Types of varnishes

To choose the most suitable varnish for metal, you need to study in detail the composition and action of each type. Let's consider a brief description of some of them.

Bituminous varnish

As the name suggests, it contains bitumen and polymer resins. After drying, the product gives the coating a black tint-like tint. They can cover not only metal, but also wood and stone surfaces. The product is heat resistant, durable and safe for human health. At the moment, it is very popular on the market, since in addition to all the listed advantages, it also has a low price.

Polyurethane varnish

It contains polymers that, when applied, create a strong adhesion to the surface. It has anti-corrosion properties, therefore it is used for processing metal products, and most often for metal dishes. This varnish can be inconspicuous (colorless), glossy and even matte. The coating can have a different shade, it can be used as a protective layer before applying paint to the metal.

Acrylic lacquer

It forms a very resistant film that tolerates constant humidity and temperature changes well. The varnish is available in the form of aerosols and a regular liquid that is applied with a brush. In the modern world, it is most often used in the surface treatment of car parts. The product easily tolerates exposure to chemicals and can even extend the life of various metals.

Alkyd varnish

Unlike previous types, after drying, it gives the metal surface a glossy sheen. The product is sold in the form of a spray and in a liquid form.

Scope of use

Varnish sprays of any manufacturer (Kudo Ku, Cramolin, etc.) have an extensive area of use

Varnish sprays of any manufacturer (Kudo Ku, Cramolin, etc.) have an extensive area of use

Lacquer sprays of any manufacturer (Kudo Ku, Cramolin, etc.) have an extensive area of use. The most popular is the universal spray varnish. They are indispensable wherever precise work is needed in small areas. At the same time, three main areas of varnish use can be distinguished:

- In the automotive industry, Plastik 200 sprays from Cramolin and other manufacturers are used after body repairs.

- The universal composition can be applied to kitchen utensils, bathroom accessories, toys, art, furniture and other interior items.

- Matt and glossy varnish in aerosols is used in the construction industry.

- Such formulations are indispensable in the electrical field, for example, the Plastik formulation from Cramolin is in great demand in this industry.

Varieties

Spray varnish can serve different purposes depending on its type.

Spray varnish can serve different purposes depending on its type.

Spray varnish can serve different purposes depending on its type:

- Tinting varnish compositions are suitable for the treatment of car bodies, individual units and parts. For example, such a mixture is suitable for tinting headlights or other glass or plastic parts. As a rule, tinting varnish helps to protect parts from weather factors, mechanical influences and aggressive chemicals. In addition, it improves the aesthetic qualities of the car, creates the effect of novelty and shine. Also, the tint spray perfectly protects wood surfaces after restoration.

-

Reflective compositions in cylinders contain special particles that, in addition to a glossy sheen, allow the surface to reflect light in the dark. That is why such compounds are commonly used to coat auto parts, road signs and other bicycle accessories, helmets, etc. Such varnishes are suitable for surfaces made of steel, glass, plastic, wood.In turn, these mixtures are divided into several subspecies, depending on the special effects they can create:

- shine of diamonds. Such compositions give the surface an incredible shine, volume and depth;

- chameleon. This coating can change its shade at different viewing angles and lighting;

- the effect of the starry sky. This composition contains multi-colored microparticles that create a diffused glow on the surface.

- Polyurethane varnish compositions. These mixtures, like Cramolin's Plastik acrylic varnishes, are designed to protect surfaces from mechanical stress, moisture, scratches, mold, and high temperatures. They are used for plastic, wood, metal products. To increase the protective effect, it is recommended to apply the composition in several layers (3-4). At the same time, each previous layer should dry completely, so consider how long the varnish you choose dries. On wooden surfaces, this varnish only emphasizes the texture of the wood and gives the product a shine.

Features and types

Transparent varnish designed to cover metal surfaces can be very different. Despite this, all such means are capable of protecting the product. Thanks to them, rust will not appear on the surface of the metal, temperature drops will not adversely affect it, and this will help to significantly extend the service life of the product. In addition, such a tool helps to protect the metal from moisture and prevent the appearance of mold. Most often, transparent varnish is used, the types of which will be described in more detail in this article.

If you choose among colorless varnishes, then you should pay attention to a polyurethane agent, which can be matte or glossy. It has a waterproof effect, which makes it widely used in both outdoor and indoor work.

Most often, a transparent varnish is produced in the form of an aerosol.

The aerosol can be easily applied to any surface without leaving smudges, which is very important. In addition, a type of varnish such as a spray dries quickly.

The polyurethane agent is a waterproof varnish that will reliably protect the metal from damage and increase its wear resistance.

Often when working with metal so-called "NC" varnishes (nitrocellulose) are used. One of the main advantages of this product is that it dries very quickly. With it, it will be possible to significantly speed up construction or repair work. Experts recommend using it mainly for internal work.

The acrylic-based product can be attributed to the same category of varnishes. It is easily applied to a metal surface, and after drying it forms an invisible transparent film that will reliably protect the product. Acrylic varnish is particularly resistant and can even withstand mechanical damage. In addition, such a surface will not lose its ideal appearance for a long time, despite exposure to sunlight or severe frost. Also, acrylic varnish is practically odorless, which makes it possible to use it while working inside the house.

Alkyd varnish is also ideal for indoor and outdoor use. It is most often sold in the form of an aerosol.

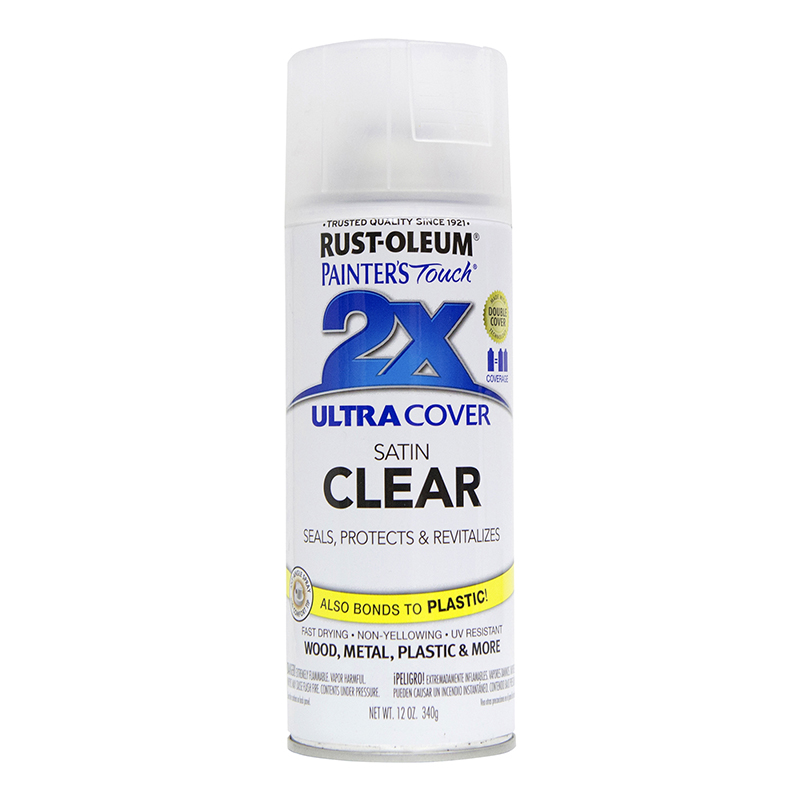

PAINTER'S TOUCH ULTRA COVER 2X CLEAR SPRAY

PROTECTIVE CLEAR VARNISH - transparent acrylic coating with silicon oxide to protect painted surfaces.

CHARACTERISTICS OF THE MATERIAL

- UV resistant, protect the surface from fading;

- has an unsurpassed hiding power due to its high binder content;

- provides long-term protection and durability;

- creates a smooth, durable transparent coating;

- a new, unique spray button system allows you to comfortably paint the surface at any angle, even upside down, minimizing finger fatigue;

- quick-drying;

- easy to apply;

- For interior and exterior use.

ADHESION: excellent adhesion to new or previously painted wood, metal, unglazed ceramics, concrete, plaster, masonry, etc.

Restrictions: do not apply to surfaces over 93 ° C and galvanized metal surfaces.

POSSIBLE APPLICATION: serves both to protect surfaces painted with enamels, decorative paints, etc., and as an independent coating.

VISUAL EFFECT: dense smooth transparent coating (matte or glossy).

COMPOSITION: acrylic, amorphous silicon oxide + org. solvents

PACKAGE: spray, net weight - 340 g

CONSUMPTION: 2 sq.m

SURFACE PREPARATION

Remove loose paint and rust with a stiff brush or # 80-150 sandpaper.

Remove all sanding dust with a vacuum cleaner, then wipe with a damp, lint-free cloth and dry thoroughly.

APPLICATION

Apply protective varnish outdoors or in well-ventilated areas. Apply at air and surface temperatures between 10 ° C and 32 ° C and relative humidity below 65% to ensure proper drying. Do not spray in strong wind and dusty conditions. Cover all surrounding objects to protect from colorful fog.

Shake the can vigorously for 1 minute after you hear the mixing ball rolling inside. If the sound of the mixing ball is not heard inside - do not start working with the spray! Shake the can frequently during application.

DRYING TIME

At 21 ° C and 50% RH

- until tack-free - 20 minutes;

- easy use - 1 hour;

- reapplication - within 30 minutes or after 48 hours;

- complete drying - 24 hours.

NOTE: On plastics, maximum paint adhesion and durability is achieved after 5-7 days.

Cleaning:

Precautions: Do not insert a pin or other object into the channel. Pressurized cylinder

Protect from direct sunlight and heating over 50 ° C. Do not pierce or burn, even after use. Do not spray near open flames or hot objects. No smoking while working. Cylinders may only be disposed of in specially designated places.

FIRE DANGER!

Keep out of reach of children!

SHELF LIFE:

Advantages of varnishes in aerosols

Such formulations are immediately ready for use.

Such formulations are immediately ready for use.

It doesn't matter which manufacturer's varnish you use, Plastik from Cramolin, Kudo Ku formulations or other brands, they all have the following advantages:

- Such formulations are immediately ready for use. They do not need to be diluted, mixed. Also, you do not need rollers, brushes and other auxiliary tools that you have to clean after use. Thus, the spray lacquer is highly mobile. You will save money on the purchase of additional tools and solvents. And thanks to the convenient volume of 200-400 ml, the varnish can be used even in the field.

- As a rule, the spray can indicates how long the varnish dries. This usually takes a few minutes. Due to the fact that the composition dries so quickly, smudges do not have time to form on plastic, steel or wood surfaces.

- Such compositions can be used not only on products made of different materials (plastic, wood, steel), but also on planes of different shapes. The surface can be flat, curved, open, or difficult to access.

- Plastik spray varnish or another variety can be used even by beginners. No special knowledge or experience is needed. If you are interested in how much varnish you need, then we can confidently say that its consumption will be minimal. This will give you an even, continuous, smudge-free layer.

- Any varnish in aerosol (universal, matte or glossy) has excellent physical and chemical characteristics. All of them are resistant to steam, moisture, high temperatures, various aggressive substances and detergents.In addition, surfaces made of steel, plastic, ceramics or wood will be reliably protected from mechanical stress, burnout in the sun, and temperature jumps. At the same time, depending on the type of varnish, you will get a matte or glossy effect.

- Thanks to the transparency of the varnish, you will retain the original color of wood, plastic, glass, cardboard or steel surfaces.

- Affordable price for a small volume (200 ml or 400 ml). As a rule, liquid varnishes are sold in large containers, so for small areas it will be more economical to buy formulations in aerosols.

Tips & Tricks

You can give some useful tips for those who are planning to work with varnish for metal products in the near future ^

When buying an aerosol, be sure to pay attention to the date of manufacture and shelf life. If the product has been stored for a long time in improper conditions, then the surface covered with it will soon lose its appearance, cracks will appear.

When working with any kind of varnish, protect your hands and wear rubber gloves

It is also worth taking care of respiratory protection and wearing a respirator.

Conventional products (not sprays) can be applied to the surface with a brush. But experts recommend using a roller to achieve a uniform application.

- The surface to be coated with the product must be smooth and clean, if necessary, it will be necessary to sand.

- Read the instructions before using the aerosol. Often, such a remedy is recommended to be preheated in a special water bath.

- If the product is applied in several layers, then you should definitely wait until the previous layer is completely dry.

How to use colorless spray varnish, see below.