Ceiling surface preparation

If a major overhaul is being carried out in the bathroom with the replacement of the entire cladding, it is better to start installing the panels after laying the tiles on the walls. Before starting work, you need to remove foreign objects and furniture from the room.

The concrete base should be free of loose plaster, dust and dirt. To do this, you can use a broom or a stiff brush. To prevent the possibility of short circuits, electrical wires are placed in corrugated polymer pipes. Areas for connecting fixtures are brought out to the outside.

Due to the material properties of plastic ceilings, there is no need for preliminary leveling of the base surface. PVC panels mask the inaccuracies of the previous finish. Builders advise treating the base of the ceiling structure with a fungicidal agent. This composition will help prevent mold and mildew.

Ceiling structure processing.

If you plan to fix PVC sheets with “liquid nails” without using the crate, preparatory work will be needed. Using cement mortar and putty, the rough ceiling should be carefully leveled. Alternatively, moisture-resistant drywall sheets can be installed on a concrete base.

Step-by-step instructions: how to make a suspended structure yourself?

Installation of a ceiling made of plastic panels is simple

- Prepare the surface, remove the old coating, clean from dust, debris, cover with a primer with antiseptic properties.

- Take measurements to calculate the amount of material and consumables, draw up a construction plan.

- Carry out accurate markings on the level, draw lines, marks for the elements of the frame.

- Build a frame, fix suspensions for spotlights, if such lighting will be organized.

- Attach PVC ceiling panels to the structure.

- Seal joints with acrylic sealant, carry out final cleaning of excess composition.

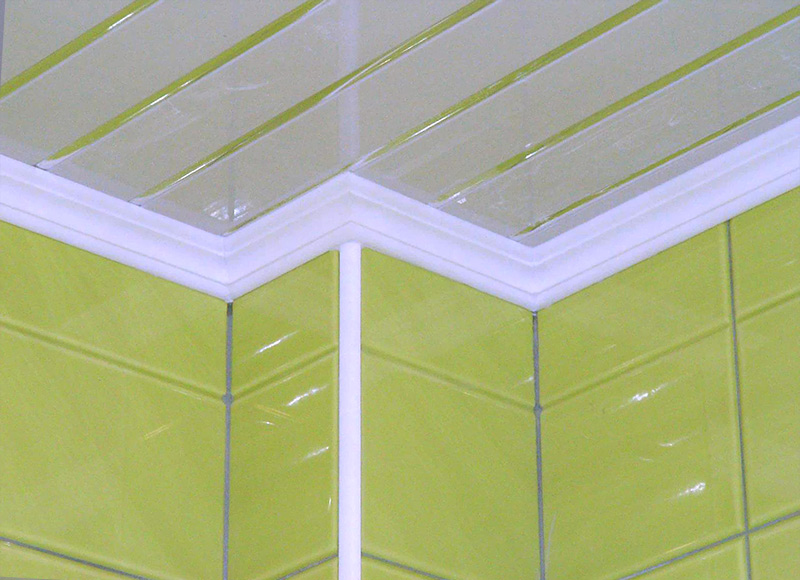

- Install skirting boards, moldings or moldings around the perimeter of the room to mask the joint between the ceiling surface and the walls.

Preparatory work

The reliability of the surface fixing will depend on the quality of the preparatory work

The reliability of the surface fixing will depend on the quality of the preparatory work

Advice

It is best to use a chopping line and chalk to mark straight lines faster. It is required to use a level to determine the "zero" line - the lowest point of the ceiling surface, which is projected onto the walls around the perimeter of the room.

Frame

Checking is carried out with a laser or conventional level with an alcohol capsule

Attention

Making a frame for one person is difficult, since fixing of long (more than 2.5 m) profiles is required, which is very inconvenient, so it is advisable to enlist a couple more hands.

Mounting

To attach PVC to the installed frame, you must perform the following steps

- Before installing the first panel, glue the ceiling plinth or molding to the ceiling, on which the first plank will fit with a groove to the wall (how to select and install a ceiling plinth?). For fixing, screws with press washers are used, which are attached to the protruding groove. It is necessary to tighten it not with a screwdriver, but by hand, so that the panel does not crack due to strong tension.

- If the length of the canvas is slightly longer than the wall on which it is installed in parallel, it is required to trim to the desired level. In this case, approximately 0.5-1 cm is left on each side of the sheet, and an incision is made under a metal square with a construction knife.

- The rest of the panels are installed with a groove in the ridge of the previous one.

- If the panel is difficult to enter, then you can use a mallet or a rubber mallet: slightly tapping, place it until it clicks. This operation must be performed very carefully so as not to break the PVC sheet.

- If the installation of point lighting will be carried out, then first you need to try on the element to the location, and then mark the place of the cutout of the hole for the lamp. A hole is cut in the ground, and the already finished canvas is suspended.

- Before attaching the last plank, check the evenness of the entire structure, then proceed to trimming the elements.

Important

In the room where PVC is being installed, the temperature should not be low. Plastic under such conditions becomes even more fragile and can crack even with slight bending.

Sealing cracks

Acrylic sealant is used to mask cracks

Acrylic sealant is used to mask cracks

Advice

Sometimes there is a situation when the sealant, after hardening, is "drawn" into the seam. Then it needs to be reapplied to such areas.

Installation of plastic ceiling surfaces in the bathroom

Before you start working with ceilings in your own bathroom, you need to prepare a rough surface. It's good when you already have a plan for the placement of lamps and exhaust ventilation at your fingertips, there is a sketch or sketches of the future design. Making edits already during installation is a rather problematic task. You should clearly know how many panels you need to use and in what order the installation of the structure will be carried out.

The panel ceiling in the bathroom must be done, knowing exactly all the measurements and parameters. It will be very useful to come to the store with a ready-made working sketch and a tape measure in order to choose the optimal sizes of plastic panels. Cuttings during the editing process are inevitable, but you don't really need extra material. The lack of panels at the final stage of work will also be unpleasant.

Note: the length and number of aluminum profiles used to equip the frame of the future ceiling are measured in the same way.

From the tools for work you will need:

- drill or hammer drill;

- crown for mounting fixtures;

- building level;

- screwdriver or screwdriver;

- a hacksaw for plasterboard or for plastic;

- assembly knife;

- liquid Nails.

Almost all of the listed tools are freely available and are often available on your own farm.

Features of the device ceilings in a plastic bathroom

For those who have an idea of finishing work and are familiar with the device of suspended ceiling structures, there should be no particular difficulties. The main thing is to follow the technology and sequence of actions. It is possible and real to make a plastic ceiling in the bathroom on your own and with your own hands.

The main condition on which the effectiveness of the work depends is the correct location of the frame guides and the precisely calculated number of profiles for the future frame. A plasterboard suspended ceiling requires the creation of a strong and massive frame with a large number of profiles, then a lightweight version is suitable with plastic panels.

The beginning of the installation comes down to determining the required distance from the rough surface. As a rule, for prefabricated structures, such a distance does not exceed 7-10 cm. We orient ourselves by the tile seam closest to the ceiling surface and set aside the required distance.

We mark the future lower edge of the new ceiling in increments of 40-50 cm around the entire perimeter of the bathroom.

Making a frame

After the marking work, the direct installation of the guides begins.Aluminum profiles are placed on the basis of your marks and fixed to the panels with self-tapping screws.

In practical terms, the installation of the frame is simplified due to the lightness of the future ceiling structure. To achieve the required strength of the frame, this method of fastening the profiles is quite suitable.

As soon as guide profiles are installed around the perimeter of the bathroom, you can start laying the stiffeners

This element of the frame is an important component that ultimately ensures the strength and stability of the entire type-setting structure. Stiffeners or supporting profiles are attached to the rough surface with U-shaped brackets

It should be said that the need to install stiffeners arises when installation is carried out in large rooms. For small apartments, where the bathroom is on average 1.5 x 2.5 meters, there is no such need. Plastic panels have sufficient rigidity to withstand the load on their own.

Laying of plastic panels

After installing the frame, we begin to lay the panels. Everything starts from the start profile. Observing the sequence of laying, you can achieve an exact fit of the cut pieces of plastic to each other. The starting profile is attached to a regular profile using tex.

Which plastic panels are best for your bathroom on the ceiling, wide or narrow, you decide. Starting from the starting profile, the entire ceiling is gradually laid, panel by panel. Each piece fits into the existing groove of the previous piece. At the finish of work, when laying the last piece of plastic, a starting profile is not required.

The set is carried out to the very last guide. Try to make sure that the last panel, which is likely to be cut to its full length, is at the far wall.

Design advantages

The ceiling in the bathroom made of plastic panels is a suspended structure that includes a frame made of wood or metal and cladding. Surface finishing in this way is carried out without preliminary dismantling of the old coating, leveling or other preparatory work, which can significantly reduce the repair time.

Plastic ceiling

Plastic ceiling

For filing, plastic canvases are used, which have a hollow structure with internal stiffeners, the width of which is 25 cm and the length of 2.70 m. Finishing the ceiling in the bathroom with this material has the following advantages:

- The device of plastic suspended ceilings allows you to quickly level the surface yourself, without dismantling the old finish.

- Decorating with suspended plastic panels allows you to hide the elements of communications, ventilation system, wiring.

- The device of plastic ceilings is done by hand, thanks to the light weight of the material, as well as the convenient spike-groove fastening system.

- The metal frame is suitable for noise insulation, waterproofing equipment.

- If necessary, plastic canvases can be easily removed, replaced and inserted into a ready-made frame and skirting board.

- Plastic is washable and moisture resistant, so bathroom ceilings keep their neat appearance longer.

Wall panel dismantling cost

The cost of dismantling works is calculated based on the total area of the proposed work. Calculating the final amount will not be difficult with our demolition calculator. Dismantling of plastic sandwich panels can be more time consuming. If such blocks are used to erect an internal wall, then they are firmly fastened to each other using a metal frame that is located between the two panels. The ceiling or transverse wall often rests on it.

Removal of PVC, chipboard and MDF wall panels - 110

rub. for 1 sq. m.The price for dismantling plastic (sandwich) panels may increase depending on the complexity of their disassembly.

Our repair team has extensive experience in dismantling work and all the necessary professional tools that will be needed at the repair stage. Removal and dismantling of wall panels is carried out by us at a time convenient for the client. Call us at 8 (495

)722-56-41 or, all consultations and departure of the master for measurements and coordination of workIS FREE .

Dismantling the ceiling

The most versatile coating for finishing the ceiling is plastic panels due to the simple installation method, hiding its irregularities, the position of communications under them, and also an acceptable price.

Sometimes plastic sheathing needs repair or refurbishment

If you inadvertently harmed the plastic, you need to disassemble the structure and change such a panel

Dismantling a plastic ceiling can be called a simple, quick and easy process. It can be dismantled by oneself in an hour and for this purpose no special tools and professional skills are required. Of course, you can invite a master and he will fix the problem for a certain fee.

But if you yourself decide to replace any damaged plastic sheet, you need to stock up on some tools and protective equipment before disassembling the plastic ceiling:

- the wrench is preferably a wrench;

- a chisel for wood, preferably wide (you can even a knife);

- screwdriver;

- screwdriver;

- gloves (to avoid cuts on the sharp edges of the structure).

When everything is ready, you need to carefully consider the suspended structure in order to have an idea of its structure for the concept of the principle of dismantling.

Pros and cons of plastic ceiling

Residents using plastic panels for lining the ceiling of a room for water treatments note the following advantages:

Large assortment of plastic panels.

- A large assortment. A wide selection allows you to create different options for decorative design. The suitable color scheme and surface structure of PVC sheets can be selected from the photo in the catalog of the trade organization or manufacturer.

- Tightness. Installation of the ceiling structure does not require additional moisture-proof treatment. The properties of the material provide protection against mold and mildew.

- Easy installation. The work is carried out without the use of liquid mixtures and adhesives.

- Easy dismantling. If necessary, access to communications for urgent repairs, the plastic ceiling is disassembled. Upon completion of the work, the sheets of polyvinyl chloride are set to their original positions.

- Profitability. The low price of PVC panels reduces the cost of finishing.

- Low weight. At the same time, lightness does not reduce stability. The inner cavity is filled with air, and the shape is maintained by stiffening ribs.

- Security. If the wiring is short-circuited, high-quality plastic will not ignite, providing protection against fires.

- Possibility of mounting any lighting fixtures.

- No need for pretreatment of the rough ceiling. The smooth surface of the panels masks flaws. Pipes, wires and other communications can be hidden under them.

Using this material for bathroom ceiling decoration, you should take into account its disadvantages. These include:

- not suitable for low rooms, since during installation the height of the room is reduced by several centimeters;

- it is impossible to hide the joints and seams, which is reflected in the decorative design and overall design;

- does not allow for multilevel structures and curved shapes.

In addition, cheap plastic profiles allow light to pass through the built-in appliances. Builders advise installing lamps with dense walls on such panels.

Panel bathroom ceilings.

How to make a ceiling from plastic panels

Installation of PVC panels is possible even for non-professionals.But you need to be attentive to each stage of the work so that the result satisfies you.

First, you need to make a drawing and calculate the consumption of materials - they should be taken with a margin.

Calculation rules:

- measure all 4 walls: opposite walls may not be the same length;

- the number of panels is determined as follows: divide the total ceiling area by the area of one panel and multiply by 1.2;

- the step with which you need to mount the ceiling profile and suspensions is 50-60 cm;

- the length of the starting profile is equal to the perimeter plus 10-15 cm;

- to calculate how much plastic profile you need, divide the length of the perimeter by 3;

- dowels must be taken with the calculation of 1 per half meter of the profile, self-tapping screws - 1 per half meter of the panel length.

All results obtained should be rounded up.

You may also need docking profiles.

You will also need to do some preparatory work:

- completely remove the old ceiling trim, if necessary, then the wiring;

- small defects like cracks need to be putty. You do not need to level the ceiling if you want to use a suspended installation method, otherwise it must be trimmed;

- treat the ceiling twice with an antifungal compound.

Then you can start making the frame:

Mark the ceiling by measuring the level around the perimeter and drawing lines on the walls. If you are making a ceiling in a bathroom with flat tiles, you can measure along the seams of the tiles.

Make a note of the location of the luminaires immediately; they may require additional space. At temperatures above + 90C, plastic does not burn, but it can deform, so it is better to purchase LED or halogen lamps.

Cut the starter profile to the length of the walls and make holes every 50 cm.

Attach it to the wall and, using the finished marks, drill holes in it at the attachment points. Before starting work, be sure to check if there is no wiring in the places of drilling. Otherwise, you run the risk of damaging the power grid or hammer drill, or even getting an electric shock.

Insert the plastic profile into the guide. Too large a distance between the supporting profiles will cause the panels to sag, so it is optimal to measure 40 cm.

If the profile is longer than one and a half meters, it must be fixed with metal hangers and twisted with self-tapping screws.

Then get ready to install the luminaires:

- wire to the places where you plan to install them. In this case, it is better to leave the wire with a margin of length and insulate the wiring well;

- additionally reinforce the places where the lamps will be installed with guides

Now you can mount the panels:

Attach the rail to the guide rail. You can use not a rail, but a ceiling plinth, gluing it to liquid nails. Cut the panels to fit the wall.

Insert the panel into the guide rail with one end, bend and insert the other end slightly, press lightly against the wall and screw. Mount the rest of the panels in the same way, tightly joining the previous one and making sure that they run the same along the entire length. Do not overdo it with pressing force, otherwise the panel will deform.

The last panel is trimmed to fit the actual dimensions of the remainder of the ceiling and inserted in the same way as the others. Seal gaps and joints with acrylic sealant if necessary.

Connect the power supply to the lighting fixtures.

Ready! As you can see, the installation of ceilings made of PVC panels is up to everyone.

Which panels to choose?

Manufacturers produce panels with a highlighted and hidden seam; glossy and matte; with or without a picture; dense (wall) and thin (ceiling). Panels often imitate wood texture. In addition, they vary in width.

Which of this variety is suitable for our purposes?

Colour

The most versatile is, of course, white. It goes well with ANY color scheme of wallpaper, floor and furniture and makes the room visually higher.

The use of PVC panels makes it possible to make a ceiling with a frame in a contrasting color or, in general, with alternating panels of different colors.

All other things being equal, glossy panels are preferable. They create the illusion of depth to a greater extent, again making the room visually more voluminous.

Any textural design is absolutely out of place on the ceiling. If you like wood-styled coatings, it is better to purchase wall panels made of MDF (pressed hardboard). The imitation of the texture looks much more convincing on them than on plastic.

Wood-styled MDF panels on the walls look great.

Density

Despite the fact that ceiling panels are called less dense panels, we need the most dense of the entire range. Why? It's not about reliability, but about the panels in the light. Both the sun's rays from the window and artificial lighting will inevitably show through the thin-walled panels. But the thick-walled lining does not suffer from this.

The seam

If the ceiling uses built-in lights or some other foreign inclusions, panels with a dedicated seam can fit into the overall concept. However, for a smooth ceiling, glossy white dense panels with a hidden seam, having a maximum width, are most suitable.

Here's what you get as a result. No, contrary to the first impression, the ceiling is not stretch.

Plastic ceiling cladding technology

Installation of the supporting frame

Wooden frame for plastic ceiling sheathing

Before you hem the ceiling with plastic panels with your own hands, you need to build a supporting structure, to which the plastic trim elements will be attached. The installation process will look like this:

- Before installing the frame, the ceiling base is cleaned of the old, poorly adhered finish. If it is held securely, you can mount directly on it.

- The direction of installation of the frame slats is chosen perpendicular to the one in which the plastic panels (lining) will be installed (see Ceiling foam panels: lightness and simplicity in one bottle). Before attaching them to the ceiling base, parallel marking lines are drawn, indicating the places of the future laying of the frame slats.

- If wooden beams are chosen as load-bearing elements, then they are fastened directly to the ceiling, using a perforator and dowels with self-tapping screws for this. In this case, they certainly make sure that the bars eventually form a flat horizontal plane. To level the beams, if necessary, use thin wooden substrates and control the degree of evenness using a building level.

Installation of hangers by marking

- When choosing a profile frame system, the strips are fastened by means of special metal suspensions. In addition, a guide profile is preliminarily mounted along the perimeter of the room under the ceiling, which serves to more easily create a flat plane of the frame system.

- The hangers are fixed to the ceiling along each marking line in 0.6m increments. After that, the strips of the main profile are inserted from both sides into the guide and attached to the suspensions along the entire length. If necessary, the length of the profiles is adjusted using metal scissors.

Now it remains only to consider how to sheathe the ceiling with plastic - a video lesson will allow you to understand all the subtleties of the sheathing process with your own hands (see Plastic ceilings: installation features).

Something like this will look like a frame, prepared for sheathing with plastic

Sheathing the frame with plastic

So, we will describe how to sew the ceiling with plastic panels with our own hands:

- Elements of plastic lining or panels are cut using a fine-toothed hacksaw (for metal) or an electric jigsaw to the desired length. The cut must be perpendicular to the element axis.

- Plastic ceiling cladding begins with how the ceiling plinth (corner) is horizontally attached to the walls under the guide profile (or beams). A small gap is provided between the profile and the skirting board (for the thickness of the plastic panel or lining). The plinth is fastened to the wall using dowels and self-tapping screws.

- The first element of plastic sheathing is installed by introducing its spike between the plinth and the guide profile (bar) attached to the starting wall (see Ceiling sheathing with plastic panels, features, advantages, DIY installation). The ends of the element are inserted in the same way into the gaps of the walls adjacent to the starting wall.

Alternative means of attaching plastic to the ceiling

- When the positioning of the first panel is completed, it is rigidly attached to the frame strips. This is done using a construction stapler or self-tapping screws. The fasteners are inserted into the wall of the groove of the plastic element closest to the frame and screwed (driven in) it almost flush. The panel should be fastened to each of the perpendicularly outgoing frame strips.

- Next, the spike of the second is inserted into the groove of the first element, and the ends of the panel (lining) are hidden behind the plinth, and fasteners are made in the same way.

The scheme of how to attach the plastic to the ceiling surface should already be clear for a simple and understandable plating of the entire ceiling surface. The last plastic panel (lining element), if necessary, is cut already in width, inserted with a spike into the groove of the penultimate panel, and the other side is hidden behind the plinth, mounting the element in an interference fit. At the same time, there is no need for a rigid attachment of the last plastic element.

We can assume that we figured out how to fix a plastic ceiling with our own hands. Let's hope that you will understand this simple technology and put it into practice without any particular difficulties. And to consolidate the stated material, we once again recommend watching the video presented on our portal - how to sheathe the ceiling surface with plastic panels.

Installation of PVC panel ceilings

Do-it-yourself PVC ceilings in the bathroom

Most often, you can find a ceiling made of PVC panels in the bathroom and balcony, but also PVC panels or plastic lining can be found in kitchens and hallways. In addition to the low cost of the material and ease of installation, such material attracts with its ease of maintenance and long service life.

Ceiling frame for PVC panels

Beat control lines with a chokline

Before you start installing the ceiling frame for PVC panels with your own hands, you need to determine its height. To do this, put a starting mark on the wall and transfer it to all corners of the room using a water level. Then, using a painter's thread or chokline, beat off the control lines between the marks.

Ceiling frame made of wooden slats

To mount the ceiling frame on PVC panels, you will need 20X40mm or 20X50mm long slats, which will be used as profiles. Soft types of wood, such as pine, spruce, alder or aspen, are more suitable for such slats. Such rocks are not so susceptible to deformation when the air humidity changes, and a staple from a stapler is easily driven into them and a self-tapping screw is screwed into them.

U-shaped hangers

If the main ceiling is flat, then the slats can be attached to it with dowels and screws, but if the slats need to be fastened to an uneven surface, then use U-shaped hangers or pawns. Suspensions are attached to the main ceiling along the line of installation of a wooden lath or metal profile, 50-60 cm from each other.

The dowel with a cap does not fall into the voids of the ceiling

- Some people use shock dowels to attach suspensions, but the ratio of the screw thickness to the diameter of the dowel included is too irrational (it's hard to say what the manufacturers are guided by) and such a dowel hammered into the ceiling or wall can be pulled out with an effort applied with one hand. The impact dowel itself is very good for concrete floors, since the dowel has a cap and does not fall into the voids of the concrete floor, but the screw in this set should be replaced with a thicker one. For example, when using a dowel with a diameter of 6mm, a screw with a diameter of 4-5mm is best suited.

- To mount a metal frame when leveling profiles, they usually use a thread stretched under the frame, but this method is not entirely suitable for wooden slats, since the thread will cling to the roughness of the rail and, moreover, the rail is often uneven and has to be corrected with suspensions. Due to such circumstances, the rack frame is easier to level with the help of a long level and a building rule.

Reinforce the light frame

If heavy (non-spot) lamps are provided on the ceiling, then the frame should be reinforced in the places where the lighting fixtures are installed. Also wire all the lighting wires before you start finishing the ceiling with PVC panels.

Fastening panels to the frame

Installation of a ceiling plinth

If you provide a ceiling plinth, then install it either on a latch previously attached to the wall or screw it with self-tapping screws with a press washer to the frame, with a groove to the plane of the ceiling.

Installation of the first lining

- Insert the first PVC panel into the skirting board and screw on the opposite side with screws or nail with a stapler. If the room is constantly changing temperature and humidity conditions, for example, in the kitchen, then it is better to use screws with a press washer.

- Insert the next panel into the first panel, screw it and so on to the end of the ceiling. When installing the last panel, cut it to the desired width, insert it, and then either click the ceiling plinth and the latch supplied in advance, or simply glue it with silicone, while the panel is fixed with screws in the cut part.

- Do not forget to remove the wires for the fixtures during the installation of the lining. If there are plate-type lamps on the ceiling, then a gasket should be installed under them (it can be made of ordinary thin plywood), since the metal body of the lamp gets very hot, and the panels will deform.

Use connectors for the ceiling plinth

Various decorative fittings are available for the skirting board. With the help of these products you will be able to go around the outer or inner corner, connect two skirting boards in the span and plug the skirting board at the end if its extension is not provided.

For more information, see the article Fastening PVC Panels to the Ceiling: Tips and Tricks for DIYers.