Plaster painting

If desired, gypsum materials can be given a completely unimaginable look, including simulating naturalness (for example, wood). Various technologies of toning, coloring, "aging" are used here.

Marble tinting. A well-dried gypsum product is impregnated with heated drying oil or shellac-rosin alcohol solution. The impregnation fits well, without streaks, creating protection from moisture. The gradually dried primed surface acquires a resemblance to aged marble.

Thanks to tinted plaster decor, it easily imitates marble

Wax tinting. An impregnation is used, consisting of wax dissolved in turpentine (gasoline) with a slight addition of yellow oil paint. After the impregnation has dried, the surface is rubbed to obtain a glossy finish.

Ivory tinting. A soap maker, nitro varnish and a little yellow oil paint are used. The surface is dull by rubbing with talcum powder.

Patination. Various shades of brown or brownish green are selected and mixed with other substances. It is recommended to paint in three layers, moreover, in the depressions, processing usually occurs with a mixture that is more viscous in consistency. The technology of applying the coloring matter itself is also important here:

- the first layer is lighter, after which it is lightly smoothed with sandpaper and wiped with acetone;

- the second layer - the coloring mixture is darker and thicker;

- the third layer - dissolve a little wax in the paint to give a matte finish.

Such additives will help to shade or enhance the imitation: bronze powder, talc and chromium oxide, graphite powder, sienna, ocher, umber, soot, green cobalt, lead or zinc white. These are all semi-professional methods of painting gypsum-based materials. Traditional plaster paints are available on the market.

The most commonly used coloring mixtures for interior work are acrylic water emulsions or dispersions. After drying, they create a strong protective film that protects the base from moisture. In addition, all water-based paints are environmentally friendly, which means they can be used inside any premises, including residential ones.

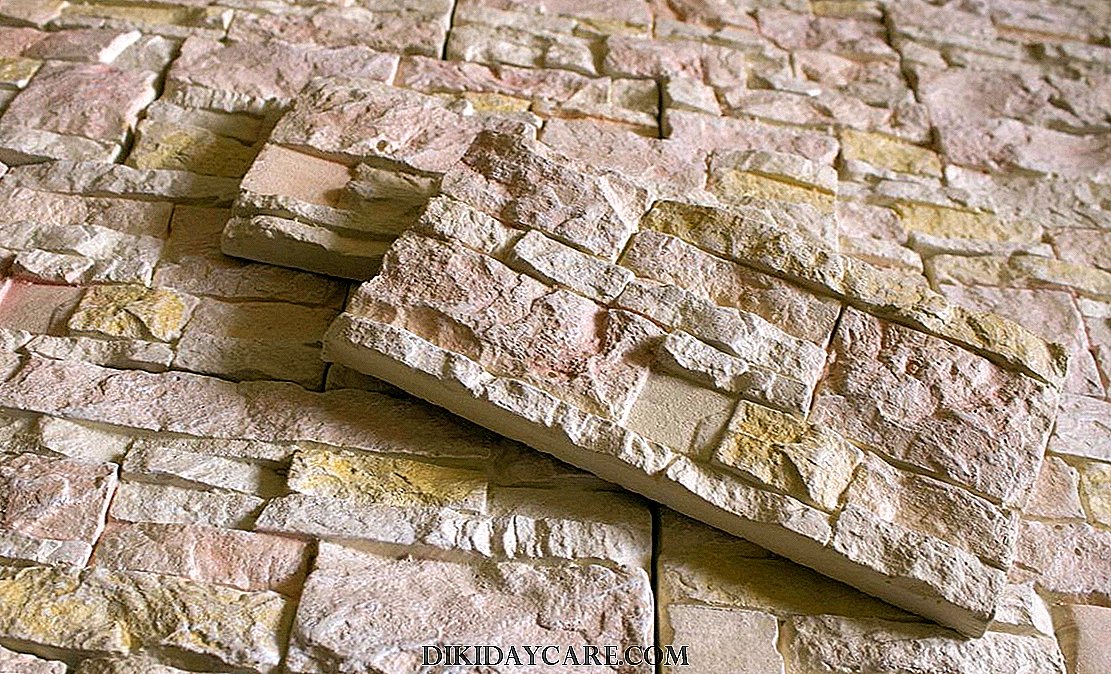

When making decorative bricks or gypsum-based stones, the working solution is tinted. For this, various pigment powders are used. Tinting of the solution makes it possible to obtain a finished brick, uniformly colored throughout the entire structure (then operational defects will be less noticeable).

To create an imitation of texture (veins), paints of several shades of color are used. And to increase the protection of the surface made of gypsum brick or stone (after all, gypsum is by its nature quite fragile), the finishing varnish will help.

Experts advise not to delay painting the gypsum finishing elements, as the adhesive properties of the materials deteriorate over time. If this has happened, then it is not superfluous to use a primer, and only after painting. The primer will also increase the strength of the plaster base and provide some protection against moisture penetration.

Plaster of Paris offers unlimited possibilities for original interior decoration. The widespread availability and ease of use made the material very popular. And having paints, red lead, varnishes, gold leaf and other pigment substances in your arsenal, you can achieve real palace luxury.

How to paint an artificial stone?

Painting the material at home is usually necessary in the case of purchasing raw products or making products yourself.In the second option, it is better to provide for the color of the plaster mass. This will allow surface staining only to highlight the desired areas.

If, when making a stone on your own, you take care of its color in advance by adding color to the gypsum mass, then less effort and time will be spent on the entire staining process.

If, when making a stone on your own, you take care of its color in advance by adding color to the gypsum mass, then less effort and time will be spent on the entire staining process.

It is not very easy to paint plaster in general, it will take accuracy and a lot of time. In addition, the result when choosing a certain color does not always turn out to be the desired one. Therefore, all formulations are recommended to be tested in advance.

For the topcoat, different types of dyes can be used to give the details the desired shade.

Acrylic paint

Water-based solution is quite popular, it allows you to decorate and protect the surface. Such a material has a number of properties necessary for an artificial stone from a gypsum mixture:

- Elasticity. Cladding elements are subject to thermal expansion, which can lead to the formation of surface cracks. Due to the slight elasticity, this problem will be eliminated.

- Water vapor permeability. This parameter is very important for plaster, especially inside the house. The fact is that this material contributes to the creation of a microclimate in the room due to the absorption and release of moisture.

- Resistance to various kinds of influences. Of course, the paint will not protect the parts from strong mechanical influence, but it will protect them from ultraviolet radiation and excess water.

Painting with acrylic paint will add additional protective properties to the artificial stone, which is especially important in rooms with temperature extremes and high humidity.

If high moisture resistance is required, a mixture with the addition of silicone is purchased. A distinctive feature of acrylic compounds is that they easily change their color; for this, a color scheme is used.

Vitriol

Iron and copper sulfate are used as impregnation. The main purpose of these mixtures is to increase the strength of parts, but there is also a side effect - staining. The iron variety gives the stone a yellow tint, while the copper variety gives it a blue.

The dry composition is diluted with water in a suitable container, the elements are immersed in the solution for two hours. The main thing is to arrange the fragments so that they do not touch each other, otherwise stand-out areas will appear.

Vitriol gives the gypsum a beautiful yellow tint, but to achieve similarity with natural stone, additional staining is performed with paint on individual sections of the tile.

Vitriol gives the gypsum a beautiful yellow tint, but to achieve similarity with natural stone, additional staining is performed with paint on individual sections of the tile.

Stain

For gypsum, mainly compositions are used that are also suitable for concrete artificial stones. They are monochromatic mixtures. There is a rich palette of shades, but if necessary, staining is done with wood stain.

There is also an acid stain

It should be handled with great care. Much depends on the composition of the gypsum tile, therefore it is recommended to test the mixture on one product.

Painting artificial stone with wood stain

Painting artificial stone with wood stain

Other types of solutions

Painting can be done with other varieties that color the surface of the stone:

- Any options for plaster.

- Varnish of various modifications.

- Impregnation. Many of them not only improve the quality of products, but also affect the appearance. For example, a penetrating mixture with a wet effect gives the surface a shine and creates the illusion of moisture.

- Self-prepared formulations. The main thing is the correct selection of components.

Specialized paints imitating natural stone

Specialized paints imitating natural stone

Painting Tips

In order for the staining work to be successful, you must first prepare the necessary materials. You will need:

- Rubberized sponge;

- Sandpaper;

- A piece of cotton fabric;

- Sprayer for paint;

- Grinding file;

- Degreasing solution;

- Dye;

- Set of brushes;

- Impregnating suspension;

- Compressor.

Finishing with colored decorative stone is often used in landscape design and facade work, therefore, the choice of paint must be treated especially responsibly.

Painting requires compliance with certain rules:

Before staining, the stone is dried for 24-48 hours;

The old cladding is pre-sanded so that the paint does not crumble;

Impregnations are used strictly in accordance with the instructions.

It is also important to consider the compatibility of impregnations with dyes;

To make the surface shine, you can use a varnish coating. However, it does not always look beautiful, since the effect of the naturalness of the material is lost.

If you follow these tips, the finish will look natural and the paint will last for a long time.

Using plaster varnish

Standard plaster products are grayish or white, and staining or toning them with colored varnish will help give the wall the desired look. With its help, you can design the surface in an original way, stylize it in accordance with the chosen direction in the interior. Varnishing helps to increase moisture resistance, because gypsum products deteriorate in contact with moisture. After varnishing in several layers, the decorative stone will be suitable even for finishing damp rooms. Also, varnishing reduces the impact of the tiles.

Varnish for gypsum decorative stone: types

On sale there are varnishes of different types, compositions, with unequal characteristics and properties.

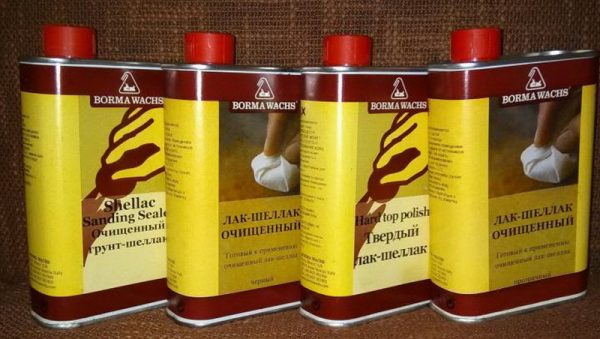

Shellac varnish

Usually this type is used in decoupage, but it is often used in finishing works. Shellac is alcohol-based, so it works well for gypsum. It can be applied as a stand alone coat or over any paint. Shellac creates a thin polishing layer that looks stylish and very attractive.

The composition is transparent and colored. There are even special age-effect varnishes used to give the base a vintage look. If you combine the agent with rosin in a 1: 1 ratio, a protective film will be created on the gypsum surface, eliminating the appearance of dirt and giving the wall a marble look.

Acrylic varnishes

Acrylic based varnishes have a decorative and protective function. They are moisture resistant, do not deteriorate from the action of household chemicals, ultraviolet radiation, temperature changes, dry quickly, and do not have a pungent odor. When thickening, acrylic varnish can be simply thinned with water.

In appearance, coatings with acrylic can be matte, semi-matte, glossy. Matte finishes help to give the stone the look of a natural, rough material. Semi-matt varnishes work in a similar way, only their transparent varieties can leave a light, light coating after drying. Glossy products shine, lead to glare, which must be taken into account when planning the decor in the room.

Oil varnishes

The composition of oil varnishes includes artificial resins, vegetable extracts. After application, a thin film forms on the gypsum stone, which protects the material from any external factors and prolongs its service life. Oil-based varnishes can be clear or colored, glossy or matte. After such a product dries, the surface of the decorative stone will look a little darker than initially.

Yacht varnishes

The most durable, durable and reliable stone varnish is considered to be yacht. It has a high degree of water resistance, making it suitable even for handling yachts. Contains solvents, smells unpleasant and is more suitable for outdoor use, although after complete drying it ceases to be toxic. For maximum surface protection, yacht varnish is applied in 2 layers.

Varnishing rules

Before applying the coating, make sure that all elements are well dried after priming or protective hydrophobization.The adhesive composition to which the decorative stone was attached must also dry out, otherwise the integrity of the cladding may be compromised.

Tips for varnishing stone:

- rough parts should be sanded before spraying varnish; fine-grain sandpaper is well suited for this purpose;

- if the stone has been impregnated, you need to read the instructions for it and clarify the possibility of subsequent varnishing and compatibility with this or that varnish;

- shiny compositions reduce the effect of the naturalness of the stone, therefore, for country styles, Provence and other directions striving for naturalness, it is better to choose matte products;

- before varnishing, it is imperative to brush off all the dust from the stone;

- during operation, the wall or elements must not be moistened - they quickly absorb moisture;

- The most convenient method of varnishing is by spraying with a spray gun or airbrush.

By connecting imagination to work, with the help of decorative stone, you can find very interesting solutions even in a small apartment. This material looks unusual, fresh and gives the house a special flavor, fills it with warmth and comfort.

Painting

paint decorative stone

paint decorative stone

To paint artificial stone, use a brush with a roller or a spray gun.

In particular, thanks to the spray gun, you will save on the consumption of paints and varnishes, shorten the repair period, the paint will lay much more evenly, it will be easier to adjust the saturation and color depth, and the entire painting area will be visible at once during the work.

You can also use brushes with a roller, however, the paint consumption will increase several times, and the quality of work will be slightly lower. However, you will need brushes in any case, for example, for touching up contrasting places, drawing colored stripes, creating a mosaic panel, imitating veins or blotches, etc.

So, make sure the hydrophobic impregnation is completely dry. Let's move on to painting.

For a start, it is advisable to practice on a small area to check the results of the work. Then apply paint to small areas of the wall holding the spray gun 40 cm from the cladding surface. It is better to set the pressure in the instrument at the level of 3-3.5 atm. By the way, two sprayers with different shades of dye are often used simultaneously.

But with brushes, you can effectively process each tile separately, while showing creative imagination, for example, to strengthen or weaken the necessary halftones, draw veins, stripes, etc. The technology of work is simple - we dip the brush into the composition and paint.

It should be noted that decorative stone, especially gypsum, usually absorbs paint unevenly across individual tiles. But this is completely natural for him. Such heterogeneity, with an individual pattern for each tile, on the contrary, will make the decorative facing more like a natural stone.

In principle, the painting work can be considered complete at this point. After some types of paint, for example acidic, the base must be thoroughly rinsed, dried again, and then covered with a hydrophobic impregnation.

Wait for the surface to dry and enjoy the renewed faux stone wall.

We wish you a successful renovation!

How to paint a decorative stone

To please the result of painting the stone, you must use waterproof acrylic paints. As an option, acid dyes are also suitable - such compositions are able to penetrate deeply into the structure of a decorative stone and resist fading quite well. Another advantage of such dyes is a short drying period.

When purchasing paint, you need to make sure of its high quality. It should not have lumps or lumps, any fluctuation in the structure indicates possible problems that must be eliminated before staining begins.

Using water or a primer, we bring the consistency of the paint to the desired state.In addition to paintwork, you can use plaster varnish - this applies to gypsum stone. After processing with such a composition, gypsum tiles get a uniform color. The varnish itself is applied evenly, without streaks, dries quickly and does not flow down the surface.

What should be avoided is the use of quick-drying nitro-varnish dyes - after drying, such a composition forms a thin film, which inevitably exfoliates during temperature fluctuations.

The use of quick-drying nitro-varnish dyes should be avoided.

Another decent option is liquid or dry colorant, which needs to be added to the water. To obtain a solution of the required saturation, mix 1 teaspoon of pigment and 400 ml each of water and acrylic primer.

In order not to be mistaken, we read the instructions that are attached to the paintwork from the manufacturer.

Tool selection

To determine the list of tools that you need to have available to start work, it is worth assessing the quality of the surface. If the surface is old, then more tools will be required, for new tiles there may be fewer fixtures. On average, the list of accessories consists of:

- Vacuum cleaner - necessary to clean the contaminated surface and remove dust;

- Sanding accessories - it can be either a sander or sandpaper;

- Sponges and brushes - necessary for touching up colored elements and hard-to-reach places;

- Spray gun or airbrush.

Unusual staining of a plaster product

Painting artificial stone can be a creative process:

Old marble

We keep it in a dark room for 48 hours.

To get the effect of old marble, you can use the following painting technology:

- We buy plaster facing material;

- We keep it in a dark room for 48 hours;

- We heat the drying oil - to protect your hands, you must use special gloves;

- We cover the tiles with hot linseed oil, using a flute brush, it is better to make the coating in two layers - we process the surface evenly, without missing unpainted areas.

When the linseed oil is dry, the gypsum tiles will be covered with colored veins that perfectly imitate antique marble. Such products have found their application in the decoration of kitchens, fireplaces and so on.

Create a bronze tide

You can also make a bronze tint when painting gypsum tiles yourself:

- To begin with, a layer of heated drying oil is applied to the gypsum products. It will take at least 8-10 hours to dry them;

- Next, you need to make a mixture of bronze powder with varnish - we apply this material to gypsum products in 2 layers;

- We leave the material to dry;

- We mix in 300 g of water 100 ml of acetic acid and 10 g of silver nitrate;

- We apply dry bronze powder to dried artificial stones and cover with vinegar solution on top - such ingredients on the surface of the facing material trigger the oxidation reaction;

- Gently wipe the finished stones with a piece of velvet.

Stain in combination with plaster also produces a beautiful surface.

Using wood stain

Stain in combination with plaster also results in a beautiful surface. It is good to apply the stain with a spray gun, but the best effect is obtained by dipping gypsum products into the solution. The stain needs to be slightly warmed up and plaster should be immersed in it for a few seconds. After that, it is enough to dry the facing material to obtain a brown finish.

Whatever you choose, you must first practice on a small area - this will allow you to evaluate the final result and adjust your efforts. The final stage of dyeing can be washing and drying products - this is important for acid paints. You can also complete the decor of the artificial cladding with a hydrophobic impregnation - you just have to wait for all the layers to dry and evaluate the result.

How to paint an artificial stone

With such a variety of materials, it is quite difficult to choose what to cover the decorative stone with.

The most popular options are:

- acrylic paint;

- vitriol;

- stain;

- various colored solutions.

Each of the materials has features of application and properties.

Acrylic paint

Water-based wall paint is popular, as it allows not only painting the walls, but also protecting the surface from weather.

Acrylic paint for decorative stone has a number of advantages:

- elasticity. Due to changes in temperature conditions, cracks and deformations can form in the surface. Due to elasticity, this problem is eliminated;

- vapor permeability. This material perfectly absorbs and gives off moisture;

- the ability to easily change the color by adding a color scheme.

- resistance to ultraviolet and moisture.

If it is necessary to increase moisture resistance, you can choose a mixture with the addition of silicone.

Vitriol

Iron and copper sulfate are used as impregnation for natural stone walls. Such compositions increase the strength of the parts. However, these compounds change the color of the treated surface. Iron vitriol paints the stone yellowish, and copper - blue. If this is exactly what is needed for decoration, the elements should be immersed in the solution for a couple of hours in this way. So that they do not touch each other.

Stain

Decorative gypsum wall covering for stone is treated with the same compounds as concrete. On sale, these mixtures are monochromatic, but if you want to diversify the palette, you can use wood stain. Acid stain is popular, however, one plate should be tried before applying to all walls.

This is important because gypsum stones can vary in composition.

Other types of solutions

There are other solution options that can be used for staining.

Choosing how to paint the surface of the walls like a stone, you can pay attention to the following materials:

- varnishes;

- impregnations that can not only paint the surface, but also improve their quality. Wet effect mixes can create a shiny film on the stone and create the visual illusion of moisture on the wall;

- gypsum paints of any modification;

- compositions created by their own hands. In this case, the main thing is to correctly select the components.

Compositions that can imitate natural stone have appeared on the building materials market. However, their cost is not yet available to everyone.

Buy or do it yourself?

Manufacturers have developed many types of finishing materials. Gypsum brick for interior decoration in catalogs is presented in various modifications:

- The glossy varnished version is fashionable.

- An interesting matte muted look, which is treated with a protective compound.

- Equally in demand are models with a flat surface, embossed or curved.

Gypsum blocks are commercially available that mimic hewn stone segments or irregular shapes of minerals, but imitation brickwork is the easiest to handle.

The whole spectrum of beige color scheme, shades of gray, brown, sand is in demand. Many consumers prefer natural brick color or plain white. The colorless surface can be painted with selected paint. The decorative gypsum material can be smooth, textured or rough to the touch.

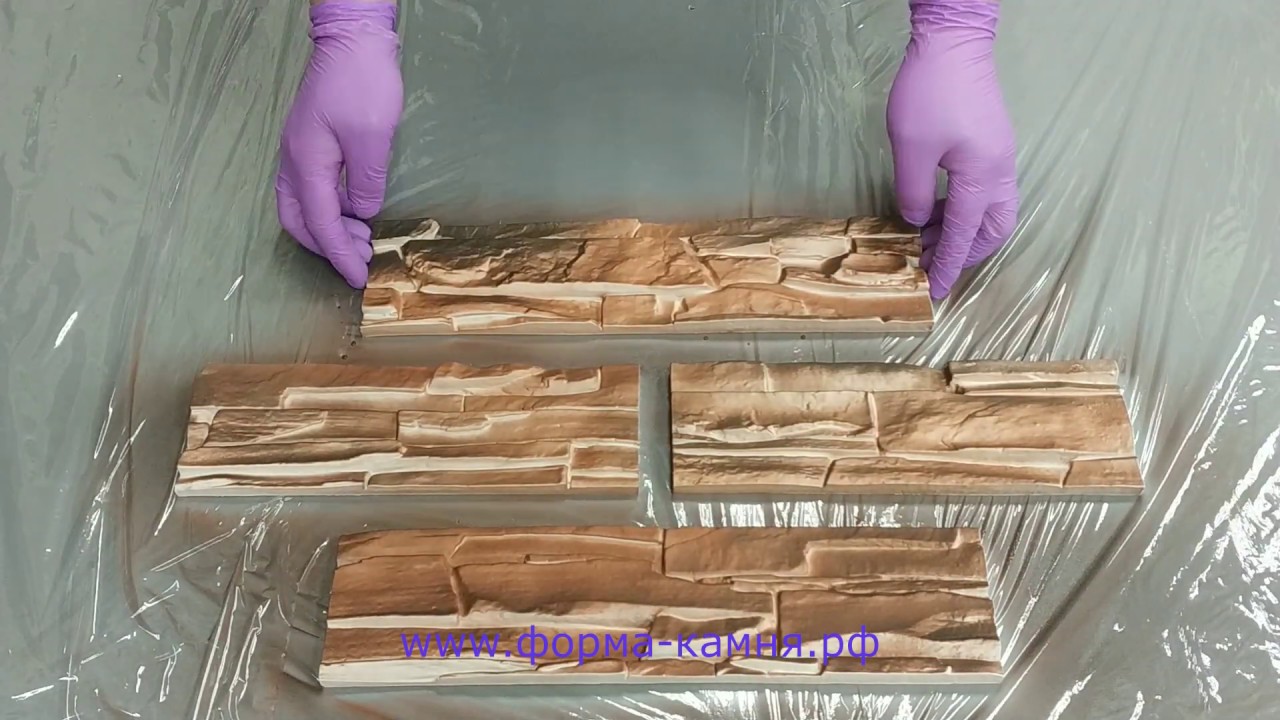

If desired, the DIYer can make a light and stable stylized brick on his own. This process is quite laborious and requires strict adherence to the recipe, the availability of suitable containers for pouring the composition. Experts advise using commercially available silicone molds.

The main ingredients for creating such a finishing material will be: actually gypsum and PVA building glue.If desired, a decorative color scheme or pigment is used, the formation of a white version is possible. To prepare a solution of the desired consistency, water is added when mixing the components.

For 1 kg of dry powder, you will need about 0.5 liters of liquid and about 50 g of PVA. You can add polypropylene fiber for reinforcement: it will need 1-2 g per kilogram of gypsum base.

The required amount of dry matter is gradually poured into the container, water and glue are also added gradually. The resulting "dough" is stirred until smooth, resulting in a composition that resembles 25% sour cream.

To stimulate the setting process, some craftsmen add citric acid to the solution: about 0.5 g per standard bucket. The coloring pigment is first diluted in water, and added to the total mass at the end of the preparation process.

Molds can be greased with vaseline oil or treated with soapy water. The mixture is poured in one layer and in half an hour the decorative "masterpiece" becomes solid. Finished products are recommended to be coated with an acrylic primer.

Coloring option

In mass

It is considered the most practical and best way. In this case, the coloring pigments in the form of powder, which are used for concrete, are added directly to the gypsum solution. Thus, you get an inside-dyed product. When cut or chipped, you will not see a white base.

The best is a beige or yellow solution, and in polyurethane form, parts of the stones can be painted with liquid pigments using a brush.

For this:

- take ½ tsp. color scheme (pigment);

- add 200 ml of water;

- add 200 ml of any acrylic primer.

When the stone has set, remove it from the mold and dry it, and after laying on the surface, apply a matte water-based varnish on it.

This option for staining decorative gypsum stone is the most effective and almost all manufacturers use it. Therefore, it is these products that we can observe in stores. The disadvantage of this method is in the rough and unnatural painting, which can be observed at close range.

By making an artificial gypsum stone yourself, you have the opportunity to work on naturalness, carefully painting over parts of the stones in the form. On an industrial scale, of course, no one will do this, otherwise the price will increase greatly.

Below, another painting technology will be proposed, which will help to make a product from gypsum tiles that is more similar to natural stone. You will learn how to paint artificial stone so that it has the same natural streaks and colors as natural.

Surface

Prepare:

- water-based (coloring pigment);

- water;

- spray or brush.

The instruction is simple - you need:

- add a coloring pigment to the water, you can even add several at once;

- dip a brush into the solution;

- soak plaster tiles with it.

Artificial gypsum stone has unique properties of manifestation of shades that are similar to natural ones due to the absorption of tinted water.

In order to give the plaster stone the desired shade and color, you do not need to have an art education. Dip the brush in dyed water and paint the stone however you see fit.

Then you can tint some with a dark solution of pigment and water. You should not think too much about the palette, since each gypsum tile, even with the same texture, will absorb the solution in different ways, which will allow you to create an individual pattern each time.

You can also use any sprayers for work, for example:

- spray gun;

- a spray bottle for glass cleaning products.

Pour the paint diluted with tinting paste in water into a container and spray on the gypsum tile. It is better to use several of these sprayers with different colors in your work, so that you can process different places on the stone.Then the painting process will be better and faster.

The advantage of self-painting

- The store offers artificial stone in standard colors and with a distinct artificial color. It lacks natural colored veins, like a natural one.

- You can purchase products in white or in a monochromatic beige color, glue them on the walls, and then paint them on the spot with water diluted in it with coloring pigments. This method makes the masonry look much more natural. (See also the article.)

- Once the gypsum stone is dry and faded and pale in appearance, open it with any silky matte or matte varnish. Thus, you can restore color saturation to the product, strengthen and protect its surface.

- If there is a desire to achieve a "wet" effect on an artificial stone, varnishes, but, be aware, this will slightly reduce the naturalness of the material.

Mass painting

There is nothing easier than painting an artificial stone in this way. We take the pigment, dissolve it in water, then add gypsum and make a solution. Then we fill it in the forms.

Pros:

- Fast painting method;

- All tiles are painted over (inside and outside);

- Fading is excluded.

Minus: only 1 color can be obtained.

After drying the stone, the color will fade, so only by testing it is possible to determine the final color of the stone. I took 1 kg of gypsum for kneading and added different amounts of pigment 3, 6, 10, 15 grams. The main thing is to write everything down, so as not to forget later, in which stone how much pigment you added.

If you want to thank me for sharing my experience with you, then write a comment on this article with any question or suggestion. Perhaps from your comment I will glean a topic for one of the future articles.

Methods for painting plaster products, tinting materials, tools

Gypsum has excellent adhesion to a wide variety of paints and varnishes, there are many ways to paint it:

Colored solution for painting plaster products

Consider how to paint a decorative gypsum stone. Plaster stucco painting can be performed with various compositions:

- acrylic;

- water emulsion;

- pentaphthalic;

- lime;

- silicate;

- silicone;

- latex.

When choosing how to paint plaster moldings, be guided by the desired texture:

acrylic paints and varnishes give a satin finish, water-emulsion paints - matte, pentaphthalic compounds are glossy, no varnish is required. Silicate, silicone and latex compounds have a rich color gamut, many interesting textures - like stone, velvet, velor, Venetian, form a moisture-resistant film on the surface

stone surfaces, but their cost is much higher than that of acrylic and emulsion ones.

Most often, acrylic, lime and water-emulsion compositions are used, as they are more economical. The metallic effect is easiest to achieve with aerosol car paints. To obtain some types of textures, natural drying oil is required. If you do not plan to frequently change the color scheme of the interior, then paint and varnish materials should be chosen with a service life of at least 10 years. To increase the adhesion and strength of the product, up to 5% of the volume of PVA glue can be added to the paint.

Copper or iron vitriol is used as an impregnation for gypsum. Copper gives gypsum a blue tint, iron - yellowish. For coloring, tiles or decorative fragments are immersed in an aqueous solution of vitriol for 2 hours, while the parts should not touch, otherwise spots of different shades appear on the surface.

When varnishing finished products, carefully choose the composition: a varnish with a high gloss can look kitsch in some interiors because of its shine, so it is better to choose a matte or slightly glossy finish.

In addition to the spray gun, brushes are used in the work - flat flutes and panels, with a rounded end, with soft or hard bristles.The hair of the paneled brushes is kolinsky, squirrel or badger, fluffy. For shading and texturing, brushes with a hard bristle, bristly French knit are used.

Tampons made of rags, foam rubber also help to shade the borders of the color scheme, they are made manually from materials that are in every home: most often by tying a piece of sponge or cloth to a wooden stick, and wrapping it with thread or wire.

Painting stucco molding with small relief details at a height requires a scaffold so that all unpainted ones are visible and not to strain your hands.

What to paint

Before staining a gypsum stone, you need to take care of reducing its hygroscopicity. To do this, it must be endowed with a water-repellent effect. This can be done using special formulations. At the same time, the vapor permeability of the material does not suffer. In hardware stores, you can find a ready-made solution or dilute it yourself from concentrates. By the time of application, the gypsum stone should already dry well. It is necessary to remove dust from it. The application of the compositions is done with a brush or spray gun.

Lucky

The following types of varnishes can be used to cover gypsum stone:

- acrylic;

- oil;

- yacht.

Acrylic varnish is water-based. It contains various resins. In consistency, it resembles thick milk. It can be used for interior and exterior decoration. Most often, this varnish provides a topcoat that will protect the base coat. It creates a special film on the stone that has a water-repellent effect. It also protects against exposure to ultraviolet rays. A dried surface can be easily cleaned using a variety of products. There are glossy, semi-matt and matt varnishes on sale. Each of them has its own unique effect. Glossy varnish gives the plaster stone a gloss

While using it, it is important to remain in moderation, because

the surface will strongly reflect light, which can spoil the idea. Matt varnish on a plaster stone looks solid. It creates an atmosphere of comfort and peace.

An oil-based varnish can be used just as well for gypsum stone. It provides excellent protection to the cladding due to the fact that until it dries completely, a film forms, which remains even after drying. It increases resistance to mechanical stress. To achieve the required consistency, special dissolve is applied. In terms of surface mattness, oil varnish has the same properties as the previous look. It is worth considering that this varnish may darken slightly after drying.

Yacht varnish will provide the most protection for gypsum cladding. It must be applied in a thin layer to avoid drips, which will be difficult to get rid of later. It dries up in about a day. This period can be increased due to low temperature or high humidity. After drying, another layer is applied. In some places, it may be necessary to sand the surface with fine emery for sagging.

Paints

Painting plaster cladding is easier than it might seem. One option would be to add pigment to a water-based varnish. You can use water-based paint with the addition of any pigment. There are special pigments that are diluted with water. Gypsum will perfectly absorb the coloring base. At the same time, you do not have to try hard and draw lines. The manufacturer often paints the gypsum veneer himself, adding a dye to the base. A video about painting gypsum stone can be viewed below.

Outcomes

Painting plaster on your own is possible subject to the basic rules:

- thorough surface preparation;

- compulsory priming;

- applying paint in 2-3 layers;

- varnishing;

- the use of compatible formulations;

- following the paint manufacturer's instructions.

In the absence of skills, it is necessary to perform trial operations on samples until a stable positive result is obtained.

Materials for painting stucco

Do-it-yourself painting of plaster is possible, but it requires certain skills, time and accuracy. Work in a dry room with good ventilation, keeping the drying time of the intermediate layers. And everything will work out!

Starting with this article completely devoted to painting plaster, we promise our readers many useful master classes that will be published on our blog in the very near future!