The choice of the binder

Glue

Today there are several opinions about which solution should be used for the installation of blocks:

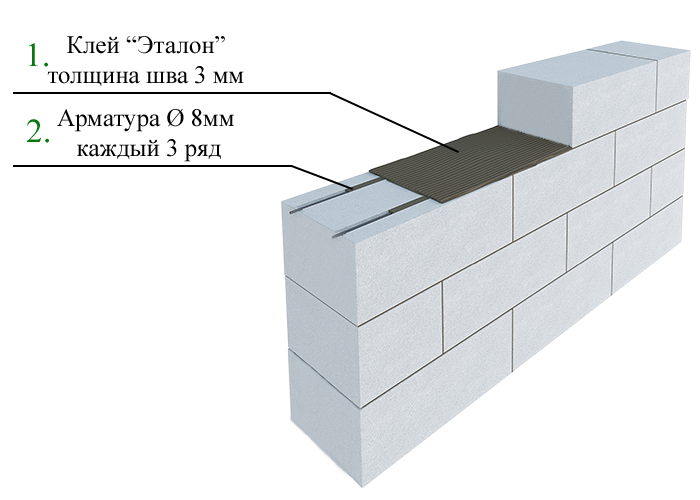

- Some say that it is better to use lime mortar the old fashioned way. Maybe this is so, because it is warmer than just sandy and at the same time, when completely dry and with a low cement content, it has a white appearance. But it has a negative side - it is very fragile. If such a solution is used, then the reinforcement of each layer must be performed without fail. It is better suited for building thick walls than partitions.

- Special cement-sand glue. It contains a plasticizer and a hardener, which allows it to be spread in a thin layer, providing an almost seamless connection of the blocks. That is why we will consider how to put gas blocks on glue.

But the first step is to buy it. It is sold in paper bags with the words "Gas block glue" written on them. You can also use tile adhesive, it has the same properties.

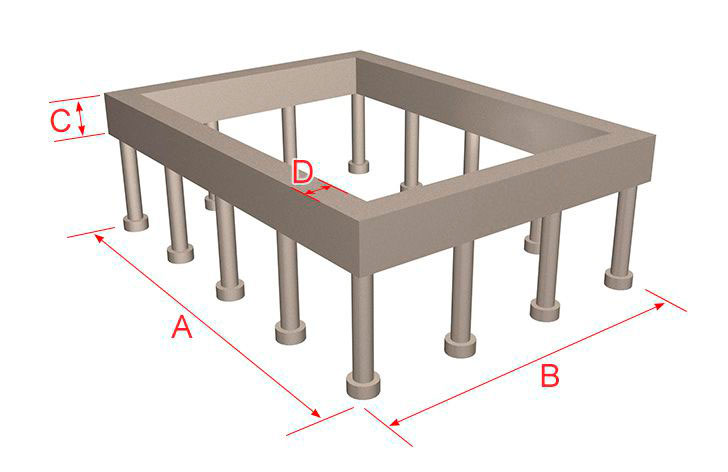

Calculation of the pile foundation

Select the type of grillage:

Grillage parameters:

Grillage width A (mm)

Grillage length B (mm)

Grillage height C (mm)

Grillage thickness D (mm)

Concrete grade

M100 (B7.5) M150 (B10) M200 (B15) M250 (B20) M300 (B22.5) M350 (B25) M400 (B30) M450 (B35) M500 (B40) M550 (B45) M600 (B50) M700 ( B55) M800 (B60)

Poles and piles parameters:

Number of poles and piles (pcs)

Column diameter D1 (mm)

Post height H1 (mm)

Post base diameter D2 (mm)

Post base height H2 (mm)

Reinforcement calculation:

Rebar length (m)

Calculation of the grillage formwork:

Board width (mm)

Board length (mm)

Board thickness (mm)

Calculate

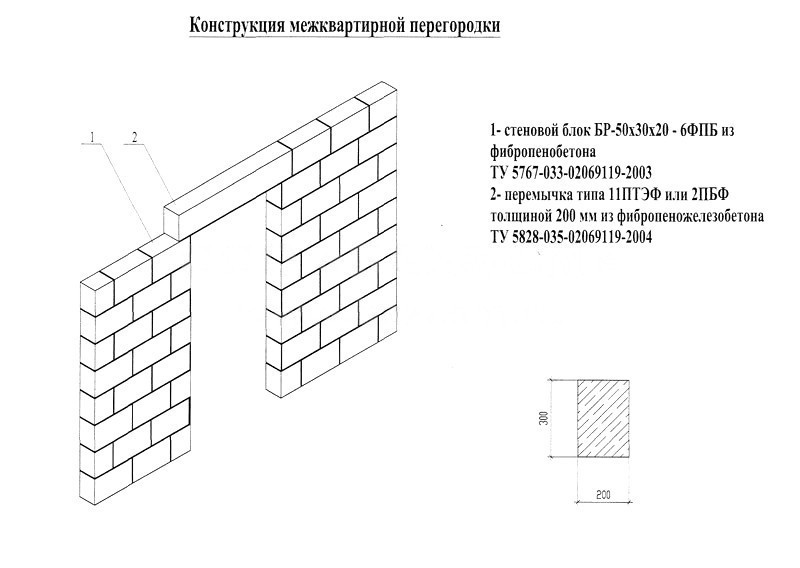

The thickness of aerated concrete partitions

For the construction of partitions inside the premises, special gas silicate blocks are produced with a smaller thickness. The standard thickness of partition blocks is 100-150 mm. You can find non-standard in 75 mm and 175 mm. The width and height remain the same:

- width 600 mm and 625 mm;

- height 200 mm, 250 mm, 300 mm.

The brand of aerated concrete blocks must be at least D 400. This is the minimum density that can be used for the construction of partitions up to 3 meters high. The optimal one is D500. You can take more dense ones - D 600 brands, but their cost will be higher, but they have a better bearing capacity: it will be possible to hang objects on the wall using special anchors.

It is almost impossible to determine the brand of aerated concrete without experience. You can "by eye" see the difference between the thermal insulation blocks density. D300 and wall D600, but between 500 and 600 it is difficult to catch.

The lower the density, the larger the "bubbles"

The only control available is weighing. Data on the dimensions, volume and weight of aerated concrete partition blocks are given in the table.

Parameters of aerated concrete blocks for partitions

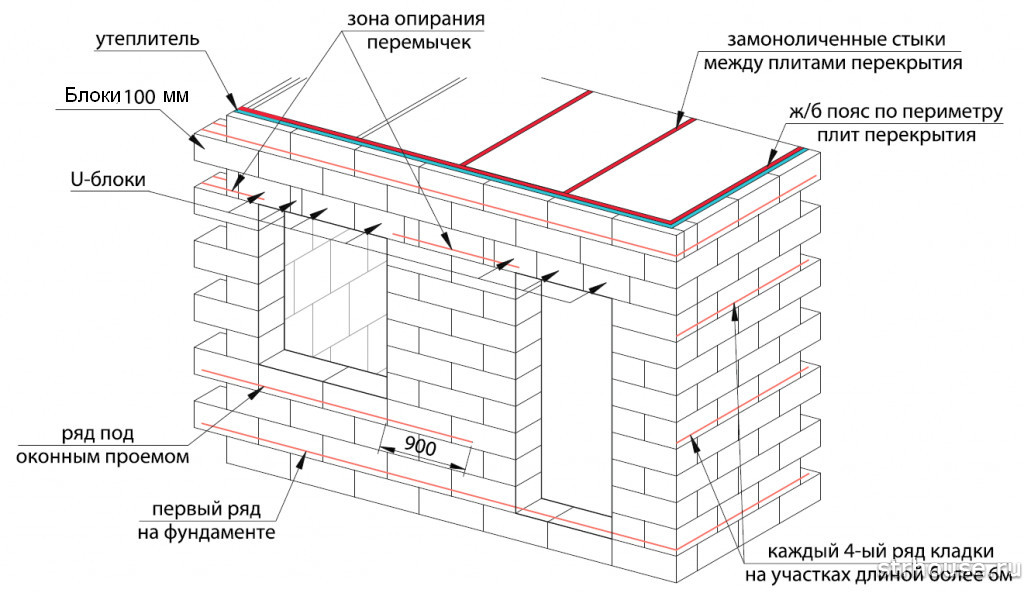

The thickness of aerated concrete partitions is selected according to several factors. The first is whether it is a load-bearing wall or not. If the wall is bearing, in an amicable way, the calculation of the bearing capacity is required. In real life, they are made of the same width as the external load-bearing walls. Basically - from wall blocks 200 mm wide with reinforcement every 3-4 rows, like the outer walls. If the partition is not load-bearing, use the second parameter: height.

- At a height of up to 3 meters, blocks of 100 mm in width are used;

- from 3 m to 5 m - the thickness of the block is already taken 200 mm.

More precisely, you can choose the thickness of the block according to the table. It takes into account such factors as the presence of mating with the top floor and the length of the partition.

The choice of the thickness of the partitions from aerated concrete blocks

Mounting

rules

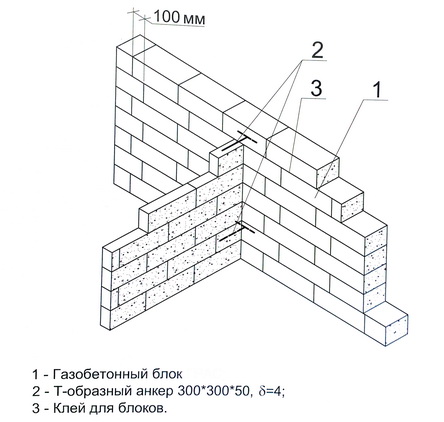

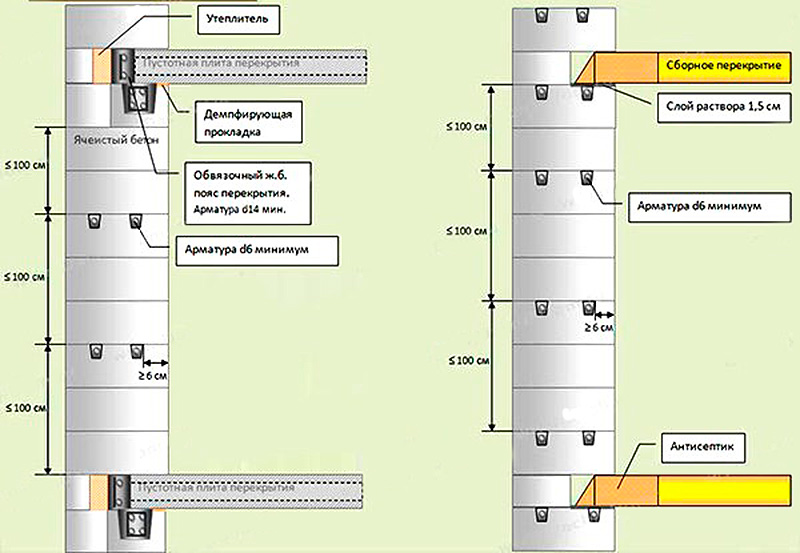

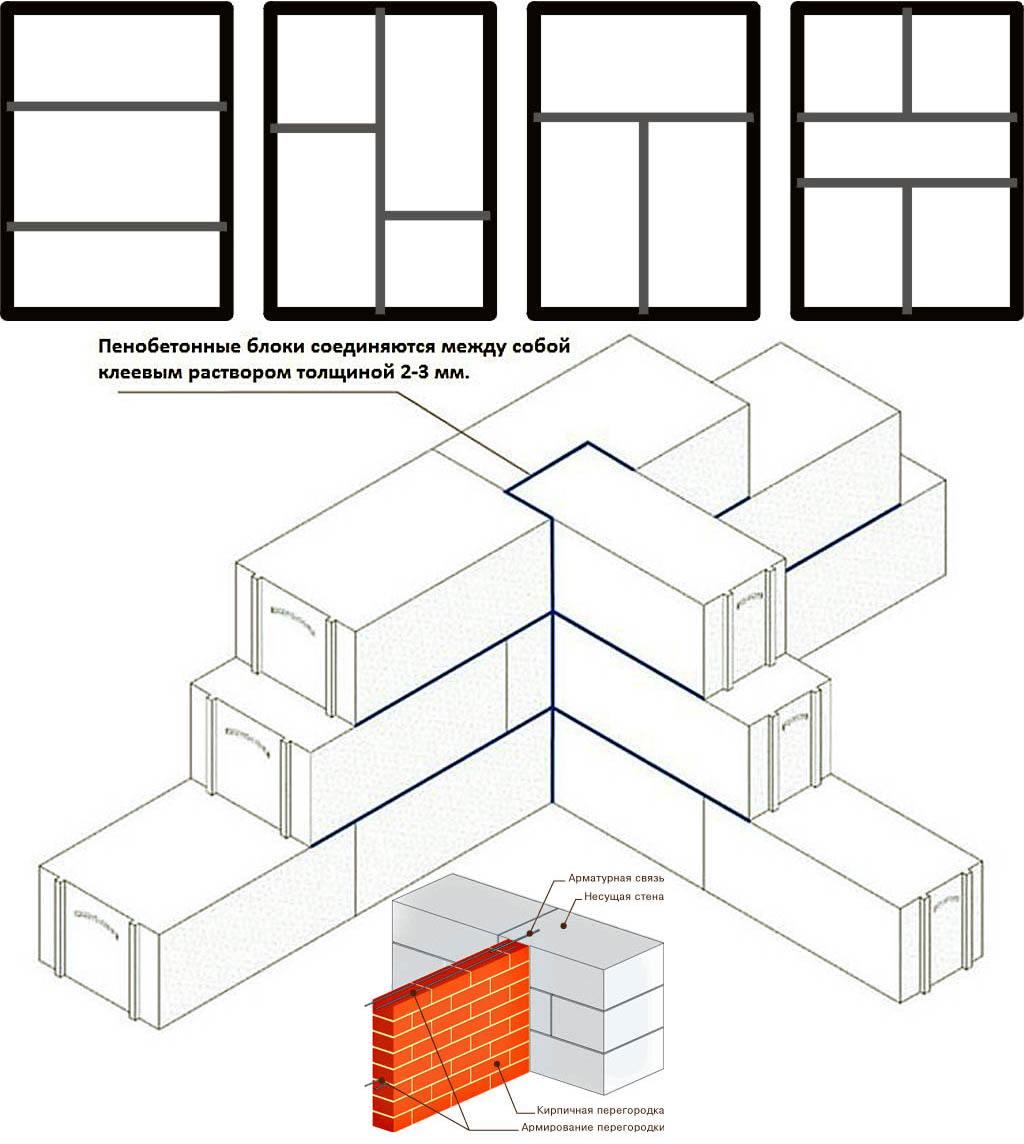

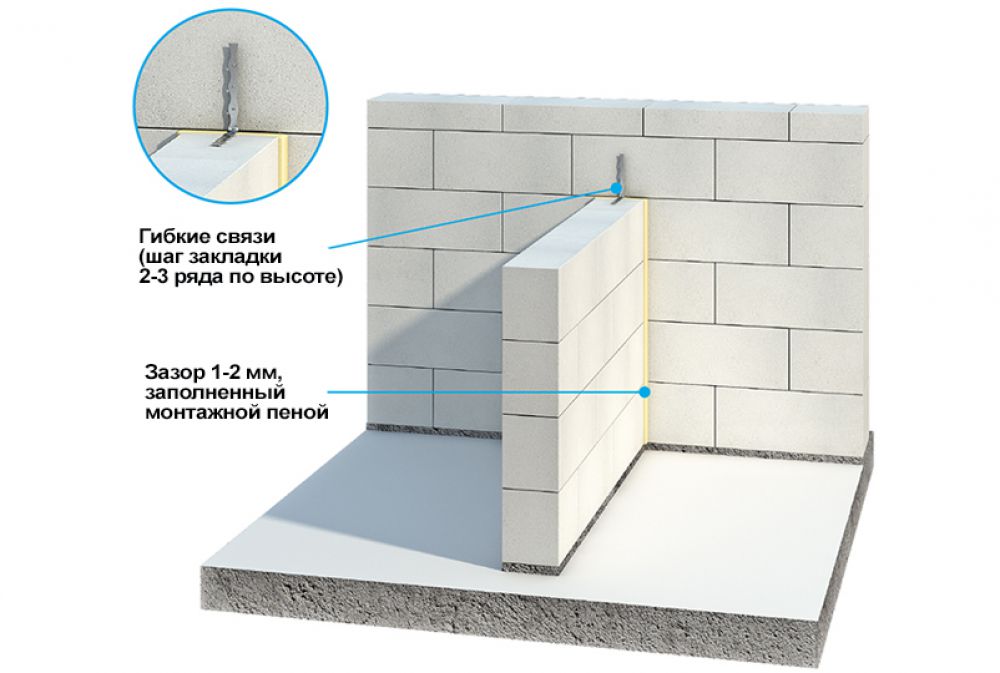

Installation of partitions made of aerated concrete blocks is performed with the obligatory bandaging of vertical seams. Simply put, the joint between blocks in the same horizontal row should not be above the same joint next to it below. The minimum horizontal distance between vertical seams is 20 cm;

Pay attention to the ligation of the vertical stitches

The top of the partition must not extend to the ceiling.Between the upper row of blocks and the overlap, there is an expansion gap of 1.5-2 cm, which is filled with polyurethane foam or any other elastic sound-insulating material. In this case, thermal expansion and deflection of the floor under load will not lead to cracks in the aerated concrete;

The joint between the wall and the ceiling is filled with polyurethane foam

The joint between the wall and the ceiling is filled with polyurethane foam

The partition should be attached to adjacent walls in increments of no more than a meter in height. This instruction is intended to provide additional stability with respect to horizontal loads, and the absence of cracks in the corners. For fastening, stainless or galvanized anchor plates and perforated strips laid between the rows of masonry are used;

Fastening an aerated concrete partition to an adjacent wall

Fastening an aerated concrete partition to an adjacent wall

For masonry, use only and exclusively special glue. The use of a cement-sand mortar will make you spend extra time sealing rough joints;

Thin glue from one of the largest manufacturers of aerated concrete

Thin glue from one of the largest manufacturers of aerated concrete

Storage of aerated concrete

In what conditions can aerated concrete blocks for interior partitions be stored before starting work, and how can they be properly unloaded to avoid damage?

- To unload pallets from transport, use belts or soft slings. Steel cables are guaranteed to damage the side walls of the blocks;

Aerated concrete pallet unloading: soft belts are used

Aerated concrete pallet unloading: soft belts are used

- Fold the individual blocks on a flat surface, placing a rag or other soft material under them;

- If repair or finishing work is underway in the room, cover the aerated concrete partition blocks with polyethylene. The film will protect their surface from paint, grout and other contaminants.

First row

Do-it-yourself aerated concrete partition erection begins with laying out the first row. The appearance and durability of the wall as a whole depends on how smooth it turns out. Yes, it is durability: uneven masonry contributes to the appearance of cracks in places of maximum stress.

Here are some rules for laying the first row:

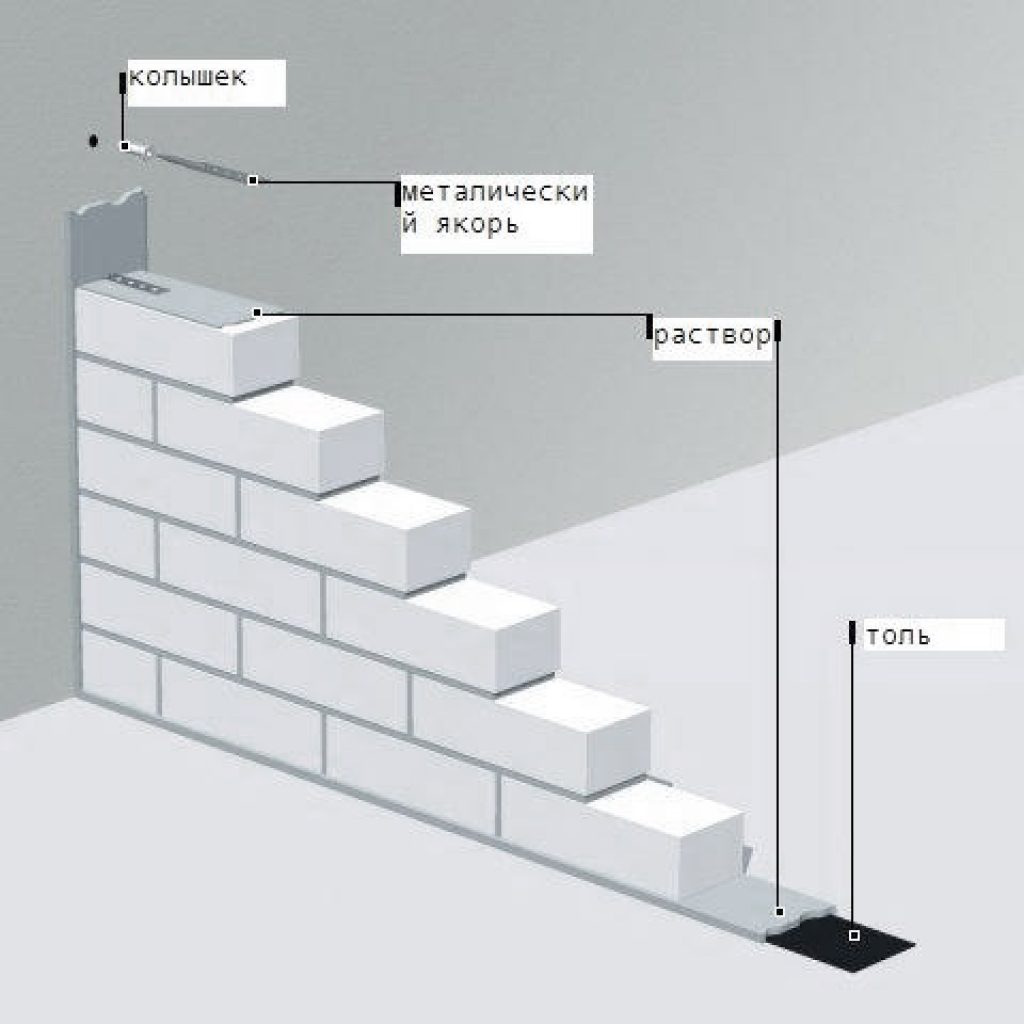

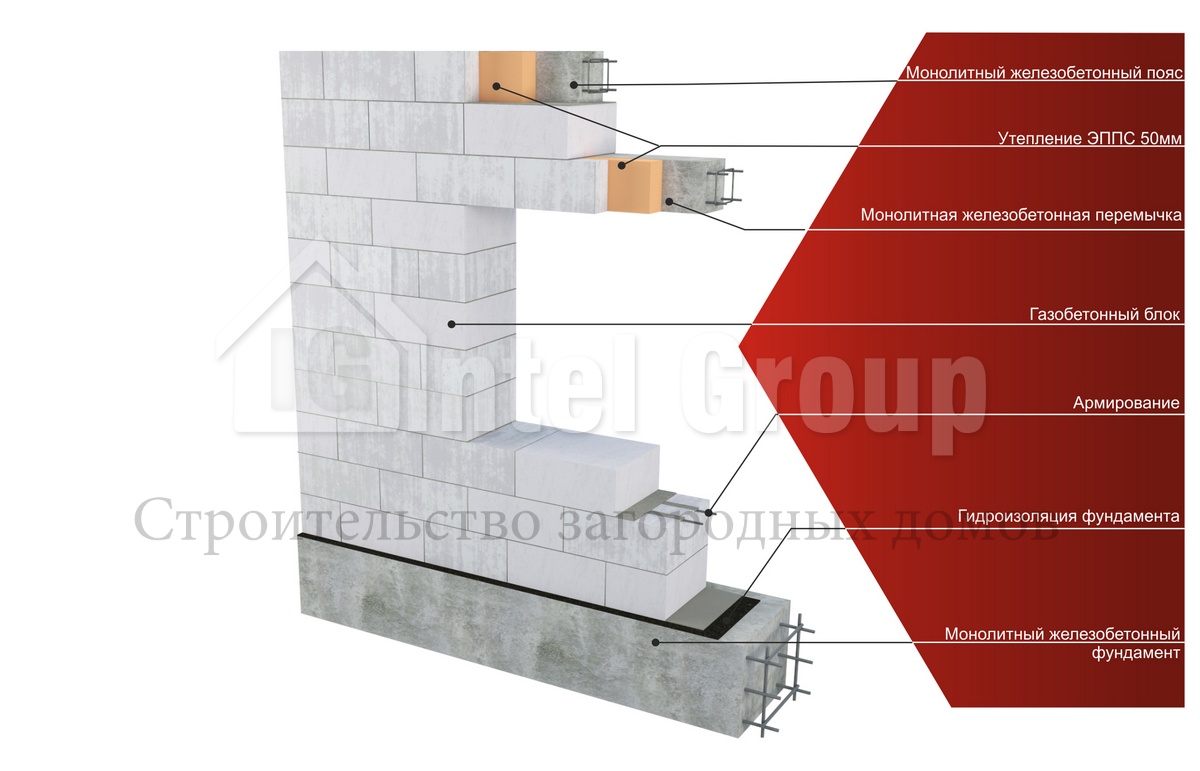

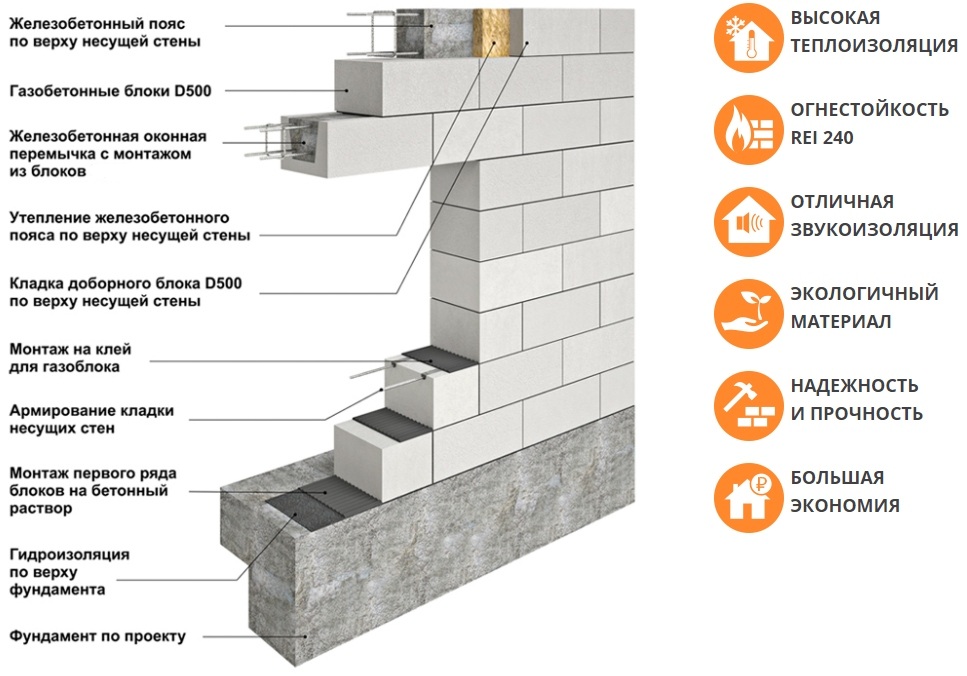

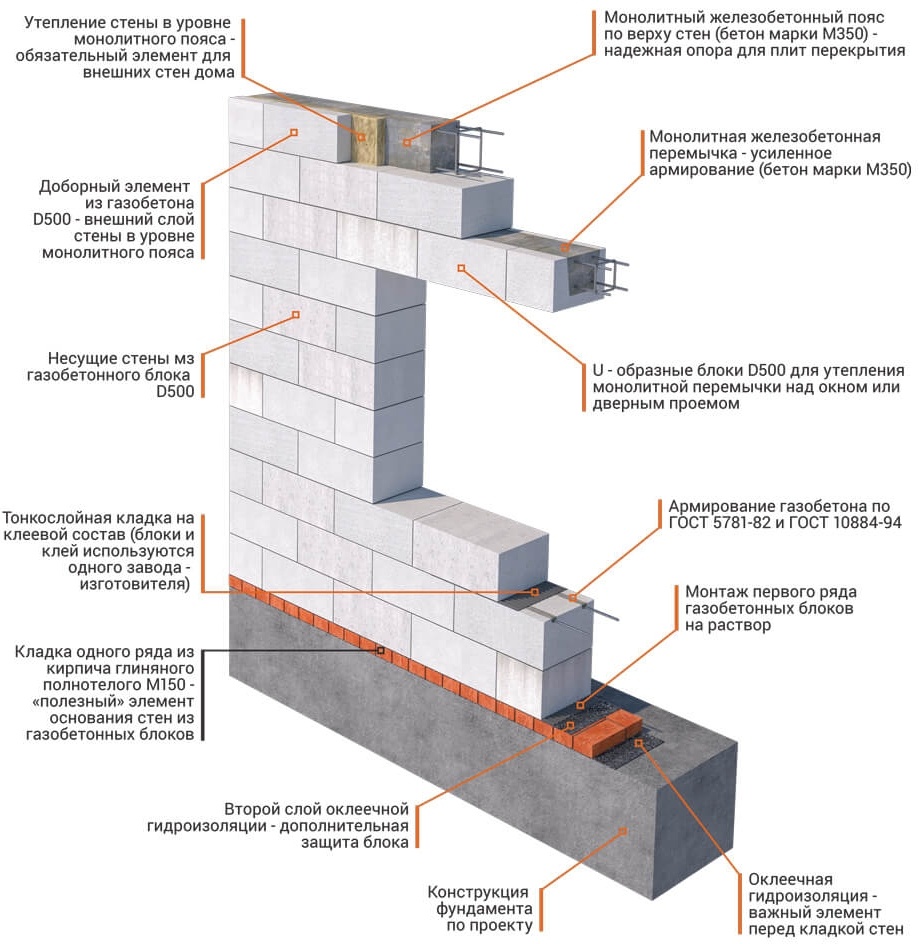

- Waterproof the wall from the floor or foundation. It will exclude the suction of moisture through the capillaries of the porous material. To do this, spread two layers of roofing material along the future partition;

- On an uneven surface, lay aerated concrete partition blocks on a leveling cement-sand cushion with horizon control along a long level and a mooring - a cord stretched at the height of the block surface;

Laying the first row. The photo shows the waterproofing and the cement-sand cushion.

Laying the first row. The photo shows the waterproofing and the cement-sand cushion.

Control the relative position of the blocks with a long level

Control the relative position of the blocks with a long level

- Having laid a row, check the absence of the slightest difference between adjacent blocks. If the differences remain, remove all irregularities with a float and sweep away the remaining dust;

- To mark and make strictly vertical the boundaries of the openings, install vertical slats with marks at the level of each new row. Between the marks on the slats, the mooring cord will move as the wall grows.

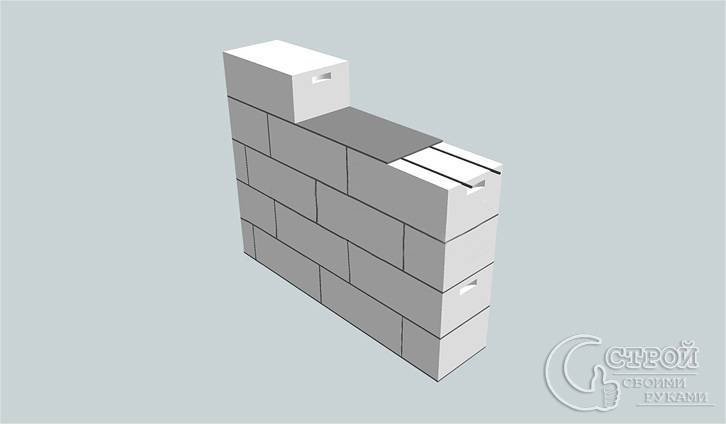

Next rows

The second and subsequent rows are laid on the same level and mooring cord. On the vertical surface of the previous block or wall, and on the top of the previous row, glue is applied with a notched bucket, carriage or notched trowel; then the aerated concrete partition block is fitted with a rubber hammer. The last in the row, the additional block is cut in place.

Application of glue using a carriage with a width corresponding to the thickness of the block

Application of glue using a carriage with a width corresponding to the thickness of the block

Features of the construction of the partition

When erecting internal walls, it is necessary to control their evenness with a building level.

At the place of the future laying of the first layer of aerated concrete blocks, a strip of material aimed at sound insulation is glued. The first level of the partition is "planted" on it. It is necessary to ensure that the laying is even and regularly check the brickwork with the help of a building level.The fewer defects on the surface of the finished inner wall, the less finishing material will be required in the future.

When laying a wall, it is necessary to arrange excellent ventilation in the room. This will shorten the drying time.

In addition, you need to constantly monitor the correct placement of gas blocks during construction. The rows of the inner wall must be laid strictly perpendicular to the load-bearing wall. In one horizontal row, the elements are separated from each other using vertical mortar seams. Place the next row so that the middle of each new piece overlaps the vertical seam of the bottom row. This option of laying makes it possible to more evenly distribute the load, as well as significantly increase the resistance of the structure to settlement.

With an interior or interior system, you need to choose high grade cement. A solution from higher quality raw materials has much better strength indicators.

The surface of the products, which will come into direct contact with the solution, must be moistened with water. This will prevent the aerated blocks from being saturated with water from the solution. Otherwise, the solution will crack from lack of water, and the elements will lose their strength and stability qualities.

If the planned structure exceeds 5 m in height, then it is imperative to impose a reinforcing mesh on it. It will make the erected wall more stable and durable.

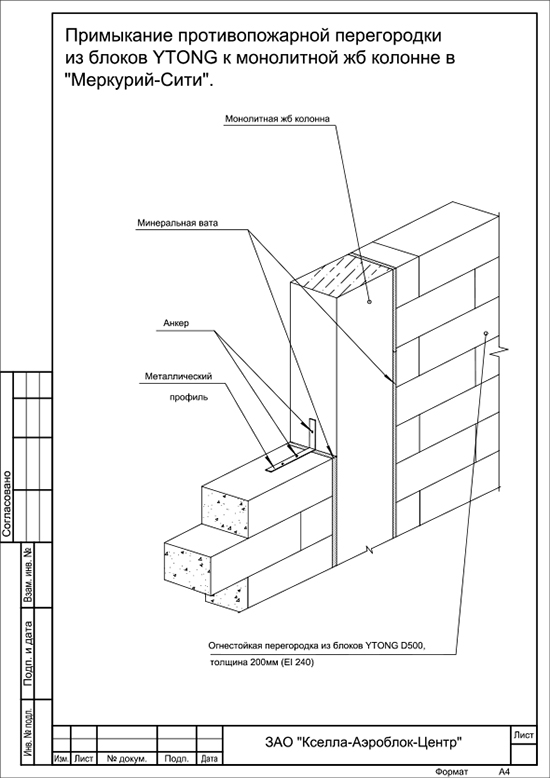

When building interior systems in the third way, that is, perpendicular to the load-bearing wall (almost touching it), the junction of the load-bearing wall and the partition needs to be strengthened. As a rule, this joint is filled with polyurethane foam or glued with the material that is used to create sound insulation. In some cases, special anchors are used to create greater stability. These elements are anchored deep into the load-bearing wall, thus providing the necessary strength to the block partitions.

Partitions are made of aerated concrete blocks, as a rule, after the erection of load-bearing walls, as well as after the erection of the floor. If there is no floor in a private house on the ground floor, then it must be done. That is, fill in the rough screed.

Partitions are made of aerated concrete with a density of 500 kg / m3 and a thickness of 10-20 cm.But in most cases, partitions are made of aerated concrete blocks 10 cm thick, such as described in this article. Blocks of this material have several advantages

, these are such as:

Light weight,

- perfect geometry,

- low consumption of glue,

- good sound insulation,

- good thermal insulation properties (although this does not matter for partitions),

- fire resistance,

- are not toxic,

- easy to install.

And there are requirements for partitions:

- The height of the partition must not exceed 3.5 m and the length 8.5 m.

Aerated concrete wall structures

Aerated concrete for external walls is produced in several types. Each of them differs in technical parameters and field of application.

Block types

You can determine the type of wall block by marking, which indicates its specific density in kg / m3. The higher it is, the stronger the material, but the lower its energy efficiency. The lower, the higher the porosity and the lower the strength.

- D300 - D500 - heat-insulating types of blocks;

- D500 - D900 - structural and thermal insulation;

- D1000 - D1200 - structural.

The photo shows the difference between materials with different specific gravity.

The photo shows the difference between materials with different specific gravity.

When choosing the type of material, it is necessary to take into account the purpose of the building and the type of walls. If for outbuildings thermal insulation characteristics are not of great importance, then for residential buildings they are no less important than load-bearing ones. Therefore, when they are erected, the construction of walls made of aerated concrete is usually carried out with blocks D500 - D600.

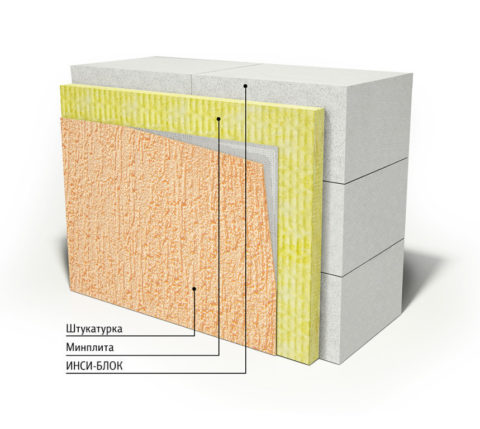

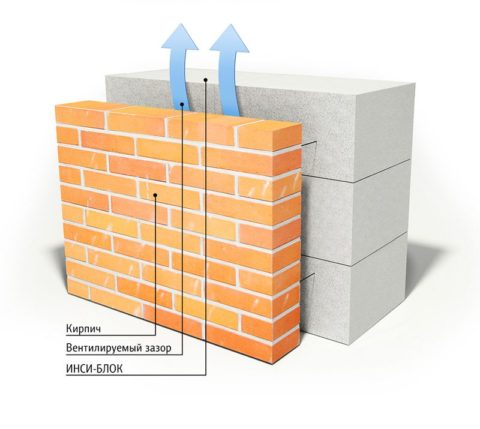

Types of aerated concrete walls

One of the main tasks in the design of such a house is to determine the thickness of the walls and their construction, taking into account the norms of heat conservation.The calculation of aerated concrete walls is based on the thermal conductivity of the material and climatic conditions in your region.

There are several options for external walls:

| Type of construction | Description |

|

|

The single-layer construction consists of blocks plastered from the outside using a reinforcing mesh. |

|

|

The plaster layer is applied over the insulation fixed to the walls. |

|

|

Load-bearing walls consist of a number of aerated concrete blocks and bricks with a mandatory ventilation gap between them. |

|

|

In this case, the insulation layer is covered with sheet facade materials along the crate. |

In the middle zone of our country, if aerated concrete wall 40 cm thick with plastering is used in the construction of a house, it is a perfectly acceptable option. In colder regions, multilayer structures are erected.

Sectional view of aerated concrete wall: gas-filled pores are visible, due to which heat is retained

Sectional view of aerated concrete wall: gas-filled pores are visible, due to which heat is retained

Mounting

A self-made solution is rarely used when laying aerated concrete partitions. It is better to use a special mixture designed for gas blocks - this is the same solution containing plasticizers and adhesives. Such additives have qualities that make the partitions strong and withstand heavy loads. It is convenient to carry out work with a special trowel with teeth. For construction work, you will need a trowel, a spatula, a grater and a level. Phased work points:

First row

You should step back a little from the wall - about 5 mm, treat the surface with an adhesive. After they put the first gas block for the partitions, then everything is carefully aligned along the fixed bars and a tracing cord.

Between the foundation and the aerated concrete panels, it is imperative to lay a waterproofing building material, in which case bitumen in rolls or specialized solutions are used. If the floor on which the installation will be carried out is not perfectly flat, then the first row is placed on a leveling cement-sand mixture. If the gap in the first row turns out to be less than the length of the whole block, you will need to make your own so-called additional block. The installation of such an element is carried out with full processing with an adhesive mixture.

Next rows

Subsequent rows should be erected with high quality and for this it is recommended to use a special draft for the blocks. The erection of a partition in a house made of aerated concrete in subsequent rows goes to the openings or to the edge of the wall with the same indentation from it - 5 mm. This is recommended in order to improve the sound insulation properties.

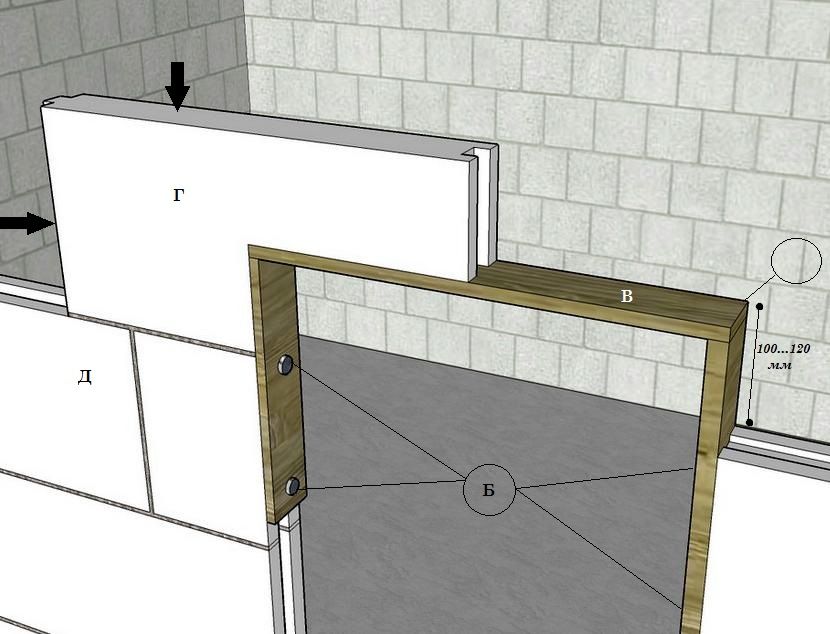

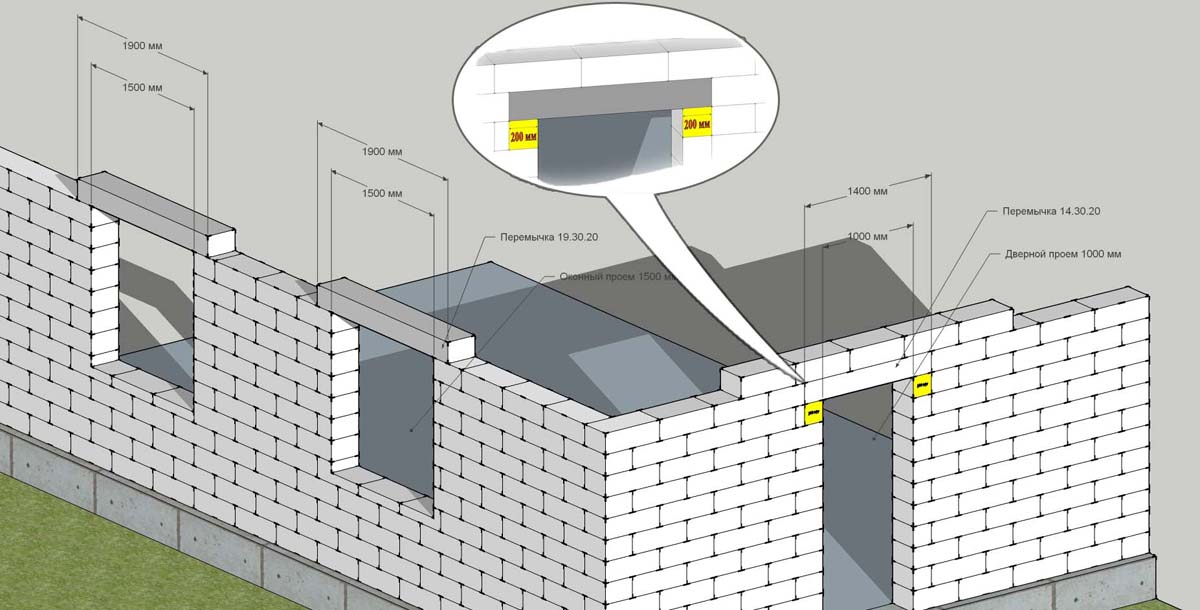

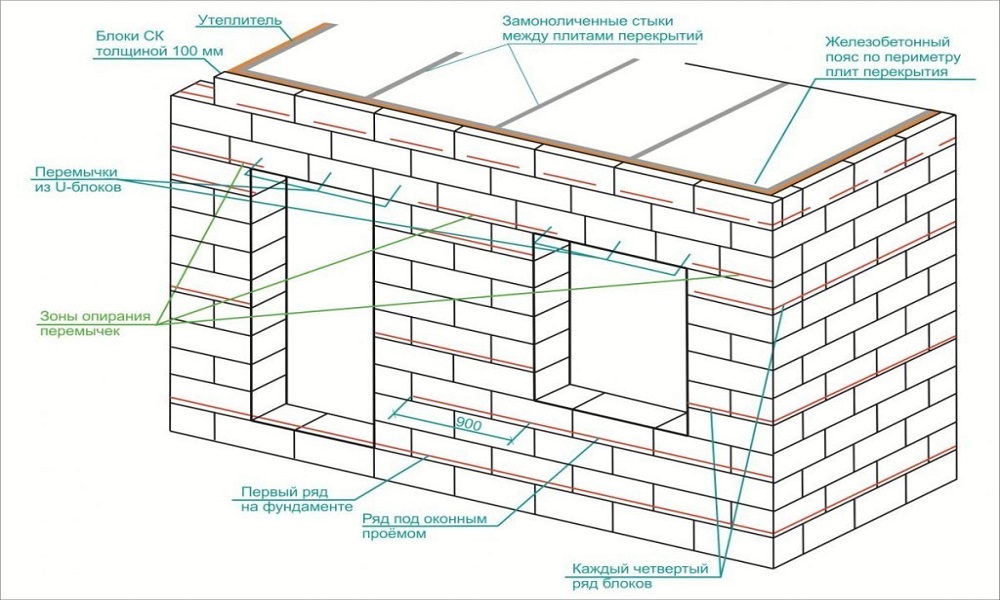

Openings

If the partition does not carry loads, standard reinforced concrete beams or lintels over the openings will not fit. For a standard door opening, two corners are laid, they will serve as a support for the blocks that will be laid above. The corners should be 30-50 cm larger than the openings; if they are wider than 60-80 cm, you will need to install an additional channel.

For narrow openings when two blocks are joined, the selection is carried out in such a way that the seams are in the middle of the opening. In this way, a stronger opening will be obtained. When mounted on corners or channel bars, the bearing capacity will be sufficiently strong and stable.

To strengthen the openings while the glue dries and to avoid metal deflections, it is recommended to nail boards in a narrow opening. At wider distances, you will need to build a support structure that will rest on the floor - this will require folding a column of blocks under the central part of the opening.

Partitions made of gas blocks are relatively light - one monolithic slab has dimensions of 60x30x10 cm and weighs 10.5 kg, this replaces 8 bricks, which weigh 24 kg.When porous masonry materials are used, doorway structures can be made without lintels.

How do I put the blocks further? After that, a solution is laid on the board, reinforcement of class A III with a diameter of 1.2 cm is installed on top.And already gas blocks are laid on top in the usual manner, while one should not forget about the displacements of the seams. It is necessary to dismantle the formwork frame after 3-4 days, when the solution is completely dry.

In front of the ceiling

Since the floor slab can bend under load, the height of the partition should be calculated so that it is 2 cm lower and does not adjoin the ceiling. If necessary, the blocks that will be laid in the upper row are sawn. As a result, a compensation gap should be obtained, it is recommended to seal it up with damping materials. This method will help reduce the audibility of sounds coming from the upper floor. Another simple option is to moisten the seam with water and blow out with polyurethane foam.

Requirements for a gas block partition

Aerated concrete partitions should be characterized by certain features. First, the structure should be quite solid. Secondly, you need to build a wall that will soundproof the adjacent spaces well. Thirdly, the wall must be safe from the point of view of fire resistance.

If the partition must separate rooms with different temperature regimes, requirements are imposed on it to isolate one room from another so that you can comfortably live in the house. If you carry out the correct finish, adding a layer of insulation to it, the wall will meet all these requirements, in addition, it will turn out to be inexpensive.

Optimal dimensions of aerated concrete partitions

The dimensions of aerated concrete blocks determine what dimensions the partition will have. Time is especially valuable today. If you want to complete the renovation or construction in a short period, it is better to use large-sized products, the length and width of which are 750 x 625 mm, respectively. The thickness can be 75 or 100 mm. This block format allows you to reduce glue consumption, speed up work and ensure ease of installation due to its low weight, which does not exceed 32 kg.

If the gas block will be used for the construction of a self-supporting partition, products of class B2.5 should be used. This recommendation is true for walls over 3 stories high. If this value is lower, the block strength should be B2. For the construction of a standard partition from a gas block, products with a size of 30 cm are used.If it is necessary to separate one room from another, blocks with a width of 15 cm should be used.The density here should be D300, since the issue of sound insulation is very important in this case.

More about sizes

The dimensions of the gas block are one of the important factors when choosing this material. Modern manufacturers produce products with a thickness of 75 mm to 200 mm. These dimensions are suitable for interior partitions, but the most common dimensions are blocks of 625 x 100 x 250 mm. Experts do not recommend using 75 mm blocks for walls with a large length, as they turn out to be echoing, and living inside the house becomes uncomfortable.

Device and features

Partitions from the gas block must be erected in such a way that a gap of 20 mm is observed between the structure and the ceiling. Aerated concrete blocks must be laid in such a way that the dressing rule is fulfilled. It is also necessary to ensure the correct connection of the structure to the side walls. Fixation is carried out with stainless steel anchor plates. There should be one fastening element per meter of height. Instead, you can use galvanized perforated tape. Aerated concrete blocks are placed on an adhesive solution, which saves money and material.

Vibration damping strips

In order for the operation of interior partitions made of aerated concrete blocks to be comfortable, they are supplemented with vibration damping strips. They are arranged using soft bubble material such as expanded polystyrene, cork or mineral wool. You can also use soft fiberboard. The layer will increase noise reduction and reduce the risk of cracking. It is necessary to lay the material between the wall and the floor, as well as the new partition.

Wall connection

When erecting a partition made of aerated concrete with your own hands, you need to correctly connect. It can be:

- elastic;

- tough.

In the second case, the inner partition is connected to the adjacent wall using strips or anchors. The half-length element is inserted into the supporting structure. The blocks should be positioned so that the seams of the load-bearing wall and the partition coincide. It is not recommended to use such a connection algorithm if the structure of the building has a rigid frame, since in this case there is a risk of cracks.

Aerated concrete partitions are sometimes also connected in an elastic way using L-shaped connectors. This eliminates the destruction of the walls and reduces the risk of deformation stresses. Such connections are nailed to the mating wall. Up to 4 pieces of such connectors are used at the height of the floor.

Openings in gas silicate partitions

If a doorway is expected in the aerated concrete partition, it should be noted that its approximate width should be 80 cm. By cutting out an opening in an already finished wall, you can reduce its strength. This can be compensated for by redistributing the load force by installing a jumper from above.

When the partition is being erected in parallel with the formation of the opening, it is necessary to install the timber lintel. The design can also be prefabricated and monolithic. The work uses U-shaped products. In a wall made of aerated concrete, the opening will not have quarters. The box will be fixed with metal brushes or galvanized nails. The space formed between the frame and the opening is filled with sound insulation, which is complemented by gaskets.

Last row: abutment to the ceiling

When erecting an interior partition from aerated concrete blocks, it is necessary to exclude the effect of the bending load of the floor on the wall. For this, the last row of the wall is laid with a gap between it and the ceiling of about 20 mm. If required, blocks of this row are sawn. The resulting gap is filled with a damper tape, you can also use mineral wool.

Many home craftsmen are wondering how to properly fold an aerated block interior partition so that it meets all the requirements, including soundproofing the space well. For a comfortable stay in a room that is separated by such a wall, it is better to provide a sound absorption level within 50 dB. Partition blocks are not able to endow the wall with such properties, therefore, when facing, the thickness of the outer layer should be increased in order to reach the noise reduction value and the standard.

Tools and materials

When aerated concrete for the partition has already been purchased, you should take care of the availability of all the necessary tools and materials. To carry out the work you will need:

- building level;

- puncher;

- hacksaw;

- putty knife;

- Bulgarian;

- ladder;

- paint brush;

- capacity.

It is imperative to prepare a tape measure, a rubber mallet and a notched trowel. You will need a solution and special glue, a sharp knife and a marker. For surface treatment, you need to stock up on a float with abrasive meshes.

First row

Before making a partition from aerated concrete blocks, the structure should be waterproofed from the foundation or floor. This will eliminate the impact of water on the porous surface of the material.To do this, you can use roofing material, laid in two layers. In the presence of drops on the base, the gas blocks are laid by leveling the surface with the help of cement mortar.

The first blocks of the aerated concrete partition are laid close to the wall. The position of the products is checked using a building level. The last blocks in the row are trimmed according to the remaining space. The gas block is laid in such a way that the thickness of the adhesive layer does not exceed 2 mm. Distribution of the mixture by a toothed trowel

It is important to exclude gaps

Next rows

The blocks in each row are checked for unevenness. If there are drops, they are eliminated by tapping on the gas block. The erection of a wall from gas blocks is carried out along a mooring cord. The seams should be displaced vertically by about 200 mm. The adhesive composition is applied not only to the horizontal, but also to the vertical surface. You can adjust the position of the products with a rubber mallet.

Openings

Reinforcement of the wall from blocks is carried out using a special mesh, which is laid in horizontal rows. For interior partitions, you can use metal rods, which are embedded in special grooves. Some masters form them in blocks on their own. In this case, the reinforcement is laid in 2 parallel rows.

As for the openings, the weight of the products must be taken into account. It is insignificant, therefore, the device of window and door openings is often carried out without the use of jumpers. Products are laid by the method of the most tight joining in the center of the opening. A wooden frame is temporarily installed to support the products. It is fixed with self-tapping screws to the partition made of aerated concrete blocks. The installation of the lintel is mandatory if the partition of the blocks provides for an opening 80 cm wide.

In front of the ceiling

Aerated concrete interior partitions should not come into contact with the ceiling, not only for the reason that they will be affected by the overlap. The expansion gap is also necessary in order to increase the level of sound insulation. Mineral wool, which acts as an outer layer, will also reduce the noise level by 50%. Decorative material is laid on its surface.

Material consumption

Before starting work, you need to determine the consumption of blocks at a certain thickness of the future wall. Everything will depend on how thick the interior partition should be. If this value is 100 mm, then 0.1 m3 of products will be needed per square meter. This is equal to 6.4 blocks. Aerated concrete products will be consumed in a volume of 0.375 m3 per square meter if the wall thickness increases to 375 mm.

Aerated block partition wall decoration

Before facing the partitions made of aerated concrete blocks, cracks in the corners and between the walls must be repaired. If the work is carried out in a damp room, the structure is treated with a hydrophobic primer, then covered with plaster. After the wall has been erected, it is usually covered with cement plaster. It is prepared from:

- cement;

- sand;

- water.

The first one should be used with the M400 marking. So much water should be added so that the composition turns out to be plastic, but does not turn out to be too liquid.

Single layer

Single layer Two-layer with thermal insulation

Two-layer with thermal insulation Two-layer with cladding

Two-layer with cladding Three-layer with ventilated facade

Three-layer with ventilated facade