PPU roof insulation: your benefits, our efforts

For construction organizations - polyurethane foam roof insulation and roof waterproofing of newly erected or reconstructed objects according to your or our turnkey project. You are getting:

- reduction of construction time;

- the guarantee covers the period of responsibility of the developer (contractor).

For owners of industrial facilities - insulation of the roof of an industrial building. You are getting:

- thermal insulation of roofs in any condition, the ability to postpone the replacement of the existing roofing;

- performance of work without violating the mode of operation of the enterprise.

For management companies, housing and communal services organizations and the municipality - insulation of roofs of apartment buildings, public and administrative buildings. You are getting:

- guaranteed fulfillment of the requirements of Federal Law No. 261-ФЗ "On energy saving and on increasing energy efficiency ...";

- "Minimal effect of presence" during work - no disturbance for residents, employees of organizations, buyers, etc.

Views

All foam heaters differ in composition and structure. Let's highlight several types of heat insulators and consider their features:

- Penoizol. Despite the fact that aldehydes are included in the foam insulation, which are harmful to health, according to the manufacturers, this is not the case. Penoizol dries longer than polyurethane foam (more on it later). This takes 2 to 3 days. Most often, penoizol is used for thermal insulation of the attic, floors and walls. It goes on sale both in liquid form and in ready-made slabs.

- Foam concrete. They are also bought in liquid form, used for pouring the foundation. It is practically not used for facade insulation, since it has a lot of weight. In addition, the price of the products is overpriced.

- Polyurethane foam is also used as insulation. However, it will not work entirely to process the walls with it, and this is not rational either. Ideally suitable for sealing joints, plate joints, holes. It is sold in small cylinders. Reacting with air, it begins to increase 20 times.

- Polyurethane foam (PPU). This option is the most common, versatile and effective when performing thermal insulation. It is often used to insulate facades, walls, and sloped roofs. It is based on two components, which are mixed in a special unit immediately before use. As in the case of polyurethane foam, it begins to increase in size. Insulation with polyurethane foam allows you to reliably insulate your home.

Safety engineering

Although PU foam is not a poisonous material, handling it can lead to accidents. In order to prevent this from happening, you should follow basic safety measures.

The most important safety features of the insulation process are equipment and protective clothing that are in good working order. The entire spraying process is best done in a special suit, in which the human skin will be completely protected from contact with polyurethane foam. The mucous membranes of the eye should be covered with glasses, the respiratory tract - with a respirator or gas mask.

The instruction will help beginners to properly prepare the sprayed composition and load this insulation into the construction gun. It is also required to have a special solvent on hand so that if drops of foamy insulation get on the skin, immediately wash it off. The cost of work is determined individually and depends on the complexity of the working surface and on the thickness of the applied foam. The exact price of installing the insulation can be said only after a visual inspection of the building.

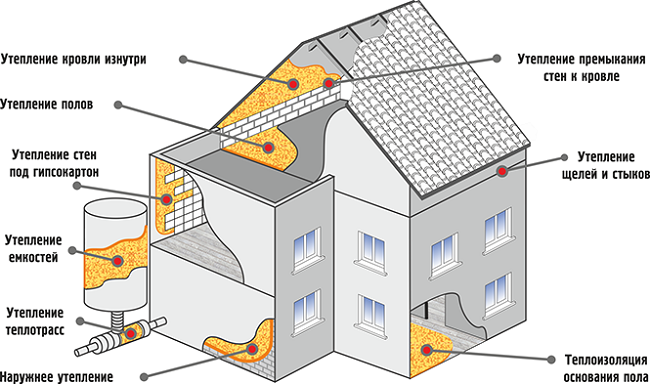

Scope of application

In light of the wide range of foams on the market today, it is necessary to have a clear understanding of the scope of use of a particular formulation.

As for penoizol, it is recommended for insulating frame structures. Such a composition fills the voids between the walls inside and outside, the wall and plastic material, the base and plasterboard sheets, as well as between the floor and the floor covering. Such a composition will provide reliable protection for the facade of the house from external factors, including precipitation.

Polyurethane foam is used when installing solid heat-insulating materials, after which the formed seams are sealed with the same composition. The products will come in handy in the process of arranging the foundation, as well as when working with the ceiling surface.

Polyurethane compounds, in addition to insulating walls, do an excellent job of sealing various cracks on them. In addition, voids are filled with polyurethane foam during the installation of window blocks and pipes. With the help of this material, basement and attic insulation is carried out. Two-component foam is purchased for treating the walls of frame-type houses.

Application

It is allowed to use Polinor insulation both inside the house and outside. At the same time, make sure that it is not directly affected by sunlight and moisture. The installation process is very simple and fast, and even an inexperienced person can cope with the task. All that is required is to install the balloon on the polyurethane foam gun.

But before that, it is important to properly prepare the surface. It must be free from dust, dirt and moistened with water

The foam application process is carried out with smooth movements, without jerking. Thanks to this, a uniform layer of insulation can be obtained. Polymerization is carried out by reaction with moisture. If you additionally moisten the surface, then the composition will be more voluminous. Rubber door seals can provide additional insulation.

On the video, the use of sprayed polyurethane insulation polynor:

In addition, the material becomes lush at a temperature of 20 degrees. But at a temperature of 15 degrees, the composition acquires density. The material can be applied both to the frame and to the wall. The choice of a particular method depends on the subsequent facing.

The following options are provided here:

- paint application;

- applying a layer of plaster;

- use of drywall, OSB, lining, siding.

Sprayed to insulate Polinor is applied in several layers. It can be used not only for thermal insulation of walls, but also for floors and roofs. Often it is used to insulate various metal tanks and communications.

The sprayed compound is able to pass through all cracks and hard-to-reach places, forming a monolithic seamless layer. It will not allow heat, steam and moisture to pass through. It is necessary to apply the material only with gloves and goggles, as it has a strong and pungent odor. It is very difficult to be in an unventilated room, but after installation the smell disappears very quickly.

You may also be interested in knowing what kind of insulation for external walls under plaster is best to use.

But what is the cake of the wall of a frame house with basalt insulation and in what cases it is used, this information will help to understand.

What are the characteristics of mineral wool insulation and where can it be used and how exactly. is described in great detail in this video.

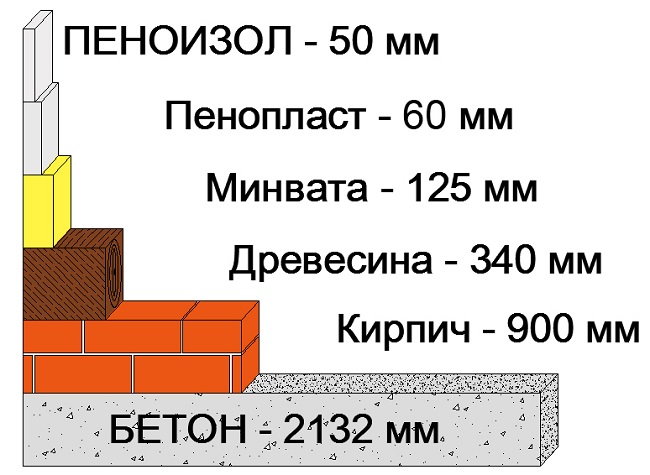

And this information will help you compare the thermal conductivity of heaters.

What is and where is the most often used insulation for the water supply pipe Energoflex, this article will help you understand.

Varieties of sprayed PU foam

Insulation made of polyurethane foam, which is applied by spraying, is divided into two industrial ones - it is sold in barrels and is used by specialists to insulate large structures and surfaces, and in cylinders with a volume of 1 liter, which is intended for independent use. Industrial PU foam is represented by several brands of different manufacturers.

The most famous are:

- Sealection 500 is an American-made material. It has an open structure and fire safety class G2.

- "Ecotermix" - is made on the basis of vegetable oils, contains a minimum amount of harmful substances. On sale there are two varieties of it: grades 300 - with a closed structure to protect the outer surfaces from the cold, and grades 600 - with an open structure for interior work.

- Healtok Soy 200 is a closed structure insulation made from soybean oil and polymer waste. Perfectly adheres to any surface, tightly fills all cracks and pores.

PPU in cylinders is made from polymer components. The cylinder has a spray tip or adapter for use with an assembly gun. Currently, this insulation is represented on the market by two brands - Polinor and TEPLIS. The material resembles polyurethane foam in its appearance. After hardening, it forms a fine-mesh coating with low thermal conductivity. One cylinder is enough for 1 sq. m of surface when applied with a layer of 40 mm.

The application technology is simple:

- The surfaces must be cleaned of dust and dirt and slightly moistened.

- You need to screw the nozzle onto the cylinder.

- Then it is shaken and the nozzle is directed to the desired location.

- By pulling the trigger of the gun, the material is sprayed.

Currently, insulation in cylinders is highly advertised, but experts do not advise you to trust it too much.

Manufacturers of industrial two-component insulation believe that one-component polyurethane foam in cylinders is practically no different from ordinary polyurethane foam, but it costs several times more. The material has a large number of open pores, therefore it is unsuitable as a hydro and vapor barrier.

Therefore, having decided to insulate your house with high quality, you should not rely on an unprofessional insulation. If you wish, you can use a spray can to treat small areas of structures or internal partitions, but it is hardly suitable for insulating large surfaces.

Liquid foam

This type of insulation includes almost all foam materials based on polymer resins. It is on them that the quality of the final product largely depends, including its environmental friendliness. There are raw materials, the use of which is not permissible for residential premises, due to the high toxicity of the polymer and its long-term emission. At the same time, such materials are quite suitable for insulating technical structures, or isolated elements of a building (if there is confidence in their isolation and the conscientiousness of working specialists).

At the moment, such types of liquid foam are common as polyurethane foam, penoizol, as well as a number of products in compact cylinders.

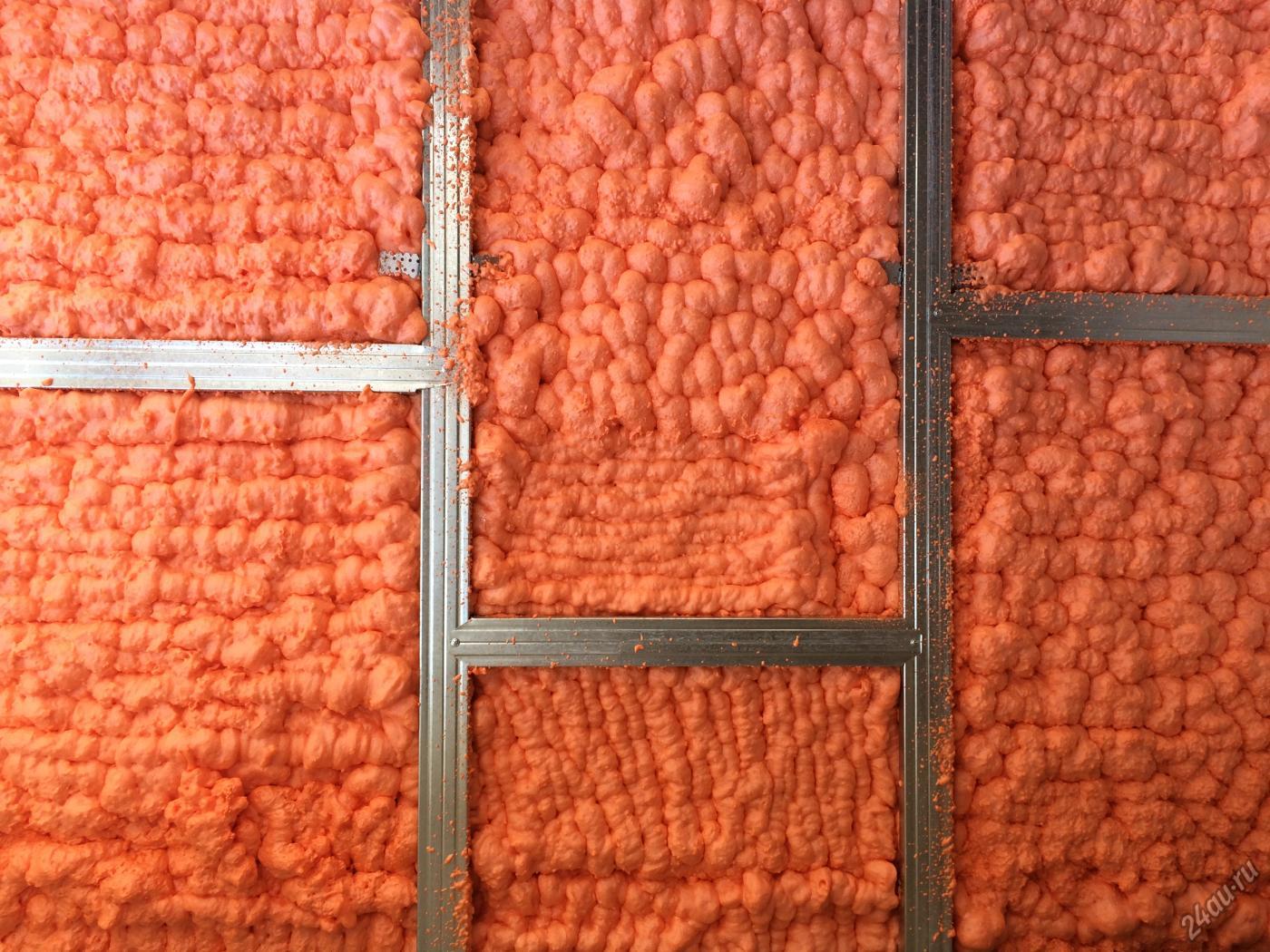

Polyurethane foam (PPU)

Viscous heterochain polymers in a liquid state are used as the main component of this insulation. In the course of chemical reactions, urethanes are foamed, which leads to their increase in volume by more than 50 times.

In the solidified state, polyurethane foam resembles ordinary polyurethane foam, the main difference in the structure is lower porosity.

Used mainly for:

- Insulation of walls of frame structures;

- Roofing structures;

- Facades of houses;

- Thermal insulation of basements and lower floors.

To apply polyurethane foam, a special unit is required, which first mixes and foams the insulation components, and then the finished mixture is supplied under pressure to the surface to be treated. The final polymerization takes place within 24 hours, after which the finish can be mounted. Polyurethane foam is suitable for the treatment of surfaces made of bricks, concrete, wood, metal, cinder blocks and gas silicate blocks.

The final polymerization takes place within 24 hours, after which the finish can be mounted. Polyurethane foam is suitable for the treatment of surfaces made of bricks, concrete, wood, metal, cinder blocks and gas silicate blocks.

The average cost of work together with the material is 1000-1500 r per m2, with a layer thickness of 50 mm.

Penoizol

A budget analogue of polyurethane foam insulation, since it is based on a relatively cheap, but more toxic urea-formaldehyde resin.In structure, this insulation is very similar to ordinary foam, but its use is more preferable due to the absence of cold gaps in the insulating layer, typical of sheet and roll materials.

The density of penoizol, even in a liquid state, is noticeably lower than its urethane analogs, which does not allow its use in loaded structures. The rest of the area of application is similar to polyurethane foam. Thermal insulation qualities are also not exceptional and are comparable to mineral wool, and two times less than that of the polyurethane foam described above.

It is applied under pressure after pre-mixing the components and foaming. Increases in volume by no more than 30 times relative to the original mixture.

Roof insulation with penoizol

Roof insulation with penoizol

Working with the material costs about 2000 r per 1 cubic meter.

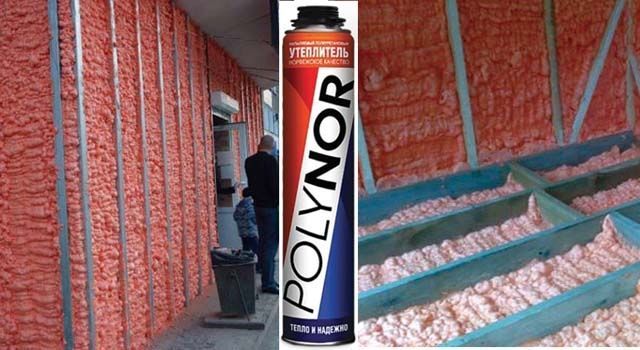

"Polinor"

It is a liquid insulation based on polyurethane. A common form of release is small cylinders, externally similar to those for polyurethane foam. Using one balloon, you can insulate about 1 m2 of the surface with a layer thickness of 6-7 cm.

Strength and heat-insulating qualities are similar to polyurethane foam, but unlike it, Polinor is more suitable for domestic use, since it does not require special equipment for application. The relatively high cost (about 500 rubles per cylinder) makes it impractical to use it on large areas.

The insulation is applied by spraying, which allows it to be used on almost any surface, for example, for thermal insulation of outdoor pipelines.

As for filling voids in the walls, this procedure cannot be performed due to insufficient pressure in the cylinder.

Polinor has the following technical characteristics:

- Thermal conductivity - 0.025 W / (m * K);

- Moisture absorption coefficient - no more than 0.03;

- No toxicity, non-flammable;

- Solid density - not less than 28 kg per m3;

- Retains all operational properties for 50 years;

- The temperature of use should not exceed + 121 ° C;

In addition, the mixture is quite chemically stable and does not interact with most reagents common in everyday life. Chloroform, dichloroethane and high concentration hydrochloric acid have a negative effect (promote swelling) on Polinor. Nitric and sulfuric acids react with polyurethane, thus destroying the insulation mixture as a whole.

Actual prices for your city:

Features and characteristics

Polyurethane foam, also known as polyurethane foam sealant, is a substance widely used in construction to bond separate parts of the structure to be joined together, heat and sound insulation, seal and fill voids that arise during operation. Usually sold in metal cans, in which the foam itself and a mixture of liquefied gases are under pressure - the so-called. a propellant that acts as a buoyant force for the contents of the cartridge. The versatility of this synthetic polymer makes it an irreplaceable assistant in many types of construction work and in almost any repair.

What is Penoizol?

This is how the applied penoizol looks like.

The method of obtaining this substance differs from the production of foam in that its production is based on a carbamide polymer, which is exposed to chemicals, as a result of which it, like polyurethane foam, swells many times over. In appearance, this material is very similar to foam plastic that is familiar to a person.

Penoizol properties:

- Has a low level of solidity in the hardened state.

- It has a good thermal conductivity, which allows you to keep warm in the living space. But polyurethane foam has a much higher rate of preservation and maintenance of room temperatures.

Since this substance in the solid state does not have a very high density, it is not often used to insulate those surfaces that may be subject to different mechanical stress or varying degrees of stress. Also, you should not use it for warming basements and any others in which the humidity indicator is higher. Penoizol is not strong enough to withstand moisture.

The most common material is penoizol, when it comes to insulating the walls of a frame house, a roof, the inner area of the roof overlap, or for location between the material presented in the form of bricks.

The transition from a liquefied state to a solid occurs rather quickly, it takes no more than half an hour in time. But further work should be postponed for about 2-3 days to achieve the best effect.

This material is advantageous in that, after acquiring hardness, it can be compared with monolithic materials. Many who used penoizol to create the outer heat-insulating layer of the dwelling were satisfied. This substance completely provides the wall material with protection from freezing, exposure to air and liquid flows. If the substance was sprayed correctly, then various defects in the form of microcracks will not form on its surface.

Insulation works should be carried out in favorable weather conditions. In order for the workers to perform the necessary manipulations, they will have to pay about 150-200 rubles for one square meter insulated with penoizol. Also, this is not the final amount, since everything will depend on what thickness the customer prefers and what the working surface will be.

In order to save a little on labor costs, it is worthwhile to independently prepare the surface that will be insulated. Namely, to clean from litter and dirt, to ensure the state of dryness and absence of dust particles.

Advantages

The most remarkable quality for the user is ease of transport and cost effectiveness. Polyurethane foam is stored in small metal containers that are light enough and quite convenient for transportation and storage. This material is absolutely not poisonous, therefore it is safe for human and domestic animal health.

This property of polyurethane foam is especially important when insulating a room from the inside. Neither temperature drops, nor interaction with liquid provoke this material to release harmful substances, so the whole process can be done with your own hands, without resorting to the services of specialists

Additional benefits

The spray-on insulation absorbs noise well and has excellent waterproofing properties. This means that moisture will not accumulate in your walls, and fungus will not start. In both cold and warm seasons, the house will maintain a comfortable atmosphere in the desired temperature range.

The polyurethane foam contains various anti-corrosion substances. Therefore, when polyurethane foam is applied to metal surfaces, a layer is formed that retains heat and at the same time protects the metal from moisture and rust.

Polyurethane foam ignites slowly and extinguishes quickly in the absence of oxygen. Therefore, the chances of it catching fire are very small. If you want to reduce the likelihood of ignition to zero, you should treat the coating with a layer of special paint.

Features of the technology of applying insulation

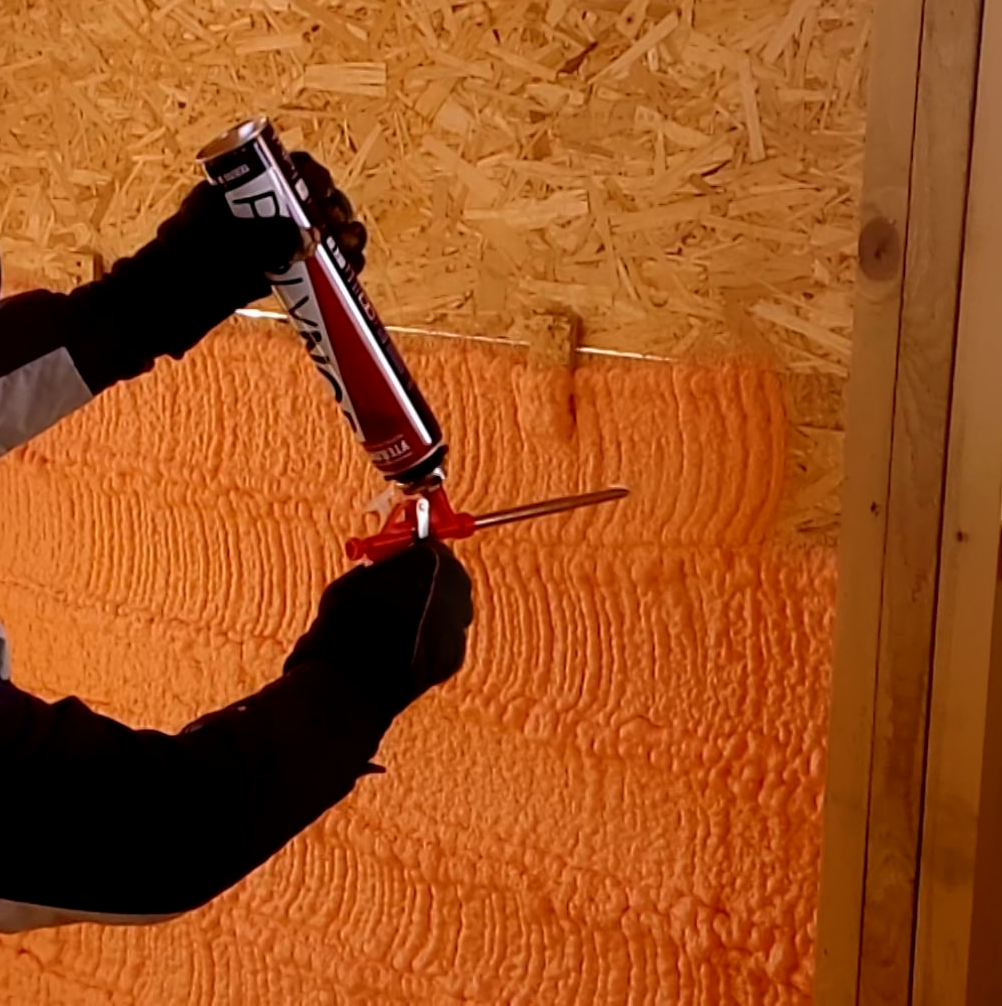

The technology of installation of sprayed insulation in cylinders provides for the following stages:

- the cylinder is equipped with a special tube or pistol, after removing the cover;

- shake the composition thoroughly for at least 60 seconds;

- before applying foamy thermal insulation, the surface is treated with water;

- the container is held upside down, filling the voids by 1/3 of the volume, leaving room for expansion of the composition.

When the foam fills the entire volume of the gap, it is recommended to spray the mass with water to improve the polymerization process. The curing time of foam insulation varies depending on the model and brand, manufacturers produce products of different quality. Surface hardening is observed approximately 20 minutes after spraying. The correction of the mass with the help of a cutting tool is started not earlier than after 4 hours. The full polymerization period of foam insulation for the floor in cylinders provides for a period of at least a day.

Provision of means of protection

When applied polyurethane foam in cylinders for floor insulation, it should be borne in mind that the composition is poorly washed off from the skin and clothes

Working clothes should be worn and protective goggles and gloves are also important. Manipulations for spraying polyurethane foam with special equipment are carried out using professional equipment in order to completely exclude contact of the skin and mucous membranes with the substance

When insulating the floor with foam, you need to use protective equipment

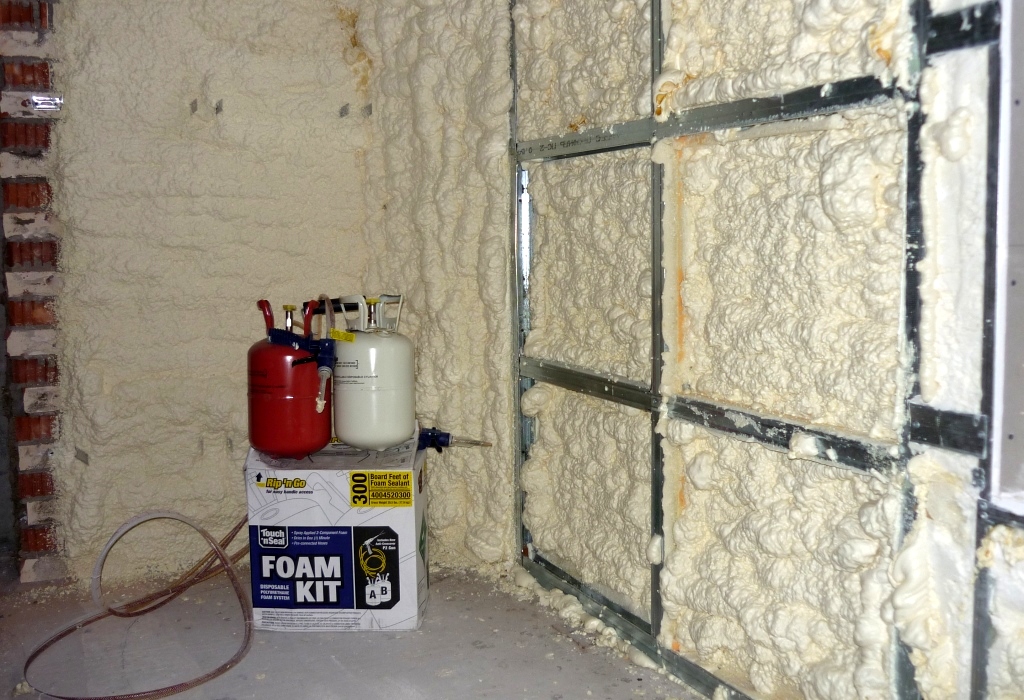

Thermal insulation of the floor by spraying

Installation of polyurethane foam for floor insulation using spraying technology provides for the use of special installations. The foam insulator components are contained in separate containers. The working composition is made directly at the facility before use. The substances enter the mixing device, then they are sent to the spray gun and are applied under pressure to the treated surface.

Features of installing foam insulation:

- a frame structure is being constructed for applying sprayed thermal insulation. Experts recommend to carry out the crate, depending on the nature of the treated area. For example, for effective thermal protection of a wall structure, it is advisable to build a wooden or metal frame with an interval of 30 cm between the guides. If you plan to insulate the floor with sprayed polyurethane foam, you should create a crate with a step of up to 1 m;

- foam composition is applied by smooth movement of the jet over the surface to ensure an even distribution of the mass;

- when processing vertical planes, a foamy insulator is sprayed from the lower perimeter, gradually filling the openings upward;

- during manipulations, the spray gun is kept at a distance of at least 25 cm from the surface to be treated. When moving to another sector, you must release the trigger of the gun to block the stream.

If you plan to insulate the floor with foam by two-layer spraying, it is necessary to withstand the time for the complete polymerization of the previous layer. After the masses have hardened, they begin to correct: cut off all protruding fragments with a sharp knife, level the irregularities.

The flooring is laid after the foam insulation has finally polymerized.

Floor insulation by pouring

The technology implies the creation of monolithic thermal insulation in the floor structure by pouring foam into specially made cavities. For example, a rough plank floor is being built on logs, small holes are made on the surface in dedicated places for pumping polyurethane foam. If you plan to heat the walls by pouring polyurethane foam, cladding is performed with a technical gap between the base and the finishing material. Next, the foam composition is poured through special holes on the facing panel.

Pouring is carried out on the basis of the same spraying installations, having reconfigured the equipment parameters. In a professional environment, special units are also used for pouring polyurethane foam, which determines a high-quality level of thermal insulation work. The foamy substance fills exclusively all voids to the smallest crevices, as a result of which a sealed thermal barrier with high performance is formed.