Types and models

There are a lot of types of dowels, let's consider the main ones.

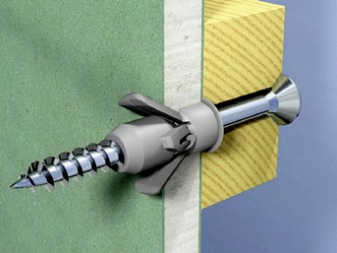

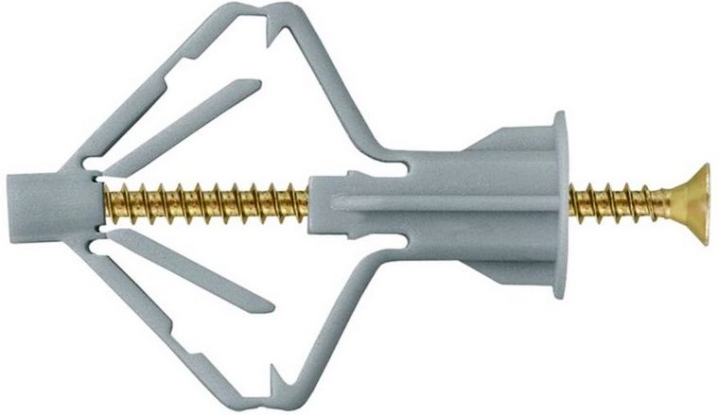

Spacer. From the name of this type of fastener, the principle of operation is already clear - this is the expansion of the legs (there may be two or more of them) of the polyethylene cylinder to securely fix it in the hole. This is a fairly large class of products that is used in various areas of repair, construction or assembly work. They come in various lengths, with a countersunk head or a protruding cuff, and can be additionally equipped with special elements to protect against rotation and secure fixation in the holes. They are produced in a large assortment of sizes with a diameter from 6 to 10 mm and a length from 5 to 160 mm, but the most popular ones are 8x30 mm, 10x60 mm, 10x40 mm, 8x40 mm, 5x30 mm (the first number is the diameter, and the second is the length).

Peculiarities

A polypropylene dowel is a fastener element that is used for a wide variety of materials and is capable of carrying a fairly decent bearing load - up to 200 kg. This does not mean the maximum bearing capacity, but the one that he is able to withstand on a permanent basis. Dowels are made of various materials, including plastic and iron, but even a plastic fastener will be more reliable in operation than a screwed in screw or a driven nail.

The main positive features of a polypropylene dowel:

- use in the production of environmentally friendly materials;

- strength;

- hardness;

- low hygroscopicity;

- excellent resistance to various acids and alkalis;

- well withstands high temperatures up to +80 degrees Celsius.

And also, unlike metal products, it does not corrode. And also a big advantage of this type of product is its low cost.

Negative features are aging and cracking with a long service life, low frost resistance. In severe frosts, the product loses its elasticity and, as a result, reliability. So this type of fastener is recommended for interior work, in rooms with any degree of humidity and aggressive environments, for example, in the chemical or food industry. But do not forget about its ability to crack and do not mount it in places where there is a high load.

How to choose?

To choose the right dowel, you need to answer yourself only questions such as:

- what to attach;

- what will be attached to;

- how much time is there.

The answer to the first question will help you understand how much force will hold the fastener, how it will look after installation.

The bases to which something can be fixed are divided into four types:

- corpulent (brick, stone, concrete);

- hollow (bricks with voids, expanded clay blocks);

- porous (aerated concrete);

- drywall.

Some of these elements can break with significant force of the spacer part on them, and the fasteners can be removed without effort. The same dowel can behave differently and will be able to withstand different loads when used in different base materials. And also do not forget about screws or self-tapping screws - their diameter must correspond to the inner one in the dowel.

And the final parameter is time. If it is limited, then it is better to use dowels-nails. Their use can reduce the installation time by almost half.