rate of its consumption will be completely different. It depends, first of all, on the porosity of the surface on which you apply it.

And although the simplest and most reliable way to determine the rate of consumption of concrete contact is simply to apply it to a part of the desired surface, an area of one square meter, let's still consider the approximate rate of consumption of this material.

- On surfaces with high porosity, such as concrete slabs, bricks or special porous stones, you should apply 0.5 kg per m2.

- For materials with medium density, such as concrete monolith or concrete tiles, you will need 0.3 kg per 1 m2.

- Low-porous surfaces (ceramics, tiles) will require at least 0.15 kg of concrete contact per 1 m2.

to the content

DIY primer application

First you need to clean the surface of debris and dirt, dust and everything else. Next, you need a roller or brush.

It is necessary to carefully place the concrete contact in the container and apply it with a roller in an even thin layer on the wall. Corners and hard-to-reach places are primed with a brush.

When performing work, you need to monitor the temperature in the room. It should not be lower than +5 ° C.

Now the main thing is done and you can rest a little. You must wait until the concrete contact is completely dry

This is very important, because if it is even slightly damp, it will significantly reduce the quality of adhesion.

Complete drying of the concrete contact usually occurs in 5-6 hours. After this time, you can proceed to further finishing.

It is impossible to delay with the continuation of finishing work, because after more than two days the surface will dry out and become dirty.

Now that you know about this wonderful type of primer, your renovation will be easy and enjoyable.

Video review of concrete contact primer.

Scope of use

Primers are used to improve adhesion properties, as well as to improve the strength of the base, which is processed with the material. For each type of soil, there is an instruction in which the composition, material consumption per m2, as well as for which work, external or internal, it can be used, is prescribed.

Concrete contact primer is used for the following purposes:

- The properties of the primer allow it to be used before screed or self-leveling floors, which is why it is often called a primer for concrete floors.

- Concrete primer is used for surface treatment before finishing with plaster or putty

- To reduce the porosity of drywall boards, before gluing tapestries or laying tiles

- The composition allows you to use betokontakt before whitening the ceiling

The technical characteristics of a concrete primer can be used for work on non-absorbent surfaces. These can be bases covered with varnish or paint, as well as tiled. Most importantly, for this there is no need to dismantle the old coating, because the penetrating primer is applied over these materials, forming a rough surface that adheres well to new finishing elements. It is worth clarifying that the concrete contact primer has an environmentally friendly composition, and this allows it to be used in any premises. Although GOST specifies what composition the primer should have, many manufacturers may deviate slightly from the list of elements, although this does not affect the quality of the material in any way.

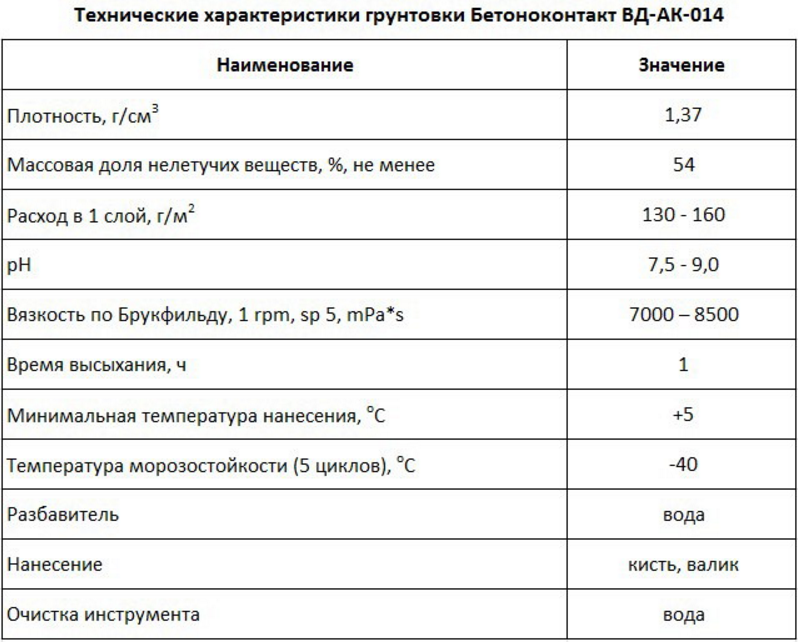

Let's take a look at the technical characteristics and properties of the primer:

| Drying process | Very fast compared to other species. On average, after 2.5 hours finishing work can be continued |

| Moisture resistance | After drying, the primer forms a film that repels water and thereby protects the base from premature destruction. |

| Life time | Many manufacturers indicate a lifespan of 80 years. However, for this, the instructions for applying the primer must be followed. |

| Application method | It is allowed to use both manual and mechanical options |

| Distribution of the composition | Pigments that may be part of the primer help to keep track of the uniformity of the application |

Consumption of concrete contact: how much does it take for 1 m2?

For most people, the word "repair" is unlikely to cause at least some positive emotions. Usually this process is associated with huge expenditures: effort, money and time.

One of those tasks that sometimes cause torment even for people with repair experience, albeit not professionals, is the need to increase the adhesion of certain materials. This is where the concrete contact primer will help.

What is concrete contact?

If you are not an experienced builder, you are probably hearing this word for the first time, so we should figure out what this substance is.

Concrete contact is a special type of primer that can turn absolutely any surface from perfectly smooth to as rough as necessary.

It consists of a very strong adhesive, as well as acrylic and quartz sand. Apply concrete contact for external and internal work. The main manufacturers of this material include Knauf, Prospectors, Master.

Advantages and disadvantages

This type of primer, like any material, has its pros and cons. Let's consider them in more detail.

- The main positive side of using this primer is that you do not have to remove old coatings from where you want to apply it before applying it.

- You can not use a reinforcing mesh during plastering work, and using a concrete contact on the plaster will increase its strength, since the solution penetrates into the plaster coating and holds it together. This means that after using the concrete contact you can, for example, drill or perform other similar work without fear of significant damage to the finish.

- When working with this substance, you may not use special protective equipment, because it is an environmentally friendly substance that does not contain any solvents or other harmful substances that can harm your health.

- Walls treated with concrete contact will not stop "breathing", and mold and other types of fungi will never appear on them.

You may find it useful to know how to prime the walls under the wallpaper. Read this article.

- You cannot store this material in the cold because it will lose its properties.

- If applied incorrectly, it will not fulfill its basic properties.

Consumption rates

Despite the fact that the name of this material contains the word "concrete", concrete contact can be used on completely different surfaces.

Accordingly, the rate of its consumption will be completely different. It depends, first of all, on the porosity of the surface on which you apply it.

And although the simplest and most reliable way to determine the rate of consumption of concrete contact is simply to apply it to a part of the desired surface, an area of one square meter, let's still consider the approximate rate of consumption of this material.

- On surfaces with high porosity, such as concrete slabs, bricks or special porous stones, you should apply 0.5 kg per m2.

- For materials with medium density, such as concrete monolith or concrete tiles, you will need 0.3 kg per 1 m2.

- Low-porous surfaces (ceramics, tiles) will require at least 0.15 kg of concrete contact per 1 m2.

DIY primer application

First you need to clean the surface of debris and dirt, dust and everything else. Next, you need a roller or brush.

It is necessary to carefully place the concrete contact in the container and apply it with a roller in an even thin layer on the wall. Corners and hard-to-reach places are primed with a brush.

When performing work, you need to monitor the temperature in the room.It should not be lower than +5 ° C.

Now the main thing is done and you can rest a little. You must wait until the concrete contact is completely dry

Complete drying of the concrete contact usually occurs in 5-6 hours. After this time, you can proceed to further finishing.

It is impossible to delay with the continuation of finishing work, because after more than two days the surface will dry out and become dirty.

Now that you know about this wonderful type of primer, your renovation will be easy and enjoyable.

Video review of concrete contact primer.

Positive properties and characteristics of concrete contact

You can use the composition in a diluted and undiluted form on any building surface, if it is clean: it can be old facing with concrete, drywall, any paint and varnish compositions, facing with tiles. If it is necessary to dilute the primer, it is better to do it with clean water.

The grain size in the liquid is 0.3 and 0.6 mm. I use the first composition before filling, the second option - before plastering surfaces. Despite the fact that the liquid does not allow moisture to pass through, it is recommended to apply it as quickly as possible so that the painted surface does not have time to be moistened by natural moisture from the atmosphere. It is also required so that the surface under the primer does not become infected with fungal infections. For this, antibacterial and antifungal substances are additionally introduced into the primer.

Features of working with universal material:

- So that the concrete contact does not begin to fall off over time, swelling on old surfaces must first be eliminated;

- To obtain a high-quality and long-lasting result, dilute the primer according to the instructions;

- Follow the application technology so that the walls are well saturated with the substance.

Consumption

It is all these signs that determine how much primer consumption you spend per square meter of surface. This indicator, most often, is indicated on the packaging, because this is the most important characteristic that allows you to know how much material it costs to purchase, so as not to run after additional materials.

The consumption of a deep penetration primer depends on the following factors:

- the amount of primer used is influenced by the material of the surface on which the material will be applied (metal, wood, stone);

- the composition of the primer itself, namely its elements, their proportion, which is directly set by the manufacturer himself;

- the amount of material used is also influenced by the type of further dye, glue and building material;

- quite an important factor - the season, weather conditions.

All these factors in one way or another affect the future consumption of material. But there is still one parameter that affects the consumption rate - this is the method of applying the material, as well as the tools themselves that are used during work.

The tools with which you will apply the primer have a lot to do with how much you will spend on the selected area. The substance itself is sold in containers of different volumes, you select the one you need.

The primer can be applied to the vertical surface with special tools. A roller is a fairly convenient way to apply material to vertical walls.

Roller

The most common option for painting hard-to-reach areas is a brush. The brush is used when applying material on the seams, when processing corners and hard-to-reach places;

Brush

Also, when applying the primer, sprayers are used.

Spray

The primer is available in a liquid version, and has a transparent composition and can be used before gluing wallpaper, but if you are processing wood, then you should choose a moisture-proof material.

It contains darkish pigments, which makes it possible to clearly see the boundaries of application when applying it, but it should be understood that using this type of primer it is worth remembering one rule: in no case should the primer be darker than the topcoat.

If it is metal, then 80-100 g per square meter is enough for it. You should be aware that work on metal must use a primer without acrylic, this is due to the fact that rust is not observed on such a primer. But before applying the primer to the metal, it must be carefully prepared for use.

If, before applying the primer, the metal surface was used quite often, then fluffy rust clearly remained on it, then it can easily get rid of it using the necessary tools (brush).

This is necessary so that the old metal does not absorb the primer, which means that if you do not process the material in advance, you can spend twice as much paint and varnish materials during further processing. In order to treat a metal surface with a primer, it is worth choosing it based on resins.

It can be used for both metal and concrete. 80-100 g per square meter is considered the smallest indicator among all available bases. The consumption rate of a deep penetration primer per 1m2 based on acrylic is 120-150 g per square meter.

Acrylic primer dissolves easily in water; you can buy it in a store in the form of a powder, or in the form of a concentrated liquid.

In structure, such a mixture will resemble a simple whitewash, therefore, it makes no sense to apply it on dark surfaces. This primer is good for painting with acrylic paints. Can be used both inside and outside the house.

Using a primer, before applying the base material, not the surface - there is a place to be. If you neglect this advice, then we can assume that the money spent on finishing materials is wasted.

There are certain counting rules based on which you can determine how much primer you need to process a particular room. The first thing to do is to calculate the total area of the room, but at the same time take into account its properties.

It should be understood that the walls, floor and even the ceiling have different density characteristics, therefore, it is worth calculating for each surface, separately. Several indicators of material consumption are indicated on the packaging of the primer.

Approximate values of material consumption:

a primer based on acrylic can be consumed with an approximate value of 110-160 g / square meter;

Acrylic

the Knauf primer, which is used for walls, can be consumed from about 50 to 130 g / square meter;

Knauf

the approximate consumption of the deep penetration primer (in general) is 100 g per square meter.

How and what drywall is primed for different finishes

There are a few more points that can affect the choice of soil. First you need to decide on the properties of the material. They are as follows: The primer must be applied twice at intervals so that the first layer dries out. They usually wait 12 to 24 hours. Although many manufacturers claim that 6 hours should be enough.

But it's better not to rush, because the humidity and temperature are different everywhere. The weight of ceramic tiles is quite large, so care must be taken to keep them firmly in place. Tile glue helps with this, but you can't do without a primer. It's not difficult to guess how to prime the drywall before laying the tiles.

It is worth choosing the same deep penetration acrylic primer with anti-fungal properties. When choosing specific products from different manufacturers, you need to make sure that they are suitable for working with ceramic tiles.

It is worth paying attention to the consumption of primer on drywall for 1m 2. This indicator is always indicated by the manufacturer on the packaging

You should always add about 10% to it to get real results.

It should also be borne in mind that the consumption is indicated for one layer, and it will be necessary to apply the primer in two layers (the second is applied after the first is completely dry). Consumption usually ranges from 100-150 grams per square meter.When the question arises of what kind of primer to prime drywall, then you need to decide what types of this material exist.

It is important to choose material by manufacturer, but still, you need to know about its existing varieties. The main types are as follows:

Additional information on the topic:

- How to assemble a frame for a niche in a plasterboard wall photo

- How to hide a beam on the ceiling in a wooden house with drywall

- How to install a drywall arch on a video profile

- Do I need to putty drywall before gluing liquid wallpaper

- How to glue ceramic tiles to drywall besides tile glue

Peculiarities

It is often quite problematic to adhere two different types of materials during finishing. Thanks to the primer, for example, betokontakt, the adhesion rate increases significantly even when the surface practically does not absorb moisture. The primer consists of cement, sand, and other special additives that create a rough layer formed by the sand, and the cement allows the mixture to adhere well to the walls.

The primer betokontakt knauf is made only from safe, environmentally friendly components that do not emit unpleasant odors, do not harm human health and do not spoil the appearance of surfaces.