Giving concrete special properties

If additional requirements and special properties are imposed on the structure to be erected, for example, water resistance or frost resistance, then additives and special concrete of exposure class XD, XF, XM or XA should be used.

To give the concrete solution special properties, various additives are added to it, which can increase and improve certain qualities of the material.

Concrete with high frost resistance requires the addition of an appropriate additive, which increases the level of frost resistance of the concrete base.

The addition of this type of additive ensures that the foundation can withstand a large number of freeze-thaw cycles.

If, in addition to frost, the structure is exposed to salts, additives with high frost resistance and resistance to thawing salts acting on the base are used.

Also, additives are used that can increase the plasticity of the solution. They are generally used in formwork mortars with frequent repetitive metal reinforcing mesh... This additive contributes to a better distribution of the mixture along the entire perimeter of the formwork.

They also use additives that increase the degree of stability of the foundation of the structure to erosion by groundwater (waterproof concrete). It is almost impossible to do without them in places where the soil is too saturated with moisture. A solution of a denser consistency is used for buildings with a thickness of 10 to 40 cm so that the depth of water penetration does not exceed 0.6, and for structures with a greater thickness - 0.7.

Preparation of concrete for a pile-rammed foundation

Compared to columnar foundations, only the calculation formula for cylindrical pillars of rammed piles changes. You need to multiply the height by the radius in the square and by the number "Pi" (3.14). Calculation example: multiply the height of 1 m by 0.0625 (radius 0.25 m2) and multiply by 3.14. It turns out 0.19, round up to 0.2 cubic meters. This calculation is for one pile post.

After pouring any foundation, you need to cover it with a protective film against precipitation. On the day of pouring overnight, pour the foundation abundantly with water, otherwise in the morning it may give small cracks, because the upper the layer dries quickly... For the first week, moisten the foundation every few hours. From the second week, you can once a day.

Aggregates - crushed stone and sand

The composition of concrete is determined by those functions and characteristics of concrete that are necessary during its operation. The most common are sand and gravel. They are subject to no less stringent requirements than the quality of cement. Sometimes pebbles are used, but only if they have sharp edges, and not round ones. In the presence of broken lines, the adhesion of the aggregate to the mortar is better, as a result, the strength of the concrete is much higher.

Sand

Construction sand can be river or quarry. The river is more expensive, but it is usually cleaner and has a more uniform structure. It is better to use it when drawing up concrete for pouring the foundation, screed. For masonry or plastering, it is appropriate to use cheaper quarry sand.

In addition to its origin, sand is distinguished by fractions. Large or medium-sized ones are used for construction work. Small and dusty ones are not suitable. The normal size of sand grains is from 1.5 mm to 5 mm. But optimally in solution, it should be more homogeneous, with a difference in grain size of 1-2 mm.

The sand should be clean, preferably with the same grain size

The purity of the sand is also important. It definitely should not contain any extraneous organic inclusions - roots, stones, pieces of clay, etc. Even the dust content is normalized. For example, when mixing concrete for a foundation, the amount of contamination should not exceed 5%. This is determined empirically.300 ml of sand is poured into a half-liter container, everything is filled with water. A minute later, when the grains of sand settle, the water is drained and poured again. This is repeated until it is transparent. After that, it is determined how much sand is left. If the difference is not more than 5%, the sand is clean and can be used when mixing concrete for the foundation.

For those works where the presence of clay or lime is only a plus - when laying or plastering - there is no need to take special care of the cleanliness of the sand. There should be no organic matter and stones, and the presence of clay or lime dust will only make the solution more plastic.

Crushed stone

For responsible construction - floors and foundations - crushed crushed stone is used. It has sharp edges that adhere better to the mortar, giving the structure more strength.

Crushed stone fractions are standard:

- extra small 3-10 mm;

- small 10-12 mm;

- average 20-40 mm;

-

large 40-70 mm.

Several different fractions are used simultaneously in concrete. The largest fragment should not exceed 1/3 the size of the smallest element of the structure to be cast. Let us explain. If a reinforced foundation is poured, then the structural element that is taken into account is reinforcement. Find the two closest elements. The largest stone should not be more than 1/3 of this distance. In the case of filling the blind area, the smallest size is the thickness of the concrete layer. Choose crushed stone so that it is no more than a third of its thickness.

Fine crushed stone should be about 30%. The rest of the volume is divided between medium and large in an arbitrary proportion

Pay attention to the dustiness of crushed stone. Lime dust is especially undesirable.

If there is a lot of it, the crushed stone is washed, then it is dried, and only after that it is poured into concrete.

Storing placeholders

It is clear that the construction site is not the cleanest and most equipped place, and sand and rubble are often dumped directly onto the ground. In this case, when loading, it is necessary to ensure that no earth gets into the batch. Even a small amount of it will negatively affect the quality. Therefore, it is advisable to pour aggregates onto solid areas.

It is also necessary to protect them from precipitation. In concrete formulations, the amount of constituents is given in terms of dry components. You learn to take into account the moisture content of the components with experience. If you don't have one, you have to take care of the condition and cover the sand and rubble from rain and dew.

Calculation of concrete consumption

Every builder is extremely concerned about the question of how much material will be spent on the construction of the foundation. Taking into account its consumption, it is possible to organize the delivery of the necessary components with greater accuracy. And this also affects the rationality of the use of financial resources.

Indicators characterizing concrete for the foundation.

How much concrete is needed for the foundation, if it is tape, can be calculated using a simple formula:

V = 2ab × (c + d).

To do this, you will have to take measurements:

- width of the foundation (a);

- its height (b);

- the length of the outside (c);

- inner length (d).

A strip foundation is not the only type of foundation for a structure, therefore, how much concrete is needed for a columnar foundation is shown by the following formula:

V = 3.14d2h / 4.

This formula is valid for cylindrical posts, where:

- h is their height;

- d - diameter.

For pillars with a rectangular base, the formula is different:

V = abh.

In this case:

- a and b are the lengths of the sides of the base;

- b is the height of the post.

The calculation results remain to be multiplied by the number of supports of the structure.

According to the formula for the concrete consumption per pillar, the concrete consumption for the slab base is also calculated. In this case, a and b are the length and width of the foundation, and h is its thickness.

The proportions of concrete on the foundation

To fill the supporting part of the building, it is important to choose the correct ratio of all components. Concrete preparation includes the following components:

- cement, which plays the role of a binder for ASG;

- sand as fine aggregate;

- crushed stone or gravel as coarse aggregate;

- water, which allows you to mix the components into a homogeneous mass, and start a chemical reaction.

Before determining the proportions of these components, you will need to select the grade of concrete for the foundation. It is not enough to know only the strength class (brand), you need to know the frost resistance of the material, its water permeability and mobility. All these characteristics depend on the amount of added components in the composition. In order to select all these characteristics of concrete, it is recommended to study the following information.

| Construction type | Strength class according to GOST 31108-2003 (grade according to the old GOST 10178-85) | Frost resistance | Water permeability | Mobility |

| Concrete preparation | B7.5 (M100)

B10 (M150) |

For private housing construction, F100 becomes the optimal value, but F50 and F150 brands can also be used. | For the foundation, the optimal resistance to moisture is W4, higher grades can be used, below the specified value is not recommended. | Mobility is determined depending on the method of feeding the concrete composition into the form (formwork). When conveying concrete in buckets, the value of P3 is required. For using a concrete pump - P4. |

| Foundations for protruding parts of the house, terraces, small buildings that perform auxiliary purposes | B12.5 (M150) | |||

| Walls in the ground, acting as props, foundations for objects with a low degree of responsibility | B15 (M200) | |||

| Foundations of buildings made of lightweight materials (frame, frame-panel, all types of wood) | B20 (M250) | |||

| Foundations of buildings made of massive materials (stone, including heavy and lightweight concrete, brick) | B22.5 (M300)

B25 (M350) |

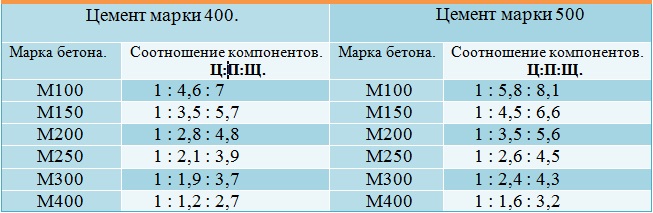

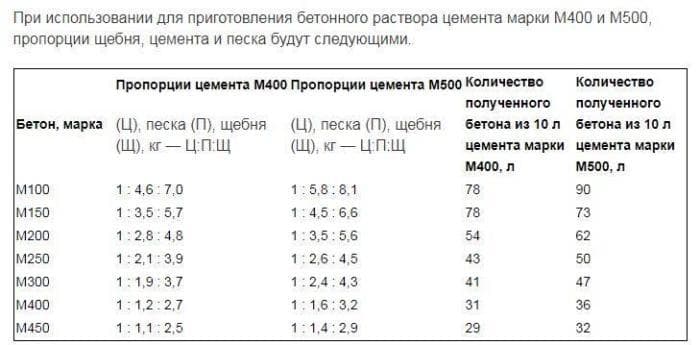

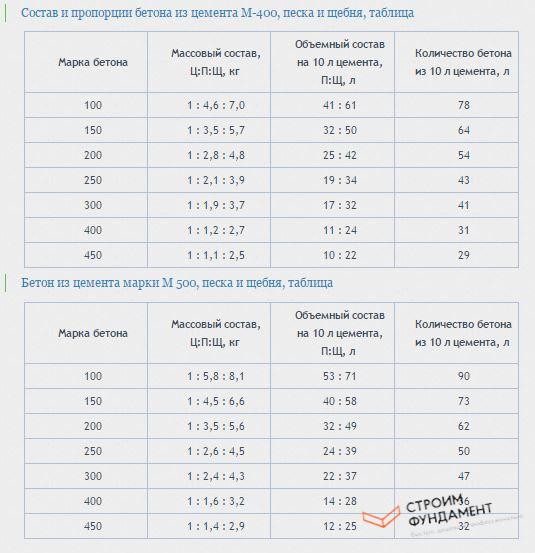

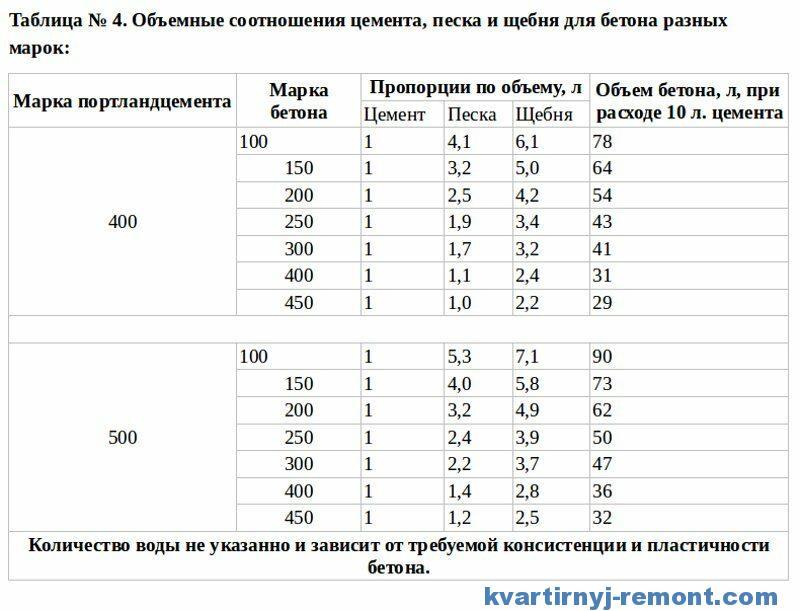

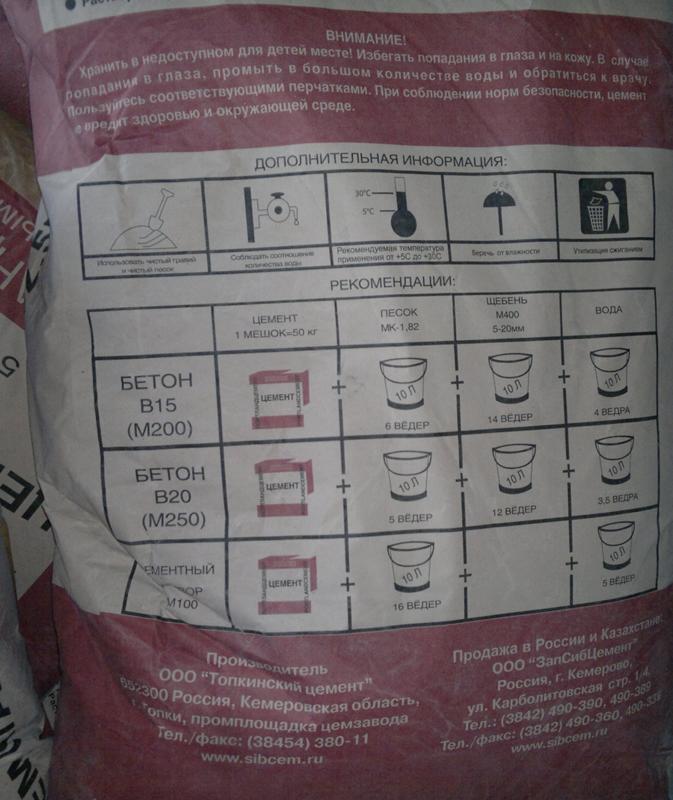

After all the characteristics are selected, they begin to determine the proportions of the composition of the concrete mixture. When buying cement, you should carefully study the packaging, some manufacturers indicate how much ASG (as well as sand and gravel separately) will be required for the competent preparation of the composition. As a recommendatory information, a table is presented by proportions, depending on the strength class.

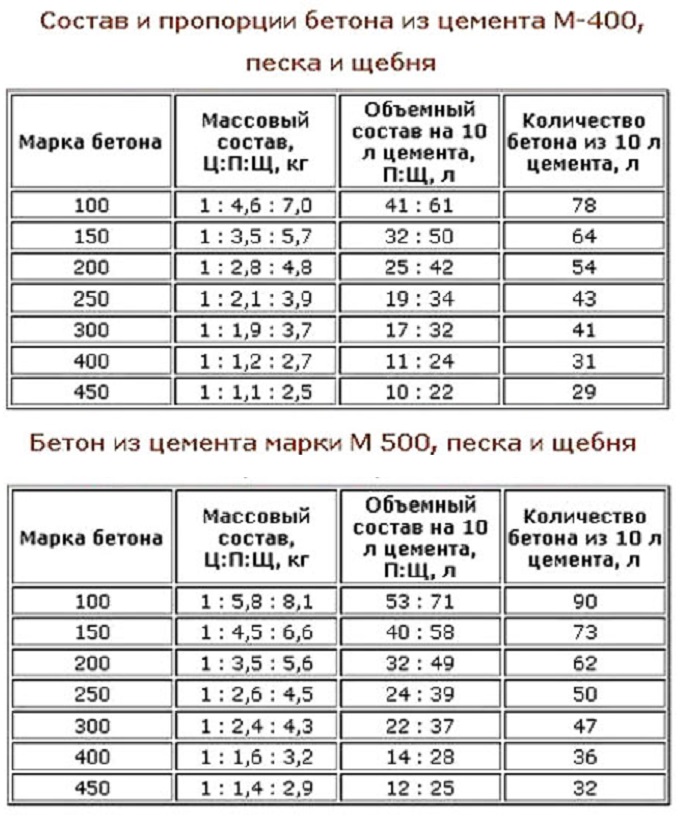

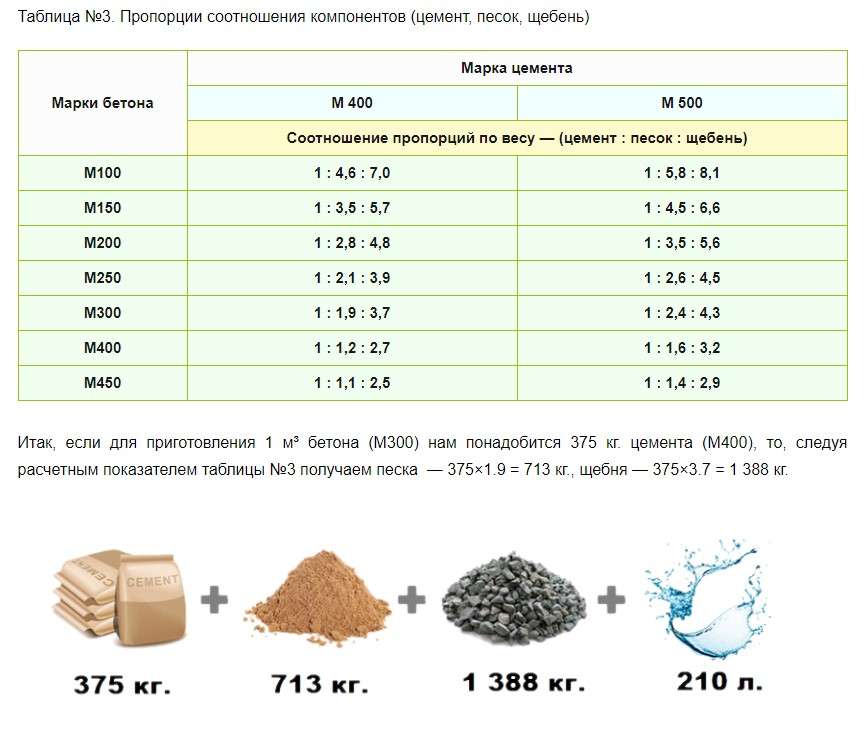

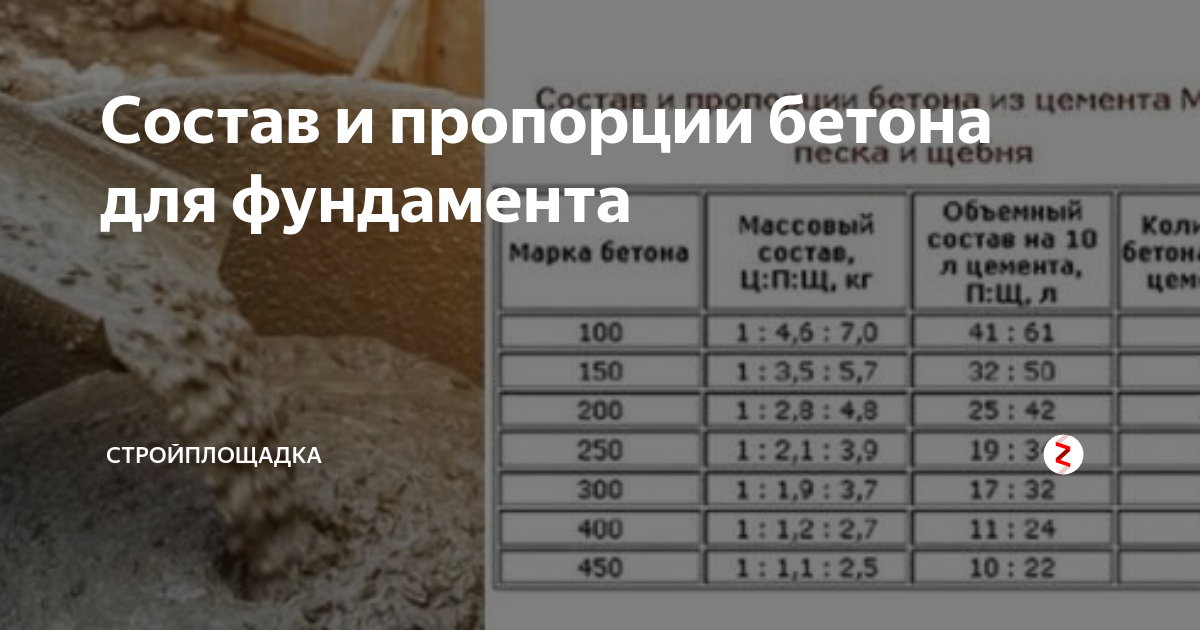

| Strength class of concrete | Volume proportions in cubic meters meters for cement grade M400 (values for grade M500 are given in brackets) | Mass proportions in kilograms for cement grade M400 (values for grade M500 are given in parentheses) | The amount of concrete that is obtained from a volume of cement equal to 0.1 m3 | ||||

| C | NS | G | C | NS | G | ||

| B7.5 | 0.01 cbm m | 0,041

(0.053) m3 |

0,061

(0.071) m3 |

1 kg | 4,6

(3,5) |

7,0

(8,1) |

0,78

(0,9) |

| B10 (B12.5) | 0.01 cbm m | 0,032

(0.040) m3 |

0,05

(0.058) m3 |

1 kg | 3,5

(4,5) |

5,7

(6,6) |

0,64

(0,73) |

| B15 | 0.01 cbm m | 0,025

(0.032) m3 |

0,042

(0.049) m3 |

1 kg | 2,8

(3,5) |

4,8

(5,6) |

0,54

(0,62) |

| B20 | 0.01 cbm m | 0,019

(0.024) m3 |

0,034

(0.039) m3 |

1 kg | 2,1

(2,6) |

3,9

(4,5) |

0,43 (0,5) |

| B22.5 | 0.01 cbm m | 0,017

(0.022) m3 |

0,032

(0.037) m3 |

1 kg | 1,9

(2,4) |

3,7

(4,3) |

0,41

(0,47) |

* The letters C, P and G denote cement, sand and gravel, respectively.

The table shows that the higher the grade of cement, the less ASG and more cement is required.

Curing time and moisture resistance depend on the amount of liquid in the composition. According to SNiP 2.03.11-85, the following values can be given for the water-cement ratio (w / c):

- normal water permeability (grade W4) - w / c 0.6;

- reduced water permeability (grade W6) - w / c 0.55;

- especially low water permeability (grade W8) - w / c 0.45.

To ensure normal resistance to water, you will need to take 6 parts of liquid for every 10 parts of cement. The brand for water permeability W4 allows you to achieve the following values for frost resistance:

- when hardening in air - F150;

- when hardening in conditions of very high humidity and in water - F100.

Preparation of concrete for the foundation

- sand, gravel (crushed stone);

- cement;

- container for mixing concrete mixture.

Table of concrete grades and corresponding grades used for strip foundations.

Cement cannot be stored for a long time and has the ability to react with moisture in the air. After a month, it can lose its original strength up to 10%, after a quarter, i.e. three months - up to 20%, and after half a year - up to 30%. Therefore, over time, its brand decreases, for example, from M200 to M180, which means that it is best to use this ingredient right away.

When mixing the mortar, in a concrete mixer, iron bath or wooden box, make sure that no impurities get into it. First, sand, gravel (crushed stone) and cement should be poured into a clean container. Then mix them thoroughly to get a homogeneous mass.After that, while mixing the concrete mixture, it is necessary to add water so that it completely and evenly moistens it. When using a concrete mixer, you first need to add water to it, and only then bulk materials. The concrete should be homogeneous in composition. The resulting solution should be used within two hours.

In what proportions to make concrete?

In most situations, for frame-type buildings, a columnar version of the foundation is used, which does not require a concrete mixture with increased strength indicators. For this type, concrete M 200 is suitable, which is made from M 500 cement, sand, crushed stone and water.

For one cubic meter of the mixture, you must:

- 300-350 kg of cement;

- 1100-1200 kg of crushed stone;

- 600-700 kg of sand;

- 150-180 liters of water.

This ratio of materials is formed by their qualities, for example, granite crushed stone has a high level of strength, in comparison with dolomite crushed stone or limestone, so it can be used in smaller quantities.

To create a mixture of concrete of the required consistency, it is best to use washed crushed stone, and only cleaned river sand, in which there are no various impurities of clay.

If you use low quality sand, holes and potholes can form in the base.

When choosing a cement, initially pay attention to the manufacturer's company. As a rule, the more famous the organization, the less likely it is to purchase a low-quality product.

Water should also be used clean, so that it is free of impurities and salts. If the construction is carried out in the cold season, then the water, like other components of the concrete solution, should be heated up to + 60C in order to give the solution the necessary consistency and strength.

How to mix concrete correctly?

For the preparation of a small volume of solution, a bucket is used as a measure of the weight of the components. The proportions are calculated in accordance with the fact that the components have different bulk density. Based on this fact, when preparing a 1-m3 solution, a ratio of 9: 5: 2 (gravel or crushed stone, sand and cement) will be needed.

The production of concrete M 200 is carried out according to the rules in order to achieve a high quality mixture as a result.

Rules for mixing concrete for a foundation:

- Initially, sand and crushed stone should be well mixed together so that there are no lumps afterwards when adding water. Furrows are made on the surface, into which cement is poured. The mixture should be mixed until a completely uniform color is obtained.

- Give the mixture the shape of a cone and add water in small portions, mix everything thoroughly.

When deciding what is the best way to mix the solution, you should correlate needs and financial capabilities. The best option would be to use a concrete mixer, but buying it for a small building is not profitable, so it is better to use manual production.

Preparation of concrete mix for strip foundations

For this type of foundation, you first need to calculate the amount of material required. The parameters of one tape (length, width and depth) should be multiplied by their number.

Example. Length 20 m, width 0.5 m, depth 1 m. We multiply these values and get, on one side of the foundation it is necessary to prepare 10 cubic meters of concrete solution.

Having prepared the required amount of the mixture, it is poured into the formwork. It is performed in layers, for example, if the depth of the base is one meter, then there should be four layers, each 0.25 cm. After laying each of them, it is necessary to tamp. Then, in order to release excess air, reinforcement should be slowly pushed into the solution every meter or two.

Preparation of concrete for a columnar foundation

Calculations in this type of foundation correspond to the strip version. The difference is that the concrete solution is not poured in stages, but immediately, after which it is rammed.

Component proportions

The components of the concrete mortar are combined in certain proportions. Using the recommended grade M-500, the ratio of cement / sand / crushed stone is 1/3/4. Violation of the ratio of components will significantly reduce the quality of the concrete foundation.

Here are the characteristic disadvantages that arise when the ratio of the ingredients of the solution is inaccurate:

- Excess sand. The dried solution crumbles.

- Excess water. Builders call this "skinny" solution. The mixture hardens slowly, in places it may not grab.

- Lack of water. The mixture sets quickly and cracks when hardened.

- Only 2% underfilling / overflowing water will noticeably deteriorate the quality of the solution.

Types of foundations

The basis for the construction of buildings is formed taking into account the load, types of soil, structure. Depending on the type of foundation and its volume, the calculation of the need for materials is performed.

- The strip base is a closed loop made of reinforced concrete, arranged under the load-bearing and internal walls of the building. How to make a tape-type foundation mortar? To calculate the requirements for materials, you must determine the volume of each section and add them. The mixture must be poured continuously, with layer-by-layer compaction and observing the protective layer of the reinforcement.

- The columnar type of base is used for lightweight structures located on dense soils. In practice, a combination of both types of foundation is often used.

- The slab type of foundation is practiced on weak, heaving soils. Made of reinforced concrete. Pouring should be done in one go to prevent delamination of the finished structure. The concrete mix is distributed evenly with compulsory compaction with vibrators or bayonet.

- Pile-rammed foundations. The volume of concrete is calculated according to the geometric formula: the cross-sectional area of the well must be multiplied by the depth of the pile and the number of rods.

After pouring into any type of base, the concrete mixture requires moistening, otherwise the structure may crack due to the rapid drying of the top layer. The first week should be regularly watered and covered with a film or tarp.

DIY foundation concrete

You can use the materials individually or ready-made sand and gravel mixture (proportions in buckets: 1 volume of cement for 5 volumes of the mixture).

Components for 1m 3 of concrete must be mixed in the ratio:

- cement - 300-350 kg;

- crushed stone - 1200 kg;

- sand - 600-700 kg;

- water - 150-180 liters.

The calculation of the amount of cement and sand, crushed stone and water should take into account the properties of materials, their qualitative composition, the value of strength, the presence of impurities (clay particles may be in the sand).

To correctly make a cement mortar for pouring the base, dry components are poured into a concrete mixer, mixed for 2-3 minutes. Then, without stopping to interfere, water is poured in portions. It is better to dissolve the necessary additives in water first. The mixing process should not be long, 5 minutes is enough.

Methods for calculating materials

The concrete recipe for the foundation includes the following components: cement, sand, gravel or crushed stone as aggregates, water. Each component is responsible for quality. In order for the final result to meet regulatory requirements, you need to correctly perform the calculation and determine the required number of components, observing the proportions.

Calculation of components and preparation of concrete for the foundation in buckets is relevant for small volumes of construction work, where 1-4 m 3 of mortar is required. The basis for this calculation is usually the volumetric value of the cement.

What should be the ratio of sand and cement for pouring the foundation

Each component of the concrete mix differs in volumetric weight, therefore, in practice, the following proportions are used: 5 buckets of sand are taken for 2 buckets of cement and 9 are crushed stone or gravel.

The preliminary calculation of ingredients can be done using the online calculator in liters or kilograms.The calculation of emergency situations is carried out taking into account the requirements for concrete and the characteristics of the main materials.

For example, to obtain 1 m³ of M200 grade concrete with a 180 l concrete mixer, M400 cement, sand and crushed stone, you will need:

- water - 215 l;

- cement - 233 l;

- rubble - 818 l;

- sand - 389 liters.

Under the given conditions, the calculator will calculate the need for materials for 1 batch and the number of downloads.

When it is necessary to adjust the consumption of raw materials, taking into account the operating conditions of the structure being erected, the type of mixture, the use of a plasticizer, the value of the coefficient of expansion of concrete particles, it is necessary to use a correction table.