What sand for sandblasting to choose?

Experience shows that for this procedure it is not enough to have one sandblaster. An abrasive is also required. It must be correctly selected and have certain characteristics. These include the following indicators:

- The degree of hardness. Based on its value, it is possible to determine the resistance of particles when interacting with others that are in a more durable substance;

- Geometric grain size. This indicator determines which tool nozzle to use and the air pressure;

- Abrasive ability. It makes it possible to estimate how much area can be treated with a given substance and for what time. This indicator is very important when preparing for these works;

- Resistant to various damage and chemical attack.

Before proceeding with the choice of sand for sandblasting, it is necessary to analyze for what purpose it will be used, which is its main task. This will allow you to select an abrasive with a set of properties that will be most effective for a given case.

What can you make sandblasting from?

Craftsmen make sandblasting machines on their own, using very convenient metal cylinders for this, gas or from under large fire extinguishers. Their metal lends itself well to welding, holds pressure and serves almost indefinitely.

Also, to get a sandblasting installation, you can use devices similar in principle of operation: a high pressure washer, a spray gun, a blow gun.

- The sandblast made from the Karcher sink works on a mixture of sand and water. A nozzle with a sand container is installed on the outlet tube, and the standard tip is replaced with a ceramic or metal nozzle. To connect the sand supply, you need a tee that will work as a batcher and a mixing unit. The main disadvantage is working with water, which seriously limits the scope of sandblasting. And the advantage is that everything is ready, you just have to add sand. And, of course, this is the only device that does not produce dust during operation.

- The spray gun is almost a ready-made installation, you just need to put a container with sand instead of a paint bottle and pierce the gun under a nozzle of the required diameter. To do this, a mixing tee is installed on the valve, into which the air supply is connected. It is quite convenient to work with such a device, but its main disadvantage is that it will then be impossible to use it as a spray gun.

- To make sandblasting from a blow gun, you need a minimum of work: everything is ready, you just need to install a tee on it with a connection to a container with sand and an outlet nozzle. It is clearly shown in the video below.

In all three cases, the ejector principle is used to supply sand: a low pressure section is created next to a fast flow of air (or water). Sand from the container is drawn into it. If none of the listed devices are at hand (or are, but they themselves are needed on the farm), you can make sandblasting from available materials.

Features of abrasives

One abrasive differs from another in a number of characteristics:

- faction;

- hardness;

- abrasive ability;

- mechanical resistance;

- chemical resistance.

Fraction

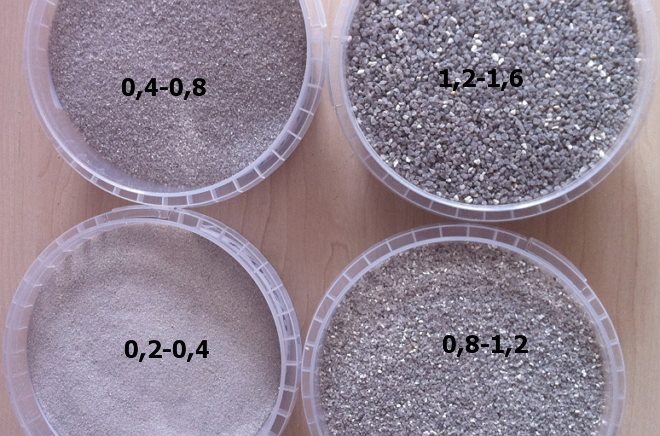

The size of the grains of consumable raw materials is measured in fractions. How does fractional distribution work? The raw material is scattered on a special sieve, the number plate of the sieve indicates the size of the particles, depending on the size of which, a fraction is isolated:

- limiting;

- coarse grinding;

- standard;

- complex;

- crushed.

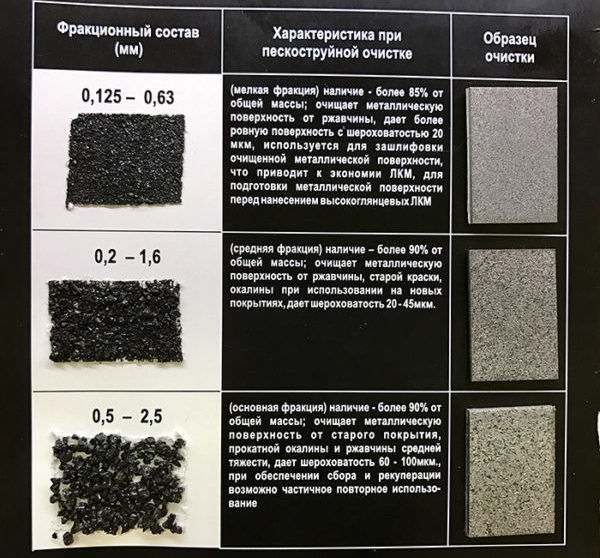

Fractional composition

Fractional composition

Hardness

A special device tests the hardness of the blasted sand. The test takes place as follows: another material with higher hardness values is pressed into the abrasive, which makes it possible to establish its stability during a destructive process.

There is a special ten-point scale of hardness:

Hardness scale

Hardness scale

- 1st group - solid as talc;

- 2nd group - like plaster;

- 3rd group - like calcite;

- 4th group - like fluorite;

- 5th group - like apatite;

- 6th group - like feldspar;

- 7th group - like quartz;

- 8th group - like topaz;

- 9th group - like corundum;

- The 10th group is like a diamond.

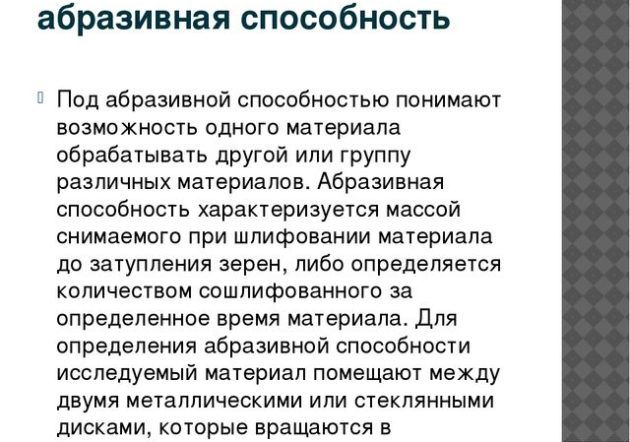

Abrasive ability

The abrasive capabilities of raw materials depend on the area of the base being treated as a result of sandblasting for a specific period of time.

Mechanical stability

To establish this characteristic, an experiment is carried out: a grain of sandblast sand is crushed, while the level of gravity is fixed at which the particle begins to collapse.

Chemical resistance

To determine chemical resistance, the abrasive powder is exposed to alkaline, acidic and other solutions, as well as water.

Where is abrasive processing applied?

When choosing an abrasive material, you need to understand the areas of its application:

Abrasion concept

Abrasion concept

- Cleaning the metal surface from corrosion traces is carried out with preliminary cleaning with dried and sifted sand;

- Crushed sand (particle size - 0.3 mm) will give shine to copper and aluminum products;

- Sand with a particle size of 0.3-0.6 mm will remove old paintwork that is well fixed to the base;

- Sand, nickel, copper slag, the particle size of which is 0.6-1.6 mm, will remove old corrosion traces;

- Coarse abrasive will remove welding scale, thick bitumen base;

- Steel and cast iron shots will clean and prepare the car body for painting;

- Electrocorundum, garnet sand will clean alloy steel, titanium;

- Clean fine sand, the particle size of which is 0.1-0.8 mm, will allow the glass to be processed for the purpose of further matting, drawing drawings;

- Small stainless beads and glass granules will allow you to process stainless steel products.

Gentlemen, where and how can you get sand for sandblasting?

Napalm Soldering Iron & Screwdriver TEAM Started by

17 years on the site user # 3615

Sobstno such a question arose.

I am thinking of organizing a genocide of rust and taking a closer look at the sandblast.

On zhdanah for 30 bucks the seller is a sandblasting gun. There is a compressor with a capacity of about 220 liters.

Do you think he's enough? Or is this pistol purely for some kind of improper use?

And the main question - where and for what they sell sand for sandblasting? And then I'll buy a gun, and then it turns out that the sand costs only $ 999.99 for a matchbox and finally we don't have a seller.

vsn Member

15 years on the site user # 19170

I suspect that ordinary sifted / dried river sand will do (it does not cake) at a cost of $ 999.98 for a matchbox :))) but seriously, look at construction stores ..

Napalm Soldering Iron & Screwdriver TEAM Started by

17 years on the site user # 3615

vsn, sanks. Well, I will probably not stir up a self-made pistol, but about the sand infa by the way

And then I phoned a bunch of our construction offices - everyone did bulging eyes

rusland76 Member

15 years on the site user # 24345

sometimes aluminum oxide is used.

rezident Soldering Iron & Screwdriver TEAM

16 years with user # 11835

Napalm, do not forget to buy gas masks

cyberdos Senior Member

9 years with the site user # 263650

A belt-driven compressor is desirable, the outlet pressure should be 6 atmospheres, then there will be a sense (compressor 300, pistol 70 plus hoses) for rent they ask 75,000 per day. I used to take sand from a ceramic factory, approaches to the piles of sand are available, so go for it.

chaka Senior Member

11 years with the site user # 138849

cyberdos, judging by the dates, he pulled away for a long time.

kreatiff Senior Member

12 years with the site user # 94991

Who sells the sand?

oleg213 Senior Member

11 years with the site user # 118478

kreatiff, in the stepyanka there is an office that sows sand, bought this spring a 50kg bag of quartz for 60 thousand square meters, 57 Geologicheskaya str.

Andryukha-2 Junior Member

8 years with user # 354551

I use ordinary sand from the excavation site closest to my place of residence. It is best to take from where the yellow sand comes straight to the surface. I come to such a place after a few hot days, find a place where the sand pours, it doesn't even need to be dried, sift it (very desirable), load it into the car - and go home!

oleg213 Senior Member

11 years with the site user # 118478

Andryukha-2, I have a bunch of sand drifts next to the garage. dry grains of sand the size of a grain of finely ground salt, even less, nothing beats off with such sand, we had to look for quartz

Andryukha-2 Junior Member

8 years with user # 354551

oleg213, yes, yes, if you have such a small fraction as you describe it is already sand dust, it really will not only bring much benefit, but also harm your health. One can easily earn an occupational disease of the sandblaster - lung silicosis. In defense, you have to work in any way. And look for sand where I advised you - where it comes to the surface. There he is large, as a rule. I think if you know your region well, you will immediately recall such a place (or maybe more than one). Personally, the fraction of the abrasive does not play a special role for me, except if it is really dust, but I manage to sift it back in my career - you are blowing in the breeze, it and the dust flies away, and the coarse fraction is cleared of debris. Another thing is with what pressure do you work, and most importantly, what is the performance of the compressor (s)?

oleg213 Senior Member

11 years with the site user # 118478

pressure 10 bar, receivers 200 liters, compressor about 540 liters per minute, the whole car with such a “set” will not have enough patience to process, but the disc or local rust is very much nothing

Nuances of use

If you purchase abrasive material in a store, then, as a rule, it does not require special preparation, however, in everyday life or in small enterprises, even ordinary river sand is used as a free alternative to purchased raw materials. The availability of such an abrasive allows you not to think about consumption and reuse, but to achieve the desired result, you should follow the instructions.

First of all, river sand must be carefully sieved in order to achieve maximum uniformity of the fraction without any extraneous inclusions. The required fraction size is determined depending on the size of the nozzle and the characteristics of the processed material, after which it is necessary to select the appropriate mesh for this particular particle diameter. Most often, they use improvised materials - from flour sieves and mosquito nets to tulle and building nets. Experienced sandblasters advise not to be lazy when using river sand and sift it 2-3 times.

Only then can you start drying. In industrial conditions, it is customary to dry the abrasive using specially produced dryers, but in everyday life, craftsmen have to come up with their own original solutions. Someone dries river sand on a metal sheet laid out on top of the barbecue, someone is more convenient to scatter the future abrasive on a film and dry it with a heat gun. The result is considered acceptable if the sand spills freely through a loosely clenched fist.

The presence of quartz is quite likely in river sand, therefore, theoretically, it would be worth using in special chambers with dust suppression. However, those enterprises where such equipment is available rarely save enough to collect sand right next to the river, and in domestic conditions there is nothing of the kind. In order to avoid the development of silicosis, it is strongly recommended to carry out sandblasting work with river sand away from residential and simply crowded areas, and the amateur sandblaster himself must reliably protect his eyes and respiratory tract from the smallest dust particles.

For information on how to prepare sand for sandblasting, see the next video.

Types of abrasives

When choosing sand for a sandblasting gun or another type of abrasive, you need to take into account the basic properties and characteristics of the latter in order to carry out the work with maximum efficiency.

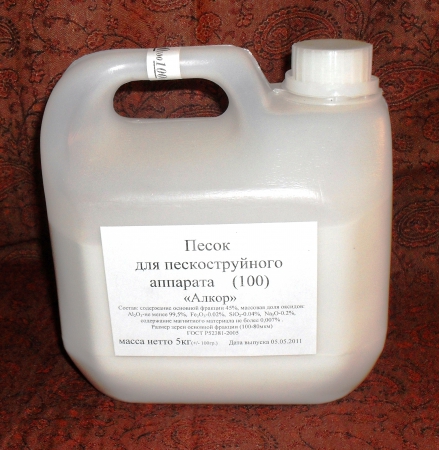

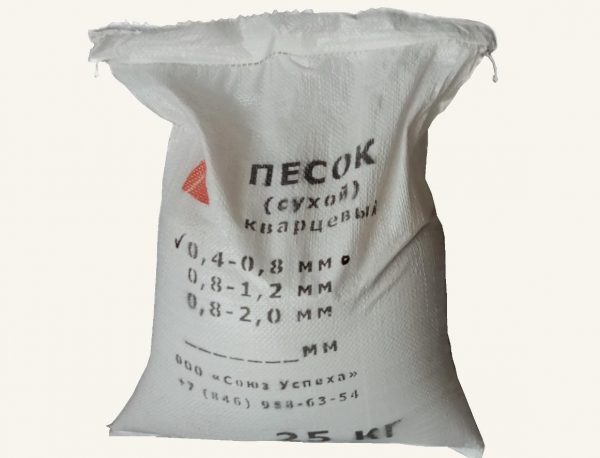

Quartz sand

It is quartz sand that is most in demand on the market for products for sandblasting and grinding. It is characterized by a low price, decent quality, and is sold everywhere. Quartz sand is made from white quartz by crushing it into different fractions:

- up to 0.1 mm;

- 0.10-0.4 mm;

- 0.5-1 mm;

- more than 1 mm.

The sand is carefully screened out, so there are practically no larger particles in its small fractions, and sandblasting can be done without harm to the product. The material has good indicators of resistance and abrasion, especially considering its availability. Sand will not damage delicate items, non-ferrous metals. Waste quartz sand after sandblasting can be sold as building material.

A significant disadvantage of sand is the release of a large amount of dust that gets into the lungs and eyes of the worker, which is harmful to his health. With regular use of sand for such grinding in the absence of personal protective equipment, a deadly disease - silicosis, can develop. To avoid such problems, all equipment should be equipped with dust removal systems, and each batch of sand should be used no more than 1-2 times.

Copper slag and nickels slag

These abrasive materials are obtained from nickel and copper production slags. They are considered reusable, economical and more efficient than quartz. Particle strength, hardness and abrasive ability of a copper slag is higher than that of a nickel slag. Such materials can be used up to 3 times without the risk of dustiness.

The use of these abrasives is advisable when cleaning expensive and complex structures, which is associated with the high quality of the result, but also with the cost of materials. Cooperslag and nickelslag are capable of cleaning the most durable types of metal and concrete, they do not crumble together with plaque due to their high strength.

Metallic (technical) shot

This material is small metal balls that are made from steel or cast iron. A technical shot can be cast, chopped, or chipped, with the first one having a spherical shape, and the rest - acute-angled. Steel and cast iron shots are used for shot blasting, shot blasting of products that require notching (profiling) or descaling. This purpose is associated with the high strength of materials and the presence of acute-angled edges at their particles. After processing, the metal base will have a high degree of adhesion and adhere well to the topcoat.

Steel shot stands out for its good quality - it is the hardest, has the highest strength characteristics, can be used several times, does not cause dust. The increased service life is due to additional heat treatment of the shot during its production. Stainless shot is used to process structures made of the following materials:

- steel;

- zinc;

- titanium;

- aluminum;

- copper;

- bronze;

- brass;

- concrete;

- granite;

- marble.

Corundum

This material is prepared on the basis of aluminum oxide and is considered one of the most durable abrasives. Its particles are in the form of crystals, and their characteristics are close to those of diamond. The price of the material is high, therefore it is used for processing mainly expensive products. Corundum can be reused many times. It is ideal for decorative sanding and surface polishing.

A kind of corundum is electrocorundum - a super-strong material obtained by adding a number of impurities to aluminum oxide. Its particles are not damaged at all during the processing of materials, therefore repeated processing can be performed a large number of times (after sieving). On the Mohs scale, electrocorundum is inferior to diamond only one position, so hard it is.Its grains are sharp-edged and have the unique ability to self-sharpen.

Pomegranate sand

Garnet, or garnet sand, is an abrasive of mineral origin, which surpasses quartz sand, nickel slag, and copper slag in terms of technical characteristics. The material can be used many times, it is used both for sandblasting and for hydraulic cutting of metal.

Differences between abrasives

An abrasive is a hard, rough-surfaced material used to abrade and polish a variety of substrates. Most abrasives are in fine powder form, but some include larger particles with sharp edges. Despite the existence of different types of abrasives, they are all characterized by a common property: they have sufficient hardness, therefore, they are able to clean metal surfaces, concrete slabs and other materials from contamination.

Abrasive particles when used in a sandblaster are blown out with a powerful stream of air. The device gives them a large kinetic energy, as a result of the existing plaque is quickly removed. All abrasives are divided into:

- natural (sand, corundum, spar, diamond, chalk, iron ore, etc.);

- synthetic (cuproslag, borazon, boron carbide, etc.).

They differ in origin and composition, degree of hardness, mechanical and chemical resistance. The most popular and inexpensive is quartz sand for a sandblaster. The sand goes through several stages of processing before it goes on sale, otherwise it can damage the equipment. Abrasives also differ in particle size: for example, for delicate or damaged substrates, choose the most gentle materials.

Hardness

All abrasives in terms of hardness - the ability to resist the indentation of another material into them - are divided into:

- superhard;

- solid;

- soft.

Even soft materials can remove dirt, but they are more gentle. The hardness index is set according to the developed Mohs mineralogical scale, dividing abrasives into 10 classes. Such a division implies an increase in hardness as the class increases (the softest - talc - has class 1, the hardest - diamond - class 10).

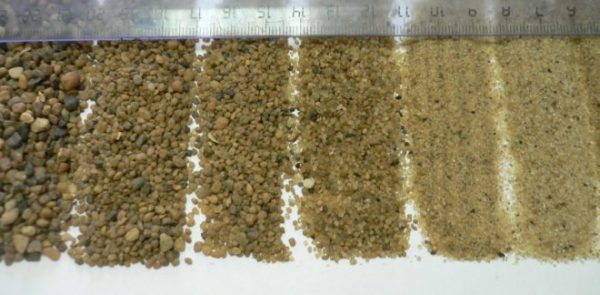

Fraction

Abrasive materials for grinding surfaces differ in the size (coarseness) of the grain, depending on which they are assigned certain numbers:

- fine micropowders (M10 – M5);

- micropowders (M63 – M14);

- grinding powders (12–3);

- grinding grain (200-15).

In other words, by fraction, abrasives are subdivided into coarse (large), medium, fine and extra fine. For their production, the main material is crushed by a press, as a result of which crumb is formed. It is sifted through special sieves, separated into powder with different grain sizes, separate crystals or fragments. Usually, to clean materials from a thick layer of plaque, abrasives of the largest fraction are used, and the fine one is intended for finishing polishing.

Abrasive ability

Abrasiveness means the time period for which it is realistic to clean a certain area of the product. This is the amount of material that can be sanded per unit of time. This property strongly depends on the size, hardness and other physical properties of crystals. Also, the abrasive ability is due to the intensity of the fracture of particles into acute-angled elements during grinding.

Mechanical stability

Different types of abrasives differ in their ability to withstand loads without breaking. Mechanical resistance depends on the ultimate compressive strength. The latter is detected in the course of pressure on the crystal of the abrasive material with the measurement of the load at the moment of its destruction. For most abrasives, mechanical resistance decreases with increasing ambient temperature. The higher the resistance index, the more times the abrasive can be reused.

Chemical resistance

This property reflects the ability of abrasive materials not to change their basic qualities under the influence of aggressive chemicals (acids, solvents, alkalis), as well as water.

Quartz sand consumption during sandblasting

The consumption of abrasive varies greatly depending on the specific processing and is determined by the power of the sandblasting, the volume of work, the fraction, the degree of contamination of the base, the size of the nozzle and other parameters. It is advisable to identify the consumption indicator at the initial stage in order to calculate the total financial costs for all work. The best choice will be an abrasive that will have the lowest cost per unit area.

A good economic effect is provided by the use of sand for sandblasting, if its fraction is ideal for a particular type of work, and cleaning is carried out in a special box. The exact consumption may change along with the initial data (for example, with different thickness of the rust layer on one product), and the calculations will be approximate in any case.

An example of calculating an abrasive for metal processing per 1 square meter

To understand which abrasive is best suited for processing, it is worth considering the average consumption of the most popular materials when cleaning metal to a degree of Sa 2½:

| Abrasive name | Consumption, kg / sq. m |

|---|---|

| Quartz sand | 60–110 |

| Nickel slag | 35–80 |

| Kupershlak | 35–80 |

| Garnet | 3–7 |

| Electrocorundum | 3–10 |

| Technical fraction | 5–10 |

For a minute of processing a metal surface, an average of 2-3 kg of sand is spent. The consumption of this material can be somewhat reduced by using modern sandblasting machines with a closed processing cycle, as well as vacuum systems for collecting used abrasives.

When removing old stubborn paint, a thick layer of rust, adhering dried cement, you will have to spend a lot of time cleaning the already used abrasive, which will have increased dust formation due to accelerated destruction. In such situations, it is worth considering purchasing a different abrasive material with greater hardness.

Applications

Sandblasting is most often required for metal and concrete surfaces. In the first case, this is a relatively simple method of cold working, which allows you to remove a damaged surface layer - scaled, rusted, burnt or simply dirty. This procedure not only allows you to restore the original aesthetic appearance of the product, but also stops the further spread of rust into the thickness of the metal, prolonging the life of the product.

At the same time, before the subsequent painting, sandblasting is literally a mandatory procedure, because the paint that lies on unreliable rust will peel off along with its base in the near future. In addition, the smallest particles of abrasive also knock out tiny metal particles from the workpiece, making the surface rough, and this contributes to better adhesion of the paint to the substrate.

The use of an abrasive for concrete surfaces is important if you need to clean the product from contamination. In the modern world, certain categories of people like to paint or spray paint fences made of concrete and other related materials, often leaving drawings and inscriptions inappropriate. The sandblasting gun allows you to quickly and relatively inexpensively restore the original aesthetics of the structure.

At the same time, it is quite obvious that dismantling the product for transportation to a cleaning enterprise is not possible, therefore, portable equipment is used with those types of sandblasting abrasive that do not give excess dust and can be used in open space.

What you should pay attention to?

To determine the best material, and, accordingly, purchase a high-quality abrasive, you should find out its main technical characteristics:

the fraction is of paramount importance, since the grain size in the sand allows you to achieve either maximum abrasive ability, or helps more gently, as if with a polish, to pass over the material without damaging its structure:

The material documentation contains exact instructions for the fraction, so the base, limit, highest and lowest values are indicated. In this case, the percentage of each indicator in the container is set:

almost always the particle size is in the range of 0.125 - 4 mm

Also, when choosing, you should take into account the power of the sandblasting and the diameter of the nozzle of the device;

hardness. Indicates the ability of an abrasive to resist pressure with a different material with greater strength. There are 10 grades in total, from the softest to the hardest;

abrasive ability is the amount of processed material for the period of time described in the standard;

resistance to mechanical stress allows you to find out about the degree of mechanical stress that sand can withstand without crushing. That is, the compressive strength of the material;

chemical resistance is the tendency of a material to resist reaction with water or solvents, acids.

After determining the quality characteristics, the question arises, where to buy sand for sandblasting? The choice of a specialized representative is a key decision, otherwise it is possible to acquire fakes or poor-quality advice, in some cases it is life-threatening.

Perm sand for sandblasting has high quality indicators.

Sand is pushed onto the part under pressure, resulting in a ricochet. Small particles are lifted into the air and form a dust column. So when performing sandblasting, it is imperative to use respiratory protection.

Factors to Consider

One of the advantages of the method is that almost any product is suitable for processing structures. Available river, open pit materials, as well as crushed quartz analogs and inexpensive building sand. Any of these options will work well for preparing the foundation. Due to the low strength of the particles, it will also not work to damage the element by choosing an unsuitable product. Why are experts looking for an answer to the question: which sand is best for a sandblaster? It's all about the quality of work, as well as the speed of cleaning

Be sure to take into account:

- The nature of the contamination and the thickness of the layer. If the film is thick and strong, then it is worth choosing solid products that can quickly remove unnecessary plaque;

- Material type. For processing alloy steel, as well as titanium parts, ordinary quartz sand is not used, since it does not give the desired result; At the same time, the natural mineral can be used in the preparation of steel metal structures.

- Purpose of processing. This technology is suitable both for rough cleaning of metal and for performing jewelry work - for example, creating patterns or decorative patterns on glass. The quality in this case will depend on the fraction of the abrasive. The smaller the grains of sand and the smoother their edges, the better.

- Speed. The speed of the process is influenced not only by the type of sandblaster, but also by the shape of the sand. For quick stripping, it is better to choose crushed quartz.

- Substrate quality after processing. The type of substrate after completion of work depends on the goals of this operation. When you need to remove the old paintwork, craftsmen use a coarse fraction - 0.3-0.6 mm. It removes paint well while retaining the metal backing. For more “delicate” applications, an abrasive with a smaller particle diameter is chosen.

Ready-made solutions from the "OPT6" company

Not sure what kind of sand is needed to solve your problem with a sandblaster? We have made a convenient table in which the material, its fraction, and also the area of application are indicated.

| type of product | The form | Fraction (size of grains of sand), mm | Application |

| Quartz | rounded | 0,1-0,3 | Giving a decorative look to details (polishing). The composition, free from impurities, is also suitable for decorating glass, mirrors and other tasks. |

| Quartz | rounded | 0,5-0,8 | Removal of traces of corrosion. The product is used for cleaning large diameter steel pipes, bridge structures, beams, tanks, etc. |

| Quartz | rounded | 0,8-1,4 | The large size of the grains makes it possible to use the material for removing viscous coatings based on bitumen. |

ADVICE: To cope with dust, specialists additionally connect a water supply to the equipment. In this case, the already wet mixture gets to the surface, which forms less dust and dirt.

We do not recommend reusing quartz abrasives as this will not produce a clean surface.

What is sandblasting?

How to clean metal from rust, scale, deposits of old grease, carbon deposits? And if not metal, but wood or concrete? Special chemical cleaners can be used not everywhere and not always, and you have to rub the surface with sandpaper, metal brushes, and then admire the mesh of small and not very scratches.

An alternative to this treatment is sandblasting. With its help, various contaminants can be removed from the surface without any problems, and the treated area is cleaned much faster and more efficiently, and dirt is removed even from porous material (for example, from wood or concrete).

Another option for using sandblasting machines is to work on wood or glass. With certain skills, you can make magnificent stained glass windows with selective matting, engravings and relief patterns.

The sandblasting machine is a rather simple apparatus in its principle. It gives a powerful stream of air mixed with abrasive (ordinary sand). They can handle both a large area and complex parts with many small elements. The flow of sand perfectly removes any build-up of dirt, oxides and carbon deposits, leaving a clean surface without scratches.

When you need a sandblasting machine on a regular basis, but you don't want to buy it (most often for financial reasons), you can do it yourself.

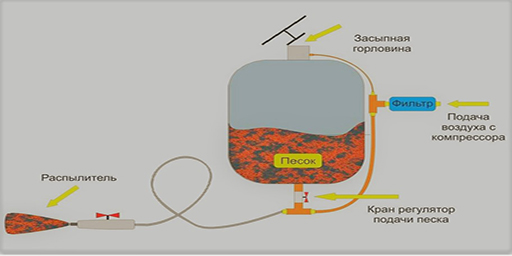

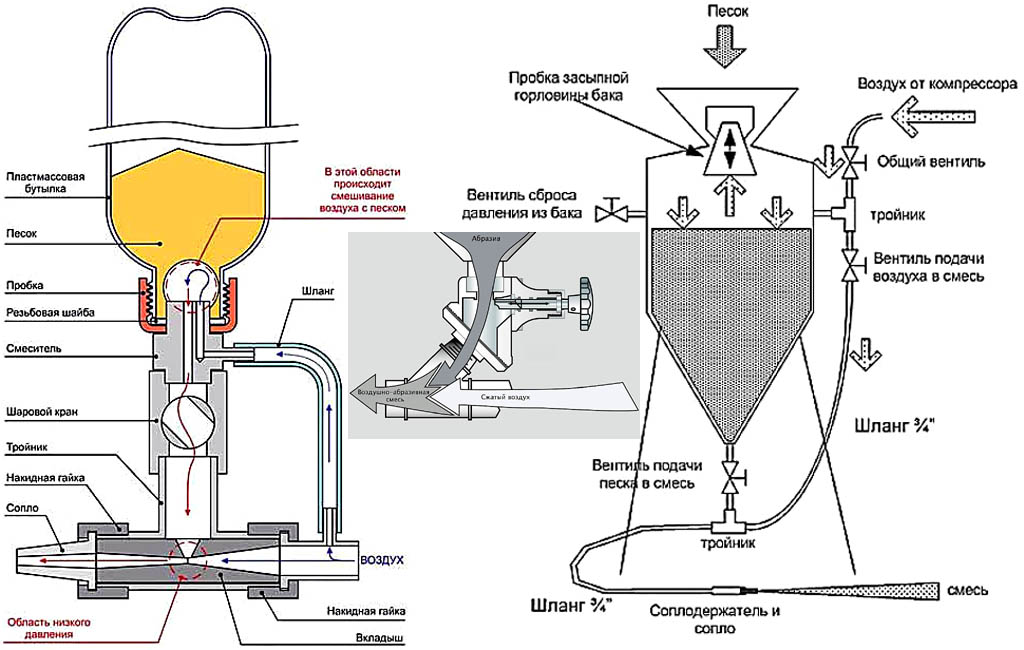

Device and principle of operation

Homemade sandblasting machine has a fairly simple design.

- Compressor, and preferably powerful enough.

- Working container (balloon) into which sand is poured.

- A branch pipe with a shut-off valve for adjusting the sand supply.

- Spray gun (nozzle).

- Connecting hoses.

Sandblasting scheme: 1 - air supply from the compressor; 2, 13, 15 - connecting tees; 3, 5 - air supply adjustment; 4 - pressure sensor; 6, 14 - pipelines; 7 - overpressure valve; 8 - dry sand; 9 - valve for adjusting the air supply; 10 - rubber gasket for the filler neck cover; 11 - sand supply control valve; 12 - a container for sand; 16 - air supply with sand to the nozzle; 17 - filling neck; 18 - filler neck cover.

Sandblasting scheme: 1 - air supply from the compressor; 2, 13, 15 - connecting tees; 3, 5 - air supply adjustment; 4 - pressure sensor; 6, 14 - pipelines; 7 - overpressure valve; 8 - dry sand; 9 - valve for adjusting the air supply; 10 - rubber gasket for the filler neck cover; 11 - sand supply control valve; 12 - a container for sand; 16 - air supply with sand to the nozzle; 17 - filling neck; 18 - filler neck cover.

It all works very simply.

- Two branch pipes are brought into the working container. Upper - for connection to the compressor to create excess pressure inside the cylinder. The lower one is for feeding sand. To regulate the flow rate, a tap is inserted into this branch pipe.

- The air flow from the compressor is divided into two parts: one goes to the upper branch pipe of the cylinder to build up pressure inside, the second is connected to the lower branch pipe to create an air-sand mixture at the outlet.

- From the bottom nozzle, a mixture of sand and air is supplied under pressure to the spray gun or nozzle.

It all looks not too complicated and is quite accessible for self-assembly.

Applications of abrasive materials

The area of use of abrasives may differ depending on their type, strength, cost, fraction. For example, river or quartz sand is most often used to remove paint and varnish materials, rust, dirt from building facades, and metal bases. To polish products made of copper, aluminum and similar materials, quartz sand with a particle size of 0.1–0.3 mm is taken; to clean the metal from stubborn paint, it is better to take a fraction of sand 0.3–0.6 mm.

Old traces of rust, which are poorly removed by a chemical method, are removed by sandblasting with 0.6–1.6 mm sand or nickel slag, copper slag. The same abrasives can be used to remove welding scale from metal structures. Technical shot is most often used for cleaning:

- small, medium, heavy casting;

- rolled products from carbon, stainless steel;

- products to be painted, electroplated;

- parts of car bodies.

Also, shot during processing helps to strengthen torsion shafts, coil springs, leaf springs. Electrocorundum, corundum is used for cleaning and grinding titanium, alloy steel, tempered glass.

How to choose the right consumable

It is clear that for sandblasting surfaces of various types, different consumables are also needed. The correct choice allows not only to increase the efficiency and speed of the processing performed, but also to significantly save on its implementation. The following factors influence which consumable material for the sandblaster to choose.

- The thickness of the coating or dirt layer to be removed and its strength. If you choose a fine abrasive with a low hardness for a thick and durable layer of the removed coating or contamination, then you may simply not achieve the desired result.

- The hardness of the material to be cleaned. For harder substrates, a harder abrasive should be chosen, and for softer ones, a less hard one, so as not to damage the treated surface.

- Requirements for the surface condition after processing. If the cleaned surface should have a minimum number of dents and chips, then a finer abrasive should be selected for processing.

- Required sandblasting speed. A hard abrasive with sharp edges provides a faster processing speed than a similar one, but with rounded particles.

- The possibility of organizing the collection and reuse of the abrasive. If this is not possible, then it is more expedient to use more inexpensive materials for processing: quartz sand, copper slag and nickel slag.

Comparison of the main parameters of abrasive materials will help you make the right choice

Preparation of river sand for sandblasting

As a preparation measure, the sand should be well dried and sieved. Before loading it into the sandblaster, it must be completely dry, otherwise the device may deteriorate. The permissible moisture level is determined by squeezing the material with your hand - it should flow freely through your fingers. The sand fraction must be ideally matched to the nozzle size, which is achieved by screening on sieves with the desired mesh size.

How to sift sand for sandblasting?

To clean the sand at home, you can use improvised means - tulle, gauze, flour sieve, mosquito net. The main thing is to sift the abrasive several times so that it has high quality, is uniform in particle size and does not include impurities.

How to dry sand for sandblasting?

The easiest way is to dry the sand in a special drum dryer. The installation has a convenient drying chamber and a built-in sieve, so the time and effort required to prepare the abrasive will be minimal.In the absence of such a device, you can dry the sand over a fire flame. To do this, a sheet of metal, an iron box, and another metal container are fixed over the fire, where the sand will be located. Some craftsmen dry the material with a heat gun, sprinkling it on film. It is convenient and easy to do, and the quality of the finished abrasive will be at a decent level.