What it is?

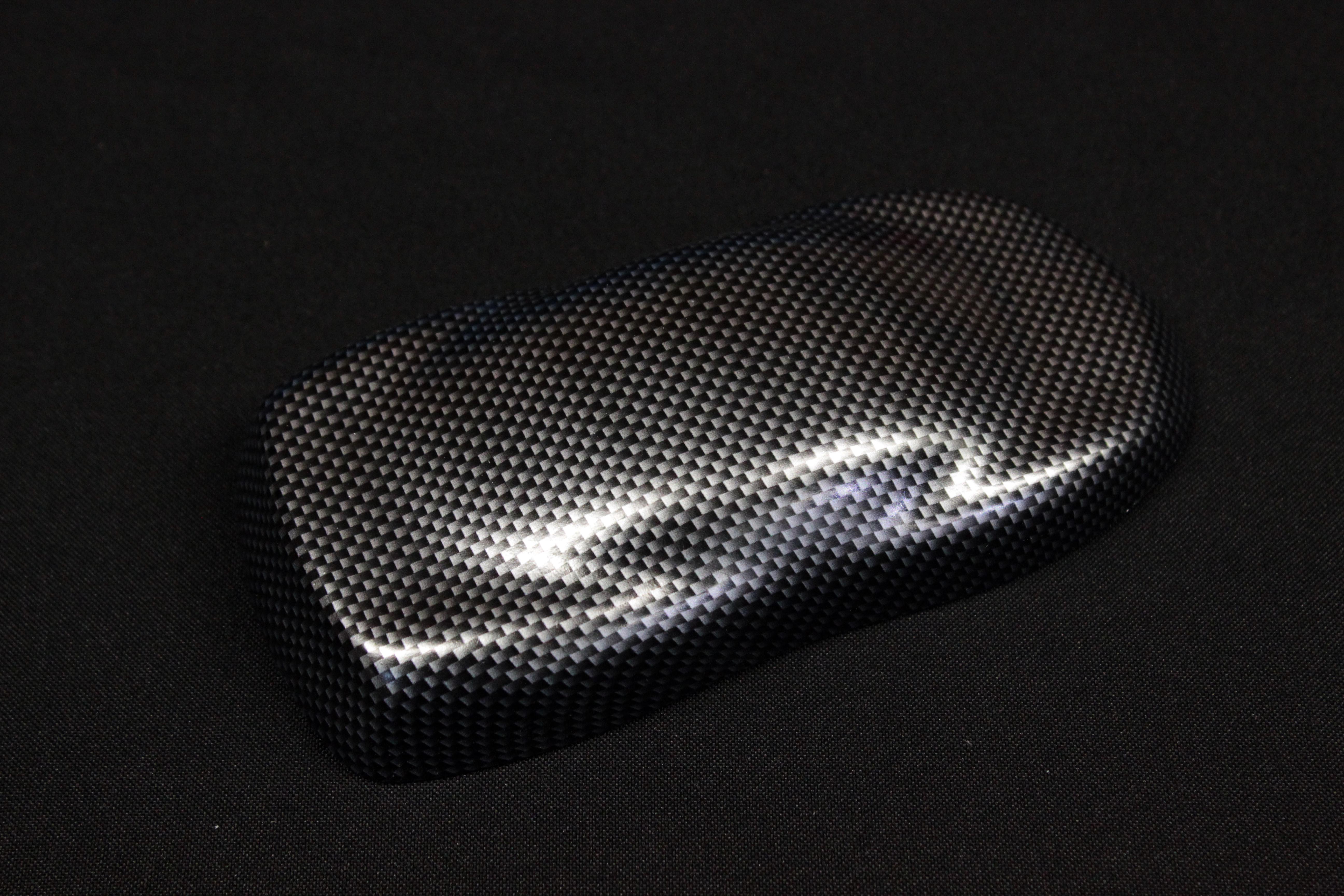

Aquaprint is one of the latest technologies that allows you to apply a special coating with a pattern to any solid volumetric surface. The drawing can be anything, imitate the texture of different materials. For example, coloring can be like stone, metal, wood, animal or reptile skin. The technology has other names as well: water-printing, immersion printing, hydro-printing. Aquaprint is not only a way of decoration, but also protection of products from various influences. The material has many advantages:

it can be applied to almost any surface, for an object of any shape;

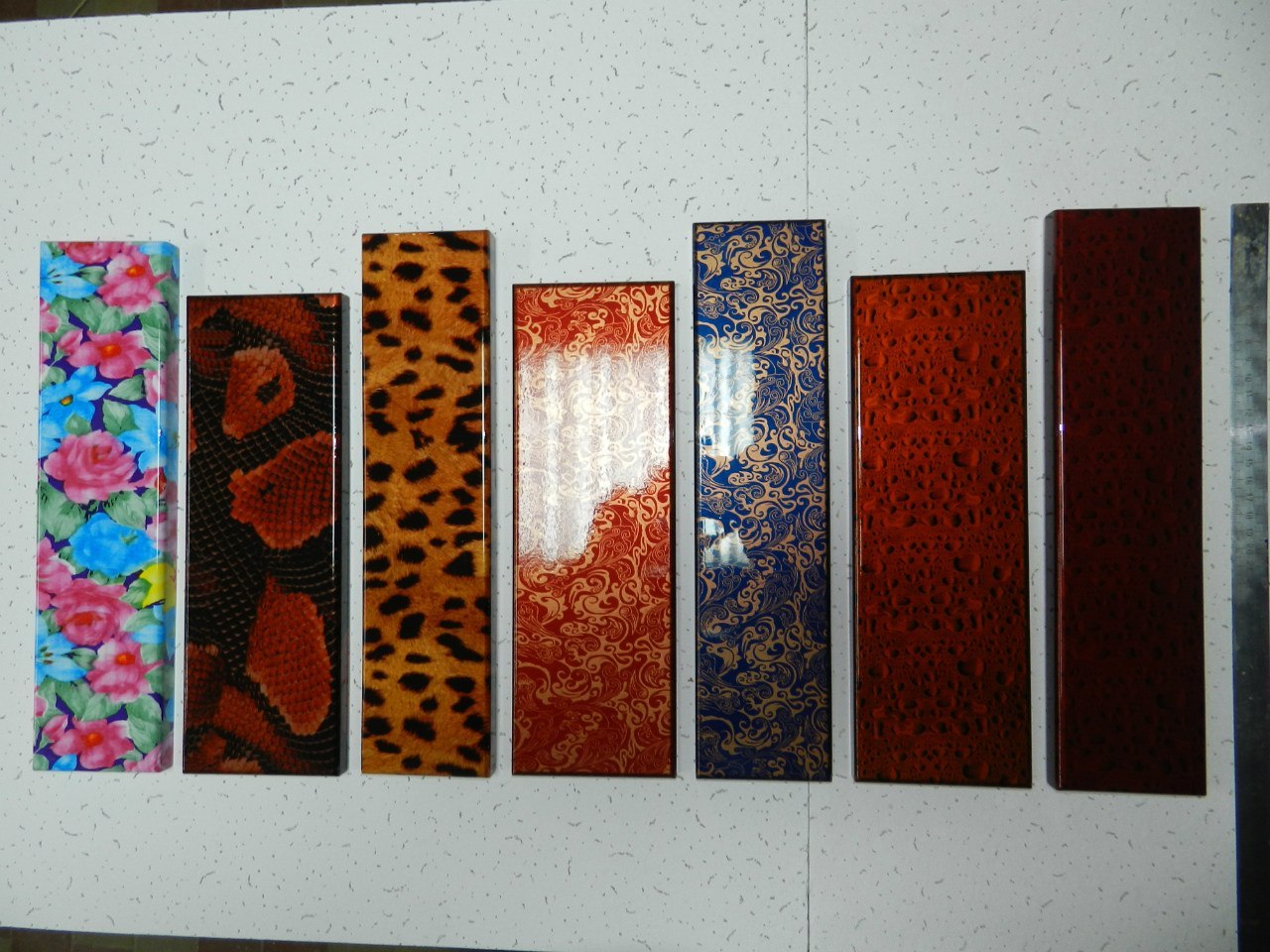

although the aquaprint film has a certain color pattern, the final version can be varied by changing the tone of the base and using different types of varnish for the finishing;

the coating is not subject to cracking and peeling;

withstands temperature extremes, products can be operated in severe frosts (up to –40 ° С) and in extreme heat (up to + 100 ° С);

does not fade in bright sun - UV radiation does not affect it;

has a high resistance to adverse environmental factors and weather conditions, the product can serve in the open air for up to 15 years;

protects parts from mechanical damage, as the material is resistant to abrasion;

tolerates vibrations well, which is especially important for motorists;

does not require special care;

the product is presented in a wide range at an affordable price.

Although the material for aqua printing looks like a film, it is not entirely appropriate to say that the film will be applied to the surface. The secret lies in the features of the application. The product is carefully placed in a container with water heated to 25-30 degrees. The dissolving layer should be at the bottom. Under the influence of water, it turns into a jelly mass. In this case, it is necessary to ensure that water does not fall on the surface of the film, otherwise the drawing will be damaged.

When the top layer softens (after about 2 minutes), the surface of the film is treated with a special liquid - solvent. It dissolves the top gelatinous layer, leaving a thin layer of liquid paint on the water.

The part is carefully lowered into the container without haste at an angle of 35-40 degrees. The applied drawing is allowed to gain a foothold in the air for several minutes, then the part is washed from the rest of the jelly mass

The dried part is varnished.

The part must be prepared before painting. It is sanded and degreased, as it should not be slippery. Then the primer is applied. Better if it is acrylic based. The color of the primer depends on the personal preference of the owner of the part.

The disadvantage of this method can be considered the need to accurately follow the process technology. It is imperative to adhere to the required values of the water temperature and the exposure time of the film on the water.

Applications

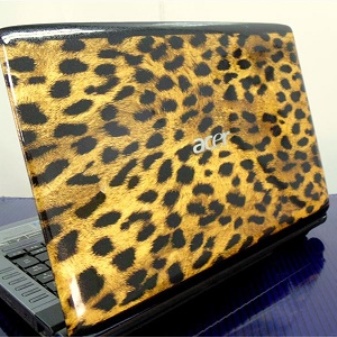

The technology allows you to make a coating on any kind of material and transfer different textures, therefore, it finds a wide range of applications. Very often it is used to decorate furniture and interior items, since the coating can be applied to wood, plastic, fiberboard, plywood, glass. The method is often used by manufacturers of souvenir products. This original method is suitable for decorating sports equipment, musical instruments, weapon parts, gadget cases.

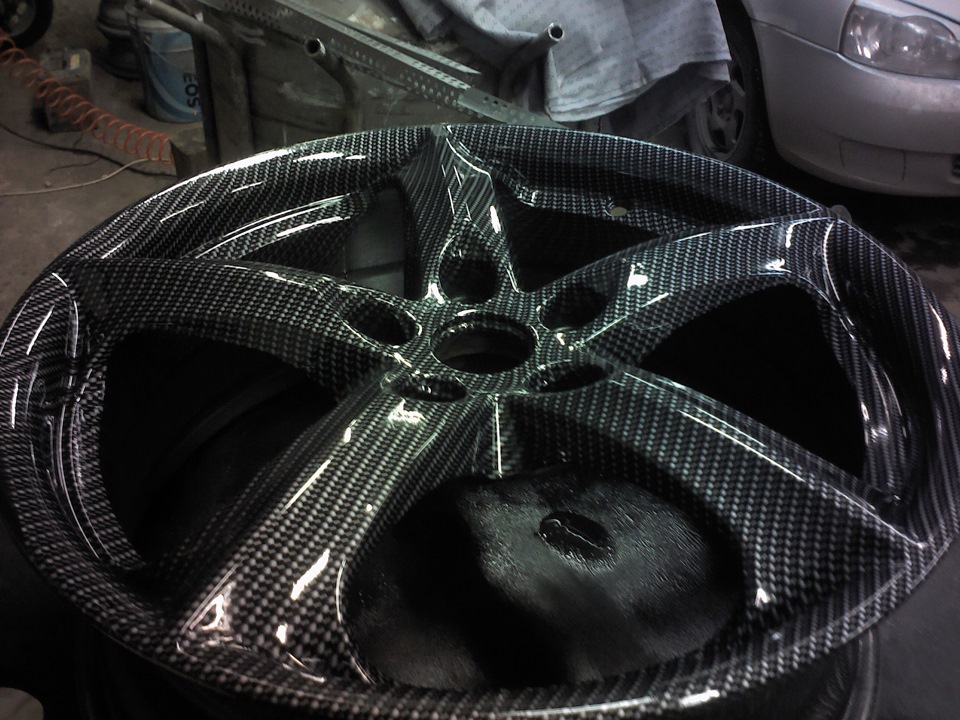

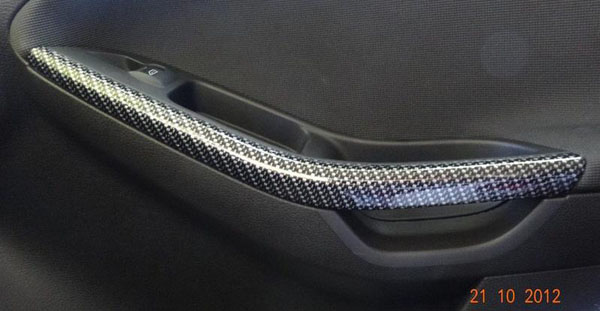

Aquaprint is especially in demand among motorists. This is not only a great way to give your car a stylish look, but also a way to hide scratches. Of course, for large volumetric parts, special equipment is needed, for example, a bathtub.A professional workshop will provide a quality service, but it will not be cheap. But aqua printing can be used not only in the professional field. Small details can be easily decorated in the garage and even at home. You should be aware that in the same composition it will not be possible to paint 2 parts.

Aquaprint

AQUAPRINT (aqua printing, immersion printing)

If you are bored with worn-out parts of the car interior (wheel disks), or you just want to give a new (exclusive) look to some parts of your favorite equipment (office equipment, furniture and much more), you should know that the new technology "aquaprint" is what you need necessary!

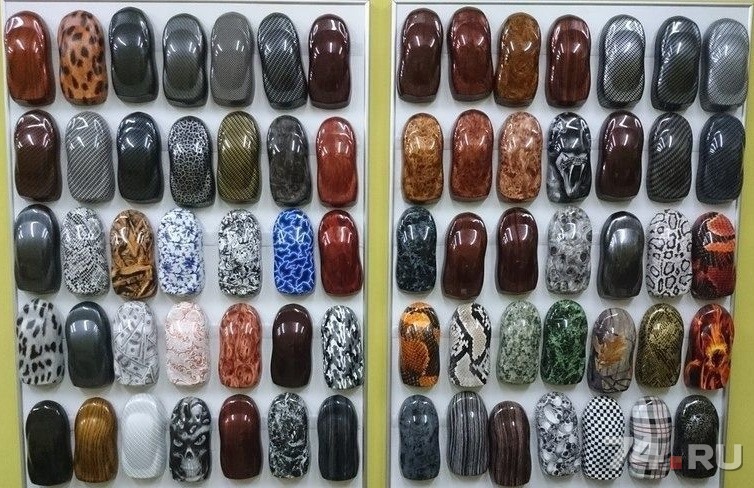

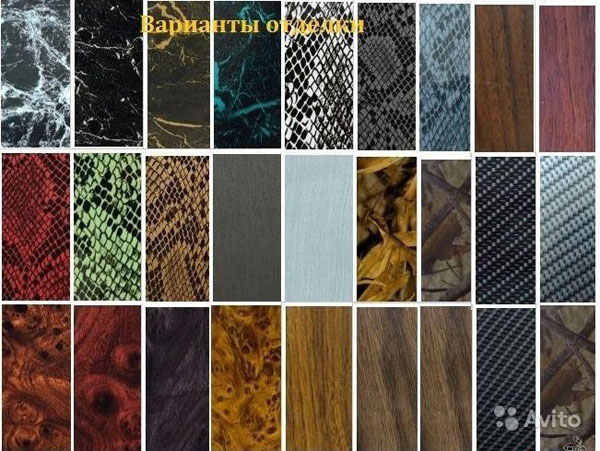

Aquaprint (aqua printing, immersion printing) is an innovative technology, with the help of which a decorative coating that imitates a variety of textures can be applied to the most complex part, imitating a variety of textures: under expensive types of wood, metal, stone, carbon, camouflage, reptile skin, animal skins, any abstractions…. Over 100 textures that mimic all of the above!

The full name of the technology is 3D decoration - "immersion printing". And the name "Aqua Print" is a synonym that has taken root in everyday life.

What material can be applied to?

Parts to which such a coating can be applied can be from a wide variety of materials: - metals or alloys - plastic - wood, plywood, MDF - glass or ceramics - composite materials

Durability and resistance of the coating

The decorative coating made using the "aquaprint" technology is multi-layered and resistant, which means it is durable. prolonged exposure to vibration, resistant to ultraviolet radiation, sea water, as well as to the effects of various reagents and other aggressive media!

Where is it applied?

Thus, the technology of aqua printing is applicable in a wide range of areas for decoration: - cars (interior and exterior parts) - any water transport (boats, yachts, etc.) - motorcycle technology, electronics, office equipment, various gadgets, household appliances, etc. - sporting weapons and equipment - airplanes - furniture and interior items - even shoe details and much more!

Layers of decorative coating "AQUAPRINT":

-

Base - the surface of the product itself, on which a new coating is applied, usually sanded, primed, primed, sanded again, then painted in a base color, which will play an important role in the final result. If the original color of the product itself corresponds to the base color, then subsequent layers are applied directly to the surface of the part.

-

The second layer is a special film with a pattern applied (a pattern that imitates a certain texture of the future coating). It is made on a water-soluble basis, which is pre-softened in water with strictly defined parameters. According to the process technology, the surface of the film is treated with a special activator, under the influence of which the film dissolves and the pattern itself remains on the surface of the water. The previously prepared part is lowered into the water and the decorative pattern from the surface of the water passes to it. This is followed by the washing and drying steps.

-

The last layer is the application of a layer of varnish for protection and decorative purposes.

At each stage of the technology, many nuances play an important role in obtaining a high-quality coating: regulated periods of time for certain moments of the process, special devices, the speed of certain manipulations. All these conditions, as well as the availability of special equipment, and most importantly - the experience of qualified specialists - a guarantee that the result obtained will satisfy you for many years!

Avto DP services - Tuning atelier

- Tuning of interior parts of a car, boat, motorcycle - Tuning of disks - Tuning of side mirrors, handles - coating of "aquaprints" diff. household items, interiors, office equipment, etc.

Avto DP - Tuning studio can offer you an individual design and the highest quality samples of the "Aqua Print" technology.

The cost of the "aquaprint" service

The cost is calculated individually in each specific order and depends only on the area of the part to be coated. On average, about 5 rubles / cm2.

Application secrets

To get the expected result, you need to follow a few simple step-by-step tips:

- first you need to decide on the front side and the wrong side. It's simple - wet your fingers and grab the tape. The side that sticks and will be the wrong side;

- it is necessary to cut off a piece of material with a margin, so as not to miscalculate. And immediately you need to make small notches around the entire perimeter, observing a distance between them of 2 cm;

- then place the aqua film in the bathroom with the wrong side down and fix it. Before that, you need to prepare the water - heat it in the range from 29 to 34 oС;

- if you are still in doubt about the choice of the color of the film material, you can prepare colored paper in a tone similar to the color of the surface to be treated and put it under the film. This will clarify the final picture. If the resulting combination does not suit you, then you can simply fix it by changing the base color. It is only necessary to choose the right shade of primer or paint;

- after immersing the film, the activator can be applied after two minutes. This requires a spray gun with a small nozzle diameter. It is applied in a zigzag pattern, first horizontally, then vertically. When interacting with a solvent, the film transforms into a jelly-like mass and floats;

- the time interval between the application of the activator and the immersion of the part should not be more than three minutes. Otherwise, the solvent will cease to work, and all efforts will be in vain;

- the selected product must be immersed in water at first with an acute angle, if any. If not, then the whole part is immersed at 45o. When carrying out this, there should be no drafts in the room. Then it is immediately taken out and sent to drying;

- after drying, varnish is applied. This is done using the same spray gun, but with a large nozzle diameter;

- the varnish is applied in several layers. Sanding must be carried out before each coat is applied (5 coats are recommended). And after completing the last, the product must be polished. You can add mother-of-pearl or metallic to the lacquer content for an unusual effect.