Tips & Tricks

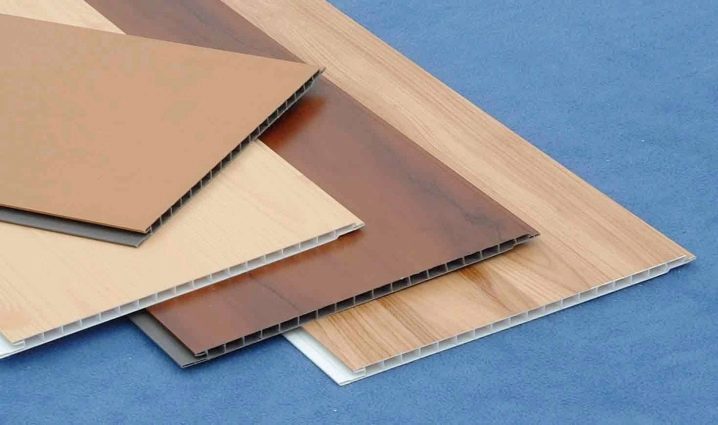

Plastic lining is an ideal material for cladding buildings with high humidity, such as baths. When buying materials, it should be borne in mind that the color of the lining will differ from different manufacturers.

When choosing a plastic panel, it is worth taking into account the cost of products, since quality products will be distinguished by a high price. However, in order not to buy expensive products of poor quality, it is worth considering the main points that will determine the quality of the lining:

However, in order not to buy expensive products of poor quality, it is worth considering the main points that will determine the quality of the lining:

- the ability of the material to withstand the load depends on the thickness of the elements. The standard panel thickness is 10 mm;

- the thickness of the front surface of the product should be such that the stiffeners are not visible through this side, otherwise a lamella of this quality is not recommended for use as a material for exterior decoration;

- the strength of the product depends on the number of ribs and their rigidity;

- the distance between the ribs should not be more than 10 mm;

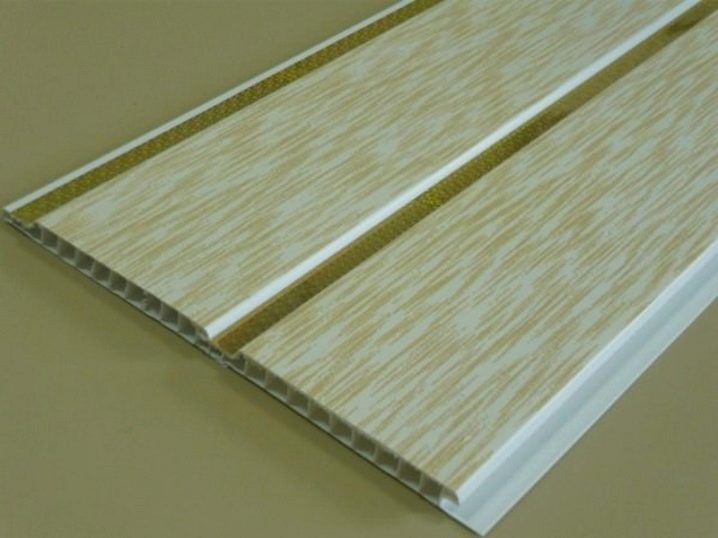

- uniformity of color of the entire product. Many manufacturers do not add a coloring pigment to the polymer composition during production, but prefer to process only the front side with it. Such lining will very quickly lose its color, and possible scratches and defects will be clearly visible on the surface.

When purchasing lining, you need to familiarize yourself with the product certificates, since the panels are made from toxic raw materials. A newly opened package may have an unobtrusive, but specific smell, which is considered the norm. If the smell is felt from a product that is in the store as a sample, then it is worth thinking about the safety of using such products.

The weight of the finished product depends on the wall thickness of the lamellas and the number of ribs. The standard value is considered to be in the range of 1.1-1.5 kg / m2. Before buying the entire batch, it is worth testing the panels for good fit with each other.

Experts agree that good quality products should not contain more than 20% chalk. Its overabundance is fraught with a decrease in the strength of the raw material. Chalk is a low-cost material, therefore it is often used in production in order to reduce the cost of finished products.

It is very easy to check the permissible content of this component by bending the corner of the panel slightly. If a crack has not formed at the bend, you can use such material. A white stripe or defect indicates an excess of its norm in the total mass.

It is not worth saving on the purchase of materials for facade cladding, since this can result in cost overruns due to the need for repair work with low-quality products. A good plastic lining will become a decoration of the house and will not change its aesthetic and physical properties for a long time.

Lining

To preserve the appearance of a traditional Russian bath, when decorating the outer walls, a common cladding material is used - lining. Euro lining is especially in demand. This is a wooden board with a small thickness. The lining has all the advantages and disadvantages characteristic of wood. To extend the service life of the euro lining, it is treated with antiseptics, varnished or painted.

In order for the lining of the bath to be done correctly, it is necessary to strictly adhere to the installation technology. The step-by-step execution of all operations will allow you to independently make the cladding:

- Install brackets on the wall. In this case, it is necessary to observe the step, which should not exceed 50 cm. The brackets must be placed horizontally.

- Cover the outer surface of the wall with mineral mats. Use prepared adhesive for fastening. The use of dowels is permissible.

- Attach a rail to each bracket. To check the correct location of these parts of the finish, use a building level, a plumb line.

- Cover the insulation with a waterproofing material.

- Attach the lining to the fixed guides.

Baths can be sheathed with clapboard with a humidity level of no more than 15%. Otherwise, after drying, unwanted gaps may appear in it.

Scope of application

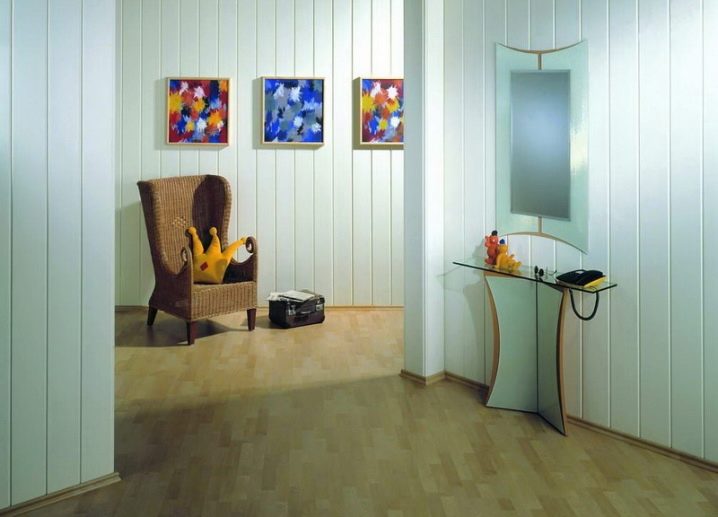

If we talk about wooden lining, then it is more often used as wall cladding inside a log house. In the interior, the lining is used as a decorative design for rooms. A design with wooden clapboard can be a bright accent on terraces and balconies.

Craftsmen who provide wall cladding services argue that the most difficult is the fastening of wide panels. And the designers advise to diversify the appearance of the cladding, combining wide and narrow lining panels.

There can be two options for lining with wooden clapboard:

- Horizontal. Sheathing is performed from the corner.

- Vertical. Fasteners are made from floor to ceiling.

There are several types of plastic lining. For example, the most economical option is vinyl wall paneling. It is only suitable for interior decoration. As an external finish for a summer residence, PVC lining is suitable for outdoor work. It is resistant to frost, as it contains special components.

The scope of application of MDF lining is inside cladding. This is a commonly used material for decorating a hallway in an apartment. Lacquered MDF panels are a common bathroom finish. Moisture and steam are not terrible for this material, as well as other negative factors.

These panels are distinguished by numerous installation options.

In addition to vertical and horizontal arrangement, such methods are known as:

- herringbone styling;

- combined styling.

Aluminum lining is used for interior and exterior decoration. They can be used on the ceiling provided they are carefully insulated. Aluminum is a good conductor of electricity, so even a small bare section of the cable will cause very large damage.

Aluminum lining can also be used as wall decoration. The order of work also implies complete isolation of the wiring.

If all requirements are met, the use of aluminum lining entails the following benefits:

- profitability;

- aesthetics;

- durability;

- easy care.

Preparatory work and necessary tools

For any construction and repair, the premises must be prepared. The same applies to balconies, or rather, to a particular extent.

The fact is that balconies of the old housing stock most often require repair and decoration. In such houses, structures have not been repaired for decades, and many floors can be dangerous to use.

Therefore, the first step is to check the quality of the floors, the base plate of the balcony. If the assessment of the load on them during high-rise work shows a disappointing option, you will have to start the arrangement with a major overhaul.

If these problems have bypassed your balcony, a number of preparatory work should be performed:

- clean the base plate;

- clean all joints and crevices of debris and dust, weld and seal them;

- remove old railings;

- remove old coatings;

- clean and prime the rust on the metal parts of the frame;

- level the base with concrete mortar.

Video for repairing a balcony slab:

With the help of these simple actions, you can give the balcony a fresher and more civilized look already at the first stage of the repair.

To carry out the work, you will need at least a basic set of tools, namely:

- Roulette;

- Building level;

- Hacksaw for metal (or wood, depending on the selected materials);

- Scissors for cutting metal (or plastic);

- Rotary hammer with a wide range of drills;

- Screwdriver;

- Bulgarian;

- Construction stapler, hammer.

Depending on what material you choose for the lathing and finishing of the balcony outside, you will also need various fasteners.

Interesting style solutions for outdoor decoration of the balcony

To finish the balcony outside was not only high-quality and functional, it is worth thinking about various style solutions. You can look for options among the balconies of neighbors, or be inspired by design solutions.

Here are some interesting ideas:

- Siding panels can be combined by color - for example, trim the lower part of the balcony with a darker shade, and the upper one with a lighter shade. Or highlight the area under the window with a wide bright stripe;

- Finishing with "brick" or "natural stone" material will make your balcony stand out from the rest. On the other hand, such a solution will be successful for giving a single style to a private house;

- You can experiment not only with color, but also with the shape of the balcony itself. One of the walls with a slope, beveled corners, a broken shape of the balcony - all this will give it a unique appearance, which can be emphasized by high-quality finishing;

- The combination of side wall decoration with fully transparent panoramic glazing of the front wall of the balcony will give a stunning effect not only outside, but also inside the room;

- For corner balconies, you can try to make a smooth rounded transition from the front wall of the balcony to the wall of the building. Such a balcony will organically fit into the geometry of new buildings.

Thus, with a little imagination and studying the issue of the reliability of materials, you can achieve an amazing result with the help of a well-executed outdoor balcony decoration. On the one hand, all neighbors and passers-by will be amazed at the original design, on the other, you can enjoy the peace and quiet on the balcony after all the stages of its renovation are completed.

Useful siding video:

Choice of materials

How to decorate the facade of a house from a bar? It is more convenient to sheathe a wooden case with materials that are easy to attach. Therefore, they choose lining, block house, imitation of timber, thermal panels, etc. The main condition for cladding is the presence of ventilation in the walls, which is created due to the gap between the wall and the finishing material. When using facing materials (bricks, tiles, plaster), they try to create ventilation holes so that the wood does not end up in thermal insulation. If the walls don't breathe, mold and mildew will form inside.

The building materials market is always ready to offer a suitable material for the exterior decoration of a wooden house. Options are chosen based on their capabilities and requests. Any building material has advantages and disadvantages:

- Imitation of a bar is an environmentally friendly material that allows you to decorate and insulate a house after standing; has unique characteristics of wood, since it is made from coniferous trees; resistant to external factors due to the resin content. The disadvantages are that there are too dense knots, increased fire hazard;

- Wooden lining is a wood material that preserves all natural properties; has high wear resistance with proper surface treatment; increases the steam exchange functions of the bar. Disadvantages: requires periodic processing and coating;

- Block house - one of the varieties of lining with imitation of the rounded surface of the log; easy to install; often ready-made structures are made from such material. Disadvantages: like other natural materials, it is susceptible to moisture;

- Vinyl siding is a lightweight, practical material that is resistant to weather conditions; available in different colors; budget option compared to natural wood. Disadvantages: does not always withstand loads, gaps may appear between the elements at high and low temperatures;

- Metal siding - imitates wood materials while remaining a fireproof material; the colors and shape are different; minimal surface care; easy to install, does not require a foundation. Disadvantages: does not allow the exit of the vapor formed in the walls;

- Thermal panels - made of high quality concrete with practically no water; the product does not crack, withstands low temperatures and retains heat; have a unique design solution, imitating brick, tile, stone, etc. Disadvantages: can be destroyed by moisture;

- Decorative brick - provides a high level of thermal insulation; durable and reliable material in a variety of shades. Disadvantages: requires a reliable foundation and sufficient roof overhang;

- Facade stone - used more often for laying paths; made of natural stone, therefore it is expensive; fits on walls according to the principle of tiles; withstands any temperature extremes, moisture resistant, but allows the house to "breathe". Disadvantages: expensive, requires professional skill when laying;

- Facing tiles - made from baked clay; for outdoor work, choose a frost-resistant product with a moisture-repellent coating; comes in different configurations and colors. Disadvantages: for laying on a timber requires preliminary leveling of the walls;

- Fiber cement panels - made using the latest technologies from cement, reinforcing fibers, mineral fillers; resistant to stress and temperature extremes; come in different colors or are painted after installation. Disadvantages: in the absence of ventilation, they retain the escaping moisture, exposing the wood to rotting;

- Plaster is a simple and affordable material that allows you to level any walls; gives the house a modern look; you can choose any color that is added to the finished mixture; the most resistant are acrylic paints. Disadvantages: tightly closes the wooden wall, making the room unventilated.

Having decided on the appropriate type of material for cladding a house from a bar outside, they prepare everything necessary for finishing work. If you plan to do everything yourself, make sure to purchase a sufficient amount of materials, as well as have the necessary tools and devices on hand. Decorating the walls in a house from a bar will require work at a height, so you must adhere to safety rules in order to prevent industrial injuries.

DIY PVC lining panels installation

Do-it-yourself installation of pvc lining panels begins with the installation of all additional elements. If the panels cover the wall to the ceiling, then a ceiling plinth is attached to the upper part of the wall. To close the cuts of the lining panels at the bottom, cutouts of doors and windows, an initial strip is used. If you want to combine the colors of the panels, use connecting elements to join them.

Insert the tongue of the first panel into the groove of the adjoining element (usually installation starts from the corner, so this will be an element of the outer or inner corner). Make sure the panel is perfectly level with the corner of the surface to be trimmed using a level or plumb line. Then fasten the bottom edge of the groove to the frame bar with a metal bracket or nail. Insert the second panel firmly with the comb into the groove of the first one, make sure there are no gaps, and secure it. The width of the last panel must be reduced from the side of the groove relative to the center of the additional element by 6-8 mm. First place the panel in the groove of the adjoining element and then push it firmly into the groove of the previous panel.The last panel does not need additional fastening.

On surfaces lined with PVC panels and clapboard, dust does not linger, they are easy to clean and do not deteriorate from water. A damp cloth is sufficient for routine cleaning. In case of severe contamination, use any detergents, the main thing is that they do not contain abrasive components that can scratch the surface of the plastic panel (lining). According to the manufacturers, under normal conditions the plastic coating will last for decades.

Materials for exterior decoration of the house

There are many different materials for finishing the facades of houses. Let's take a closer look at the pros and cons of the most popular of them.

Fake diamond

Artificial stone is perfect for the design and construction of luxurious columns and cornices, it is much lighter than natural, so its transportation and installation will cost less. In addition, there is a huge selection of colors and shades of artificial stone. A significant disadvantage is the shorter service life.

A natural stone

It is an environmentally friendly material that is absolutely safe for human and animal health in any climatic region. Natural stone is more durable, has high energy savings and is easy to install, so you can do the cladding of the house yourself, thereby reducing the cost of work. Its disadvantages include a fairly large weight and high cost compared to other materials.

Block house

The block house is distinguished by good mechanical strength, which allows it to withstand the effects of the external environment. In case of damage to the material, the appearance can be easily restored by sanding or painting. Natural wood finish makes the building more attractive. Also, the advantages of a block house include a small load on the foundation, ease of installation, and the provision of additional insulation of the house. In order for the material to retain its properties of durability, aesthetics and reliability, it must be periodically covered with paint or varnish.

Special facade tiles

For cladding facades, clinker, terracotta and decorative tiles are most often used. Clinker tiles protect the facade of the house in conditions of a sharp drop in temperature and humidity. The variety of its colors gives the house individuality and unique look.

Terracotta tiles are durable, have high frost resistance and heat resistance. It costs much less than other facing materials, but it looks quite aesthetically pleasing and attractive.

Decorative tiles are durable and not affected by atmospheric precipitation and chemicals. It significantly increases the thermal insulation of the house and does not require serious maintenance work.

Siding

Siding is a durable material, it is resistant to corrosion, decay, retains its appearance, original color under mechanical stress. It is easy to install, which can be carried out at any time of the year, and does not require large costs for repair and maintenance. To avoid deflections and swelling of the siding, it is worth following the rules specified by the manufacturer, and then this material will serve the house for a long time and efficiently.

Lining

The advantages and disadvantages of lining directly depend on the type of wood. For example, pine lining has a huge selection of colors from the presented colors and a good value for money. Oak lining does not rot and is easy to work with. Linden lining, with proper processing, is resistant to high humidity, is not susceptible to mold.

What to consider when choosing

In order not to be mistaken in the choice of material for finishing the facade, you need to take into account a number of factors, the main of which are: