Species overview

Perforated decorative panels are of high density fiberboard (HDF), metal, plasterboard, plastic. As for HDF, they can be divided according to the method of coating into the following types:

- polished uncoated slabs;

- lamination was done on one side;

- lamination is done on both sides;

- paintwork;

- the use of foil to decorate the front surface;

- veneer application.

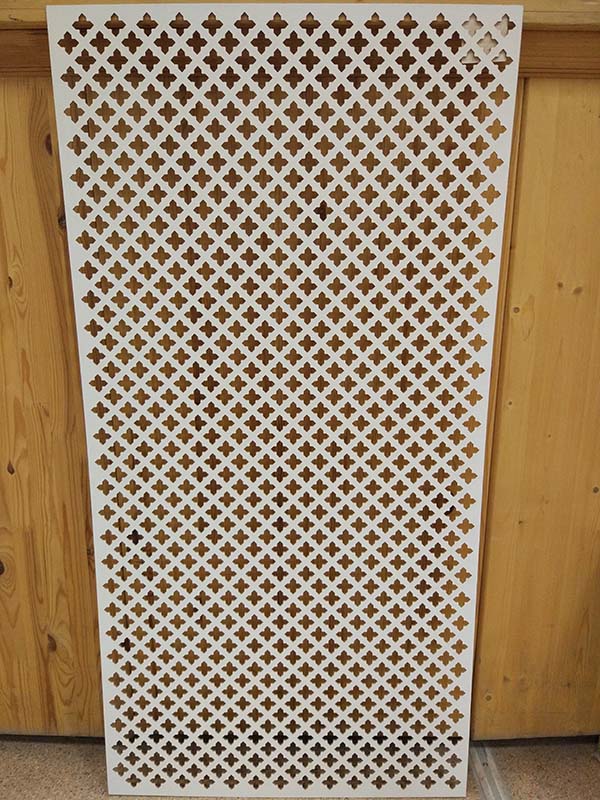

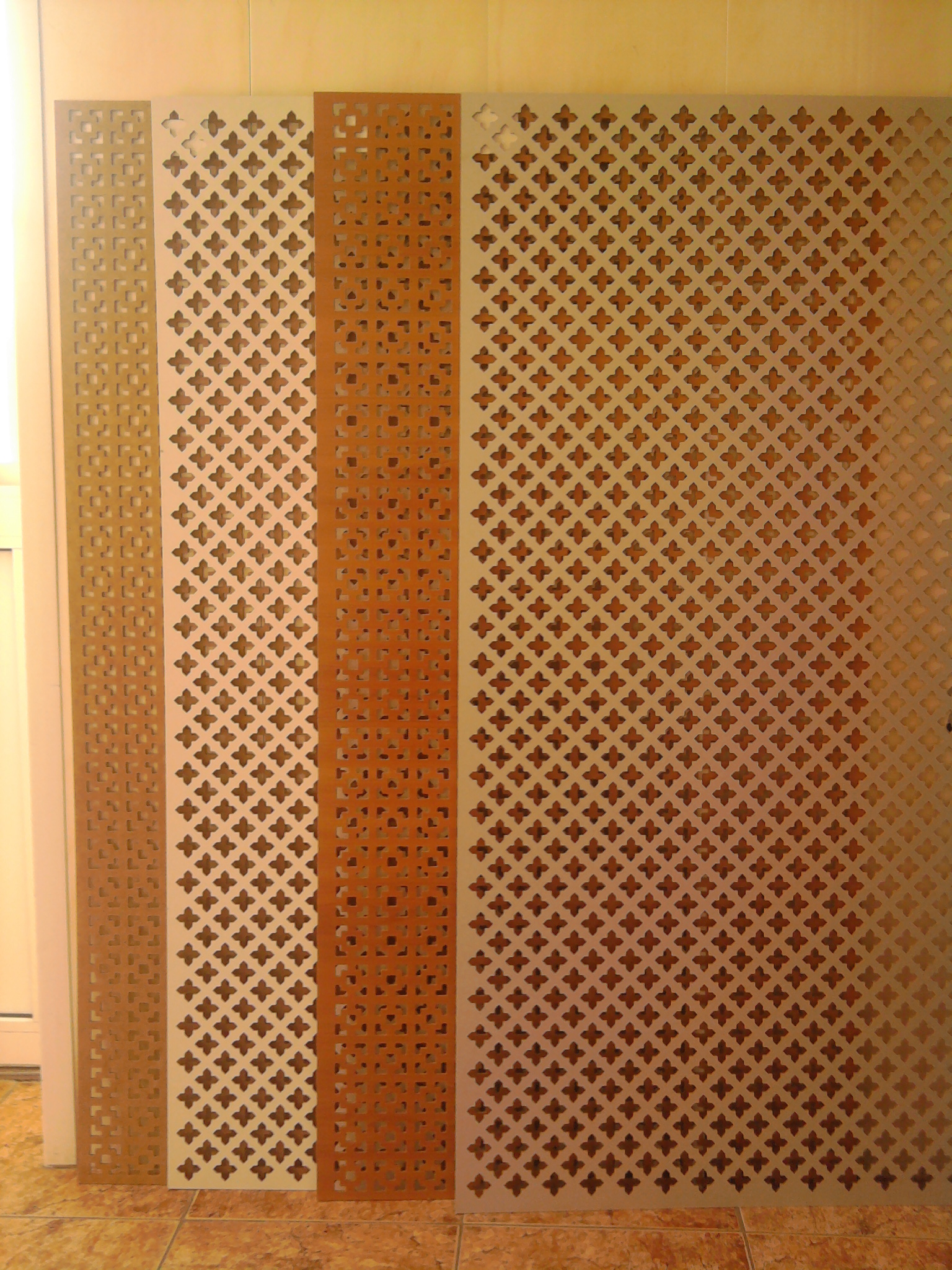

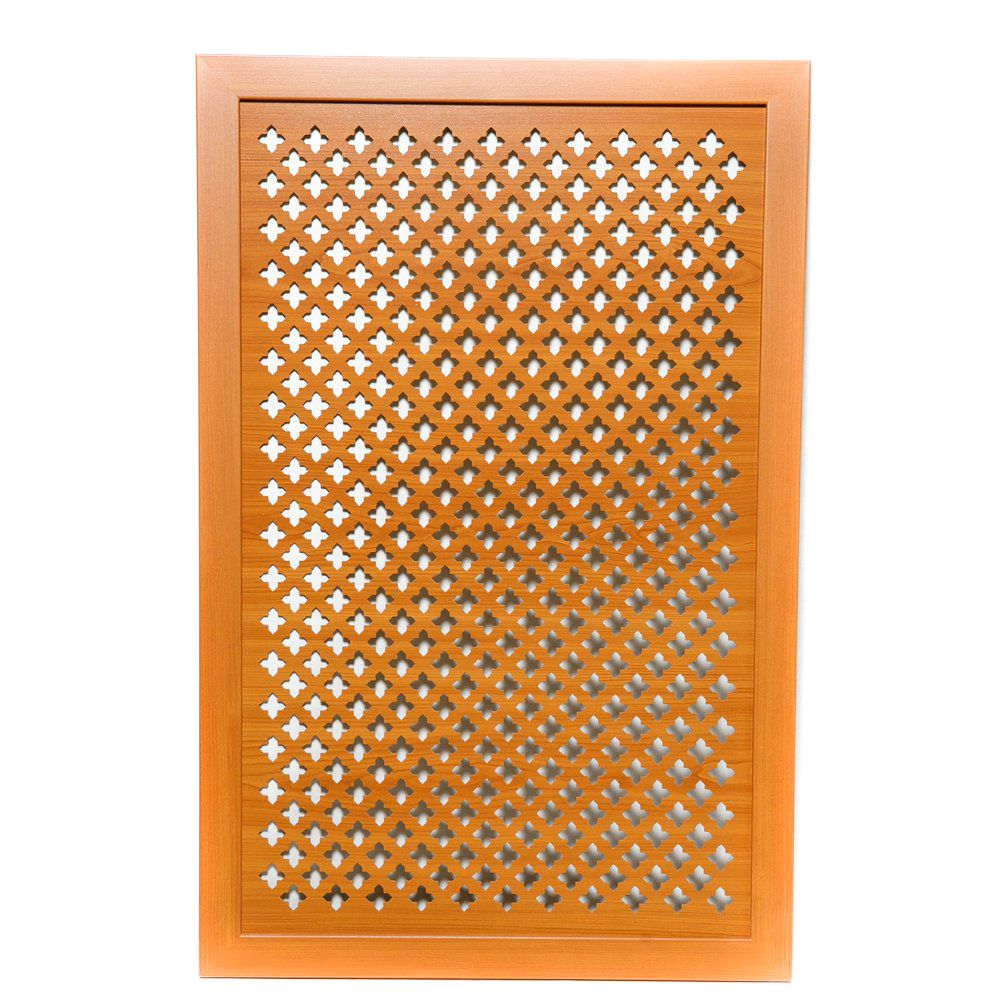

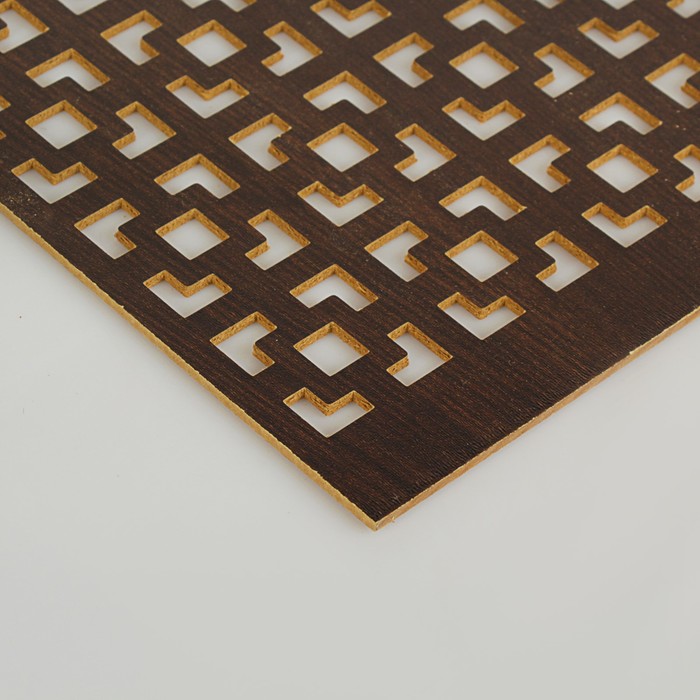

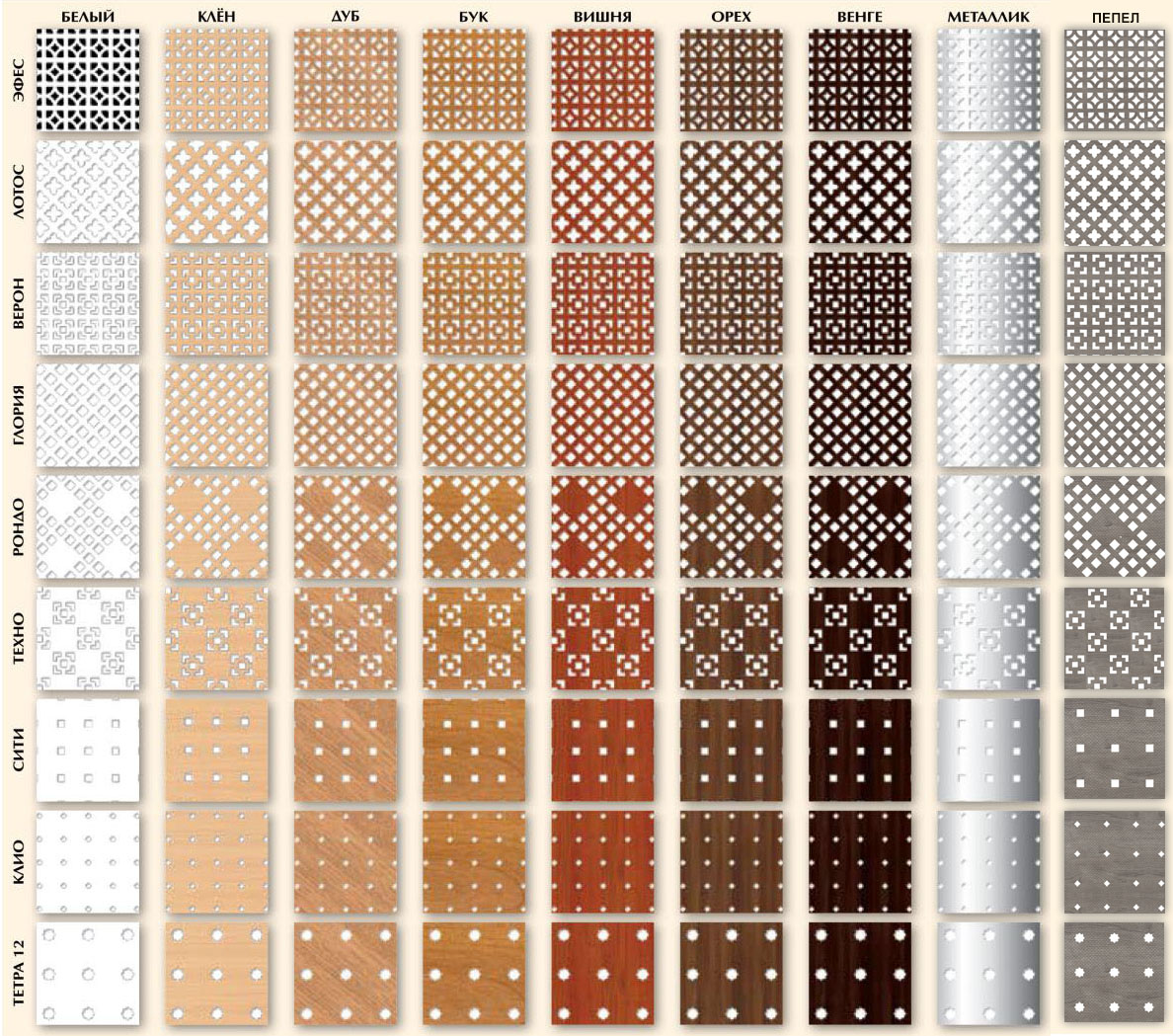

Perforated sheets differ in the shape of the holes, they have different divisions and sizes of sections. Holes are square, round, triangular, rhombic, oblong, artistic. Manufacturers often give names to perforated patterns, thereby dividing them into types such as:

- Quadro - the drawing is made in the form of squares of different sizes (Quadro 10x20, Quadro 8x28); the figures are at different distances from each other;

- Circus - perforation is a circle in a shell (with a contour), closely pressed against each other;

- Foro - circles, sequentially punched on the plane of the screen;

- Franz - the drawing is made in the form of crossed oblique stripes, with rhombic slots formed at the intersection points;

- Veronica - the circular image of the holes resembles the outline of the sun;

- Gothic - the slabs are made in the form of a lattice with beautiful artistic crosses.

Peculiarities

Let's try to figure out what a perforated HDF is. Let's start by defining "perforation". This is the name of the many small holes located in a certain order on the surface of the sheet, plate, screen. Most often, simple shapes are cut, but more complex combinations can be made. The basis for cutting is wood products, metal, plastic and other materials. Wood products suitable for perforation include three types of panels, such as:

- Fiberboard is the most budgetary type of product, but only a dense variety - "hardboard" is suitable for applying a through pattern;

- MDF - slabs, denser than the previous material and their cost, respectively, higher; products are classified as medium strength options;

- HDF - panels of this type have the highest density among wood-based panels.

The production of products comes from waste obtained after processing different types of trees. The chips are hot pressed under high pressure to form panels of specified dimensions. HDF is much cheaper than wood, but in terms of density it is almost not inferior. HDF boards can be perforated successfully. Finished products are distinguished by the following characteristics:

- excellent density and strength make them resistant to abrasion; despite the apparent elegance, the material is quite strong and able to serve in places with a large passage of people;

- moisture resistance allows HDF to be used in kitchens and bathrooms;

- good resistance to ultraviolet and high temperatures makes it possible to decorate fireplaces with HDF plates and use them for outdoor furniture;

- fingerprints and stains do not remain on the surfaces of products;

- the choice of slab sizes provided by the manufacturers makes it easier to use them during the production of furniture and interior design;

- the variety of decorative holes on the perforated canvas expands the choice; moreover, you can order your own drawing for a specific stylized setting;

- plates are universal, suitable for a wide range of applications; they are easy to install and do not take much time during the installation process;

- the material is highly flexible and can be used in situations where surface plasticity is required;

- perforated HDF slabs are endowed with excellent soundproofing properties, they are often used in cinemas and concert halls;

- the effective appearance of the material allows it to be introduced into many interiors; for some designs, models are selected that imitate certain types of wood; multi-colored slabs are also produced, more suitable for modern environments; there are products intended for painting - they are necessary for complex interiors that require several color solutions at the same time.

Care Tips

Perforated products are more difficult to care for than a solid, smooth surface, since dust settles in the slot patterns. In order not to create problems for yourself, you should wipe them with a soft, damp cloth regularly, without lengthy gaps, not allowing dust and dirt to take their place in the tiny holes. A soapy detergent can be added to clean water several times a month. It is not necessary to bring perforated surfaces to the need to use hard brushes or metal scourers for maintenance. HDF is a dense pressed material that can withstand a lot, but scratches cannot be avoided for a poor quality product.

If the perforated elements can be separated from the general structure, for example, by removing the cabinet doors or the radiator screen, they are transferred to the bathroom and the impurities are washed off with a strong pressure of water. HDF has good moisture resistance, but, despite this, it is better to immediately wipe the product dry with a soft cloth and install it in its original place.

In the next video, you will see the milling of a perforated panel.

Areas of use

Perforated HDF panels, despite their strength, visually appear light. They do not burden the space and improve its aesthetic appearance, wherever they have to be. Due to these properties, the products have a wide range of applications, namely:

they are used to decorate walls in residential buildings, offices, restaurants, concert halls, wherever it is necessary to improve the possibilities of the interior; in addition to the aesthetic component, the walls acquire ventilation properties;

panels are great as openwork partitions when it is necessary to zone the space in a living room or in an office;

suspended ceilings made of perforated slabs are unusual and make an unforgettable impression, they also have a practical purpose; in damp rooms that need good ventilation, ventilated ceilings are necessary;

in concert halls, ceiling cladding can be combined with the same walls and get excellent acoustic capabilities;

the material is used for the manufacture of window platbands, if the perforation feature is needed for a design concept;

screens of this type are used to decorate exhibition equipment, their unusualness attracts attention, speaks of the solidity of the supplier, which helps him to receive additional bonuses;

as lightweight fences, panels are used for gazebos, open verandas and balconies;

perforated screens successfully hide radiators without disturbing the circulation of warm air in the room; they can also be used to hide other engineering communications.

Separately, I would like to dwell on the use of HDF in the furniture industry. The perforated lattice is used not only to create facades, but also in the following cases:

- make lightweight doors for sliding wardrobes;

- decorate the doors of kitchen sets;

- decorate upholstered furniture with perforated elements;

- used to create bar counters;

- add variety to children's headsets;

- decorate the headboards;

- wardrobes, chests of drawers, closed shelves are decorated with ventilated inserts.