Practical advice

- When designing the location of the planks on the facade, try not to place them more than three in a row.

- For painting, processing the ends of the boards, use not a brush or roller, but a small sponge. The work will be more accurate.

- When using nails for fastening, choose resistant to corrosion, protect the surface from it with a paint and varnish coating. Otherwise, the appearance of rust stains on the surfaces is inevitable.

- The nails used can be made invisible, or almost invisible, by hammering each of them into the bar and stripping it off (cut with pliers). Then it is driven into the wood with a small drift. Remaining small dents can be hidden with wood putty (if final painting of the facade with an opaque paint is intended).

- You can use homemade putty to hide the dents from the nails. Mix one part of clear varnish (which will cover the surface later) with one part of sawdust of this planken wood (it is easy to collect when cutting off excess pieces of boards at corners, in niches). The mixture is used to cover the dents with a construction knife or an artistic palette knife.

Fastener palanquin snake

Installation of the facade of the house from the palanquin is carried out using a mounting plate (fastening for the "Stepfix-M" planken). The optimal profile for these purposes is an oblique plank (diamond-shaped). This shape of the plank profile allows you to hide the expansion gap, and at the same time the supporting frame is not visible, and the facade is protected from accidental rainfall. When preparing for the installation of the plank, it is good to conduct a geodesy of the future facade. Initially, we select the planken lengths we need, based on the step width of the subsystem. The easiest way to use subsystems for ventilated porcelain stoneware facades... But, in order to save the customer's money, it is not uncommon to use a dry coniferous bar on supporting corners. Carrying out fastenerspalanquin a snake on the facade of the house, the compensation gap for our climate is 4-5 mm. This value is determined by the possible expansion along the width of the board, which can reach up to 5%. Before installing the planken, be sure to treat the end of the board with a protective compound that prevents moisture exchange along the edge of the end. After installation, the outer surface of the plank is treated with protective compounds. The subsequent care of your home will be required in 5-7 years, and the facade itself will serve you for many years.

Installation of a terrace board.

The installation scheme for a terrace board (decking) is similar to the installation of a facade board. The Stepfix-M terrace board mount is easy to use and gives excellent results and is very reliable. The step between the guides depends on the thickness of the decking, but usually ranges from 350 to 550 mm between the joists. It is advisable to leave the compensation gap between the boards 5-7mm. After installation, it is better to cover the terrace board with a composition based on natural oils with good protection against UV radiation. Subsequent processing is desirable every spring. Then the decking will serve you for many years. Mountingthe deck of the board, decking is carried out by the deck method or in a run using fasteners for the plank Stepfix_M.

Fastening the front board.

Larch planken is perhaps the only species suitable for use on the facade of houses and cottages from growing tree species in Russia. Fastening of the facade board is carried out using the same technology as the installation of planken from exotic species

You just need to pay special attention to the protective coating and it is important that the materials used pass the chamber drying up to 12-14% humidity. Using chamber-dried larch planken for installation, you will be sure of the reliability and durability of your facade.

Fastening for concealed mounting of a snake plank.

Over the years, we have studied the behavior of wood products with regard to their application to ventilated facades. At the present time, we have obtained an excellent result in the technology of mounting a facade board using a planken fastening using a plate for concealed mounting of a snake Stepfix-m. We make it from impact-resistant and frost-resistant plastic that is not subject to rotting and swelling in the environment. Due to the high initial rigidity, the plank fastening ensures stable fixation of the facade board throughout the entire period of operation of the facade board. The use of reliable metal guides as a subsystem (subsystem for ventilated facades made of porcelain stoneware) allows the structure to withstand practically any climatic changes. The technology offered by the "Redles" company is available for installation by both professional teams and those who first started work on the installation of a facade board.

Photo of the installation of planken made of larch from materialssupplied by our company.

Types of cladding installation

Snake

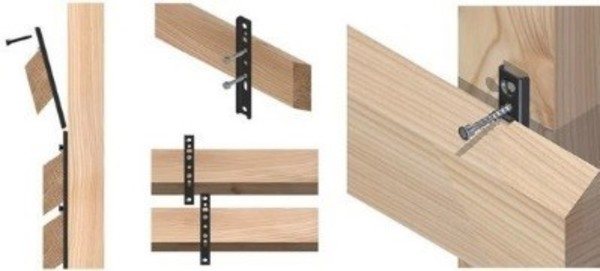

The type of fastener has a second name - "duet". With the help of details, the walls are clad with panels with beveled edges. Perforated metal strips are placed on the back side of the plank so that the boards of the aligned panels are adjacent to each other relative to the vertical axis of the marking.

From the back of the cladding, the vertical row of fasteners looks like a snake. The height of the plates must exceed the width of the boards by at least 30 mm. With a panel width of up to 110 mm, fasteners with a length of 145 mm are used, and over 110 mm, strips with a height of 190 mm are used. All parts are manufactured in a standard width of 15 mm.

Step-by-step instructions for installing a beveled planken

- Vertical racks made of timber with a section of 40x40 mm or 50x50 mm are attached to the wall. Fasten the crate with metal corners to the wall with dowels, to the timber - with screws.

- At the corners of the building, the timber of adjacent walls adjoins each other. The racks are installed with a step of 1.5–3 m. At the joints of the ends of the panels, two racks are placed at a distance of 20–30 cm.

- At the bottom, along the perimeter of the house, a horizontal belt from a bar is fixed. The markings for the installation of structures are made using a laser level.

- The snake strips are screwed onto the back of the facing boards with a screwdriver in accordance with the marking of the vertical racks of the crate.

- Installation begins with the second row of panels. The plank is mounted so that it rests tightly on the belt made of a bar, leading the lower end of the plank behind the back of the horizontal belt. The upper projection of the plate through the hole is fastened with a screw to the rack of the lathing.

- In the same way, the subsequent rows of cladding are mounted to the very top of the facade. The joining seams of the finish in accordance with the uprights should be located at a distance of 0.5 m.

- The corner ends of the panels are cut at an angle of 45˚. The ends are treated with a special impregnation before the panels are installed.

- Dismantle the horizontal belt from the bar by unscrewing the screws.

- Install the bottom row of cladding. The underside of the boards is attached to the racks with planfix corners.

Planfix

A metal corner with two holes for nails (self-tapping screws) and a spike serves as a fastening element for a straight planken.

Installation of straight planken with planfix

- Install vertical racks from a bar of 50x50 mm.

- Make markings on the racks with a laser level.

- On the sides of the racks, the corners of the planfix are nailed or screwed so that the spike of the second shelf of the fastener is facing up.

- Each row of boards is attached to the horizontal side of the corner through the hole with a self-tapping screw.

- The following panels are tamped with a rubber mallet on the planfix spikes.

- Then self-tapping screws are screwed in with a screwdriver through the holes in the corners.

In the same way, the plank is mounted on the floor and ceiling. The fasteners allow you to use a timber with a section of 20x20 mm as a lathing. The gap between the panels is 2–3 mm, which is quite enough for ventilation of the interior decoration space.

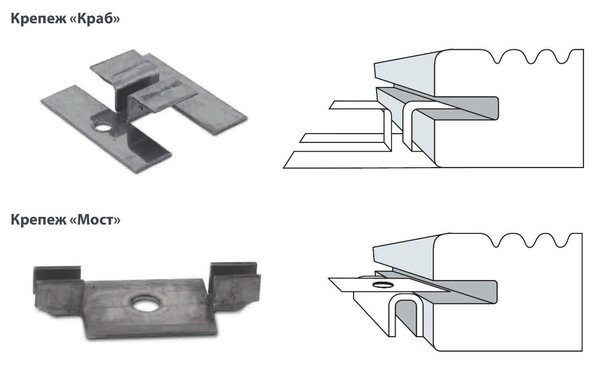

Bridge and crab

The clamps are made of galvanized iron. Fasteners are intended for cladding facades and surfaces of internal fences of a house or apartment. Mounting parts serve as fasteners for planken with longitudinal side slots.

Bridge

The bridge is characterized by the presence of 2 arcuate supports and a support platform that fits into the grooves of adjacent panels. Through the hole in its center, a self-tapping screw is screwed into the vertical rack of the crate. The platform with its edges goes into the depth of the groove by 7 mm, leaving the mounting hole free.

Crab

The latch with this name has two platforms with mounting holes. Between them are two L-shaped lapels. The platforms are attached to the rack, and the lapels are inserted into the grooves of the panels.

Installation of a planking board: open and closed method

The simpler is the open method of installation, which involves fixing the boards with self-tapping screws. However, this method is not very aesthetic - the screws will be visible to the naked eye. In addition, before fixing the plank, for example, from larch in an open way, it will have to be drilled, which increases the installation time significantly. Otherwise, the board may crack. Therefore, if aesthetics are required, it is better to turn to a more complex, closed method.

When using it, the boards are fastened using special plates or corners, which should be purchased along with the finishing material. How to fix the fasteners will depend on the type of plank. Surely the Dear reader will be interested to know what is the technology of fastening the planking board. The editors will gladly satisfy curiosity.

Qualitative characteristics

Pine has a resinous structure that is rich in antiseptic substances that are beneficial to human health. In the rooms, fully or partially sheathed with wooden planken, the space is environmentally friendly and the healing properties of pine are preserved in it for a long time, helping to stimulate vitality.

Pine has a resinous structure that is rich in antiseptic substances that are beneficial to human health. In the rooms, fully or partially sheathed with wooden planken, the space is environmentally friendly and the healing properties of pine are preserved in it for a long time, helping to stimulate vitality.

The service life of pine planken reaches up to 20 years. But at the same time, it must be additionally coated with impregnating oils once every 1-3 years to maintain its appearance, anticipate the appearance of various rodents, bugs that destroy the tree from the inside, excessive moisture with strong changes in weather conditions.

In general, the nature of the tree is resistant to fungal infections and rotting, mechanical damage and changes in weather conditions. Pine planken protects the house well from the wind, has excellent heat and sound insulation characteristics.

Planken brushing process

Boards are exposed to brushes, sandblasting machines or abrasive tools. Thanks to this, the texture becomes clear, as natural as possible, and the pattern stands out and becomes brighter. The essence of the treatment is to remove soft fibers in order to improve the visual effect and quality characteristics after brushing.

It is possible to carry out the brushing process on your own, but this is a rather complicated procedure.

This will require:

- burn the boards with a burner;

- clean with a stiff brush;

- clean the surface with sandpaper;

- open the planken with varnish;

- rub with a wax or oil composition, which will better help to highlight the wood pattern.

Installation technology

The planken facade board ideally replaces a block house, lining, imitation of a bar. For correct and high-quality installation, the work is carried out in several stages. The first thing to do is sew on the crate.As a rule, the width depends on the dimensions of the thermal insulation boards, its standard step is 50 by 50 cm. Before using the lathing bars, they must be covered with an antiseptic compound. The cross-section of the bar is 50 by 50 mm if the ceilings are even. If the surface of the ceilings is uneven, then a bar measuring 50 by 40 mm is taken. Such a section is selected in order to smooth out irregularities by turning the bar and setting the required level.

After the guides are installed, the gaps between the bars are filled with insulation, then the waterproofing is sutured. Experts do not recommend using ordinary cellophane as a waterproofing material, as it provokes the appearance of condensation. Next, fixing with dowels is made, and a control lathing is again laid on top, for which a bar with a section of 50 by 20 mm is used. This will provide a ventilated gap and fresh air. After that, they begin finishing work with a facade board. Installation takes place in one of 2 ways - open or hidden.

Open way

Fastening in an open way is considered to be the simplest. The lamellas are fastened using self-tapping screws in the face way. Self-tapping screws must be made of stainless steel, otherwise, after 1.5-2 years, ugly streaks will appear around the cap. The method is reliable, easy to use and suitable even for inexperienced hands. However, the appearance of the finished surface leaves much to be desired, since the visible screw caps spoil the visual effect.

Hidden option

The hidden version will require special fasteners - these are the so-called snakes and planfix. A snake is used for a beveled profile, a planfix for a straight one. This type of fastener simplifies the installation of the plank with the same gap. The hidden method is considered a reliable installation of the cladding, in which the appearance remains flawless. Hardware for interior decoration is made of stainless steel with a thickness of 1 to 1.5 mm. The products have a curved section, which increases their strength - each of them can withstand a load of up to 50 kg, and their shape provides micro-ventilation between the plank surface and the crate

This is important when the planken is made of hardwood.

Corner processing requires a certain algorithm: two boards are fixed at right angles, and only after that the installation takes place on site. Experts advise treating the facade board with a protective oil composition before starting the fastening - this increases its service life and gives a colorful visual effect. Planken material is a modern solution for interior finishing works or cladding of building facades. The price range allows you to choose between budget and luxury options. It is possible to use inexpensive planken for interior decoration of bath rooms, bathrooms, toilets and other rooms. At the same time, for the decoration of residential premises, a facade board of elite, expensive varieties is used. In any case, planken is beautiful and prestigious.

In the next video, you will be installing a plank on the ceiling with a pneumatic gun.

Advantages and disadvantages

Planken has positive and negative qualities. The first are:

- High decorativeness - allows you to create different surfaces that are combined with many architectural styles. Using several types of installation, different types of wood, many coatings, you can create a unique look of a city, country house, its courtyard, auxiliary buildings (baths, gazebos, swimming pools).

- Ease of installation - requires a minimum of tools, skills - a cordless screwdriver, a hammer, pliers, a cut-off saw (it will be replaced by a hand-held hacksaw with a good miter box), an angle grinder, a mallet, a level. Installation consists in the systematic, accurate placement of fasteners, screwing in screws. You need to take your time, check the position of each board with a level.

- Durability - they use hardwood, which, without processing, does not collapse for a long time under the influence of rain, sun, cold. By impregnating the surface with water-repellent, antibacterial compounds, the service life can be increased to 25-30 years.

- Environmentally friendly - does not contain synthetic, toxic resins, artificial materials, etc. On health, the environment does not have a negative impact. The main thing is that when using the material during construction, do not worry about preserving nature. Planken is made from renewable resources (wood).

- Resistance to adverse influences, aggressive environments - made of larch, high quality pine. Oak, cedar material is used for interior decoration. The resilience of these rocks is well known and needs no proof. It should be said separately about larch - it is popular because of its high consumer qualities - resistance to moisture, decay, swelling.

- Light weight. Compared to other methods of interior and exterior decoration of the house, this one does not require serious load-bearing elements. You need a simple vertical or horizontal lathing.

- Variety, availability of fasteners. Fastened with ordinary nails. Better to use screws, metal fasteners. This will create a more beautiful view, more comfortable service. There are many types of fasteners. They will help to realize any architectural, design idea.

Beveled variety

Beveled variety

There are only three cons:

- High price. Modified edged board, more expensive than euro-lining. It is structurally and technologically more complex. The reason is commitment, the desire of manufacturers to maximize profits at a minimum cost due to the popularity of the material.

- A varnish-and-paint coating is required. Although manufacturers cover the seamy side with hydrophobic, antibacterial impregnations, the front side and ends need processing. These are stains, varnishes, opaque paints.

- Accuracy during installation. Planken with a horizontal, vertical installation needs control of indents, adherence to the ground. In the first case, the slats are placed in parallel, in the second - perpendicularly. The work will be simplified by a building level, a square, tabs-templates, factory or homemade origin (we are talking about a-spacers).

Wedge-shaped variety

Wedge-shaped variety

Breed

Conventionally, two of the most demanded species of planken can be distinguished - larch and pine.

Larch is considered the most popular species for interior decoration. It is durable, practically does not rot, and with prolonged contact with water it only becomes harder. Fire resistance and the ability to resist destruction by fungi and other similar microorganisms in hardwoods is high. The resins of the Siberian tree act as a natural antiseptic that repels carpenter beetles.

Interestingly, larch finishing materials have a positive effect on the well-being and general health of a person. It has been scientifically proven that aromatic oils of the Siberian tree relieve migraine headaches, help with heart ailments and neuroses. Larch phytoncides are natural prophylactic components for GDVI, colds and other viral infections.

But planken from larch has the property of "crying" - to release essential resins from resin pockets under the influence of high temperatures. As a result, smudges form on the coating, which create the effect of tears. Even with the purchase of Extra grade material, there is no guarantee that there are no hidden resin pockets inside the board. Larch also deforms during operation - it swells, dries up, bends, cracks.

Thermal pine is an excellent option for finishing facades, but not terraces. Pine planken is very soft with no pronounced texture. An excellent argument when buying this finishing material is its price.So, imitation of a timber from thermosine is much cheaper than from larch.

| Pine plank | Planket larch |

One cannot fail to note the beneficial effect of the coniferous aroma, which spreads throughout the house after its interior decoration. This aromatherapy is an excellent prevention of respiratory diseases.

Has pine planken and some disadvantages. With an excess of moisture, it turns blue and rots, needs additional treatment against insects, which are happy to equip their homes with this tree.

About profiles and installation

Above, we have already said that the planken profile can be different, we even considered two varieties. But there are three of them:

- Straight section profiles: installed by means of "planfix" or "snake" fasteners;

- American (profile also known as wedge): in this case, you can use fasteners of the "snake" type;

- Beveled profiles: Duet fasteners or the same snake will do.

The beveled planken profile can be called the most demanded. This is partly due to the fact that when performing work, it is always possible to leave a technological distance between the elements, which is important when there are no joining gaps. This profile is ideal for combining the main advantages of planken and lining in one.

- It is possible to mount the lining (wooden facade board) either in a spike on special mounting strips or with an overlap;

- The connection "in a thorn" at the exit gives an almost ideal plane - but it is almost impossible to avoid deformations: because the tree tends to swell;

- Because of this, the lining is best suited for some kind of interior finishing work;

- The grooved lining has another drawback - you will not be able to replace any board without first disassembling the entire structure;

- If the plank is assembled with an overlap or end-to-end, you can always leave the necessary margin of space, taking into account the fact that the dimensions of the material may change. That is, such material is the optimal solution for outdoor decoration;

- In addition, in this case, it is possible to replace a separate strip without any problems - you will not have to break the entire structure for this.

Why Planken

Just watch the video about larch planken - this will surely give an answer to many exciting questions, in particular why it is worth using this material.

Planken is very beautiful and natural. With its help, you can radically transform the interior of your home or the architectural appearance of the whole house. Due to the fact that the material very naturally imitates timber (almost 100%), even a modest cottage house made of SIP panels or a lightweight concrete structure can be given the appearance of a real wooden house (which looks very status).

Any surface finish looks solid if planken was used

That is, using planken for decoration is much cheaper than building a log house, and the natural durability of larch, together with modern means for wood processing, will provide your investment with an effect for many years. The house, which has an external planken finish, looks noble, solid - the same can be said about offices, shops, etc.