Film Oracal 641 in the design of wardrobes

One of the most spacious and at the same time stylish pieces of furniture is the wardrobe. Compactness and laconism allow you to successfully fit into the design of a modern home, and a wide range of colors makes it a suitable element for any interior style.

Film on the front of the cabinet

You can effectively decorate the wardrobe with the help of the Oracle film, which is glued to the glass surface of the doors. This film has several undeniable advantages:

- Reliably glues glass. Ensuring safety is especially important in rooms with small children. If the glass breaks, then its fragments will not be scattered throughout the room, but will hang on the film.

- Does not have a negative effect on the body. The materials used in the manufacture of the film are absolutely safe.

- Limits the visibility of the interior of the wardrobe.

- Does not require special care.

- Durability. Resistant to moisture and sunlight.

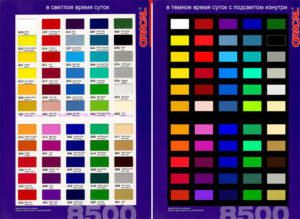

In the catalog of the OracalTrading company you can see all 60 shades of the Oracal 641 film. There are options with both a glossy and a matte surface. All colors of Oracal 641 can be seen in the photo.

Where is it used?

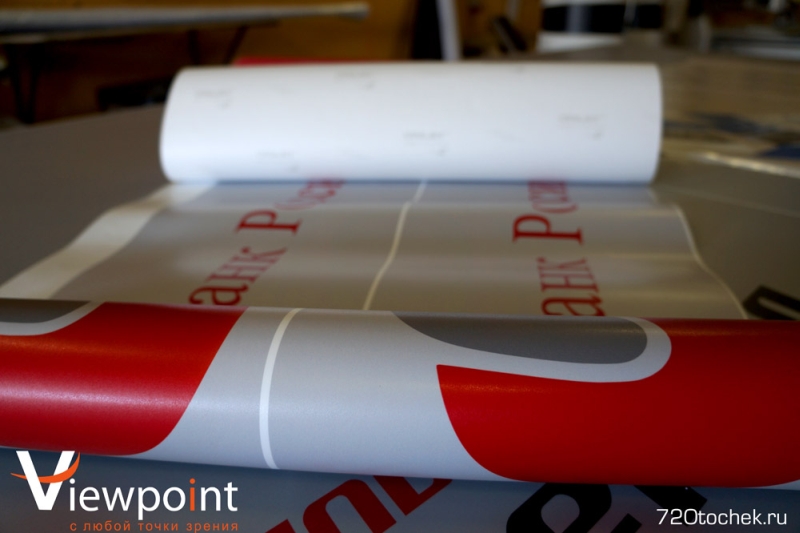

The scope of application of oracal films is very extensive. Simple advertising and information materials are made from economical options: stickers on glass and mirror surfaces, on doors and walls. Interior films are used to decorate walls and furnishings. They lend themselves well to cutting with a plotter, they are attached with magnets to any metal surface. A sliding wardrobe with an oracle applique takes on a designer look. In addition, with the help of a film, interior doors, screens, partitions are often decorated. Oracal is well suited for printing images using offset or screen printing, silk screen printing, flexography.

The film is used in advertising - when applied to vehicles, including buses and trolleybuses. Matte and glossy options are selected based on the requirements for use. Light-scattering films are used to create special advertising structures, ensure their visibility in any lighting. Self-adhesive metallized polyester film for plotter cutting works well for printing or as an appliqué backing. With its help, stickers, cut symbols and other elements used for decoration or are of an informational nature (plates, labels) are made.

The fluorescent oracle is used mainly where the visibility of the applied image is required in any light. It is used to make identification marks for specialized vehicles and equipment. Stained glass products are suitable for decorating windows and glass structures.

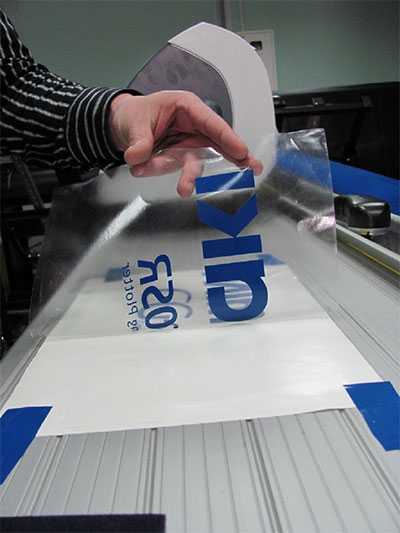

Thanks to the transparent structure, light transmission is not lost. This decor allows you to achieve an original interior design, is well suited for commercial objects, and is easy to apply. Oracal mounting film is used for stickers, helps to transfer them to the surface of glass, car body, display case.

Usage Tips

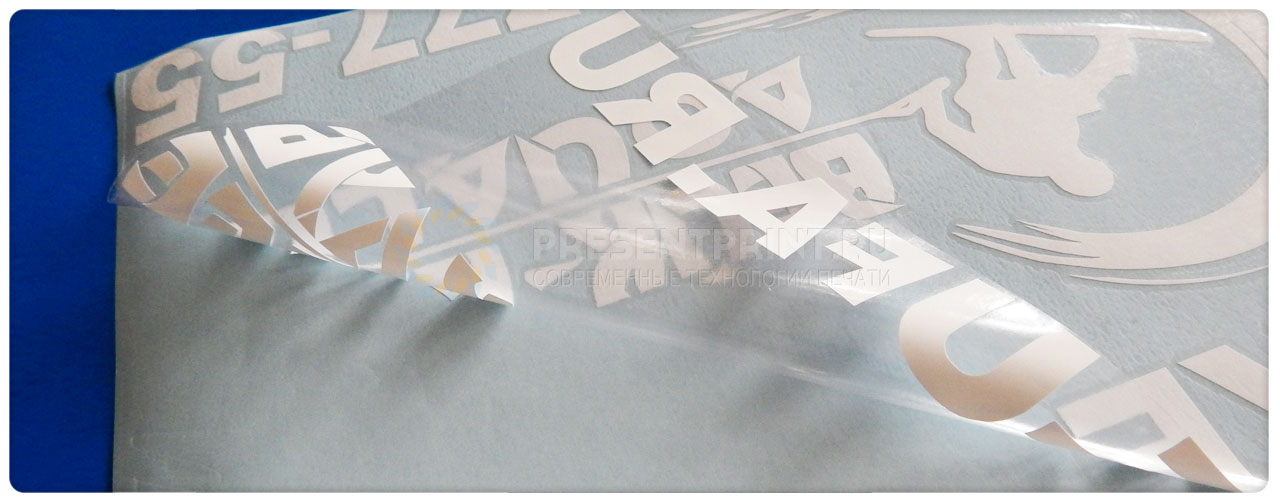

The use of the oracle film implies the observance of a certain sequence of actions. To create appliqués, a plotter is used - a special tool that allows precise cutting. Self-adhesive rolls are used in bulk, often with an image already printed on it. Plotter cutting is used only to obtain curly parts.

You can glue the film on the following surfaces:

- glass;

- metal;

- wood;

- concrete and brick;

- plastic;

- building boards and plywood.

Before pasting, any base must be carefully prepared. It is cleaned of dust, dirt, roughness, it is recommended to clean it, remove greasy deposits with solvents or alcohol solutions.

To carry out the work, you will need a sprayer with clean water, a scraper or squeegee, a stationery knife for cutting. Let's consider the order of actions.

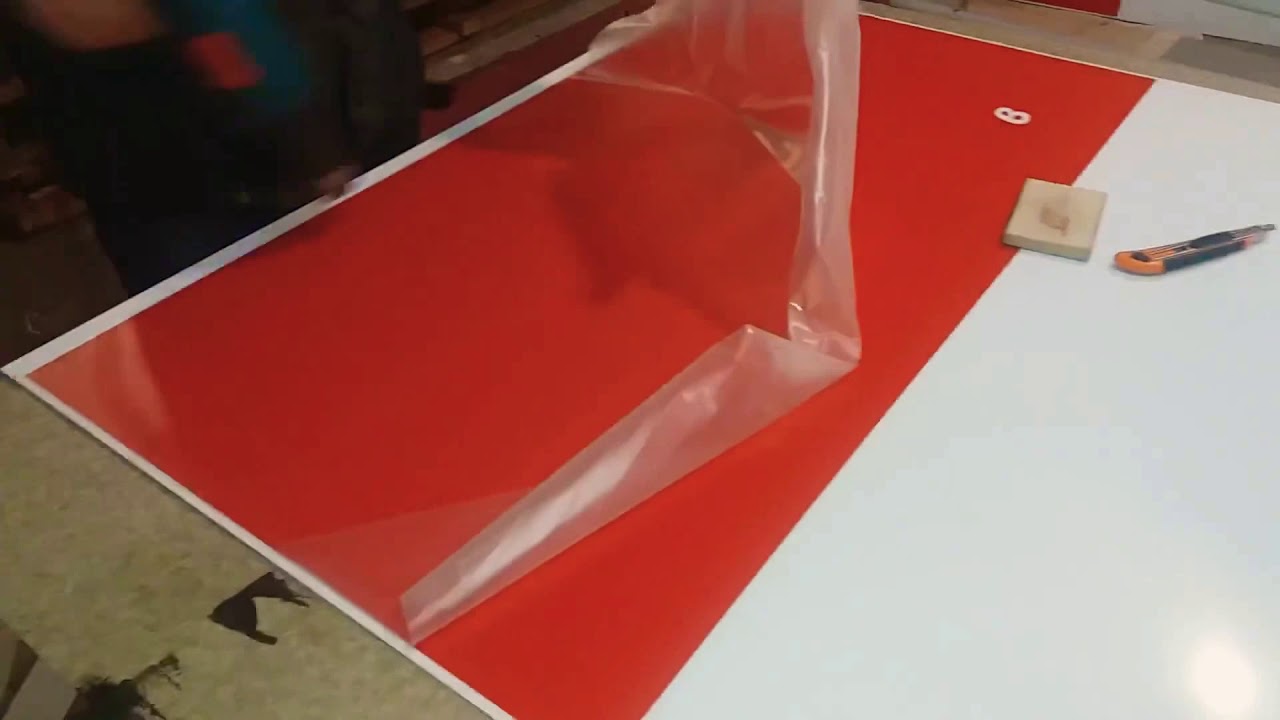

- The prepared and cleaned surface is moistened.

- The film is peeled off from the substrate.

- You need to mount the coating from the center to the edges. The squeegee smoothes out wrinkles and creases. You need to work with the tool carefully, avoiding strong pressure.

- Having completely flattened the sheet on the surface, the film is inspected for the presence of air bubbles. If they are found, punctures are performed with a sharp needle.

- With a wet method of application, the oracle can be corrected, glued. Average drying speed at room temperature is 3 days. If there is a forced ventilation system in the room, check the tightness after 1-2 days. If you find areas extending from the surface, you will have to re-iron the film with a squeegee.

With the dry method, the vinyl covering is gradually released from the backing. Bonding starts from 1 corner, you need to move gradually, freeing no more than 1–4 cm of the oracle at once. The film should be kept slightly taut, pressing it to the surface. This method is good for appliqués, but does not allow you to change the position of the stickers if they have already adhered to the coating.

For information on how to properly glue the oracle film, see the next video.

What it is?

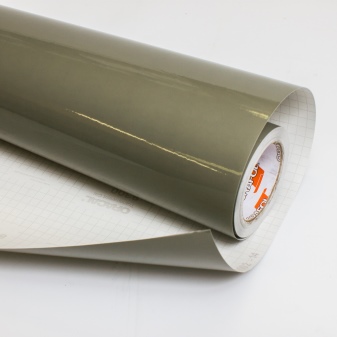

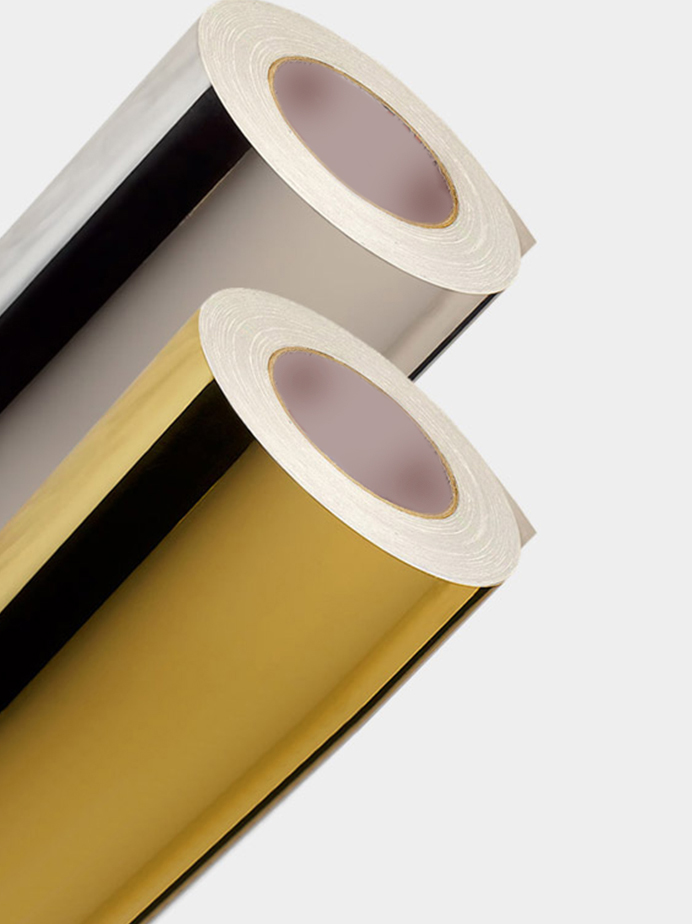

Oracal film is a self-adhesive vinyl or PVC-based material used for indoor or outdoor finishing work. Its structure is two-layer, with a paper backing. The front part is white or colored, the back of the base is covered with an adhesive. Oracal is considered to be a plotter film - quite dense to be cut with special machines. It comes in rolls.

All products are divided according to their characteristics and purpose. There are options for applications, full pasting, aggressive environment, metallized and fluorescent. With the help of plotter cutting, a wide range of advertising products, auto-tuning elements, and interior decor are successfully produced from this material.

Features of the film Oracle

Oracal is a soft plastic PVC film. A layer of varnish is applied to it, ensuring its strength. Oracal film is a self-adhesive material. It can be matte or glossy. This film has proven itself well in the design of shop windows, exhibition stands and cabinet furniture facades. This material is economical, so it is used by firms that like to frequently change the design of their outlets. When used outdoors, the service life of the Oracle film reaches three years. Indoors, their service life is not limited.

Closet

The Oracal trademark belongs to the German company Orafol - the world leader in the production of self-adhesive films. Official dealer of the Orafol company - OracalTrading. On the company's website, you can see the product catalog, familiarize yourself with the Oracle film palette. The material is produced in rolls 50 meters long.

Oracle product catalog

ORACAL 970 - cast film for full car wrapping

High-quality injection-molded self-adhesive PVC film that meets the highest requirements for durability, strength and dimensional stability, with optimal data for cutting on plotters.

The film has successfully passed tests for resistance to UV rays (according to the Volkswagen standard PV 3930), has excellent weather resistance, water resistance, including seawater. Retains an excellent glossy surface even under mechanical stress. Self-extinguishing. Resistant to most oils, greases, fuels, aliphatic solvents, weak acids and alkalis.

For ease of installation, the adhesive has a weak initial adhesion, which makes it easy to reposition the film when gluing. The pasted film can be easily removed using a hair dryer and special means to remove glue from the surface.

Colors - 25 colored glossy films, as well as matte black.

This series is designed for long-term outdoor use, including in extreme conditions. Recommended for full wrapping of vehicles, including racing cars. Colors # 117, 026, 711, 070, 363 are especially recommended for use on boat hulls. The film can be applied on uneven and convex surfaces, as well as over grooves and seams.

ORACAL 970 is very well suited for inkjet printing with solvent based inks as well as for offset printing.

Service life for black / white films - 10 years, for colored films - 8 years, for metallic colors - 6 years Thickness 0.1 mm (excluding the protective substrate and glue) Application temperature from -50 to +110 ° C Gluing temperature not lower than +8 ° C

Characteristics and markings

Oracal films are marked with the letter name of the trade mark and numbers indicating the series to which the product belongs. The dimensions of the roll material depend on its width. Usually it is 1 m or 1.26 m, the length of rolls is always the same - 50 m, in sheets it is sold at parameters 0.7 × 1 m.Oracal film density varies depending on the series, its substrate has an indicator of 137 g / m2 , made of siliconized paper. Thickness - from 50 to 75 microns, thin versions are more often used for surfaces with a large coverage area.

PVC films for plotter cutting may have certain designations.

Oracal 641. The most popular and affordable economical film has up to 60 color variations. It can have a matte and glossy surface, varying degrees of transparency. Especially popular when decorating mirrors and furniture.

Purpose of Oracle films

The oracal film is used for advertising purposes and for decoration. It has a number of advantages:

- Has a wide range of colors;

- Available in various textures, imitated for a specific material;

- Does not leak water;

- Withstands high and low temperatures;

- Does not fade in the sun;

- It is used as a decoration on buildings, premises, in vehicles;

- It adheres perfectly to all surfaces.

Thanks to these qualities, the range of application of the oracal film is wide:

For vehicles. Usually chosen when it is necessary to change the appearance of the car, which is much cheaper than repainting it. Thanks to the adhesive film, surface defects can be closed. A material with a glossy or matte surface is used. There is an oracle with an imitation of a drawing for airbrushing.

Fluorescent film. Used for advertising purposes. The fluorescent oracle has bright colors that are visible even in the dark

Used in the design of information stands when it is necessary to attract attention. It is used for decoration work in places of entertainment, mass gatherings of people.

Such an oracle can often be seen on signs and road signs. Used in the design of advertising on transport.

Mirror. Has a glossy or matte texture. Usually used to decorate a sign or plaque.

Metallized. Adheres to a wide variety of surfaces. It is used for decoration of transport, advertising stands, shop windows. It can also be used in the manufacture of personal warning signs, stickers.

Stained glass. She decorates shop windows. Used to decorate glass, used to create a design pattern in the style of stained glass. Has a bright color. Does not lend itself to sunlight. Has a wide range of colors.

Mounting room. Used to transfer images to a surface. The desired drawing or applique is cut on a plotter. Then the resulting design is transferred to the surface, which is the mounting film.It is used in the manufacture of plates for offices, shopping centers and other public places.

Oracle with a seal. It is in high demand among consumers. The film absorbs paints well, allows you to apply any drawings and texts to it. Usually used for shop decoration. Allows you to create both small forms - in the form of small stickers, and large forms - for decorating shop windows and buildings.

How to glue oracal film

The material adheres perfectly to any surface:

- glass;

- plastic;

- metal;

- wooden;

- painted;

- concrete;

- acrylic, etc.

Then the place of pasting must be wiped off. For this, solvents are used - isopropyl alcohol, anti-silicone. You can use pure vodka or ethyl alcohol.

There are two ways to apply the film:

- with water;

- dry method.

Tools required: squeegee (scraper), office knife, water spray.

For those who have not yet gotten their hands on gluing the oracle, it is recommended to use the water method. It allows you to correct the film, eliminates bubbles and unevenness. You can use soapy water.

The liquid is applied to the surface. You need to start gluing from the central part, moving towards the edges. Blisters and wrinkles are removed with a squeegee. It is not necessary to press down on the tool so as not to damage the surface. The bubble can be punctured with a thin needle, removing air from it.

The glue can dry for up to 3 days. It depends on the weather conditions. If the work takes place in a room where there is a ventilation system, then it will be necessary to check the sticker the next day, as the edges of the film can move away from the surface due to exposure to air. In this case, you will need to go through the squeegee again and press the film against the base.

The dry method is used by experienced craftsmen. Part of the vinyl is freed from the backing, with which it was decided to start gluing. A comfortable edge is usually chosen. It is pressed against the surface and smoothed with a squeegee. You need to move to the center, slowly, gluing 1-4 cm of the oracle.

Oracle remains the most demanded material in advertising and design activities. There is no alternative to it yet.

Varieties

All types of oracal self-adhesive films can be divided into categories. The main division is carried out according to the type of coverage. Gloss is used in the manufacture of vinyl decorative elements, matte options can be used in auto tuning and other areas. By the presence of pigment, transparent and colored films are distinguished. Both options are suitable for printing a variety of images and text on their surfaces.

Special varieties are focused on a narrower application. For example, reflective or light-scattering films are successfully used in the advertising industry in the manufacture of light boxes, signage, display cases with minimal energy consumption. Fluorescent applications are clearly visible on the sides of vehicles, in the beams of headlights - they look brighter under artificial lighting.

Cast

Films of this type are products of increased strength, resistant to stretching. The range of thicknesses is higher here - from 30 to 110 microns, glossiness reaches 80-100 units. The equipment for the production of film is small, the mixture is prepared in portions, which determines wider possibilities for the manufacture of decorative products with an original texture.

During casting, the PVC mixture is fed directly onto the surface of a special paper that sets the texture. This film can be embossed, textured, matte and glossy. Oracal of this type is well compatible with uneven surfaces, is not afraid of temperature extremes. In some cases (for destructible control labels, warranty seals), easily destructible materials are made, but usually their tensile strength is quite high.

Calendered

This category includes all economy grade films made from vinyl chloride resins.They have a thickness of 55–70 microns, shrink when operating temperatures change, and do not withstand significant stretching. During production, the molten base mass passes between calender rolls, stretched, embossed, cooled and wound into rolls. Already at the entrance to a special machine, the width and thickness of the future material are set.

In terms of glossiness, the range of calendered films is 8–60 units. Oracal of this type is not suitable for pasting complex curved surfaces. But it is as easy to use and cheap to manufacture as possible in comparison with cast analogs.

Manufacturers overview

Oracal film is a registered trademark owned by Orafol Europe GmbH. It is the only official manufacturer authorized to sell products with this name. However, the name itself managed to spread among designers and became a household name. Today, almost any PVC film with an adhesive backing can be unofficially designated this way.

In addition to Orafol, large brands include the following companies:

- Japanese 3M;

- Chinese Promo Film;

- Italian Ritrama;

- Dutch Avery Dennison.

On sale, all of these films can be presented as vinyl. It should be noted that European manufacturers always focus on the quality and reliability of their products. The average service life of Oracal branded film reaches 3 years with the most intensive use.

Asian brands later started production but quickly caught up with their competitors. Today, even eminent designers use Chinese vinyl products, paying tribute to its variety and design. Orafol, which owns the Oracal brand, is an internationally recognized company headquartered in Berlin. The company traces its history back to 1808, its modern name has been since 1990. During the XX century, the company was called Hannalin GK, later - VEB Spezialfarben Oranienburg. Since 1991, it has been privately owned; in 2005, a representative office was opened in the United States.

For a long time the company specialized in the production of paints for the printing industry. As a leading manufacturer of film materials for design and advertising, it began to position itself after 2011, after the acquisition of the American Reflexite Corporation, which produced ORALITe, Reflexite. Since 2012, ORACAL A.S has become part of the Orafol group of companies. Today, this division is based in Turkey.

ORACAL 352

Transparent or metallized polyester self-adhesive film with high dimensional stability and good aging resistance. A special layer is applied to the surface of the film to improve the print quality. We recommend laser, offset and screen printing with inks intended for printing on PVC, with preliminary testing. Available colors: transparent, glossy chrome, matt chrome, glossy gold, double-sided glossy gold, scratched silver.

Suitable for outdoor and indoor use. It is used for the production of high-quality decorative labels, name and technical plates, interior decoration and points of sale using applique. Especially suitable for decorating transparent bases. In such cases, a double-sided metallized film with an intense gloss gives a special effect.

Names, characteristics

Oracal consists of three layers: plasticized PVC, an adhesive layer and a backing. The property of the material and the direction of application depend on their composition.

Oracle 641

Used to decorate various surfaces. It is used for decoration work both outdoors and indoors. Resistant to weathering, does not fade in direct sunlight. Oracle 641 can be matte and glossy.

In the first version, it is used for interior decoration, advertising stands design. Gloss is used to draw attention to advertising, which is facilitated by its reflectivity.

Oracal 641 has the following characteristics:

- Withstands temperatures from - 40 to + 80 ° С;

- Roll length - 50 m;

- Thickness - 0.07 mm;

- Has two standard widths: 1 m and 1.26 m;

- The service life in the premises is not limited, in outdoor conditions about three years.

Oracal 641 is recommended to be glued at temperatures from + 10 ° С and above. Has a wide palette of colors - up to 60 shades.

Palette Oracle 641

Palette Oracle 641

Oracle 8500

Refers to the translucent type. It is used for interior decoration, production of advertising projects. Often the film can be seen on light boxes, signs, volumetric letters. The surface of the film is non-reflective due to its ability to absorb sun glare. The light is distributed evenly. Well resistant to weather conditions and ultraviolet radiation.

It has a translucent structure and a silky surface. The color palette is presented in 55 shades.

Palette oracal 8500

Palette oracal 8500

Oracle 8300

It is used for illuminated advertising of shop windows or backlit stained glass windows. Presented in 32 shades of color. It is possible to obtain an intermediate tone by overlaying color films. Has a high level of strength.

Palette Oracle 8300

Palette Oracle 8300

Fluorescent film oracal 6510

The material has a semi-glossy surface. Well visible in the dark. Used to attract attention. Limited in color gamut, presented in only 6 shades. It is used for registration of transport, designation of markings, production of plates and signs. Used in the design of entertainment venues.

Palette Oracal 6510

Palette Oracal 6510

Oracal 970

Designed for outdoor use, in particular for pasting vehicles, including racing cars. Very durable. Withstands temperatures from -50 ° С to + 110 ° С. Resistant to oil, grease and alkali. Available in 36 glossy colors, with a matte finish in three colors: white, black and saffron yellow.

Oracal 970

Oracal 970

Oracle 551

It is used to design advertisements on cars and other vehicles. Usually used in lettering. It is presented in gloss in 98 shades, with a matte surface in only two colors: in white and black. It tolerates the effects of the atmosphere well, does not fade under the sun's rays.

Oracal 551

Oracal 951

Has a mirror-glossy surface. Available in 49 metallic colors and 97 high-gloss colors. It is used for outdoor applications, most often for advertising on vehicles. Withstands the effects of weather at any time of the year. Calmly tolerates extreme temperatures of -50 ºС. It does not lose its properties even at very high temperatures above +100 ºС. It is used for difficult and uneven surfaces.

Oracal 951 palette

What is Oracle film

The self-adhesive material got its name from the American trade mark Oracal, which belongs to the ORAFOL company. Now this is the name of any film, regardless of the manufacturer, which is made of polyvinyl chloride and has an adhesive base. The second name of the film is vinyl.

Oracal is produced by:

- ORAFOL Europe GmbH from Germany, which is a division of the American brand;

- manufacturer Ritrama from Italy;

- manufacturer Avery Dennison from Holland;

- manufacturer 3M from Japan;

- Promo Film manufacturer from China.

Chinese manufacturers of self-adhesive films have appeared relatively recently. They offer prices lower than European counterparts. They managed to raise the quality of products and compete on equal terms with well-known brands from Europe and America.

Oracal material production technology divides it into two types:

- Calendered;

- Cast.

In the first case, the plastic mass is rolled through special shafts. In the second case, the film is produced without mechanical stress.

Cast film has many advantages against its background. Elastic, does not shrink. Can be applied to embossed surfaces.

As for the glue, two types can be used in the production of oracal: water-based and solvent-based.