Installation technology

A significant minus of the material is significant weight, therefore, the state of the foundation is assessed before starting work. If necessary, it is additionally strengthened. It is recommended to highlight the basement area against the general background of the facade cladding.

Sheathing device and insulation

To create a frame, a beam or profiles are used, the method is selected based on a specific situation. The first variety is more suitable for log houses, the second for brick, concrete or similar surfaces.

Wooden structure

The process begins with the preparation of the racks: they are treated with special protective compounds that prevent decay and fire.

You need to fix the parts in the following order:

- The frame elements are dried, the surface is marked. For this, the optimal spacing of the parts is determined, the standard value is 50-60 cm. This distance allows you to lay the thermal insulation.

Metal crate

Installation of such a frame takes place a little differently:

- The preparation of the base is carried out, the marking is carried out.

- Hanging brackets are set along the existing lines and fixed with a pitch of 35–45 cm on self-tapping screws and dowels.

- Rows of insulation are laid. It can be penoplex or stone wool. The material is pricked onto structural elements and additionally attached to the walls.

The convenience of the method lies in the fact that there is no need to erect a counter-lattice, since the thermal insulation is not lined flush with the external elements.

Fastening panels

To clad the house, initially the slabs are cut to the desired size. For these purposes, a grinder with a concrete nozzle is used. Reaming is carried out according to the location of the frame parts.

- Facade material is transferred with retention along the edges with a slight slope. This will immediately set the element in place.

- A rail is laid along the upper section of the base. It must have the required clearance thickness.

Finishing work on OSB-plate

OSB finishing outside can be done with a variety of materials.

It is important to start by deciding what funds you have. If your budget is small, you can choose a staining method

Perhaps the most expensive cladding options are decorative stone and siding. Plaster looks modern and simple. But from the inside, OSB plates are most often pasted over with wallpaper or tiles.

Painting

The outside and inside of the OSB board can be lined with paint. For external cladding, you should choose formulations with additives that provide protection against ultraviolet radiation. If the surface does not provide for leveling, polymer-based blends should be preferred. They fit well on uneven ground and protect walls from external influences. At the first stage, the wall is prepared by grinding. The next step is to fill in the irregularities with a putty. The facade or internal walls are covered with a primer, which dries well, and after that it is painted.

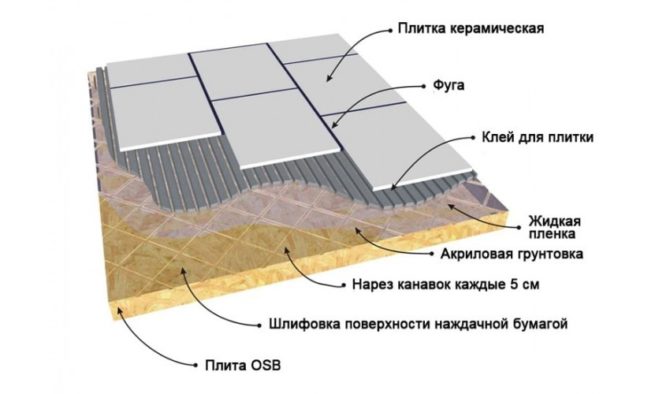

Facing with ceramic tiles

The inside of the oriented strand board can be tiled. This perfectly protects the material from moisture and temperature extremes in the bathroom or bathroom. Sometimes the canvases are additionally leveled with plasterboard or cement-particle board, but this will increase the thickness of the coating and reduce the height of the ceilings.

The service life of the cladding can be extended by covering the OSB with a reinforced mesh.In order to increase adhesion, the gloss is removed from the substrate with sandpaper. All dust is then removed, and a primer is applied to the surface. Next, you can lay the tiles on the grid.

Wallpapering

The walls are prepared by sanding and priming. Each layer must be allowed to dry. If the wallpaper is dense, it can hide the unevenness of the oriented strand board. Otherwise, it is recommended to additionally grind the blades.

Plastering

Seams should be repaired before plastering. A silicone or acrylic based sealant is suitable for this. The sander will remove all defects. In the absence of a tool, you can use sandpaper.

For wall application, it is better to use a glue-based composition. It spreads over a plastic or metal mesh. It is fastened with staple staples. When the first layer is formed, the mesh is completely hidden. In order to achieve perfect evenness, you can apply a second layer of putty, but this should be done only after the first one is completely dry.

Siding outside

Outside siding begins immediately after the house is built. A frame made of wood or metal is installed. The guides should be located not only on flat surfaces, but also in corners and openings. Thinking about the question of how to decorate OSB from the outside, consumers often choose siding. If you are one of them too, you need to familiarize yourself with the technology. At its next stage, you can start facing the area around the openings.

On the main facade, the lamellas are stacked from bottom to top. Sometimes the installation technique is used from one corner to another, but this way you can face the problem of mismatching the dimensions of the wall and profile. Installation of decorative panels should be carried out without distortions. For this, a building level is used.

Installation of decorative stone

The outside of the OSB board can be finished with decorative stone. They quite often sheathe not only facades, but also plinths. This material does not load the foundation, it is simply installed, and looks very realistic. If you have already decided how to decorate the OSB outside, and it will be a decorative stone, then you should know that it is installed on glue or frame.

If you chose the wet installation method, the surface will need to be cleaned of dust, the pores should be closed by applying a primer and the fiberglass should be glued. It will reinforce the facade and make the cladding stronger and more durable. At the next stage, tile adhesive is applied to the reverse side of the products, which are then applied to the base and aligned horizontally and vertically.

Wood cladding

Wood in construction and decoration is not used for centuries, and it looks like it will be relevant for a long time. All thanks to its excellent appearance and the ability to regulate the humidity in the room. This is perhaps the only material that will remove excess moisture without problems, regardless of what material the walls are built from.

Wooden sheathing can have a completely non-standard look: different colors and sizes, different directions. It's simple, and the effect is amazing

The most popular wall cladding materials are block house and imitation timber. There is also a lining for exterior decoration - it has a greater thickness compared to that intended for interior decoration of a house, but otherwise is no different.

The block house imitates the surface of a rounded log - the front part has a rounded shape. Timber imitation is very similar to planed timber. Both types of cladding are attached to the lathing, then sanded and coated with protective impregnations, if desired, they are also varnished or painted.

What lumber looks like for exterior cladding of a house

If you cannot decide how to sheathe a foam block house from the outside, consider wood cladding. In this case, a crate (metal or wooden) is nailed to the walls. If necessary, a heater is placed between the strips - basalt wool (foam or expanded polystyrene cannot be used), and then wood sheathing is nailed.

This building is sheathed with imitation timber. Under the cladding there can be a brick, a log house, a frame or any of the building blocks.

If the cheapest option is needed, for most regions of Russia this is an ordinary planed board. Its thickness is from 40 mm, it is stuffed in the same way as the lining or block house on the crate, the lower end of the top board goes 10-20 mm to the one located under it. It turns out the principle of the bump. So you can cheaply revet a country house or even a residential one. With proper processing, such a cladding has a very good appearance.

How is it cheap to sheathe a house outside? For central Russia - a wooden planed board

The disadvantages of such a finish are the same as for any wood: it can be damaged by pests, rot, without proper care it quickly loses its decorative effect, becomes dark and ugly. If you want to sheathe a house and not think about it for years, this is not your choice. The wood sheathing requires maintenance, and, most often, annual.

Read how to brick a house here.

Scope of OSB and types of plates

In a classic chipboard, sawdust is mixed together with a type of epoxy resin, as a result, in the finished solidified layer, they are located chaotically. In the OSB board, they are oriented by vibration not only in the layers, but also in the direction of laying, as a result of which the board receives a much higher fracture strength. In fact, OSB is one of the options for composite materials.

OSB boards differ in the degree of their resistance to high humidity, as well as in strength characteristics: how well they are able to hold the fracture load. There are 4 brands of OSB: from OSB-1 to OSB-4. Each of these types uses its own types of adhesives, which give the corresponding properties to the finished board.

OSB is used both for interior decoration of premises and for exterior. It is necessary to use different types of boards according to their resistance to moisture. OSB boards are durable and practical, they allow you to form complex facades for subsequent painting or plastering from the outside or wallpapering from the inside.

Installation of OSB on external walls

The technology for laying OSB on the street includes several stages that must be performed sequentially. The main goal is to get a flat surface.

Preparation of the base

Algorithm of actions:

- If the old decorative coating interferes with the work, it is removed. The protruding objects are removed. Communication systems, if necessary, are completely replaced or transferred. The surface is cleaned of dust and dirt.

- The condition of the foundation is assessed. All cracks and cracks are embroidered, primed and covered over. If there are traces of mold and mildew, the areas undergo special treatment.

- Damaged places are replaced or strengthened. When working with old buildings, it may be necessary to reinforce the foundation.

The load-bearing base does not require perfect leveling, it is enough to patch up the cracks and treat the surface with a complex protective primer

The load-bearing base does not require perfect leveling, it is enough to patch up the cracks and treat the surface with a complex protective primer

Further processes are carried out only on condition that the base is well dried and the residual moisture will not affect the structure in the future.

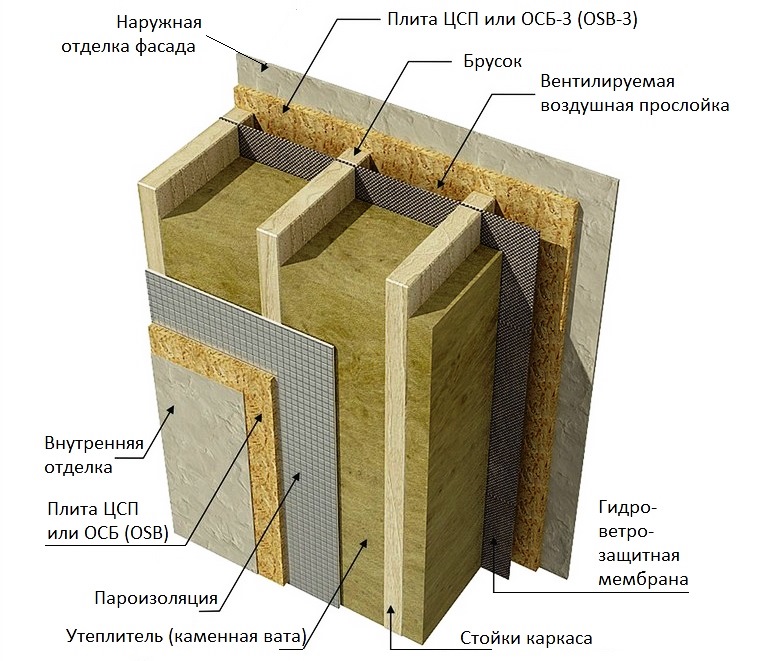

Erection of the frame and laying of insulation

The sheathing of the outer walls of the OSB is carried out along the crate, which creates the possibility of additional thermal insulation of the house, therefore the process should be approached very responsibly.

Scheme of work:

- For installation, it is better to use a wooden beam. In this case, the fixation is the most reliable; moreover, the materials have similar indicators of thermal expansion.

- Frame details must be prepared. The process includes drying, sampling and impregnation with protective compounds.

- The fixing of the lathing elements is carried out according to the scheme. The extreme corner fragments are exposed first.

- The placement step depends on several factors: the type of insulation, panel dimensions and direction. When using a sheet of size 122 * 244, the optimal distance between the posts is 40.7 and 61 cm, and with dimensions 125 * 250 - 62.5 cm. Naturally, these parameters depend on the specific situation.

- If necessary, first install a vapor barrier. This is especially true when working with wooden bases.

- The racks are fixed vertically directly to the wall of the house. To align between the extreme elements, a cord is pulled and a level is used. To ensure the required evenness, boards are placed. In exceptional cases, hangers for metal profiles are used.

- The selected version of the insulation is placed without a gap in the formed cells. If required, then it is fixed with special dowels.

- Fastening of wind protection is carried out.

In order to ensure reliability and rigidity for the frame being erected, a frame is preliminarily created in which the racks are placed.

Installation of slabs

Before fixing the OSB on the crate, it is necessary to take into account a number of nuances:

- Fixation is carried out with the front surface outward. Determining the right side is easy: it consists of larger fragments of chips than the wrong side.

- When using parts with a thickness of 9 mm on a one-story house, placement is done horizontally. For taller buildings, slabs with a thickness of 12 mm are placed vertically. Many experts point out that the first option provides better reliability due to the larger number of racks. It is taken into account that in this case the slabs are staggered.

It is necessary to fasten the OSB to the frame according to the following instructions:

- The first part is exposed from the corner of the building. A gap from the foundation of 10 mm is necessarily formed. To do this, you can use spacers that are placed around the entire perimeter of the building.

- For fixing, galvanized rough nails or self-tapping screws with a zinc coating and incomplete thread are used. Each option is suitable for any job site. It is taken into account that with a plate thickness of 9 mm, the screw size cannot be less than 45 mm. The screw-in or drive-in step is 10-15 cm.

- Adjacent slabs must be fastened with a gap of 2–4 mm, all edges must touch the frame posts.

- After laying the bottom row, the next level is laid. It is shifted one step between the posts.

- It is necessary to overlap fragments of adjacent sections of the wall in order to form a straight joint.

Despite the high density, oriented strand boards are subject to slight thermal deformations, therefore the elements are mounted with a damping gap of 2 - 4 mm

Despite the high density, oriented strand boards are subject to slight thermal deformations, therefore the elements are mounted with a damping gap of 2 - 4 mm

It is possible to sheathe the house outside the OSB with a do-it-yourself slab in the presence of a second floor according to the same scheme, but it is recommended to lay the sheets so that the connection of the first and next tier is overlapped with one fragment.

CHARACTERISTICS OF OSB (OSB) AND DSP

OSB boards (OSB) are described in detail in the article: Characteristics of OSB boards (OSB) and their areas of application

CHARACTERISTICS OF CSP PLATES AND AREAS OF THEIR APPLICATION

To the positive characteristics of CBPB, indicated in the table, it is necessary to add their significant fire and environmental safety, high moisture, frost and biological resistance.

The negative properties of CBPB can be attributed to their high weight and weakness in breaking thin slabs (less than 10 mm thick), requiring increased care when tilting and fixing the slabs. The complex of the specified properties of the CBPB plates determines their high versatility, which makes it possible to use CBPB practically in all parts and structures of the building, where a slab structural and finishing material is required.

The complex of the specified properties of the CBPB slabs determines their high versatility, which allows the CBPB to be used in almost all parts and structures of the building, where a slab structural and finishing material is required.

Fields of application of DSP in individual housing construction

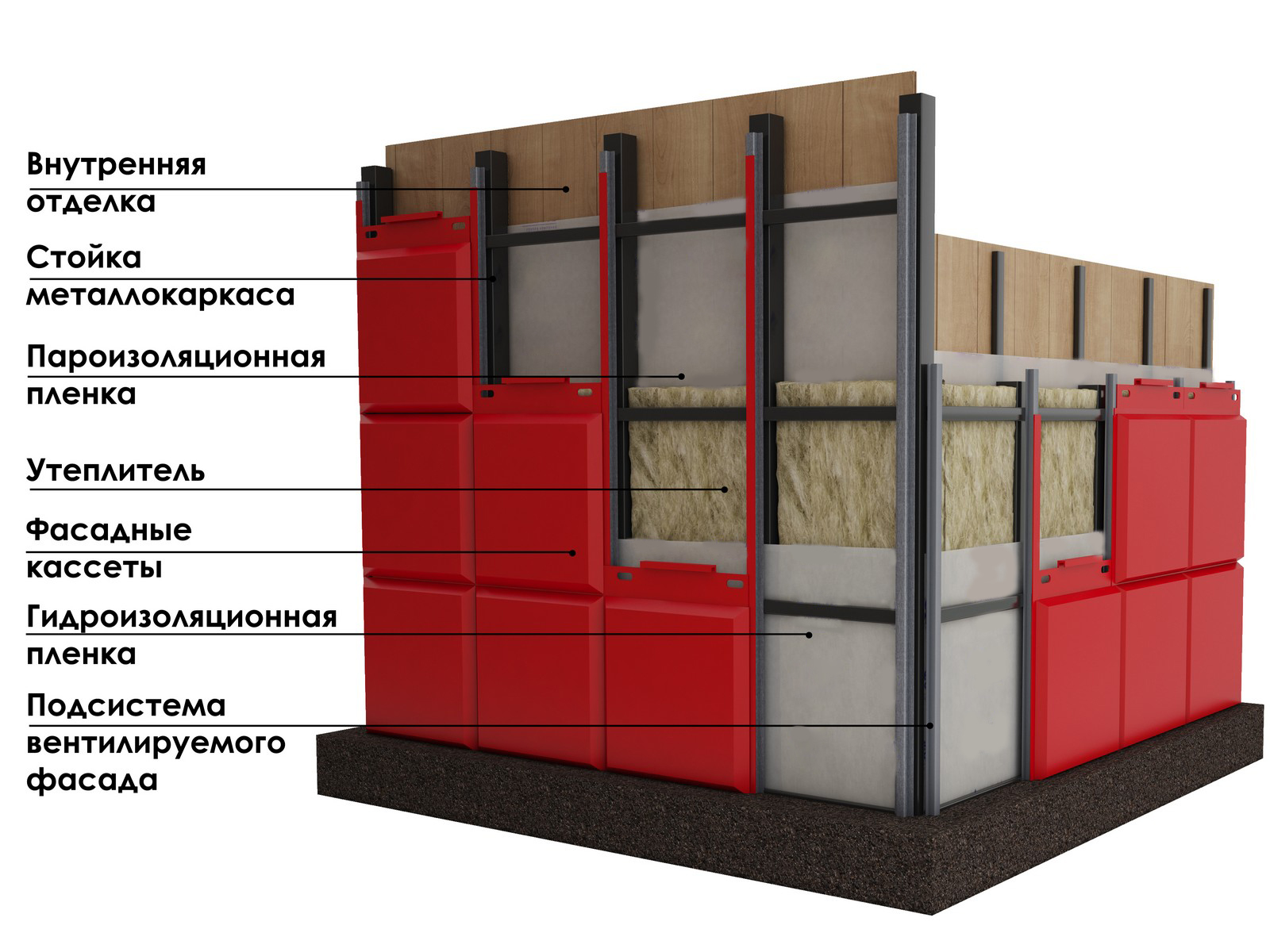

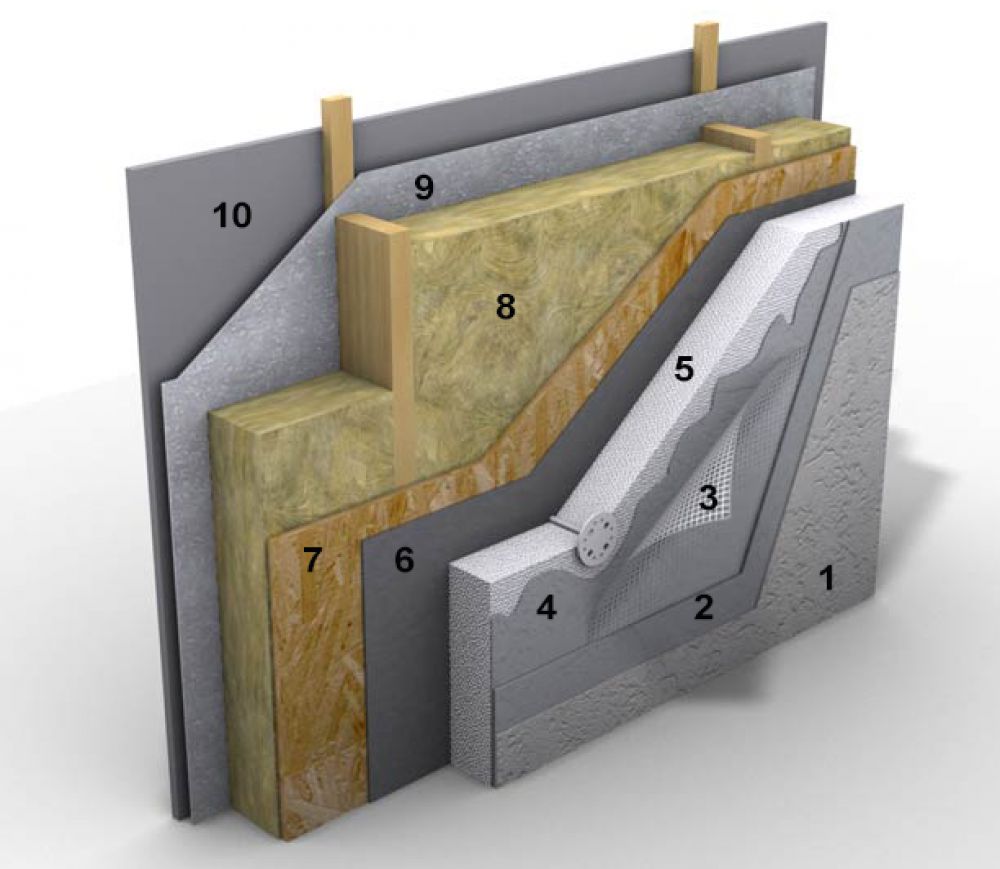

Installation diagram of CBPB plates in the outer frame wall

In facade systems, CBPB slabs with a thickness of 12 - 16 mm do an excellent job, both with constructive (power) functions, giving high strength and rigidity to the frame of the house, and with the role of a ready-made base for external finishing. The smooth cementitious surface of DSP perfectly holds the outer finishing layer of almost any material: facade paint, decorative and protective plaster or tiled cladding (ceramic tiles, artificial stone, etc.).

So, answering the question: "What kind of board material is better for the outer cladding of a frame house?" OSB-3).

views: 183466

| rating: 4

Finishing a frame house made of DSP

The outer cladding of the DSP can be done in a certain way, in which the walls of the DSP house are insulated or not. In both cases, first, a timber crate is attached to the wall at least 50x50 millimeters in increments of sixty centimeters. In this case, the lathing consists exclusively of horizontally or only vertically placed bars.

The lathing for DSP can be at the same time made of a galvanized profile used for plasterboard cladding. Then, between the crate, insulation is laid, in particular, basalt wool - it is fixed to the wall with the help of snipe, and on top the insulation is covered with a membrane that reliably protects the structure from the wind - it is attached to the crate using a stapler. In this case, the painted ventilated facade must have a gap between the membrane for wind protection and the outer edge of the sheathing of at least two centimeters.

In the facade panel, at each edge resting on the lathing, it is necessary to drill at least three holes of the same diameter as the self-tapping screw - thanks to it, the DSP will be fixed to the lathing. When finishing DSP, self-tapping screws should be used exclusively anodized and galvanized, and dark self-tapping screws will not work, since they are susceptible to rust due to which the appearance of the surface may deteriorate. To protect the structure from thermal expansion, it is necessary to make the joints of the DSP with a gap of four to five millimeters - they need to be sealed with a sealant made of silicone or putty for external work.

In the facade panel, at each edge resting on the lathing, it is necessary to drill at least three holes of the same diameter as the self-tapping screw - thanks to it, the DSP will be fixed to the lathing. When finishing DSP, self-tapping screws should be used exclusively anodized and galvanized, and dark self-tapping screws will not work, since they are susceptible to rust due to which the appearance of the surface may deteriorate. To protect the structure from thermal expansion, it is necessary to make the joints of the DSP with a gap of four to five millimeters - they need to be sealed with a sealant made of silicone or putty for external work.

If necessary, the DSP cutting is carried out using a grinder with a circle designed for stone or concrete material. A cladded facade for CBPB without decor can be painted or finished with decorative plaster, before that having processed the primer - while the primer for CBPB is applied with deep penetration.

When installing DSP on the facade for painting the boards with paint, you need to make a deepening of all screws by one millimeter and putty.

At the same time, the putty for external work can be used as a putty for cement-bonded particle board. After the putty is dry, you will need to remove the roughness with sandpaper and wipe the dust from the stoves using a damp cloth. First, a layer of deep penetration primer is applied using a brush or roller, and then, after the primer is dry, paint can be applied over the cement-bonded particle board.

Features of the use of cement-bonded particle boards for the facade

To install correctly, you should take into account some recommendations:

- Although all work can be done by hand, due to the significant weight of the panels, it can be difficult to transport and fit, therefore it is advisable to involve an assistant. But if you have to mount the products alone, then the parts are cut to a smaller size.

- For cladding, plates with a thickness of 12 to 20 mm are used. They have sufficient strength and are better able to withstand any environmental influences.

- The technology assumes that the panels will be laid on the frame. The facade must be ventilated, therefore, a counter-lattice is preliminarily arranged, especially if it is planned to insulate the building.

- An important point is the ultimate evenness of the base. The fact is that cement-bonded materials have low bending strength. Curvatures can lead to internal stress, which can lead to cracking.

- Galvanized self-tapping screws are used for the installation of DSP. For them, holes are pre-drilled, which should be slightly larger in order to exclude screwing in end-to-end.

- The cladding instructions assume that an expansion gap will be set between the slabs. It is necessary to prevent deformation during thermal expansion and shrinkage of a private or country house.

- Panels can be either sanded or unpolished. The first variety is more expensive, but is completely ready for painting, and the second one needs to be laid with plaster.

- The formed joints are sealed with polymer elastic putty or conventional sealant. If a large-scale finishing is expected, then a reinforcing tape is additionally used. An interesting solution is the use of overlays, which is especially important for the half-timbered style.

Such a number of features can be alarming, but their presence is explained by the fact that the decoration of the facade of the DSP is not yet widespread.

Is it possible to plaster osb

Having conceived to veneer the facade of their house with OSB or use particle boards indoors, homeowners carefully consider options for their finishing. In this case, the question of whether it is possible to plaster an OSB slab arises first in most cases. After all, if we neglect decorativeness and leave OSB without an external coating (especially on the facade), then even wood covered with water-repellent compounds will absorb moisture.

This water is enough to swell the stove in summer and defrost it in winter. The OSB will darken, warp and lose its strength. In addition, a serious disadvantage of OSB is the chemical component of the binder, which is why the boards must be protected from temperatures above + 30 ° C. Therefore, since the beginning of the production of slabs, builders have thought about a protective coating for them.

The following types of finishes are most often used:

- painting (the cheapest and easiest option);

- wallpapering (suitable only indoors);

- cladding with decorative panels attached directly to the plates (a rather expensive method that does not solve all the problems of preserving smallpox);

- covering with siding (does not eliminate the problem of flammability of the plates, requires additional measures for vapor barrier OSB);

- facing with tiles (suitable for rooms, but "blocks oxygen" to the wood);

- facing slabs with decorative stone coating (the most expensive and time-consuming method);

- plastering.

Types of OSB finishes

Properties that a protective coating for OSB should have:

- waterproof and waterproof;

- sufficient mechanical strength;

- temperature stability (withstand sudden jumps);

- vapor permeability;

- environmental friendliness;

- fire safety;

- long service life;

- maintainability;

- unattractiveness to mold, mildew and rodents;

- resistance to solar radiation;

- light weight;

- affordable price;

- simple operation at no extra cost;

- the ability to do it yourself.

Finishing methods

Craftsmen who have completed work with OSB panels in facade work often ponder the material that is best suited for decoration. The choice of material should directly depend on the performance that the craftsmen plan to endow the house with.

Painting

This is one of the simplest and most economical methods, but work should be done carefully. One incorrect application can ruin the overall appearance of the tiles. When carrying out work on painting the surface, the following rules must be remembered:

This is one of the simplest and most economical methods, but work should be done carefully. One incorrect application can ruin the overall appearance of the tiles. When carrying out work on painting the surface, the following rules must be remembered:

The paint selected for surface coating must be free from water

Excessive water will swell the panels and ruin the product.

In the process of work, you need to pay special attention to the edge of the slabs and paint over these places abundantly.

Experts recommend using oil-based paints when carrying out such work. This paint does not damage the structure of the panels and is deeply absorbed, creating a rich color.

In order for the texture to be completely painted over, you need to apply the paint in several layers

Do not forget that each layer must be allowed to dry.

Sometimes the owner of the house wants to additionally protect the walls with a fire retardant compound, but one must take into account the fact that not all paints are combined with such impregnations.

In such cases, priming the surface will be an additional treatment, which will be located between the impregnation and the paint layer.

Plastering

This option for covering OSB panels is the most demanded and justified for outdoor work. This type of finish has a number of features:

- experienced craftsmen carry out additional waterproofing of the surface using liquid rubber or roofing material;

- for greater stability, a plaster mesh is used, which will prevent the formation of cracks;

- for plastering the mesh, a special composition is used to carry out reinforcement in facade structures;

- it is customary to complete the plastering of the external facade with a layer of decorative plaster, which will not only be a strong protection from external influences, but also give the building a characteristic individuality.

Siding

Cladding with siding is an economical way to improve the appearance of a building.

Siding can be reinforced on the installed OSB surface.

Siding panel options are presented in a large number, so if you want, you can choose a model that imitates a block house or brickwork.

The advantage of such cladding is that if OSB boards are already glued to the side of the facade, it is not necessary to mount a flat frame. However, one cannot do without a membrane that will protect against wind and moisture.

If you do not put this additional fastener, then the siding will periodically sweat from the inside, and the OSB will swell under the influence of moisture.

If you choose between two types of siding panels - PVC or acrylic, then you can stop at any type, since there are no significant differences between them.

Facing products are produced in one thickness, ranging from 0.8 to 1.3 millimeters. They are able to withstand temperatures reaching 80 degrees Celsius and exposure to sunlight, under which they do not fade.

Both species are highly resistant to the spread of fire and chemical reagents. Acrylic panels have a rich color, but otherwise hardly differ from PVC products.

Is it possible to mount siding directly on the OSB - for practical advice on installing siding from professionals, see the video:

Durability of OSB

Usually, everyone who decided to do something like this is primarily concerned about the question - what will happen to the facade in 3-5 years if you sheathe it with OSB.

Someone thinks that the plates will swell, tk. OSB is not an outdoor finishing material.Someone thinks that such a cladding option is possible and moreover, it is optimal in terms of reducing financial costs and the possibility of self-repetition.

Victor BanevForumhouse user

Whether or not to use OSB on the facade - opinions differ. I decided that the game was worth the candle in terms of speed, ease of installation and low cost of such a facade. Just note that the OSB facade is an economical option for thrifty summer residents. To decorate a capital structure - a cottage, more weather-resistant materials should be used.

Looking ahead, let's say that the lifespan of a facade made of OSB boards has already gone to its third year, and how it looks is clearly demonstrated by the following photo.

Wall Pie with OSB

The result is impressive, and now let's get down to practice. There is an old uninsulated summer cottage measuring 6x8 meters. Outer sheathing - inch board. On top of the boards - painted hardboard. The place of alteration is the Leningrad region, i.e. an area with higher humidity than Moscow, with frequent rains, fogs and short summers.

It is required to insulate the building from the outside and make a beautiful facade. The budget is minimal. This means: work without hired workers, using relatively inexpensive materials and technology, feasible for two people. Also interesting is the user's train of thought when choosing methods of facade decoration.

Victor Banev

I don't like siding on the facade. It's boring. The block house is too expensive. The well-proven option with the use of DSP (cement-bonded particle board) for further painting and imitation of half-timbered timber also disappears. It is expensive and, due to the large weight, it is difficult to lift the sheets, and even more so, to mount them at a height. Sheathe clapboard - also not that. But I, as they say, fell for half-timbered houses and began to think how to bring this idea to life.

After going through several options, the user decided - to make the facade he liked so much for a half-timbered house based on OSB plates. This, according to the user, is much cheaper and easier than messing with the DSP.

Material selection

To sheathe a house, you need to choose the right products. For every indoor and outdoor process, there is the most suitable type of product.

OSB is divided into categories according to technical characteristics and size, therefore, when choosing, it is necessary to know the properties of the material that must be appropriate for a particular situation.

Due to the interlacing of the chip elements with each other, OSB is also called bonded plywood.

Due to the interlacing of the chip elements with each other, OSB is also called bonded plywood.

Types of OSB

There are four main types of products:

- OSB-1. The lowest class used for interior work. Such slabs are laid only in areas that are not subject to stress.

- OSB-2. This variation is more resistant to impact, but only suitable for dry rooms.

- OSB-3. The most popular type, which is used for indoor and outdoor work. Products are able to withstand constant load and variable humidity.

- OSB-4. This option is characterized by increased moisture resistance and resistance to serious mechanical stress.

It is the products of the third class that are universal and suitable for all stages of work, which allows you to minimize costs.

With a reasonable distribution of material, you can save up to a third of the budget, so it makes sense to spend on moisture-resistant OSB-3 or OSB-4 for interior work only for facing rooms with high humidity

With a reasonable distribution of material, you can save up to a third of the budget, so it makes sense to spend on moisture-resistant OSB-3 or OSB-4 for interior work only for facing rooms with high humidity

Optimal size

Products are selected by thickness, depending on the characteristics of the structure:

- For cladding a frame house, plates of 9.5 and 11 (for one-story buildings) and 12 and 12.5 mm (2-3 floors) are used.

- Finishing vertical surfaces inside rarely requires the use of parts thicker than 9–9.5 mm, except in situations where the structure will experience stress or act as partitions.

- Products with a thickness of more than 15 mm are used for the construction of main and interfloor floors.

To sheathe a summer cottage for seasonal living, you can choose OSB-6 (the number indicates the thickness in millimeters).

When buying a material, in addition to the thickness and level of moisture resistance, you need to take into account the size and weight of OSB boards

When buying a material, in addition to the thickness and level of moisture resistance, you need to take into account the size and weight of OSB boards

Types of tiles and panels for finishing the basement

The tile is used to imitate natural surfaces - stone, brick, etc. Its advantage is a thinner surface and faster installation. For finishing the foundation, the following tiles are produced:

- clinker;

- stone tiles;

- polymer sand tiles;

Clinker tiles imitate the surface of a brick. It exactly repeats its dimensions, except for the thickness

In the installation of the material, it is important to correctly lay out the first row.

To do this, you need to calculate the level of calculation. The calculation is done as follows: divide the height of the base by the width of the tile, increased by the width of the joint. If you get an empty gap, after all the tiles have been laid out, it can be repaired with acrylic or polyurethane compound.

Stone tiles are mounted on the foundation of a wooden house in the same way as clinker tiles. It is alternately laid out on the surface of the foundation, fastening the material with an adhesive solution.