Installation features

The reliability and durability of the fastening made with the frame-type anchor bolt also depends on how correctly the installation is performed. First of all, you should prepare the tools, without which it will be almost impossible to perform such a procedure. These tools are easy to find in almost any home workshop. These include:

- a perforator with which a hole will be made for mounting a frame anchor;

- a drill, the diameter of which must correspond to the size of the cross-section of the spacer sleeve of the fastener;

- a screwdriver with a cross-head working part, with which the anchor screw will be twisted into the spacer sleeve;

- hammer required to drive the anchor element into a previously prepared hole.

Briefly about the installation of the frame anchor

Step 1: Installing the frame in the opening and securing it with spacers

The frame, which you are going to securely fix in the window opening, must first be set up using wooden spacers for this. When exposing the frame, you should carefully align its elements relative to the horizontal and vertical planes using a regular building level. Spacers or wedges that are used to pre-fix the frame can be hammered in. If, when setting the frame, any flaws are found, then at the stage of preliminary fixation it is quite easy to eliminate them by knocking out the wedges and moving the window structure in the desired direction.

Plastic window fixing scheme

Stage 2: Marking of the places for drilling and preparation of the recesses ("sweep") in which the screw heads will be located

After the window frame is securely fixed in the opening with the help of spacers, you can start marking the places in which the holes will be drilled for placing the anchors. If you are going to secure a small frame with such elements, then four bolts will be enough, and for larger structures, the number of fasteners must be increased.

There are generally accepted requirements according to which the anchoring elements should be placed at a distance of 30 cm from the upper and lower edges of the window frame (if necessary, the position of the fasteners can be adjusted). If in the window frames that you are going to install, the manufacturer did not provide for recesses for placing the heads, then they should be made independently using a drill of the appropriate diameter.

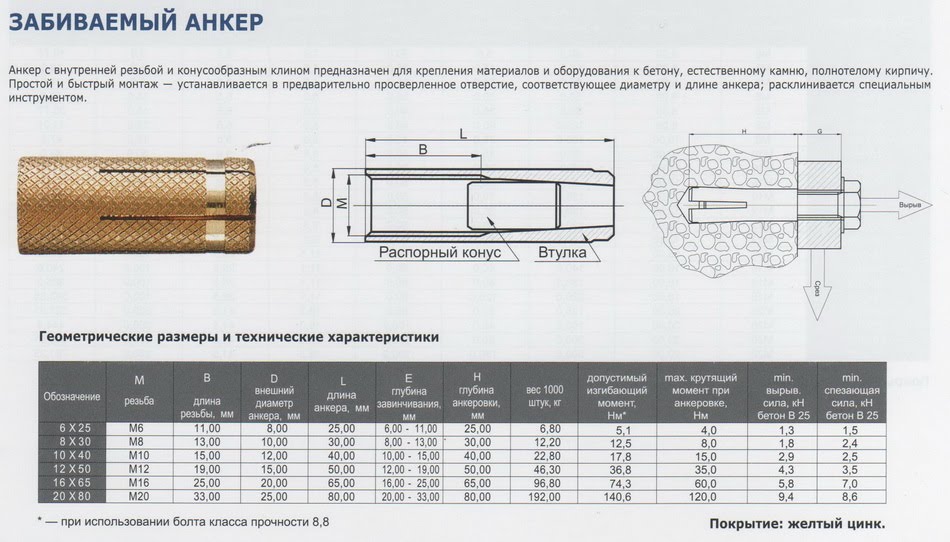

Setting parameters for frame anchors with a diameter of 10 mm

Step 3: Mounting the fasteners

After all the above manipulations are completed, you can proceed directly to the installation of frame anchors. To do this, it is necessary to drill through the wooden frame in the designated places, going deep with a drill into the surface of the window opening to the required depth.

Drilling a mounting hole for an anchor

It is advisable to clean the prepared holes of construction dust and pieces of crumbled material. Only then can the frame anchoring elements be inserted by passing them through the frame. The anchors inserted into the prepared holes must be tightened using a screwdriver with a Phillips head. After tightening the screw heads, the inner spacers will expand to secure the entire structure in the window opening.

How to fix it?

To install a frame or door jamb, in addition to a set of anchors, you cannot do without some tools:

- hammer drill with a set of drills for drilling the wall material and for drilling a hole in a metal structure;

- hammer;

- Phillips screwdriver or a corresponding bit for installation on a screwdriver, some craftsmen manage with the same perforator in drill mode at low speeds;

- building level;

- pencil.

Fastening the frame with anchors step by step looks like this.

- The frame must be wedged in place, making sure to adjust the vertical and horizontal levels. Wedges can be made of wood or plastic. You will need a hammer to install them.

- Frame marking for holes. It is customary to drill at a distance of 30 cm from the corners, but this is not an unshakable truth, sometimes you have to take into account the features of the wall and change the standard distances, as a rule, this does not affect the quality of the frame installation. In the places chosen for drilling, it is necessary to make a sweep for the anchor head.

- Holes are drilled in the designated places. Further, after changing the drill, it is necessary to drill the wall material to a depth sufficient to install the fasteners.

- Clean the drilled hole to remove debris, dust and material debris.

- Insert the anchor into the drilled hole. You may have to use a hammer, this should be done without undue effort.

- Use a Phillips screwdriver or bit to tighten the anchor.

- When installing the next anchor, check the position of the frame with a level - if no displacement has occurred, do all the operations described above.

For the installation of a small non-swing frame with a side of less than 1 m, 4 dowels are sufficient. Usually, two anchors are used to install frames on each side of the frame.

In the next video, you will find examples of the installation of various anchors.

Peculiarities

The main difference between the frame anchor and any other anchor-type fastener is the elongated pin with a countersunk cone head. All this necessary forto anchor the three-dimensional structure of a window frame or doorframe to the normally solid wall material. The fasteners are excellent for the installation of hollow structures, such as modern frames of metal-plastic windows or jambs of metal doors.

The task of fastening is to securely fix the frame in the opening. Since such structures, in addition to constant loads, constantly experience variable dynamic effects (arising from their functionality), special requirements are imposed on the fasteners intended for their installation. It must be strong against tearing and bending, while tolerating vibration.

The metal anchor bolt and the spacer sleeve make it possible to combine all the requirements for such a fastener, which has significantly expanded the scope of application of frame anchors. Currently, they are purchased not only for installing a window or door, but also for installing various kinds of structures, decor or hanging not very heavy equipment.

The appearance of frame anchors caused the need for their standardization, as a rule, they correspond to the technical specifications, since during the development of GOSTs such fasteners did not exist at all. But the alloy (steel, stainless steel, brass, aluminum) used for their manufacture must strictly comply with GOST, according to which the products of metallurgical enterprises are standardized.

Dimensions (edit)

In addition to the material from which the frame fasteners are made, its size - length and diameter - is also subjected to standardization. Due to the peculiarities of the fastening, in which metal tabs are formed, wedging the fasteners, it cannot be too short

Wedging in the immediate vicinity of the surface of the material - it doesn't matter whether it is brick or concrete - can cause its destruction and, accordingly, the connection loses its main properties. This is most relevant, of course, for brick structures.

It is for this reason that the minimum length is 72 mm.

Dowels of this length are available in two standard diameters: 8x72 mm and 10x72 mm.The first sample can withstand a standard 30 kg for fracture, and the second is designed for the installation of heavier structures. The least long anchor dowel is designed for the installation of non-frame structures, has a modest size of 10x32 mm; this product is quite rare, since the tasks for which it was developed are successfully solved with cheaper fasteners with a plastic or polyethylene sleeve.

The following size group has a standard length of 92 mm. Accordingly, it is possible to purchase anchors 8x92 mm and 10x92 mm, depending on the effort to which this fastener must resist. It is very problematic to use the first two size groups for the installation of window frames or door jambs due to their small length, part of which will be covered by the most mounted frame structure. Their area of application is somewhat different: facade elements, decor, non-hollow structures of small thickness. Dowels can be considered frame proper length from 100 mm... They are also divided into two groups depending on the diameter: 8x100 mm and 10x100 mm.

The next standard size group with the same diameters has a length of 8x112 mm and 10x112 mm. Such anchors are quite suitable for the installation of standard window structures, and if they do not have opening sashes, this fastener can be considered ideal.

In the case when the size of the structure is larger than the standard, and even at the same time, large sashes are mounted in it, which seriously affect the center of gravity when opening them, you will have to choose elongated anchors: 8x132 mm and 10x132 mm. They can also be considered minimal when installing metal doors. In the family of frame fasteners there are also real "monsters" used in the installation of structures of large mass and size: 8x152 mm and 10x152 mm.

The first ones are quite rare, since products of this length are used mainly for large-sized structures that are heavy, the reinforced version of fasteners is still more popular with users. Very specific anchors 10x202 mm are also rare.

Principle of operation and design features

The technical capabilities of the frame anchor are determined by the features of its design. When choosing a frame metal anchor for installation work, one should take into account the fact that it is not designed for significant loads and for a large weight of objects fixed with it. The weight of an object fixed on a vertical surface by means of one anchor of this type cannot exceed 30 kg.

Frame anchor device

The main structural element of the frame anchor bolt is a metal sleeve with longitudinal slots, which form a kind of petals that expand during the installation of the fastener. A flare nut is responsible for unclamping the petals on the side of the sleeve. It, twisting onto the rotor, acts on the inner surface of the slotted hub, thereby unclamping it. The bushing, having increased in diameter, comes into tight engagement with the inner walls of the mounting hole, securely fixing in it.

In order to make it more convenient to manipulate the screw screwed into the spacer sleeve, a hat with slots for a figured screwdriver is provided on its upper part. A feature of the frame anchor is that its head is completely buried in the mounting hole, therefore the lateral surface of its head is tapered. Using such fasteners, one should not only drill holes for their placement, but also provide for a special "sweep" into which the bolt head will enter.

Frame hollow anchor structures has an enlarged spacer zone (butterfly) and a flat nut, working on tightening

Where is used

Anchor bolts today are one of the most popular types of fasteners, which is associated with their unique technical characteristics and wide versatility, which makes it possible to use such elements for fastening a wide variety of structures and objects of different sizes and weights.

The metal frame anchor got its name because it was originally used for high-quality and reliable installation of window frames and door frames. Today, a metal frame dowel (another name for a frame anchor) is still used in the installation of window and door structures, but its scope has expanded significantly.

Securing a door or window frame - typical examples of using frame anchors

Specialists working in the field of construction and repair paid attention to the versatility of such a design, as well as to the high reliability of fixation that it provides, and began to actively use it for the installation of finishing materials, elements of building structures, as well as items for various purposes. In particular, this anchor has gained particular popularity when installing wooden beams on various types of surfaces.