Features and purpose

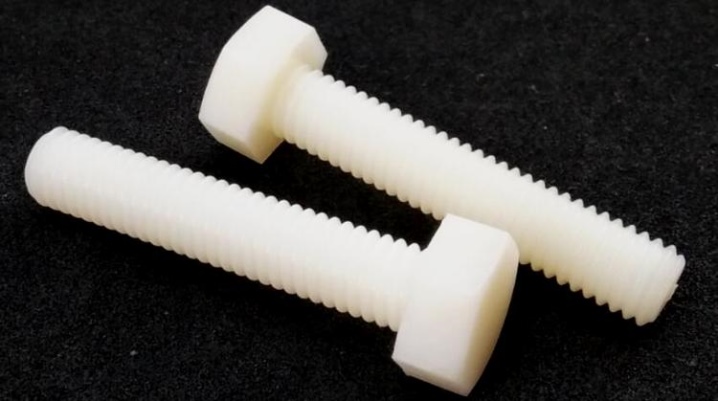

Recently, people have been trying to use inexpensive, but at the same time, high-quality materials for the construction of structures, the manufacture of household items and fasteners.

For this reason, the use of plastic hardware is now especially relevant. Due to the change of metal fasteners to polyamide, the cost of manufactured products has been significantly reduced, its weight has decreased, and the manufacturing process has been facilitated.

The bolts are made of plastic mass in the foundry. Initially, a pressed mold is produced, namely a matrix consisting of two halves. After that, thanks to the action of pressure, the finished plastic fastener is removed. Since plastic hardware is lightweight, it takes less money, materials and time to make it, which cannot be said about similar metal products.

In addition, this hardware has good impact strength and elasticity even at temperatures of -20 degrees Celsius. The plastic bolt is not adversely affected by alkali and acid. Also, this product, resistant to an aggressive environment, does not deteriorate from ultraviolet radiation and atmospheric precipitation.

In order to save money, many manufacturers replace metal hardware with plastic ones, as they value their advantages:

- sufficient level of strength;

- corrosion resistance;

- resistance to negative environmental factors;

- the ability to thermally insulate and dielectricize the surface;

- ease of processing;

- ease of applying paint and varnish coatings;

- environmental safety;

- affordable price.

The disadvantages of plastic products include the following points:

- low bearing capacity;

- not too long service life;

- the ability to hold extremely light material, for example, wood, plastic.

It has found its application in the fastening of sandwich panels, cable structures, plumbing, furniture. Also, universal hardware is relevant for lag fasteners, toilets, and all kinds of decor.

Varieties

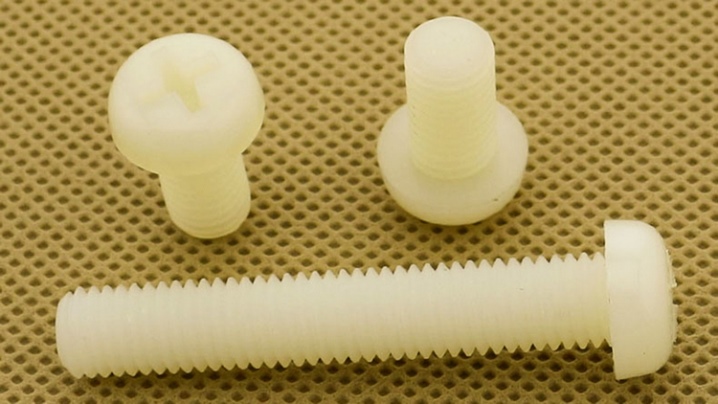

There is a wide range of plastic bolts on the hardware market. According to the standards, they can be of such varieties.

- DIN 933 is a bolt with a hex head and full thread.

- DIN 931 - a product with an incomplete thread, in which a hex head and strength class A, B.

- DIN 603 is a plastic type of fastener that is used in the furniture industry. The bolt has a semicircular head and a square headrest.

The consumer can purchase a bolt made of plastic with a different leg length, which ranges from 2 to 50 millimeters. Also on sale there are products for fasteners, which are black, white, silver, copper and gold, so everyone can choose a suitable hardware option for solving their problem.

Among the popular types of plastic fasteners are the following:

M6;

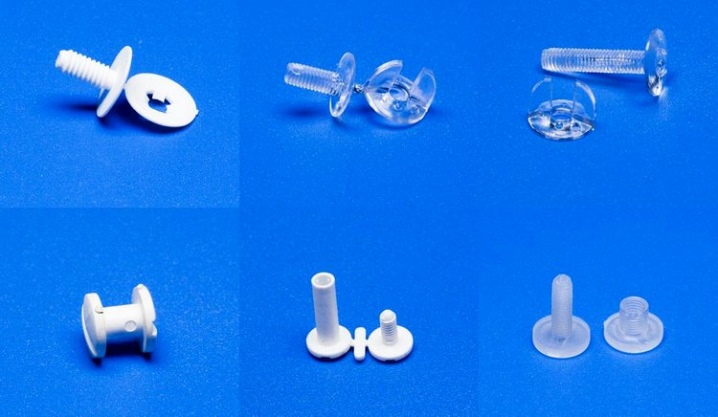

By design, bolts are divided into furniture, construction, plumbing, and universal. The heads of this type of hardware can be of the following varieties:

- notched;

- with a headrest;

- with a semicircular and hex head;

- with an eyelet;

- with T-shaped heads;

- with an eyelet, whisker or flange.