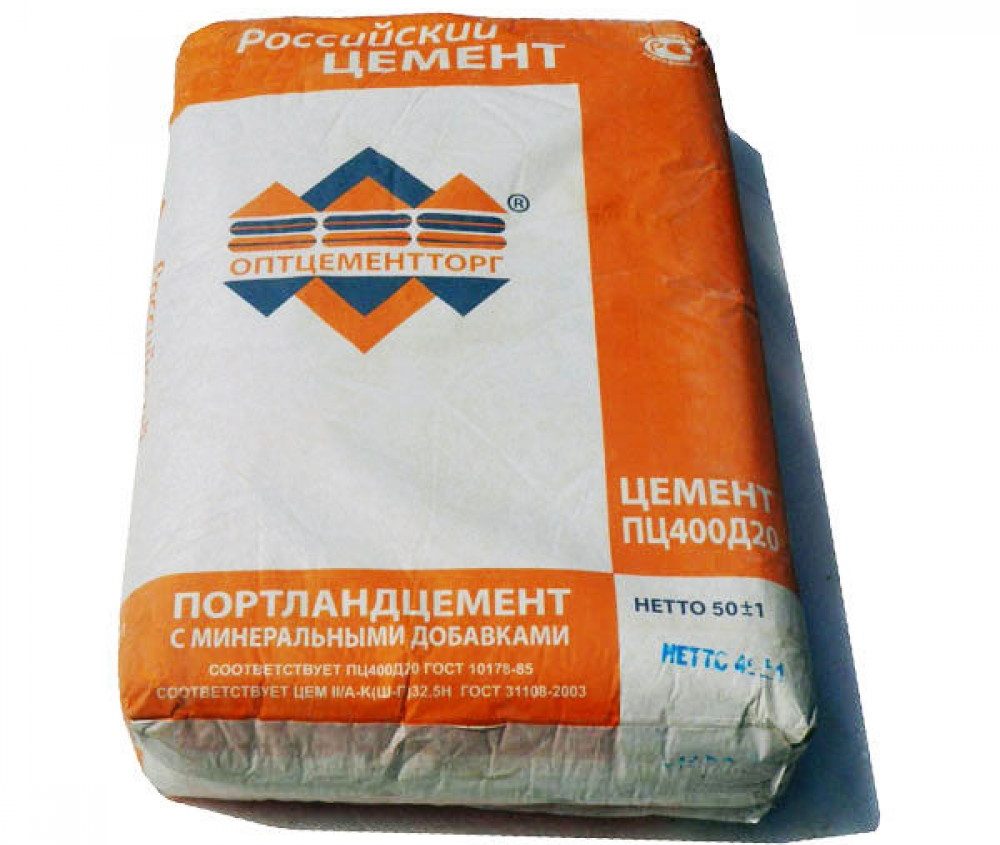

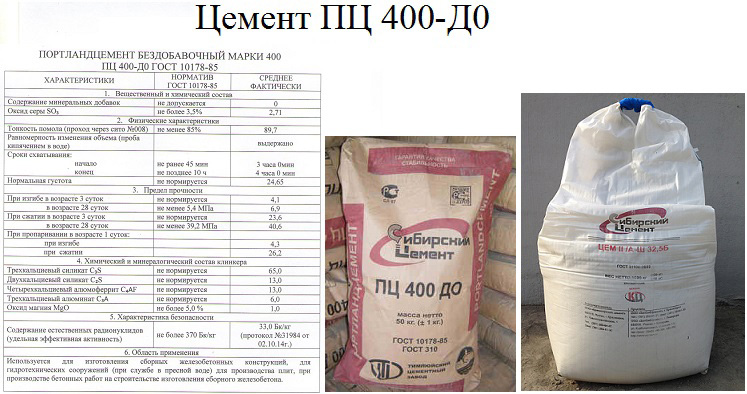

M400 specifications

Few owners of future houses realize that the durability of the structure will depend on the quality and density of the cement. When choosing a material, builders take good adhesion as a basis, and also study and analyze in detail the components that make up the composition, physical features play an important role here.

Today one of the most purchased cements is the M400 grade, which belongs to the type of Portland cement. It is often used in various construction areas, the reason is hidden in high quality and affordable pricing.

As for production, cement is obtained through grinding the intermediate clinker product with the further addition of minerals from the class of sulfates CaSO4 • 2H2O and other chemical elements.

The decoding of the abbreviation indicates that after complete solidification, the material will withstand the load without any problems, which will fluctuate around four hundred kilograms.

M400

The content of CaSO4 • 2H2O in the composition of cement according to the GOST under consideration cannot be more than 5%, active mineral components, as a rule, constitute from 0 to 20% of the total components. It was the additives that played one of the main roles in the water resistance and corrosion resistance of the material.

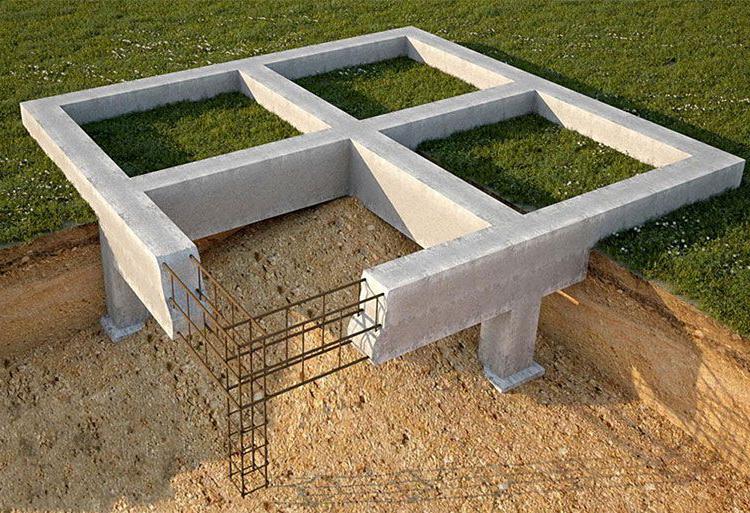

This can explain the possibility of using cement 400 when creating structures from reinforced concrete, they will also be resistant to moisture changes.

The material in question is considered durable. This characteristic is determined by manufacturers through a variety of freezes and thaws during the testing phase. For cement 400, this technical characteristic is equal to one hundred cycles.

It is often used during the construction of facilities that will be operated in the Far North. Few people know that in these parts, temperature readings often reach -50. The high water resistance of cement 400 was achieved thanks to special additives.

The production of the cement in question is carried out in accordance with technical standards. Finished products are subject to mandatory quality control.

Today the companies produce three types of brands:

- BEFORE.

- D2OB

- D2O

Each type is distinguished by its individual properties, composition, as well as the scope of use. If you want to achieve instant hardening of the solution, opt for the first type.

It is also characterized by high water resistance, due to this "DO" is often used for the construction of structures with high environmental humidity (underwater and underground structures). "DO" also showed itself excellently at the stage of collecting concrete and reinforced concrete structures.

The second type of the 400th cement is famous for the active mineral additives that are included in its composition, thanks to which it can be used during the construction of residential areas. Also "D2O" finds its application in industrial and agricultural construction.

This cement is actively used in the CIS countries and in Europe. It hardens significantly longer than the previous version, the average time is from 10 hours.

M400 D20

The last type of M400 can be attributed to a fast-hardening material. It is actively used during the construction of industrial facilities. The main feature of this brand is its high strength, which can be noticed within a few minutes after complete hardening.

Advice

When choosing a cement mixture, carefully study the packaging of the building material

Pay attention not only to the marking, but also to the presence of other characteristics

- weight value. Some manufacturers, selling their goods at a low price, do not specify that the bag contains less than 50 kg of cement. A trick like this helps to capitalize on the buyer's carelessness;

- there are several types of GOST, therefore, before purchasing a product, determine which GOST is used to mark this type of cement;

- all information about the cement manufacturer. The presence of a specific address and telephone number, city, mobile number cannot inspire confidence;

- the date when the mixture was made, otherwise you risk purchasing stale goods at a high price. You shouldn't buy cement at all without a date;

- indication of all designations, especially fillers and additives.

Do not buy cement with a large stock, you may not use it completely, and it has a short shelf life.

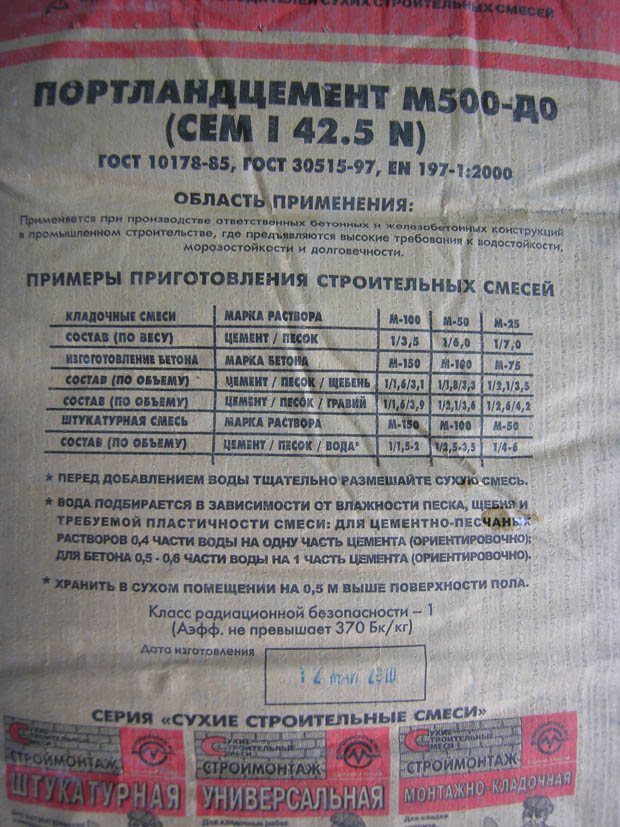

Technical characteristics of M500 cement

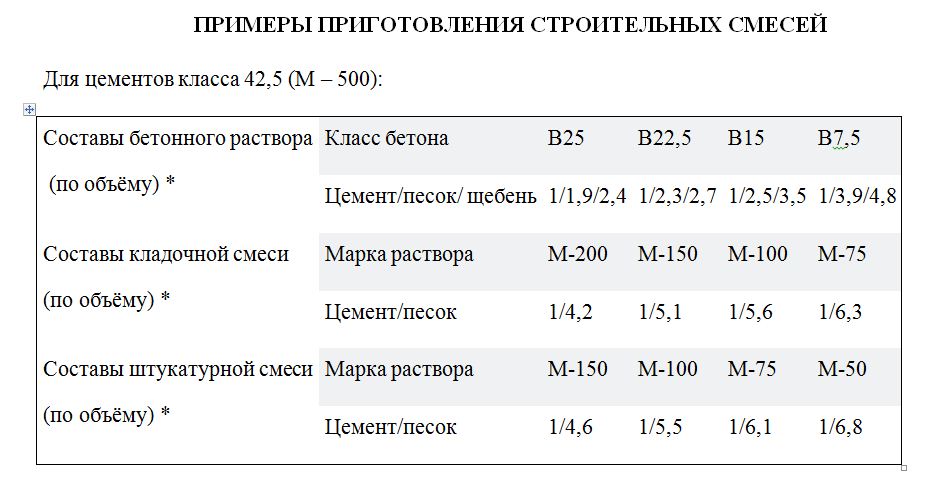

Cement of class 42.5 is a finely ground gray powder consisting of a mixture of clinker and gypsum, supplied in packaging or in bulk, used as a binder in the preparation of mixtures for concrete and mortars.

Main characteristics:

- High compressive strength.

- Clinker type - Portland cement (PC). Alumina cements and mixtures of PC with sulfoaluminate cannot be compared in strength with Portland cement of class 42.5, since this parameter is determined in them after 3 days.

- The hardening rate (compressive strength after 2 days) is 10 MPa for normally hardening (marking H) and 20 MPa for fast hardening (B).

- The specific gravity of M500 cement is from 900 to 1700 N / 1 m3.

- Composition. A binder of class 42.5 may contain slags in addition to Portland cement clinker. The type of PC and its properties depend on their presence and quantity.

- The beginning of the setting is 60 minutes.

- Flexural strength after 28 days - 5.9 MPa (60 kgf / m²).

- Type of mineral supplement. Portland cement clinker can be supplemented not only with slag, but also with fly ash (in the marking it is designated with the letter Z), limestone (I), and other mineral components. Ash slows down the setting rate, but increases the strength of the finished structure. The presence of limestone extends the service life of the products.

Characteristics of M500 cement.

Even if the storage conditions are observed, the shelf life of M500 cement in bags (in undamaged packaging) is only 6 months. After 3 months, 20% of strength is lost, and after six months - up to 50%. Hardening, lumps and cement stone are possible. In open form, cement of class 42.5 is stored for no more than 45 days.

Packaging types:

- For the preparation of repair mortars, you can buy cement of class 42.5 in a package weighing from 2 to 25 kg.

- For private construction, a convenient option is cement in paper, polypropylene bags (M500). They are stacked on pallets (30 pcs.) And covered with foil.

- For large volumes of work, it is better to choose packaging in big bags of 1 or 1.5 tons.

The most popular option is a 40 kg or 50 kg bag of M500 cement.

Specifications

Another name for concrete of class B40, made on the basis of M600 cement, sounds like "military" in view of its scope: most often this brand is chosen for the design of special-purpose structures and the installation of military facilities.

M600 (by marking):

- B - fast-hardening powder, which is usually chosen when performing emergency recovery work

- PC - ordinary Portland cement, which is considered the most popular and versatile on the market

- BC - white Portland cement M600, which is usually purchased for decorative and finishing work

- H - normative cement produced according to a particularly strict recipe

- GF / PL - hydrophobic / plasticized cement, demonstrates a high level of frost resistance and excellent workability

- VRC is a fast-setting binder that can increase in volume during hardening (usually used when sealing cracks, seams, wells, in ship repairs, etc., when it is necessary to urgently eliminate defects and the ability of the material to harden as quickly as possible)

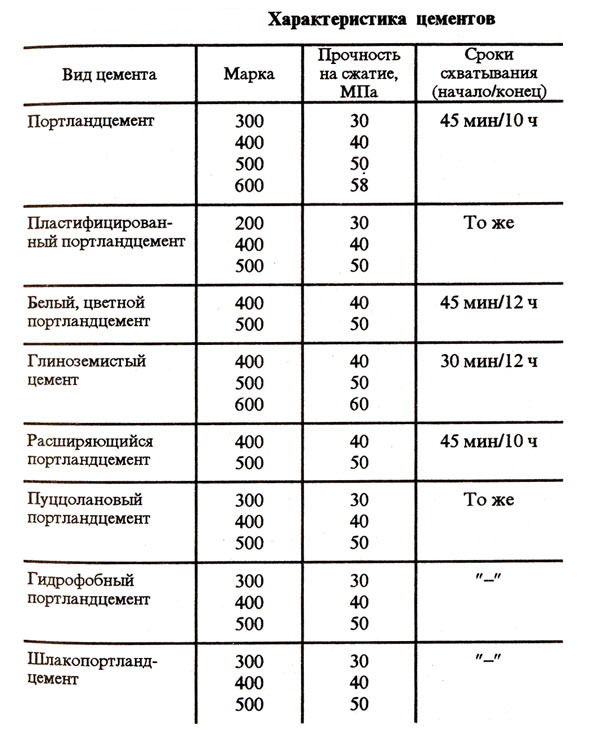

Main characteristics of M600 cement:

- Strength class of concrete prepared on the basis of a binder - B40

- The beginning of setting - after 45 minutes

- Completion of setting - after 10 hours

- Flexural strength (after 28 days) - 6.4 MPa

- Compressive strength (after 28 days) - 58.8 MPa

- True density - 3200 cm2 / g

Due to its high level of resistance to fire and moisture, M600 cement is used in construction where it is necessary to ensure the best quality and reliability. The binder is used for mixing heavy-duty concrete of various grades, used in the most demanding jobs.

Under normal conditions (ambient temperature, humidity) concrete based on M600 cement sets in 40-60 minutes after preparation. The cast monolithic structures harden within 3-4 days, and in a month and a half they are ready for further work.

Buying material: what you need to know

The quality of this type of material largely depends on the storage conditions. Manufacturers recommend storing mixtures so that they do not get moisture. For this, a separate dry room must be allocated. It is best if the material is stacked on pallets, otherwise the bottom bag of cement in each stack can become damp.

Therefore, when planning to buy a material, first of all, it is necessary to pay attention to how long ago it was made: the longer the product lay, the higher the probability of getting a poor-quality mixture in your hands - in just a month, if stored improperly, cement can lose 50% of its strength. What is very beneficial for consumers - you can buy 50 kg or 25 kg bags of cement.

This allows you to buy exactly as much material as is necessary to solve a specific construction problem and then not ensure the correct storage of the leftovers.

What is very beneficial for consumers - you can buy bags of cement of 50 kg or 25 kg. This allows you to buy exactly as much material as is necessary to solve a specific construction problem and then not ensure the correct storage of the leftovers.

Scope of application

Cement grade M500 is used where increased strength is required from structures to withstand severe loads. And its good setting speed allows it to be used in emergency repair work.

The main area is the manufacture of monolithic reinforced foundations, slabs and columns. Usually, for the preparation of concrete in these cases, cement without additives is used (marked D0). On the basis of D20, plaster and masonry mortars are made. For finishing work, such a high strength of the coating is not required. But by adjusting the content of Portland cement, you can get mixtures with almost any characteristics.

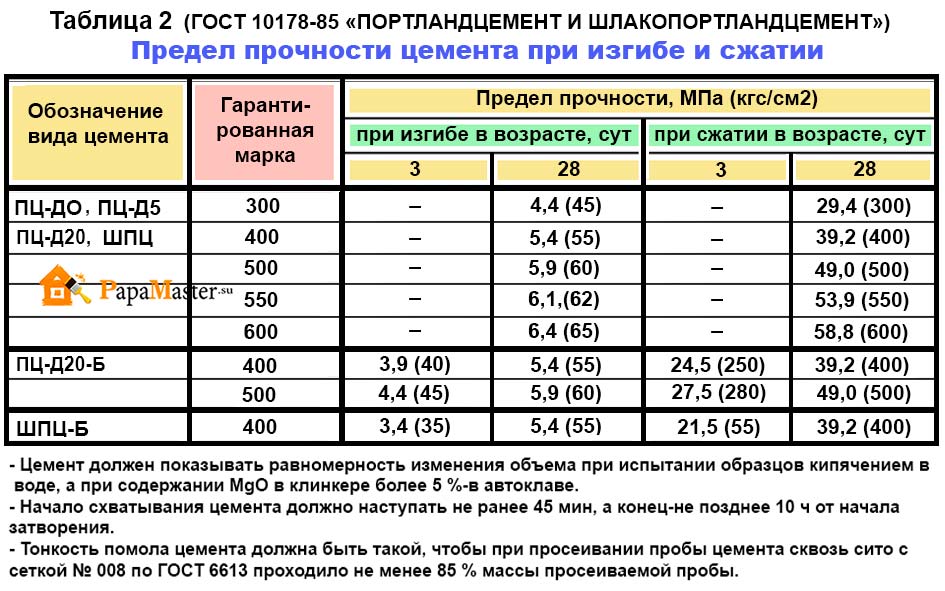

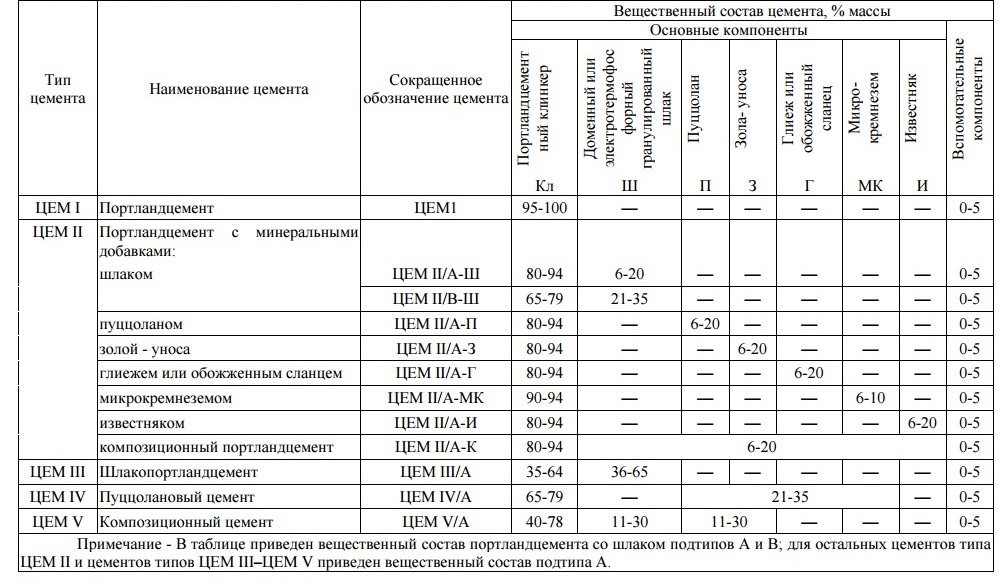

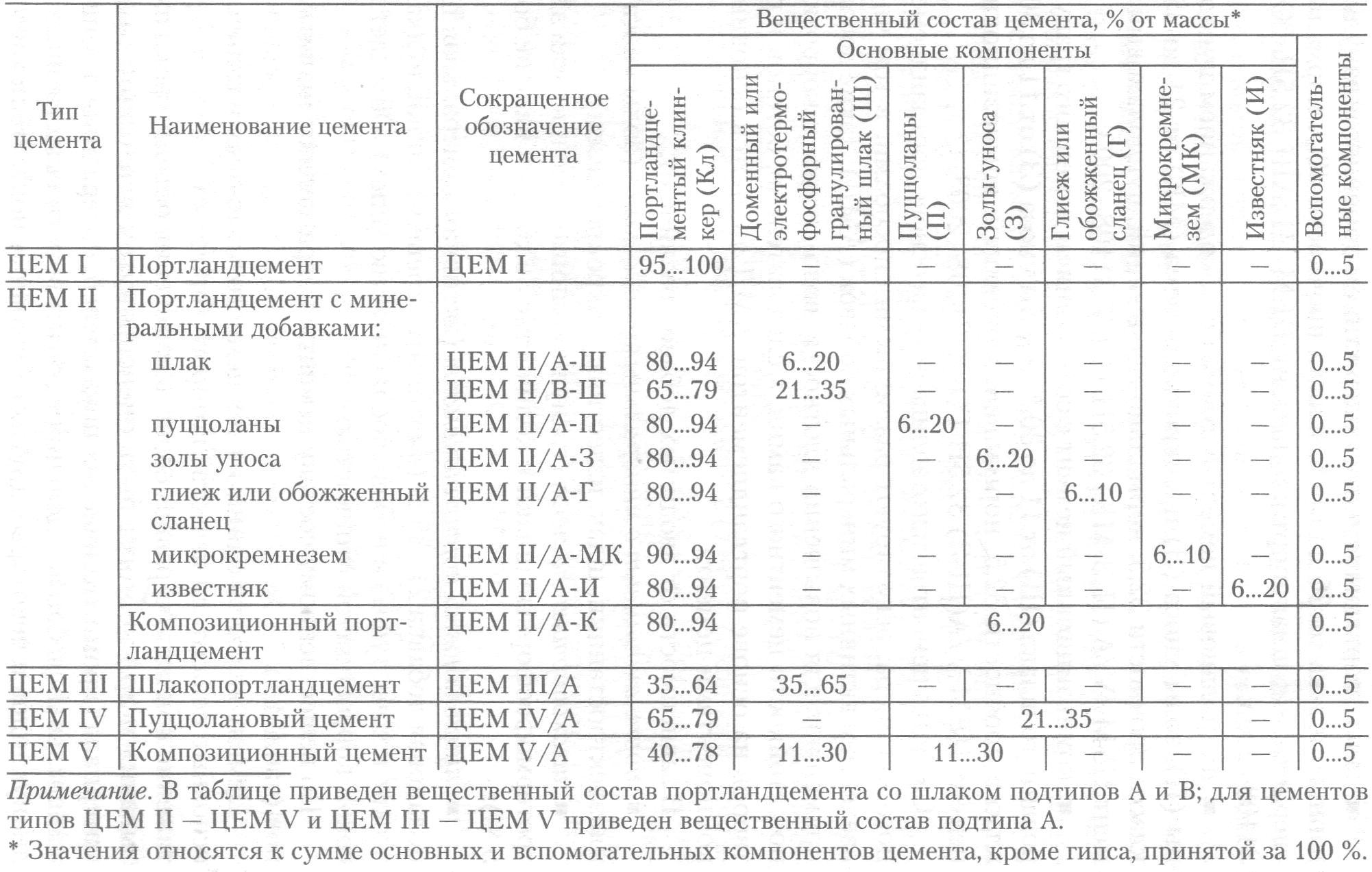

Marking

According to the outdated, but still widely used GOST 10178-85, cement is marked in accordance with its strength indicators. That is, ordinary cement with a strength of 500 kgf / cm2 is packed in a bag with the M500 marking, and Portland cement with the same characteristics is sold under the PC M500 brand. According to the new standards (GOST 31108-2003), its designation looks like this:

- CEM I 42.5 (for D0);

- CEM II / A 42.5 (for D20).

These are just different names for the same product, which do not affect the cost of cement in any way. Eurolabelling absolutely does not mean production according to the "European standard". In addition, the content of mineral components D0 or D20 is also encrypted in the brand designation. The letter "D" denotes the addition of ground blast furnace slag, and the number indicates its percentage. This is a very important indicator, so it must be taken into account when buying.

Comparison of D0 and D20

The difference between D0 and D20 is quite large and is not limited to one line-up difference. The characteristics, and, accordingly, the scope of application of such materials will also differ:

1. D0.

It is made of pure clinker with a small amount of gypsum, which helps it to set faster. Such a composition provides concrete with the greatest durability, allows you to create waterproof reinforced concrete structures of increased frost resistance. Products made of no additive Portland cement serve excellently even in conditions of constant humidity and are not subject to corrosion.

Thanks to such unique characteristics, M500 D0 cement is most widely used not only among private developers, but also in larger-scale works: during the construction of bridges, power transmission line supports, and pavements at airfields.

2. D20.

Due to the high content of mineral additives, M500 sets a little faster. But the clinker itself is only 75-80%, which slightly reduces the cost of the building material, although it does not affect its strength. The rest of the characteristics of the D20 are slightly lower than those of the non-additive one. So this brand can be called a transitional form from M450 Portland cement.

Cement with additives is used as a binder component of repair and construction mortars. High-strength facade plasters and self-leveling floors are made from D20.

average cost

If concrete work is to be carried out mainly by hand, it is better to purchase cement in bags, packaged in 50 kg. This weight is easier for one person to carry, and multilayer packaging will protect the unused dry mix from accidental moisture ingress.

In the capital, you can buy Eurocement and Mordovcement brands the cheapest way. But only if you order a bulk consignment from 20 tons with free delivery in Moscow. The retail price for a bag of the same Eurocement ranges from 250-280 rubles. For small volumes of repair work, the Hermes company offers a solution - 3-5 kg bags of cement, costing from 44 to 62 rubles.

| Manufacturer | D0 | D20 |

| Rusean | 255 | 250 |

| Stone Flower | 260 | 260 |

| CSM | 260 | 250 |

| Eurocement | 265 | 260 |

| De Luxe | 308 | — |

Buyer Tips

Take the time to read the information on the bag. In addition to the brand, you should be interested in the following data:

1. Weight (some manufacturers declare low prices for their goods, but do not specify that the cement package contains less than 50 kg).

2. Brand, with an indication of the specific GOST, according to which it was assigned.

3. The manufacturer and his contacts - up to the address of the office, production facilities and landline phone number (the mobile should already alert).

4. Date of manufacture - without this information, you will not set the "age" of the mixture.

5. The name of all the additives included in the composition.

Label elements and their designation

According to the first GOST (10178-85), the following information is located on the bag or other container in which the material is sold:

- cement grade - a number from 300 to 600;

- PC, SHPC - Portland cement or slag Portland cement;

- D0, D5 or D20 - the number of additives: D0 - no additives, D5 - no more than 5%, D20 - no more than 20%. Additives give special properties - resistance to sea water, corrosion resistance, accelerated hardening, etc.

- B - quickly hardening;

- PL - plasticized with increased frost resistance;

- H - standardized composition.

In the second GOST (31108-2003), the marking is as follows:

- CEM I, - without mineral additives;

- CEM II, - with mineral additives;

- CEM III, IV, V are not Portland cements (therefore, they are not considered in this article).

There is no concept of a brand, but there is a concept of a strength class. Designate it with numbers - 22.5; 32.5; 42.5 or 52.5 in megapascals (MPa). Subclasses: H - hardens at normal speed, B - hardens rapidly. Additives are indicated in the name of the cement.

There are several grades of Portland cement: 300, 400, 500, 550 or 600. The grade shows how much force the sample will withstand without breaking. Measured in kgf / cm 2.

Cements are divided into PC and SHPC - Portland cement and, accordingly, Portland slag cement. The difference is that slag pounded into dust is added to Portland slag cement during manufacture. Slag is not added to Portland cement.

Example of designation: Portland cement CEM I 42.5B GOST 31108-2003.

Cement M500 - application

On the basis of this material, high-quality building mixtures are produced, such as heavy concrete, masonry and plastering mortars. A distinctive feature of finished structures is strength, stability, durability. Cement is widely used in the most critical construction sites:

- For pouring foundations for multi-storey and industrial buildings.

- For the construction of public and industrial buildings and premises that are experiencing increased stress (for example, shopping centers, train stations, large warehouses or port docks).

- For emergency repair and restoration of reinforced concrete and concrete structures. The characteristics of the material make it possible to carry out the work in the shortest period of time and with the proper quality.

- For the construction of hydraulic structures such as dams, bridges, dams, locks.

- Used in the construction of highways and roads, etc.

Now cement M500, the price of which depends on the volume (wholesale or retail) and starts from more than 200 rubles per bag (50 kg), is increasingly used for the manufacture of eurofences, paving slabs, gas silicate blocks.

Cement is a building material that acts as an inorganic binder. During contact with water, it forms a solution, which allows you to learn a monolithic structure of high strength. The material is used in the manufacture of concrete and other compositions that are used at various stages of production.

The main components of cement are limestone, clay and additives, thanks to which, after crushing, it is possible to obtain a friable substance. Today, very often in the field of construction, cement of the M500 brand has been used. This demand is not caused by chance, because this material is characterized by high strength indicators, frost resistance and other characteristics, which will be discussed below.

Cement of this brand can be of two types: M500 D0 and M500 D20. The first type in its composition does not have impurities and additives.

It is used in the construction of industrial facilities, can be added to concrete to give additional strength, resistance to moisture and frost.

According to GOST 10178-85, M500 cement is produced on the basis of the following components:

- gypsum stone;

- clinker - a mineral component, for the production of which the method of sintering limestone and clay is used;

- blast furnace charge;

- a variety of active ingredients that improve the quality of cement, they can be of hydrophobic, plasticizing and acid-resistant origin.

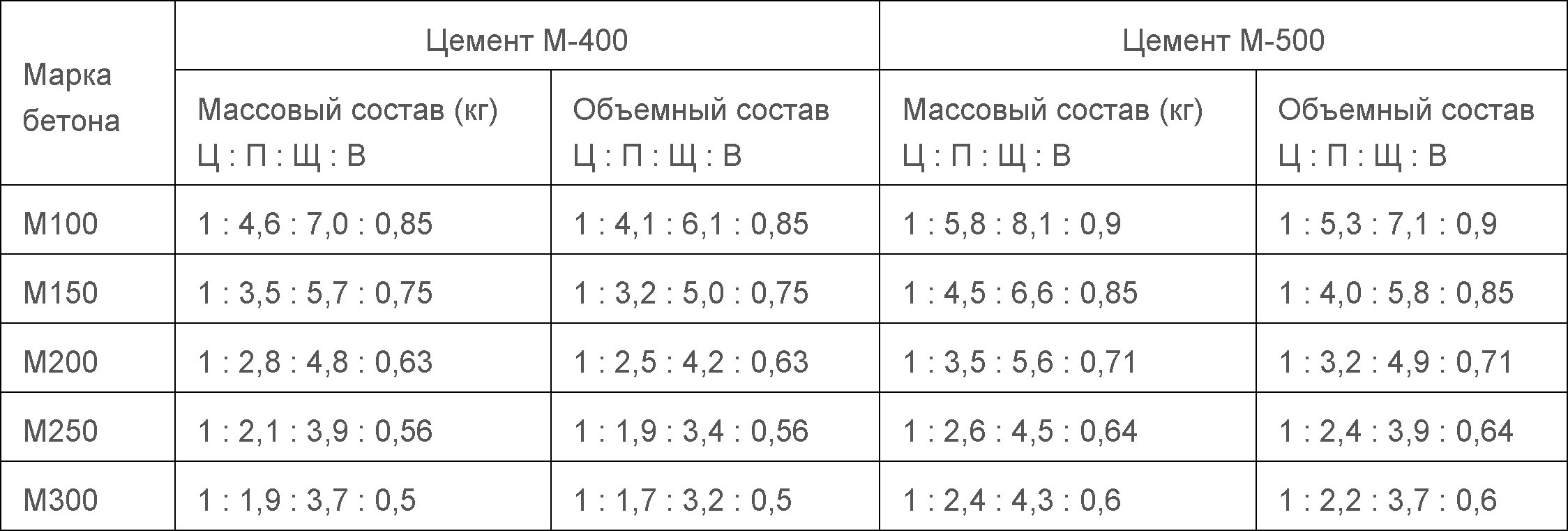

The solutions obtained on its basis have high resistance to low temperatures, and can also withstand corrosion and aggressive environments. Such material is in great demand when carrying out work in the winter. To prepare the solution, it is necessary to use the following proportions 1: 3: 6, where there is cement: sand: aggregate. Do not mix M500 with other brands of cements. This interaction leads to a deterioration in the properties of the specified brand.

What is the specific gravity of cement M 400 indicated in this

After you have already become closely acquainted with certain technical characteristics of the M500, you can proceed to its main advantages:

Since there are active mineral additives in the composition of the cement, the increased value of corrosion resistance can add to the existing list of advantages.

Cement brand M500 in bags

Cement M 500 is very popular due to the most optimal ratio of price and quality. Usually it is delivered in containers of 50 kilograms, which guarantee the convenience of loading / unloading, transportation, and making calculations.

D0 is produced and packaged on modern equipment, with precise dosage and compliance with GOST. All components are quality tested and measured in the right proportions. All parameters correspond to GOST 31108-2003, according to which the mixture demonstrates a compressive strength equal to 19 MPa, already after 1-2 days after preparation and use of the solution.

The packaging has a marking that gives complete information about the cement and includes instructions for preparing the mixture. Cement M500 D0 belongs to the class of fast-setting mixtures with a complete absence of additives. Strength class corresponds to parameter 42.5.Clinker is contained in the total mass in the range of 80-95%. When calcined, the dry powder weight loss does not exceed 1%. The mixture contains about 2.5% sulfur oxide (VI) and 0.02% chloride ions Cl-.

Already after 28 days (full cycle of curing with concrete solution), the strength of the monolith is 46 MPa. Concrete is set in 45-120 minutes after mixing with water. The final setting takes place 180 hours after mixing. The false setting effect is completely absent.

The specific surface area of M500 cement demonstrates a value of 350 m2 / kg, which is an indicator of the excellent quality of grinding and the complete absence of various impurities and particles that negatively affect the quality of the mixture itself and the concrete prepared from it.

Eurocement M500 D0, supplied in bags, is a modern building material of excellent quality, which is widely used in repair and construction works. The choice on the market is quite large, so it will not be difficult to choose a material that is suitable in terms of characteristics and cost.

When choosing, you need to pay attention to the reputation of the manufacturer (it is advisable to trust the best and proven ones) and the date of production of the mixture - the less time has passed since the creation of cement, the better (the total shelf life is 6 months).

In Moscow and the regions, you can find high-quality cement in building supermarkets and directly from manufacturers.

Specifications

General characteristics for all types of m400 cements:

- Compressive strength at the age of 28 days for cement 400 spts, pc and the rest is 39.2 MPa, which corresponds to grade 400;

- The bulk density of dry cement m400 depends on the clinker grinding fraction and the presence of impurities, on average it is 1000 ... 1200 kg / m3. Caked cement weighs up to 1700 kg / m3, and wet cement weighs like concrete - up to 3000 tons per cubic meter. For calculations, take specific gravity of cement m400 with an average value of 1100 kg / m3;

- Hardening rate: beginning of setting no later than 2 hours, strength gain up to 98% - after 28 days;

- The resistance to aggressive media, including sulfates, is insufficient for PC. To increase stability, cement m400 d20 with special additives (slag, additives) is used;

- Frost resistance not less than F100;

- Operating temperature range of operation -60 ... + 300 ° С;

- The mature stone has high water resistance; to achieve absolute impermeability, structure seals are introduced into the composition and additionally waterproofed.

Volume weight of cement m400 changes due to storage conditions, transportation and production subtleties. Various additives affect the density of the mixture. However, knowing this indicator will help you avoid purchasing a poorly outdated or moist binder!

The average weight of 1 m3 of cement m400 should be 1100-1200 kg / m3. Exceeding the value may indicate long-term storage of the material, which is why compaction has occurred. The reason for the increase in weight can be the depressurization of the package and the moistening of the binder.

The shelf life of cement m400 in paper bags is 6 months, for polyethylene containers and packaging GOST defines 12 months. However, it is possible to obtain concrete or cement mortar of the expected grade only with the use of PC within 2 months from the date of shipment. Over time, the design strength of dry powder decreases at different rates, on average - minus 100 positions in 2 or 3 months. That is, the M400 will turn into the M300 in a season.