Overview of impregnations from different manufacturers

A large selection of concrete impregnations can be found on sale, but only some models deserve attention.

Reinforcing primer for concrete floors Protector

The product is designed to dedust the surface and increase the resistance of the material to chemicals. Impregnation is in demand in the construction of concrete surfaces for various purposes. Among them:

- Floor coverings.

- Street paths.

- Runways.

Hardening - Retroplate

The tool is used to remove dust and improve the strength properties of low grade concrete (less than M300), as well as restore old floors with a mosaic surface.

When starting treatment with such a composition, it is important to pay attention to the following features:

- The impregnation is not intended for uncured concrete (waiting time - about 2 weeks).

- Application of the composition is allowed at a temperature of at least + 5 ° С.

The cost of 1 liter of such impregnation is 400 rubles.

Organic - Protexil

This series of impregnating solutions for concrete floor intended for industrial buildings. It provides a high degree of protection against aggressive influences and has the following properties:

- Penetration depth - 5-10 mm.

- Consumption - 0.3 liters per 1 m2.

- Working temperature - within -40 ... + 80 ° С.

- Drying interval - up to 6 hours at a temperature of + 20 ° C.

1 liter of impregnation for the floor - 175-195 rubles.

Universal - Monolith 20-M

The product is water-based, therefore it meets all environmental safety requirements and is protected from fires.

As a result, the impregnating agent has the following effects on the concrete product:

- Improves the moisture resistance of the material by 3 marks.

- Increases wear resistance and strength by 30%.

- Eliminates the problem of concrete warping and cracking.

- Removes dust from the surface.

- Provides good adhesion.

- Increases resistance to organic acids and petroleum products.

For 1 m2 of product area, 3-5 liters of impregnation are required.

Aquastone

The tool is designed to remove dust from the surface of concrete pavement and screeds based on a cement-sand mixture. The impregnation is characterized by deep penetration and guarantees an increased degree of strength and hardness. 1 l - 240 rubles.

Aquasol

This concrete floor impregnation is intended to isolate the structure from moisture and precipitation. The cost of 1 liter of the substance is 210 rubles.

Epoxol

This is an epoxy water-dispersion impregnation, which is used to increase the strength properties and protect the concrete structure from destruction. With its help, it is possible to achieve a 2-3-fold increase in strength and resistance to intense loads. Epoxol is applied to damp concrete and is indispensable for premises in the food and pharmaceutical industries, medical institutions and public buildings. 1 liter of the product - 380 rubles.

Ashford Formula

The product consists of water-based silicate polymers and increases the strength of concrete coatings. 1 liter of substance -110 rubles.

Features of use

Hydrophobic coatings for concrete are applied in two ways:

- It is added to the solution during its preparation. The composition is distributed evenly, binds with other elements. The output is moisture resistant and durable hydrophobic concrete.

- The surface of ready-made concrete structures is covered with a roller or brush. It is absorbed into concrete, passing through the capillaries of a living stone.Forms a durable waterproof film. It is used before levkas walls, pasting wallpaper, or before applying any other decorative coating.

Before applying to the base, it is necessary to remove dust, grease from the concrete wall and dry thoroughly. The hydrophobic impregnation is then applied with a roller or brush. After applying the first layer, let the wall dry. It is allowed to start applying decorative materials to the surface of the structure only the next day.

Effect of concrete impregnations

The most widespread at present are organic impregnations. They are acrylic, polyurethane, epoxy.

Acrylic-based impregnating compounds have good qualities at an affordable price. The concrete processed by them does not lend itself to the influence of chlorides. He is not afraid of high humidity. It is highly resistant to ultraviolet radiation. During operation, the color of the concrete is not lost.

These impregnations are used to eliminate formation dust on concrete floors, the load on which is insignificant. This process is repeated after 2 - 3 years of operation, since the durability of acrylic-based compositions is not so great.

The best effect is given by impregnations made on the basis of polyurethane. They also get rid of dust, provide inertness to chemical compounds. In addition, these impregnations significantly increase the strength of the concrete and make it moisture-proof.

The depth to which such impregnations penetrate reaches six millimeters. They can be used to impregnate concrete screeds, concrete and metlakh tiles, bricks.

Restrictions are the conditions prohibiting the use of such compounds in open areas without awnings, as well as the mandatory presence of waterproofing under the concrete.

The use of polyurethane impregnations increases the strength of concrete products. The resistance of concrete to wear increases eight to ten times. Its ability to withstand shock loads is doubled.

The concrete becomes waterproof and resistant to chemical compounds. By eliminating the formation of dust, floor care becomes easier, the appearance of the surfaces becomes aesthetically pleasing.

Impregnation classification

According to their content, impregnating compositions are divided into two types:

- organic (polymer);

- inorganic (silicate).

Organic water-repellent solutions act on concrete in the following way: the binder fills the pores, improving the material's ability to withstand aggressive influences and enhancing the water-repellent qualities of the coating. Also, impregnations solve the problem of surface dustiness and improve its strength characteristics.

Inorganic impregnating compounds work differently. They are not aimed at filling the pores, but interact with external molecular compounds, which then dissolve and become immune to other reactions. Due to the interaction, concrete acquires a higher strength and water resistance.

When choosing an impregnating material, it is recommended to take into account the following factors:

- Inorganic compounds are used for: dedusting at low cost, with significant surface irregularities, with high loads on the floor.

- Organic matter is relevant in the following cases: constant interaction with chemicals, maintaining an attractive appearance of the coating, the need for dedusting the mosaic.

Today, organics are the most common. This is due to the better functional characteristics of organic compounds.

Different impregnations differ in the method of action on the concrete base:

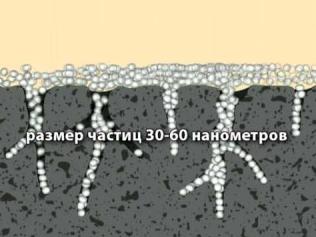

- Deep penetrating impregnating compounds (silicates, silaxins, silanes) promote concrete fluidity.Sealing components penetrate microscopic pores and interact with calcareous molecules, increasing the crystallization of calcium. Thus, the fluates reinforce the material from the inside out.

- Liquid hydrophobizing compounds form a thin protective film. An example is acrylate-based impregnation. Epoxy mixture and numerous types of polyurethane impregnations also work.

Acrylic compounds

Acrylate-based impregnations are distinguished by affordable prices and acceptable quality. They protect the material from moisture and chlorides, are UV resistant, and retain the natural color of concrete. Acrylic compounds allow dust to be removed. However, impregnations of this type are short-lived - their effect lasts no more than 24-36 months.

Polyurethane compounds

Polyurethane is more effective than acrylates. Impregnating solutions based on polyurethane de-dust the surface, are resistant to chemicals, moisture-resistant, and provide durability. Polyurethane mortars are used to treat not only concrete, but also cement screeds, outdoor paving blocks, stone and brick objects. Polyurethane penetrates deeply into the concrete layer (up to 6 mm) and is used both indoors and outdoors.

Note! The use of polyurethane compounds implies the presence of a waterproofing layer under the concrete base, which closes the penetration of capillary moisture into the structure of the material. After treatment with polyurethane mortar, concrete acquires several new qualities:

After treatment with polyurethane mortar, concrete acquires several new qualities:

- increased durability to the level of M600;

- wear resistance increases 7-10 times;

- impact resistance is doubled;

- improves water resistance, resistance to chemicals;

- dusting is excluded;

- maintenance of the coating becomes easier;

- the appearance of the surface becomes more attractive.

Polyurethane impregnating compounds are easy to use and financially beneficial. The impregnated surface begins to be exploited on the same day, when it comes to pedestrian traffic. In the case of transport, you need to wait three days for the concrete to reach its maximum characteristics.

Epoxy compounds

Impregnations based on epoxy resin used only indoors, as they do not withstand exposure to ultraviolet radiation and turn yellow. The composition is a mixture of two components, which includes epoxy resin and hardener... The latter are phenols or tertiary amines. Proportions between hardener and resin may differ depending on the consumer characteristics of the product. Compositions are offered in both color and colorless versions.

The advantages of epoxy impregnations include the following qualities:

- high strength;

- resistance to abrasives;

- moisture resistance;

- slight shrinkage;

- lack of a pungent odor;

- attractive appearance, as the surface resembles "wet concrete".

The disadvantage of epoxies is that they are less resistant to chemicals and mechanical loads when compared with polyurethane impregnations.

All about concrete dedusting

In fact, all impregnations are a full-fledged independent protective layer that does not require any additional protective coatings. The layer will not become an obstacle if you need to cut reinforced concrete with diamond circles.

The chemical basis of all impregnations are special polymer compounds.

Impregnations are used for the following purposes:

- Dedusting concrete floors.

- Giving additional strength to the concrete structure.

- Providing waterproofing, that is, preventing water from entering the pores.

- Avoiding the floor covering with a fine network of cracks, if, for example, diamond drilling of holes in concrete is required.

The concrete base is already dust-free and completely ready for use

Impregnation types

There are several types of impregnations, each of which has certain properties.

The following categories can be distinguished:

- Polyurethane. This concrete impregnation is the most popular among builders. This popularity is fully justified by the fact that its price is low, and the range of tasks performed is quite wide. Let's display it in the form of a table.

| Sealing | The composition ensures complete water resistance. |

| Dedusting | Especially important for concrete floors. |

| Chemical resistance to external influences | The structure is completely protected from the ingress of various chemicals on it. |

| Strengthening function | Allows to significantly increase the impact resistance of the floor. |

| Depth | The additive penetrates deep into the protected surface. The penetration depth reaches 2-3 mm. This makes it possible to raise the strength characteristics of concrete up to M600 and even higher. The strengthening function realizes itself in a similar way. |

| Decorativeness | A certain positive role is played by the decorative effect, which this substance can give to any surface. |

- The next type is deep penetration impregnation for concrete. Its main distinguishing feature is the ability to penetrate deep into the building material up to 5 times deeper than polyurethane. For example, concrete floors with medium grade strength are impregnated to a depth of 5 mm.

This type is used if it is necessary to carry out the maximum possible impregnation of the surface.

This mainly applies to the following cases:

Institutions and facilities where floors are subject to a high abrasion effect. In such cases, the component must penetrate as deeply as possible. It also helps protect the surface from dust.

Schematic representation of the principle of deep penetration

- High strength industrial products and floors have low porosity and are difficult for common additives to penetrate. Deep penetrating impregnations are needed here.

- If it is necessary to strengthen the weak screed as much as possible, the deepest penetration is necessary.

- If there is an urgent need to apply impregnation to wet concrete, then the only possible option is deep penetration.

- An acrylic additive is used for surfaces that are not subjected to stress, and if they are, then this load is insignificant. An example is utility rooms, or floors covered with linoleum on top.

Applying an acrylic component to a concrete surface

Impregnations have found their application in the road sector. The point is that the constant repair of roads is a time consuming process. In order to minimize repair work and significantly increase the strength of the surface layer of the roadway, it makes sense to apply impregnation for asphalt concrete.

This is what asphalt concrete looks like before and after processing

Independent work

One of the advantages of impregnations is the fact that all the work on adding them can be done independently.

The instruction divides the entire workflow into the following steps:

- Preparatory work, which involves the removal of all debris.

- The composition is poured on the floor and try to distribute it as evenly as possible over the entire surface with brushes. You can also apply the composition with a synthetic winterizer roller.

- The composition is left on the floor for 1 hour for primary soaking to occur. Then a little water is added to the composition and redistributed (lithium impregnations do not require redistribution).

- After 20 minutes, the excess mixture is removed with a squeegee, and the floor is thoroughly washed with water.

Self-application of the composition to the surface of the frozen solution

Advantages of impregnations for concrete floors and screeds

The main action of impregnations is to completely absorb into concrete pores, fill them and thereby strengthen the concrete. After this event, the concrete structure acquires high strength and durability. As a result, there is also dedusting of the surface.

Impregnants for concrete have the property of durability, so they can be applied only once during the entire period of operation of the concrete floor.

Another important advantage of impregnations is their protective properties. As a result of their application, the floor becomes resistant to the adverse effects of cold and various aggressive environments.

Water resistance is also improved.

After applying the impregnation, the floor can be used within a few hours.

There are various impregnations, each of which has its own characteristics and properties. Let's consider the popular brands "ArmMix Hydrophobic" and "Monolit", which are presented here: go to the website of the manufacturer and supplier of concrete impregnations "fibroblok.ru"

ArmMix Hydrophobic: purpose and advantages

Acrylic-silicone impregnation is very effectively used for the treatment of concrete floors and cement screeds (including semi-dry ones).

The tool belongs to the type of hydrophobic impregnation. As a result of application, it has a water-repellent and hardening effect. The liquid product does not contain toxic substances, therefore it can be used in any premises.

Among the properties and advantages of ArmMix Hydrophobic are:

- It is a deep penetration impregnation;

- Gives concrete strength, durability and frost resistance;

- Prevents the appearance of mold and other harmful lesions;

- Reduces freezing in the winter season and thereby facilitates the removal of ice from the surface;

- Protects from moisture;

- Provides breathability.

When applied, the impregnation completely fills the air pores and microcracks in the concrete and thereby ensures its strength and moisture resistance.

The only drawback of the composition is a decrease in the adhesion of the tile adhesive to the base. Therefore, if it is necessary to impregnate the floor with acrylic impregnation, and then glue tiles on it or lay porcelain stoneware, then you can use the ArmMix “Universal” impregnation primer, which does not contain a silicone water repellant and is both a strengthening impregnation and an excellent adhesive composition.

Impregnation for concrete "Monolith"

Monolith 20M "

Monolith 20M is a water-based product that is harmless to human health. The composition has a characteristic lemon color and is odorless.

Penetrating deep into the pores of concrete, Monolith 20M creates crystals in them, which, when moisture occurs, begin to expand. As a result, the structure acquires high moisture resistance and frost resistance. At the same time, crystals do not form any internal stress in concrete, since their expansion occurs only in the pore space.

After applying impregnation, concrete also acquires such qualities as high strength and wear resistance.

Impregnation "Monolit 20M" is recommended for use on concrete surfaces of residential buildings, shopping centers, industrial warehouses, bridges, car repair services, parking lots and other structures, incl. increased load.

Impregnation of the "Monolit-20M-L" brand will help not only to strengthen, but also to polish the concrete floor. The product contains lithium silicate, thanks to which all these qualities are given to concrete. The transparent product is perfectly absorbed into concrete (up to 40 mm) and forms crystals that have a strengthening effect. It is recommended to use this agent for old concrete floors that are exposed to mechanical stress or chemical attack. Also, the composition effectively strengthens porous concrete floors.

After applying the product, the frost resistance and durability of the concrete structure is significantly increased. Dust formation is reduced to naught. Monolith-20M-L reliably protects the floor from moisture, organic acids and petrochemical products. The floor treated with the Monolith of this brand is easily polished, forming a radiant shine.

Your thanks for my article is a click on any button below. Thanks!

Waterproofing of concrete with "liquid glass"

Liquid glass is a mixture of sodium and potassium silicates. In composition, liquid glass is similar to office glue. The silicates that make up the liquid glass react with concrete components and plug microcracks in layers close to the surface.

Liquid glass is a penetrating waterproofing. It is applied very simply - with a brush or roller. You can do the work yourself. But, it should be noted the fragility of the composition after drying, therefore, such waterproofing requires protection from mechanical damage.

Waterproofing of concrete with "liquid glass"

In principle, when using high quality cement mortar and high inherent strength, as well as when creating certain conditions for forming and drying, it is possible to obtain practically waterproof concrete. Such concrete is used in the construction of high-rise buildings and structures for special purposes. Under normal conditions, it is very difficult to make such concrete. Especially when it comes to low-rise private construction.

To increase the service life of buildings and to reduce the effect of the destructive effect of moisture on them, concrete waterproofing is necessary. Various materials can be used for this: concrete sealant; hydrophobic additives for concrete; concrete mastic; overlaid or glued rolls. The main thing is that the waterproofing is selected suitable, and the processing is done professionally.

The device of the self-leveling polymer floor

To arrange a self-leveling polymer floor, it is necessary to follow the technology and sequence of actions.

The main stages of laying a polymeric self-leveling floor:

- Substrate preparation - cleaning, patching up minor defects, leveling, removing dust and dirt, surface grinding. If the floor is applied on a fresh surface, wait 28 days after pouring.

- bases - quartz fine sand can be added to it, which will improve adhesion. When the soil is applied, wait a day, remove the remaining sand with a vacuum cleaner.

- Arrangement of the base layer of the self-leveling floor - the prepared solution is simply poured onto the surface, used for distribution with a squeegee, air bubbles are removed with a needle roller. Work is best done at ambient temperatures ranging from 5 to 25 degrees Celsius.

- When the base coat is dry, a thin finishing polymer layer is poured over. There are mixtures that do not involve this stage.

Popular impregnating compounds

There is a huge variety of concrete primers on the market. Let's consider only the most famous of them:

- Strengthening compound "Protector". Differs in high resistance to chemicals. Makes the surface harder. Has a dedusting effect. Improves the adhesive properties of the surface. "Protector" is used to strengthen structures for various purposes, including runways, roads, sidewalks, etc. Reinforcing impregnation is available in 20 liter containers.

- XTREME HARD. It is an inorganic-based waterproofing primer. Includes silica dust that penetrates the concrete structure and interacts with the cement base. In the course of the reaction, a crystallized mass and structures appear that block micropores.

- "Retroplate". A hardening impregnation containing a modifier. This element is used to harden and dedust a concrete structure. The primer is applied at temperatures above 5 degrees Celsius.The impregnation is incompatible with immature concrete.

- Protexil. It is used for impregnating floors in industrial facilities. Components "Protexil" protect concrete from the effects of mechanical damage and contact with chemicals. The impregnation layer dries in about 6 hours at 20-degree air temperature.

- "Monolith 20-M". It is a universal primer. "Monolit 20M" is produced on a water basis. Differs in environmental friendliness and fire safety. The action of the impregnating compound can reduce the occurrence of cracks, improve water resistance, increase wear resistance, and also dedust the concrete. The primer penetrates 20-30 mm into the material and increases the durability of the painted surfaces. Consumption "Monolit 20 M" - about 1 liter for every 3-5 sq. m of concrete base.

- Aquastone. Differs in powerful dedusting and water-repellent effect. Aquastone for cement screed penetrates deeply into the concrete structure, strengthening the material and improving its adhesive characteristics. Impregnation is possible in wet floor conditions.

- "Broke". Water-repellent primer for cement-based materials. Probetil also provides resistance to chemicals.

- "Master floor". Refers to epoxy compounds. It is used for dedusting and strengthening of magnesia and concrete floors, as well as cement screeds. Thanks to the use of "Master Floor", the strength of the base is increased threefold. The peculiarity of the primer is the ability to soak a damp floor.

- Ashford Formula. The composition includes a water-based silicate polymer. Strengthener "Ashford Formula" is intended for the treatment of floors under intense mechanical stress (industrial enterprises, roads, logistics terminals, etc.).

- Litsil. Russian development - "Litsil" - has the ability to dedust, polish and strengthen concrete. Differs in affordable cost and environmental friendliness.

- "Ceresit". Primer "Ceresit" is used for hardening concrete, cement screeds, lime surfaces. Improves the adhesive properties of the material, increases the surface density and its resistance to moisture.

Alternative options

Impregnations have a lot of advantages, but they cost a lot. Alternative methods of improving the quality of the concrete can be used if desired. The most common material is liquid glass. It has antifungal activity and creates a moisture resistant surface. However, it does not strengthen concrete at all.

Another option for a primer is a regular varnish. Its properties are similar to liquid glass.

Acrylic impregnation for concrete

Acrylic impregnation for concrete is rightfully considered a universal tool that simultaneously protects the coating from moisture, mold and destruction.

Acrylic impregnation for concrete is rightfully considered a universal tool that simultaneously protects the coating from moisture, mold and destruction.

This tool belongs to the group of water repellents, and is successfully used for wood, cement, expanded clay concrete and other bases with a porous structure. The impregnation also removes dust from the concrete surface.

Acrylic compounds can be used for both indoor and outdoor use. Often, acrylic compounds are used to further strengthen crumbling and fragile surfaces and porous structures.

It is for such materials that acrylic solution with silicone filler is most effective.

Thanks to its deep penetration, the impregnating compound reliably seals the screed and prevents the formation of mold due to its biocidal action.

These compounds adhere well to both new and old screeds. Colorless formulations do not change the original shade, but only enhance the shine.

In practice, various pigments are widely used, which, when added to aqueous dispersion of acrylic compositions, allow you to get floors of any color. The consumption of acrylic solutions is low - about 80 g / m2.

When applying acrylic compounds, it is necessary to take into account some features. So the process of distributing such impregnation can be done manually, with a roller or soft brush, or with a spray.

The temperature range of use ranges from 10 to 30 degrees Celsius... The moisture level during application should be 60-80%. Ideally, acrylic compounds are best fixed with a polymer-based finishing varnish, since they protect the concrete from moisture, and not from abrasion.

The polyurethane varnish can be applied one to two hours after the distribution of the protective solution.

Free from organic solvents, acrylic impregnations are safe for people and the environment. They can be used in all designated areas, including hospitals and kindergartens.

It is possible to apply acrylic compounds to damp surfaces. However, they should not be very wet. For example, on a fresh base, such a composition can be used only after five days, the screed installation field.

More than a hundred years have passed since concrete floors were invented. For the entire period, not a single worthy analogue of such grounds has been found. But there were whole technologies for strengthening cement mortars, including with the help of polyurethane, epoxy, acrylic resins and water glass. In this article, only a small part of these methods was considered.

Brands and manufacturers

When purchasing one or another type of impregnation, it is necessary, as with the purchase of any building material, to look back at the manufacturer. Construction is not a field where you can make mistakes and overlook the little things. Therefore, the authority and name of the supplier on the market is a kind of quality guarantee. Below is a ranking of the best impregnations for such surfaces.

Among the impregnations that have the proper trust:

"Tread". The main positive quality is resistance to chemicals. Belongs to the category of hardeners. Useful quality: removes dust from the surface, allowing the material to continue to "breathe" while maintaining its vitality.

Such an impregnation for concrete walls and other surfaces performs so well that it is even used for the treatment of runways.

"Retroplate" is another concrete impregnation from moisture, the main function of which is hardening and dust removal. Working with it requires compliance with some requirements.

First, work with the composition only at air temperature above +5 degrees. Secondly, it can be applied to concrete only two weeks after it has been laid.

Floor after using the "Retroplate" impregnation

Floor after using the "Retroplate" impregnation

"Monolit 20-M" is a universal water-based composition. It helps to reduce mechanical damage to concrete from shrinkage, and also enhances its moisture resistance. The hardness of the material is increased by a third.

Samples one processed "Monolith 20m" the other is not

Samples one processed "Monolith 20m" the other is not

In addition, it becomes immune to the harmful effects of fats, oil products and other substances that are not favorably related to unprotected concrete. At the same time, the impregnation improves adhesion to paints, increasing the durability of the latter.

Functions of impregnating compounds

Concrete is characterized by porosity, and its strength characteristics are largely determined by the process of cement hydration. Due to the technological features of manufacturing, concrete pores contain a gel component of cement, moisture and air. These elements adversely affect the properties of structures made of concrete.

Due to the presence of microscopic pores, concrete has two drawbacks:

- insignificant hydrophobicity, as moisture penetrates through the pores;

- low density of the material, which reduces the indicators of its strength.

At the modern technological stage, it became possible to change the porous structure of concrete to a waterproof one. This is done using impregnations.

The use of impregnations allows you to solve the following problems:

- protection from the effects of aggressive chemical substances and the environment;

- increasing the strength of the material;

- increased wear resistance;

- no dust formation on the surface due to crumbling of the material;

- strengthening of aged structures;

- extending the service life of concrete products;

- more attractive appearance of concrete surfaces.

Hydrophobic compositions are used for concrete processing at such facilities:

- exhibition complexes and retail premises;

- warehouses;

- car service shops, car washes, car parks;

- open spaces with concrete surfaces;

- livestock farms;

- industrial enterprises;

- administrative and residential buildings.

Note! Depending on the scope of application, the composition of the impregnations can vary significantly.

Mode of application

Polyurethane impregnation can be applied not only to concrete, but also to other mineral substrates, but the technology is always unchanged.

- First of all, using grinding equipment, the concrete surface is leveled, the cement laitance, loose layer, oil, and the layer obtained as a result of ironing are removed.

- The joints are cleaned with a manual grinder, and solid particles of cement and sand are removed with a brush. Thus, the pores of the material are opened.

- Additional three-stage grinding is aimed at obtaining a filler pattern (crushed stone cut). First, rough processing is carried out by 2–5 mm, then moderate grinding, at the end - grinding with a fine-grained abrasive.

- The surface is cleaned of dust with a vacuum cleaner.

- This is followed by a primer with polyurethane impregnation until a uniform layer is formed. The mixture should not be allowed to accumulate in the form of puddles.

- For different grades of concrete (M 150 – M 350), 3 coats are used. When screed concrete of a category greater than M 350, as well as for bricks, slate and ceramic tiles, 2 layers are sufficient. For this, material such as "Politax" is suitable.

- All layers must be thoroughly dried. At a temperature of 0 °, drying will take no less than 6 and no more than 24 hours, at lower, minus temperatures, no less than 16 and no more than 48 hours. A test application of impregnation will help determine the consumption of polyurethane.

To give greater strength, on the contrary, it is recommended to make additional layers. Polyurethane impregnation provides uniform penetration throughout the entire thickness of concrete, enhances the mechanical properties of the material and its chemical resistance, which guarantees an increase in the service life of the structure by 2-3 years, and also simplifies the procedure for maintaining the coating.

In the next video, you are waiting for the application of a hardening impregnation on a concrete floor.