Views

The Makroflex company specializes in the production of a wide range of quality products, which are divided into several types.

- Macroflex Shaketec is an all-season option.

- Macroflex Winter is successfully used in cold and dry conditions. It is used at low and high temperature conditions by means of a special tube in the form of an applicator. This tool creates excellent sound insulation, fills the gaps in the roof well, seals the openings of windows and doors.

- Macroflex Premium is made of polyurethane for professional use, has the unique property of doubling in volume. It is a luxury product and has a special attachment - a pistol.

- Makroflex Premium Mega is designed for work in winter at temperatures up to minus 15 degrees, shows strong adhesion to various hard materials, has a unique property of expansion, allowing accurate dosing of the mixture.

- Makroflex Pro is applied with a special attachment in the form of a nozzle. There is an excellent property of adhesion to various textures of building materials. This professional product does not contain any organic matter in the form of chlorides or carbon compounds.

- Mounting composition Makroflex Whiteteq is an innovative product of our time, presented in the form of heavy-duty white polymer foam. Microporous structure resistant to ultraviolet radiation. A special ball is placed in the container of the cylinder, which ensures good mixing when shaking. It is used in most construction work.

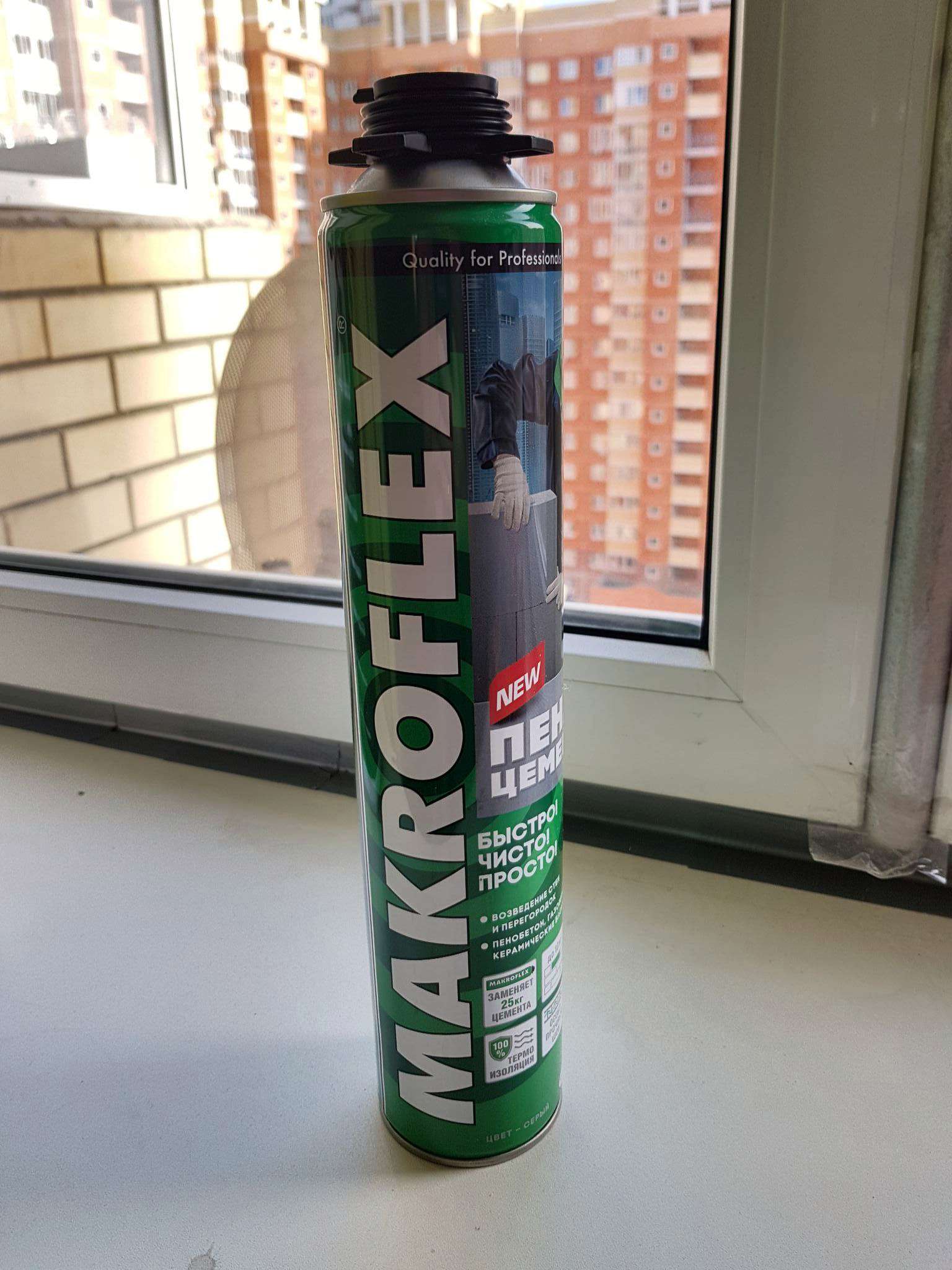

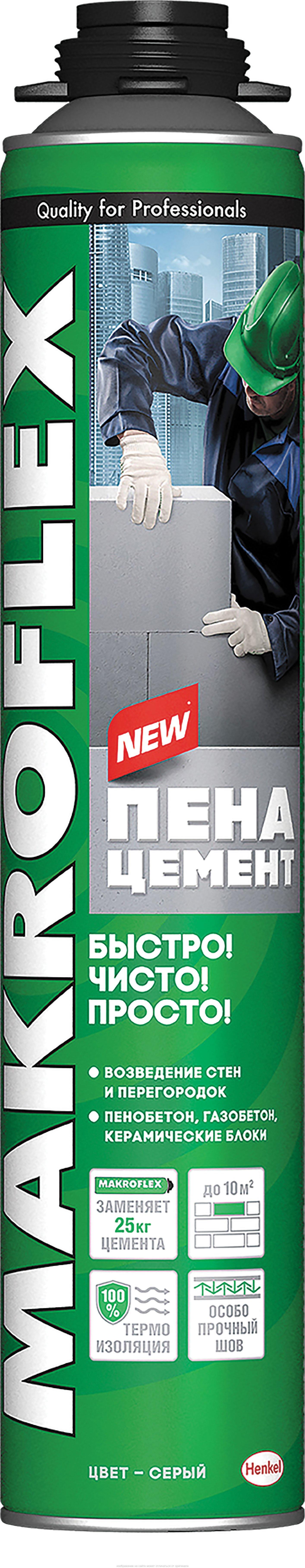

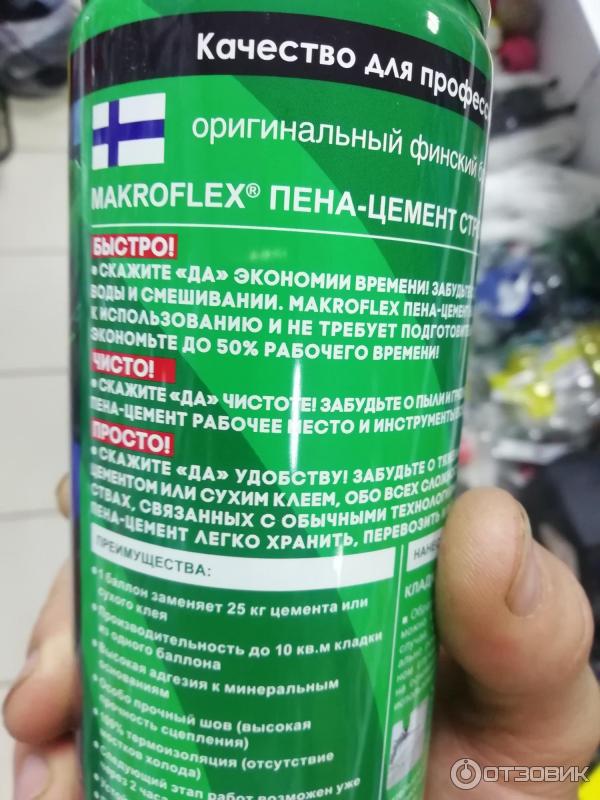

- Makroflex foam-cement is a versatile product that can replace a large number of bulky bags with a cement composition, and is designed to bring communications. It is successfully used when installing stair steps, parts for window sills, as well as fastening materials to walls.

Foam Specifications

You can work with foam at ambient temperatures from -5 to +35 degrees. The ideal temperature of the balloon when applying the substance is +23 degrees, the allowable temperature is within + 5 ... + 30 degrees. After hardening, the material can be operated at temperatures of -40 ... + 90 degrees. Let us admit short-term heating of seams up to +110 degrees.

The main technical parameters of the composition are as follows:

- density - 20 kg / cu. m;

- the term for the formation of the surface film (initial setting) - 5-9 minutes;

- curing time - up to 30 minutes;

- the ability to change the volume - up to 5% (up or down);

- moisture absorption rate - less than 1% / day, no more than 10% / 28 days;

- thermal conductivity - 0.037-0.4 W / m * K;

- sound absorption - 60 dB;

- adhesion at break with wood - 2 MPa, with PVC, ABS - 1 MPa, with concrete, glass, ceramics and other non-porous bases - 0.3 MPa, with foam and bituminous bases - 0.2-0.5 MPa;

- foam consumption - 850 ml (one can) per 10 sq. m of masonry.

Foam-cement is practically not used for fastening gypsum plasterboards, galvanizing, mineral wool, since the adhesion index in this case will be no more than 0.1-0.15 MPa. It is possible to use "Macroflex" for such surfaces only under the condition that even a small load will not fall on them.

Advantages and disadvantages

The main advantage of Makroflex polyurethane foam is its ease of use, instant readiness. Fastening building materials no worse than cement, it does not require additional labor costs: just open and shake the can well. In addition, in comparison with most of the usual assembly mixes in bags, foam makes it possible to work in the off-season at rather low temperatures.

There are other benefits to an innovative composition.

- Ease of use and cost-effectiveness. A special nozzle-gun allows you to apply the composition to specifically designated places and in a certain amount. This makes it possible to avoid overspending of the cementitious adhesive. According to the manufacturer's application, 1 can of foam can replace 1 bag of cement. At the same time, it is equally easy to apply the foam on both horizontal and vertical surfaces.

- Versatility. Cement foam can be used on a wide variety of substrates.

- Slight shrinkage. This cement foam compares favorably with other assembly compounds.

- Can be applied to dry and wet surfaces. Makroflex foam adheres equally well in both cases. The only limitation for application is the presence of ice or snow cover.

- Can be used not only for masonry, but also for gluing or fixing individual parts.

- High speed of hardening, which allows to reduce construction time.

- Sealing and penetrating properties, thanks to which the foam can fill even the most inaccessible crevices and pores, reliably sealing them.

- High quality and durability of the hardened material.

As for the disadvantages of the Makroflex assembly composition, they also exist.

- Sun-resistant. To prevent the destruction of the hardened foam, it must be covered from above with a building compound or finishing materials.

- The possibility of a negative impact on the skin, mucous membranes and the human respiratory system in case of violation of safety measures when working with the composition.

- Quite a high price.

Views

The manufacturer Macroflex produces a wide range of products not only for assembly foams, but also various types of sealants and adhesives.

Polyurethane foams Macroflex includes the following varieties in its product line.

- Macroflex SHAKETEC all-season.

- Macroflex Winter is a foam used in dry and cold conditions. It is applied at temperatures ranging from -10 to +25 degrees using a special applicator tube. Such a mixture can create excellent sound insulation of partitions, fill voids in roof systems, and mount window and door openings.

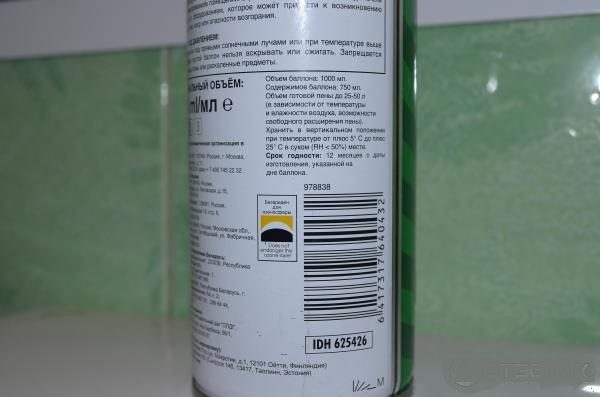

- Macroflex Premium is a professional polyurethane foam. When used, it doubles in volume. Premium foam is applied with a pistol. Excellent adhesion to materials from wood, metal, concrete, stone is formed. It is allowed to use foam with damp surfaces. The volume of Macroflex Premium foam is 750 ml, at the exit of the product, from 25 to 50 liters of foam are formed.

- Macroflex Premium Mega is a professional winter polyurethane foam. Such a mixture can be used at a temperature of -15 degrees, thereby ensuring reliable and strong adhesion to building materials made of wood, concrete, metal. Due to the fact that the material is self-expanding, the mixture is precisely dosed at the exit.

- Makroflex Pro is applied with a special device, and the yield is about 65 liters of finished product. Has good adhesion to many building materials. The mixture of this type of foam does not contain organic substances in the form of chlorine, fluorine and carbon. Thanks to this, it is used for the special insulation of windows, doors, filling voids. Also, the sealant is used as a heater.

- Polyurethane foam Makroflex Whiteteq is a new generation product. White polymer foam is made according to the Whiteteq method, which is based on the ideal cleansing of the components that make up the mixture. The result is a crystal-white foam shade, a microporous Quattro structure and UV resistance. A special ball is located inside the can, which ensures the uniformity of the elements when mixing.The installed valve in the cylinder ensures the preservation of the foam quality. It is used in many construction works (insulation, filling voids, fastening materials).

Macroflex sealants are a separate type of product, which includes the following types of materials.

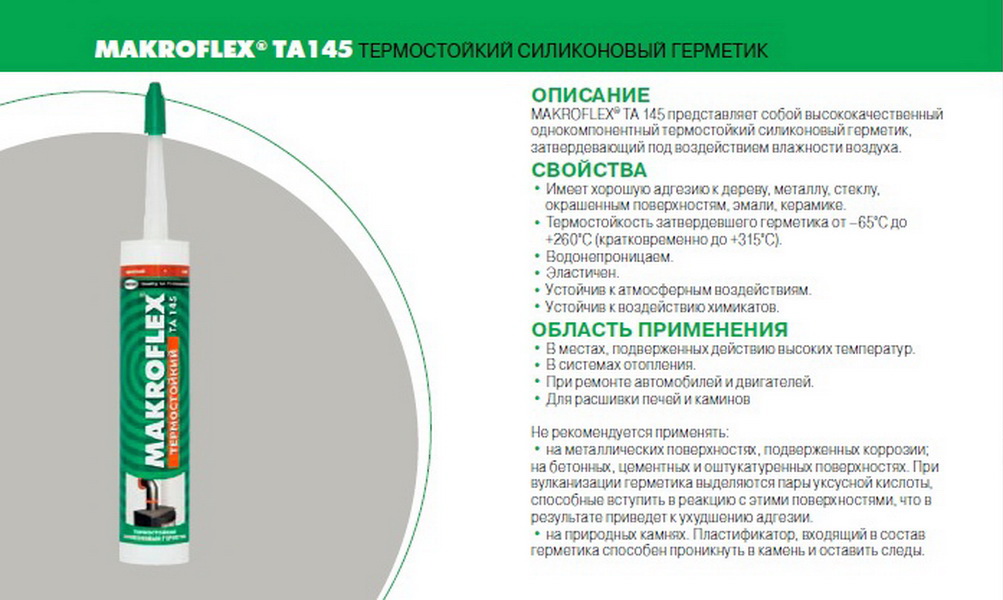

MAKROFLEX TA145 is a high temperature resistant sealant designed for use in rooms with high temperatures or sudden changes in temperature conditions (ovens, ceramic tiles on kitchen tiles). The solution hardens due to air humidity.

Comparative reviews of researchers have shown that Macroflex sealant has a great advantage over conventional sealing solutions. When ignited, the foam burns without cracking, through which smoke and toxic substances can pass. The time for applying the glue to the surface is about 15 minutes. Withstands temperatures from -65 to +315 degrees.

- Macroflex NX108 is an indifferent silicone sealant. Has good adhesion to wood, glass, metal, ceramics, plastic and concrete coatings. The sealant is resistant to rust formation on metal coatings and to UV rays. The main advantage of such a sealing mixture is that it can be used in rooms with high humidity (bath, bathroom).

- Macroflex FA131 is an ultra-effective frost-resistant polyacrylic sealant. This type of sealant is used to seal seams and cracks both indoors and outdoors. The advantage of the sealant is that it is highly resistant to freezing and thawing during storage and transportation. It is possible to paint the sealant with acrylic dyes. It is not recommended to use the material in rooms with high humidity. It is used for sealing joints and cracks in coatings made of concrete, brick, wood, tiles, plaster.

Main properties and specifications

Makroflex polyurethane foam-cement is a completely ready-to-use polyurethane-based mixture. It not only holds various building materials together, but also perfectly seals joints, improves heat and sound insulation of building structures. The mixture can be used in the temperature range from - 5 to + 35 ° С (the optimum temperature is + 21 - + 35 ° С). All this is made possible by the technical characteristics of the foam.

The main properties of the assembly composition are:

- density - 20 kg / m3;

- setting, or the time of formation of a surface film, - from 5 to 9 minutes;

- complete foam hardening - 30 minutes, under certain conditions it can be reduced to 25 minutes;

- change in volume - 5% up or down;

- water absorption - no more than 1% in 24 hours and a maximum of 10% in 28 days;

- sound absorption - 60 dB;

- thermal conductivity - 0.037–0.40 W / mxK.

According to international standards, the assembly mix aerosol can does not contain CFC propellants. In addition, when squeezed out, the foam has a mild odor, which disappears when the composition solidifies.

Characteristics and properties

Macroflex is in fact a liquid polyurethane that hardens when combined with moisture from the air. Specifications are the benchmark for similar products. The consumption of the mixture depends on the weather conditions, but is considered the minimum possible. Polyurethane foam Macroflex is characterized by the following data:

- Expansion - 2 times (error - 5%);

- Curing time - 1 hour;

- Density - 25-35 kg per cubic meter. meter;

- Fire resistance - B3 (according to DIN 4102);

- Compressive and tensile strength - 3 N / cu. cm for one-component and 5 n / cc. cm - for a two-component composition.

Premium foam is more resilient and more durable than standard foam.

Foam Macroflex Pro

Foam Macroflex Pro

The foam hardens under the influence of air humidity, is easy to use and safe. There is a faint smell, but it disappears quickly.

At an air temperature of + 20 degrees. and humidity not less than 30%, setting time - 15 minutes.At 100% humidity, this takes an hour. Under difficult conditions, complete curing occurs in a day. Resistance to temperatures - in the range from - 55 to +90 degrees.

Equally important information on the topic: Service life of polyurethane foam

The material is not flammable; melting requires a temperature of over 400 degrees. The recommended shelf life in the package is 15 months.

Macroflex White Technology

Macroflex White Technology gets rid of most of the disadvantages of other types. This new generation foam is created on the basis of polymers with high purity and a finely porous structure with four times as many cells. Pure polymer guarantees correct hardening, snow-white color, cellular structure with great strength and elasticity. She is immune to ultraviolet light. The hardened foam provides excellent thermal and acoustic insulation performance. White Technology is characterized by low expansion pressure, which provides ease of installation and compensates for joint movements - over 25%. Due to its thermoplasticity, it guarantees long-term insulation and sealing.

ShakeTec technology has been implemented - a metal ball inserted into the cylinder improves the miscibility of the components when shaken. The bottle is equipped with a new valve that retains the properties of the product. The composition does not contain freons.

A little about the content of the spray

A little about the content of the spray

General rules of application

The surfaces to be glued are cleaned before applying the glue-foam. Remove dust, bitumen, grease, dirt. They work only with dry aerated concrete blocks.

Ultraviolet radiation affects the properties of the glue, therefore, after hardening, it is covered with a protective layer, a layer is applied on top:

- gypsum;

- paints;

- sealant.

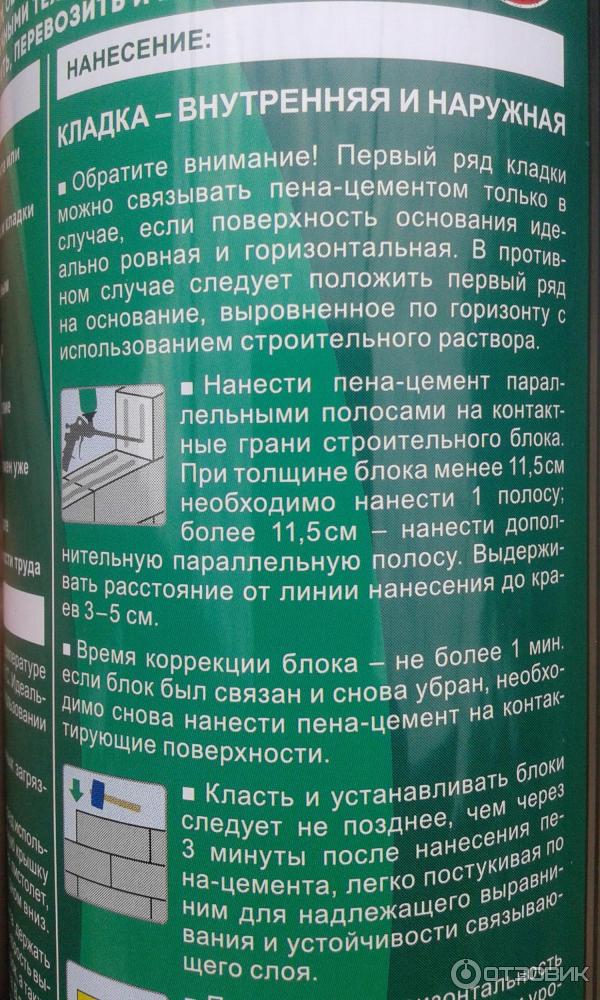

Masonry

Glue-foam "Macroflex" is used to connect blocks of partition walls. The product is not intended for load-bearing walls. The masonry is made in blocks of the correct shape of the same size. Deviations in dimensions should not exceed 1 mm. Do not use foam if the blocks are hollow. The base for the first row is leveled. It should be flat, strictly horizontal. Controlled using a building level. Glue-foam is applied to the ends of the block (vertical, horizontal) in strips, retreating from the edge of 3-5 cm. It is necessary to remove the unsuccessfully placed element within 1 minute.

During work, 3 minutes are taken as a reference point, this is the time during which several operations need to be performed:

- apply glue to all surfaces of the block;

- install it in place;

- easily tap the block from above to align it horizontally;

- check the horizontal level.

A wall folded with Macroflex glue-foam can be plastered after 2 hours.

Gypsum panels

First prepare the surface of the wall (ceiling). Remove remnants of previous finishes, wallpaper, paint. Prime if the surface quickly absorbs moisture, then proceed to the main work:

- put the panel on a flat surface;

- retreat from the horizontal edge 5 cm;

- squeeze out the first strip of Macroflex glue-foam, leading it parallel to the edge;

- apply subsequent strips in 15 cm increments, observing parallelism;

- place the last strip 5 cm from the edge.

For a quick and high-quality application of glue-foam, it is worth purchasing a specialized (professional) model of a gun. When installing a gypsum panel, you need:

- apply glue;

- install the panel in 3 minutes;

- press down the panel to the main surface, adjusting its position;

- hold for 5 minutes until the foam holds the materials together.

After 2 hours, you can start the next stage of work.

Window sills

Clean the surface of the window opening. Dirt and oil stains impair adhesion. You can remove them with white spirit. Squeeze glue foam onto the prepared window sill. Apply it in parallel stripes. For a firm fixation, 2-3 extruded tapes are enough.

Stair steps

When fastening steps to wooden spacers, the glue strips are applied parallel to the edge. For a narrow step, 2 spacers are enough.The wide one requires 3, 2 at the edges, one in the middle. When applying glue, a standard distance of 10-15 cm is maintained between the strips. Within 3 minutes, the step is set in place, aligned, pressed. So that it does not rise up, they put a load weighing at least 10 kg on it. They remove it after 60 minutes.

Applicability and benefits

Some of these formulations are intended for household use, others for professional and special use. They are available in spray cans and applied in the usual way or with a pistol.

Anyone who has ever used standard Macroflex foam will say with confidence that it has a wide range of applications.

Macroflex standard

Macroflex standard

It is used by:

- As a sealant - when erecting a roof, installing window and door systems, sealing joints and cracks;

- Filling voids;

- Increased noise insulation;

- Sealing pipe connections;

- Roof installation, docking and insulation.

Polyurethane foam has properties that allow it to be applied to various types of surfaces. It is suitable for wood, concrete, plastic, stone, glass. The manufacturer guarantees resistance to acids and alkalis, but not UV protection. The foam copes well with moisture, but does not tolerate frozen surfaces. Macroflex is a profitable solution that really saves time and money. The cost of the foam is commensurate with the real Finnish quality. The manufacturer offers a number of advantages:

- Ready for use;

- One hundred percent adhesion;

- The cylinder is used instead of 25 kg of cement;

- The strength of the connections;

- Lack of cold bridges and thermal insulation;

- Significant temperature range;

- Suitable for indoor or outdoor use;

- Simplicity in storage and unpretentious transportation;

- High heat-insulating and sound-insulating properties of the cement composition;

- Excellent stability;

- Non-flammable and non-toxic;

- Low cost.

Use of foam cement

Use of foam cement

Pros and cons of Macroflex foam

Foam "Macroflex" is a one-component composition that is completely ready to use, it does not need to be mixed or diluted. Thanks to the packaging in the form of a tube, the foam is very convenient to apply - all you need to do is purchase a suitable assembly gun.

To work, you do not have to carry heavy bags, buy expensive tools and equipment, waste electricity, water, dilute dust and dirt. The absence of the need to mix the mortar significantly reduces time costs and helps to carry out construction and repair an order of magnitude faster.

Other properties and advantages of the composition are as follows:

- high strength of any joints (no less than that of standard cement mortars);

- the ability to replace dry building mixtures in many situations;

- effective joining of homogeneous and dissimilar building materials;

- suitability for work with both horizontal and vertical surfaces outside and inside the premises;

- reliable sealing and insulation of seams from moisture and minimization of heat loss;

- short time to complete solidification;

- ability to withstand heat and freezing;

- the ability to carry out work at low temperatures;

- control of foam consumption due to the special design of the package;

- lack of chlorofluorocarbon propellants in the composition;

- low price and low cost of the work performed.

Foam-cement "Macroflex" effectively glues, seals, seals gaps, strengthens and provides moisture, sound, thermal insulation of structures, therefore it can be called a universal building material.

Despite the impressive list of advantages, foam also has disadvantages. "Macroflex" is a composition that, after hardening, is prone to shrinkage. However, due to the strong expansion after setting, this shrinkage is often unnoticeable.

Under the influence of ultraviolet radiation, the foam gradually collapses, but this minus can be smoothed out by protecting its upper layer with mortars, putties, and sealants."Macroflex" cannot be used for the installation of load-bearing walls - the composition is suitable only for lighter structures.