What it is?

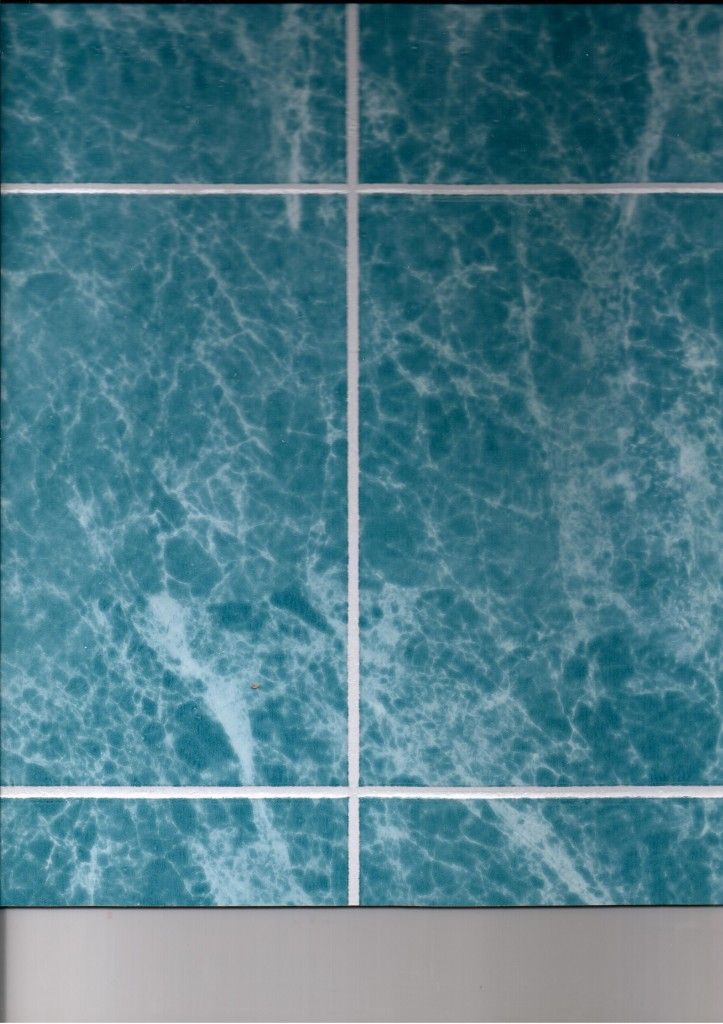

Before you go wandering around hardware stores or surfing online catalogs, you need to decide for sure whether a product of this type is right for you. Sheet panels are a fairly popular topcoat, which is increasingly being installed in both domestic and decent public bathrooms, as well as for exterior cladding of buildings. It is a moisture resistant material made using calcium silicate components and several other additives.

Thanks to this composition, the panels are water-repellent, insensitive to temperature changes and, in general, are excellent for bathroom decoration... In appearance, plastic sheet panels are practically in no way inferior to more expensive finishes, which is also an undoubted advantage. Here are some more obvious advantages of this type of coating:

- Low price. Of course, the cost depends on the manufacturer, the quality and type of sheet panels, but, in general, it comes out much cheaper than tiling a bathroom.

- Easy to install. Installation of such panels does not require special skills and a lot of time - you can easily install them yourself. And this is also a kind of savings, because for repair work you do not have to pay for the services of a professional. Also, plastic sheet panels can be mounted both vertically and horizontally, which gives additional opportunities during repairs.

- Reliability. Such material is quite resistant to physical exertion, does not fade, is able to withstand high temperatures and daily exposure to moisture, so that its appearance will not change in any way from the negative effects of the environment.

- Soundproofing. Thanks to the honeycomb structure, the panels enhance the soundproofing properties of the walls, which is quite useful in the bathroom.

- Easy to care for. The decoration does not require any special cleaning costs - it can be cleaned with any household chemicals. The only thing you shouldn't do is use a metal mesh, because it can scratch the plastic.

- Fire resistance. The plastic panels only light up if the ambient temperature reaches 400 degrees.

- Practicality. Sheets are great for hiding behind them plumbing, wall surface defects and other external imperfections of the bathroom. And in the event of any accident, the pipes will be very easy to get to.

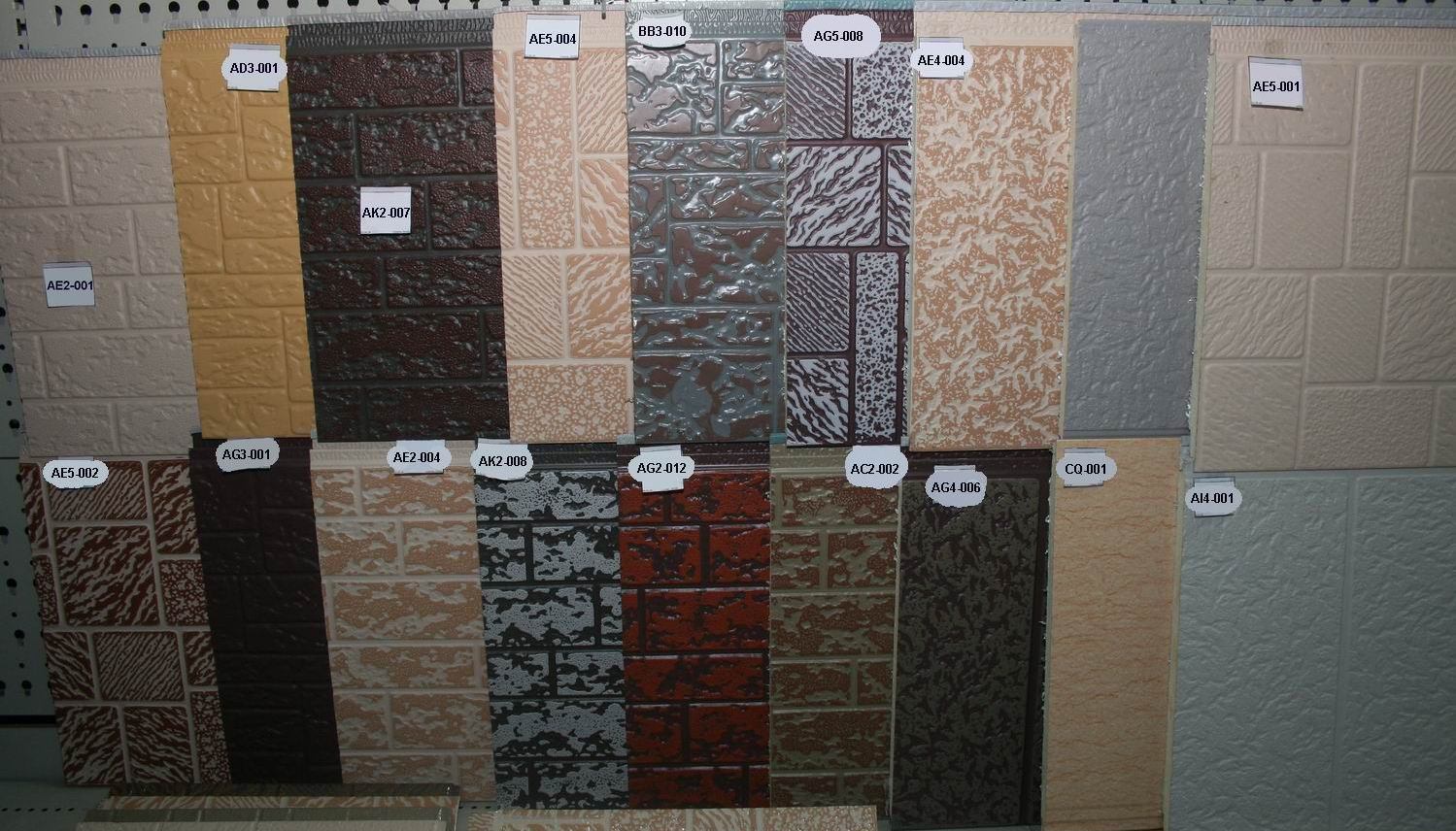

- A large assortment. The choice of colors and shades is more than acceptable, so choosing the right bathroom cover will not be so difficult.

- Versatility in design. It is easy to hang lamps, shelves, a mirror, hooks and other interior elements necessary in a bathroom on such a coating.

Against the background of the numerous positive aspects of sheet finishing, there are also small disadvantages. First, the material is inconvenient to transport. Wide panels will not be easy to transport to an apartment alone. Secondly, during installation, they take up a certain amount of usable space, especially when they are mounted using a wooden crate, and this can be noticeable if the area of the bathroom is limited.

Luxurious bathroom in brown.

Moisture resistant bathroom panels: advantages and disadvantages

Getting acquainted with these materials should start with studying their advantages and disadvantages - they are the ones that can influence the choice of a person in favor of their use in the bathroom. Let's face it - the advantages that waterproof bathroom panels have are many, and the following factors can be attributed to them.

- Low cost, which, in comparison with tiles, can even be called scanty. Moreover, a small price is typical not only for the material itself, but also for the prices for its installation.

- Since this material is supposed to be used in rooms with high humidity, it simply must have antiseptic properties and resist the formation of mold and mildew on its surface (and especially at the joints of the panels). Almost all bathroom panels have this protection.

- In most cases, all wall panels are rigid enough to hide many surface imperfections. Simply put, their installation does not require any special preparatory work.

- A lot of advantages are also given by the space, which, as a rule, is formed behind the panels when they are installed on the frame - there you can install insulation, built-in spotlights, and you can also freely lay both electrical and plumbing communications behind them.

- Resistance to mechanical damage. This advantage can be attributed not to all types of panels - for example, plastic panels do not have it. If we consider moisture-resistant MDF panels for a bathroom, then there is both high impact strength and their ability to withstand bends and breaks. In general, with the help of such panels, even an arch can be freely sheathed.

- Easy maintenance. Only for this it is necessary to install the correct panels that fit together without seams. And the seams, as you know, basically represent the biggest inconvenience in the process of cleaning the walls.

- Easy installation technology that any DIYer can handle. We will talk about it a little later.

As for the disadvantages of moisture-resistant panels, they are all due to the specific type of material from which they are made. For example, the weakest point of waterproof MDF panels is their decorative and protective layer, which is nothing more than a thin film - every scratch left on it with careless handling impairs the material's ability to withstand moisture. If we talk about the notorious plastic PVC panels, then their negative qualities include fragility and weak ability to withstand shock loads.

Varieties of wall panels

Finishing types

Depending on the shape, panels of the following types are distinguished:

• slatted type-setting - are oblong planks made of wood, chipboard, PVC, fiberboard or MDF. These interior wall panels are 240 to 370 centimeters long, 12.5 centimeters wide up to 30 centimeters and thickness - from 0.8 to 1.2 centimeters. The panels have grooves and spikes to connect to each other. Installation of cladding in horizontal and vertical orientation is allowed;

• tiled typesetting - are squares with sides from 30 to 98 centimeters long. Such wall panels are great for creating mosaics, because each of them has its own color and texture. Coating material - MDF, fiberboard, PVC and chipboard. To connect the plates, grooves and inserts are used;

• sheet - better than others have proven themselves when decorating large walls. The dimensions of their sides can vary from 122 to 244 centimeters with a thickness of 0.3 to 0.6 centimeters. Unlike other materials, wall panels are made only of wood or resin-impregnated fiberboard.

Rack type panels of various widths

The methods of fixing the plates are different. So, slatted type-setting panels for wall decoration are fixed on the crate, tiled ones - with the help of clamps or adhesive. Glue is also used for fastening sheet panels, and the seams between the covering elements are masked with moldings.How to install PVC on the ceiling yourself? watch the video and read here.

Classic paneling solutions

When finishing with plastic panels with your own hands, you need to take into account not only the type of coating elements, but also the material of their manufacture.

Wooden products are considered reliable, they are made from such types of wood as alder, maple, oak or cedar.

Sometimes the finish has a wax coating, due to which it can be used in rooms with high levels of humidity. Since wood wall cladding panels are environmentally friendly, they are recommended for use in residential areas.

Popular products made of fiberboard - a material consisting from woody plant fibers... They are also safe for human health, resistant to high humidity, but deteriorate in direct contact with water. In turn, facing panels made of chipboard for interior wall decoration are similar in appearance and qualities to wood. This is due to the fact that chipboard is a compressed waste from wood production. The disadvantage of this material is the poor tolerance of sudden changes in temperature and humidity conditions.

Panels made of MDF are highly resistant to almost any environmental factors. Fiber boards are produced by using the dry pressing method, so they are not afraid of moisture and mechanical stress. Wall decoration recommended MDF panels such as those rooms where conventional materials are short-lived or ineffective.

All mentioned types of panels are recommended for use in residential premises. With proper care, their service life will be more than 10 years. Wooden wall panels for wall decoration have a particularly long service life: if they are made of high-quality wood, they will retain their original appearance for several decades.

Panels from new materials

The panels made from gypsum vinyl are renowned for their reliability and durability. The material of their manufacture is a modification of drywall, and is similar in properties. Plastic panels for walls for interior decoration, which are not demanding on operating conditions and are easy to maintain, also demonstrated their best side.

New products on the building materials market are glass panels and 3D panels. The former are intended for applying photographic drawings to the surface of the walls, the latter have an unusual texture with a hypertrophied relief. 3D panels are made from all of the above materials, as well as from aluminum.

Wall decoration with plastic panels is allowed in residential, commercial and public institutions. This coating is often used in schools and kindergartens because it is considered environmentally friendly. In turn, glass panels are as safe as plastic and are able to withstand significant mechanical stress, but are less common because they are more expensive. The same goes for the increasingly popular 3D panels.

3D panels create an unusual effect

Advantages and disadvantages

Like any other material, panels have strengths and weaknesses. The product benefits include the following product qualities:

- Good level of moisture resistance, due to which the panels are recommended for use in bathrooms.

- Quick and easy installation of products - anyone can cope with the task of installing MDF panels or plastic elements, it is enough to have minimal construction experience. To carry out the work, there is no need to purchase specialized tools, the products are lightweight.

- For the installation of panels, it is not necessary to provide a perfectly flat base, as required by the tile.

- Thanks to the use of such products, the level of thermal insulation increases, since plastic and chip elements are warm raw materials.

- The level of soundproofing of the bathroom is increasing, which is important for residents of apartment buildings.

- The products are characterized by such qualities as durability and long service life, however, the correct installation of products in this case plays an important role.

- The elements do not need specific maintenance; to keep the panels clean, it will be enough to wipe the surface with a damp cloth and avoid prolonged exposure to water.

- Wear resistance and resistance to mechanical stress.

- Acceptable cost, which can be attributed to the absence of the cost of paying for the work of a specialized hired force and the purchase of expensive consumables.

The disadvantages of moisture resistant bathroom panels are:

- Unlike conventional tiles, MDF furnishings swell when immersed in water. It follows that in situations where the bathroom is flooded from the upper floor, the material will be irrevocably damaged.

- Low level of impact strength of panels.

- The absence in some models of grooves at the joints between products, due to which the gaps will need to be filled with a sealant.

Mounting

There are several ways to lay the panels:

- using glue or liquid nails;

- on a special frame.

Arrangement of the frame is carried out using an aluminum profile according to the following technology:

- the arrangement of profiles is performed, the stiffeners of which are placed horizontally;

- the fastening step is calculated based on the width of the product, but this value should not exceed 50 cm;

- then the preparation of the slats is carried out - the ends of the elements made of MDF are recommended to be additionally treated with a sealant;

- in the case when the floor in the room has an insufficiently even surface, the resulting gaps are hidden with the help of a plinth;

- all areas where switches, sockets or communication outputs will be located must be indicated;

- the fastening of the rails is carried out on self-tapping screws or staples, in some cases you can use special clips.

Installation of panels on glue can be carried out in bathrooms, where the bases have an even geometry, and also do not require specific preparation. Otherwise, the walls should be pre-finished with plaster and the surface should be primed.

After completing such work, you can start gluing the panels. The technology for performing this task is as follows:

- Joints between elements of the composition, including corners and places of joining panels to the floor and ceiling, can be decorated with moldings. This option will provide a cleaner appearance to the surface. This work is not necessary if the fixing of the components is carried out using grooves or other fasteners.

- The application of the composition to products can be done pointwise or in the form of zigzags.

- The panel with the composition applied to the back is applied to the wall and pressed over the entire area.

- If excess glue has come out around it, it must be carefully removed from the base.

- Installation of panels should always start from a corner.

- All unattractive places where the cuts on the edges of the products are visible are best hidden under the skirting board. It can be made of any material and have a similar color, or vice versa - serve as a contrasting component of the created composition.

Mounting options

As mentioned above, decorative fiberboard wall panels can be installed in a variety of ways. Each of them is good and has its own distinct advantages and disadvantages. In any case, they are all easy to implement with your own hands. It is enough to have instructions and know the sequence of work.

Glue mounting

At first glance, this is the simplest method of working with products. On the one hand, this is so.The main requirement (it is also a disadvantage of the method) is the presence of a perfectly flat surface. Then the work will be done quickly and easily. If the walls are uneven and it will take a lot of time, effort and money to eliminate defects, it is better to consider another installation option.

The essence of the work is as follows:

The wall is being prepared for gluing. It is cleaned of old material, grease stains, dust and dirt are removed. Then the surface is primed in two layers with a drying break. This improves adhesion. Further, the fiberboard panels themselves are prepared. They need to be cut to fit the wall. It remains to apply an adhesive to the back surface of the panel and glue the sheet in place. Glue is applied in dots or in zigzags

Particular attention is paid to the edges

The entire surface is processed using this technology. Since the sheets are large, the work speed is high. However, you cannot do without an assistant, because the panels are heavy.

If the first sheet is glued evenly, then the subsequent elements will fit perfectly.

Mounting on screws or nails

Fiberboard panels for walls can be fixed to the wall with ordinary nails or self-tapping screws. The requirements for the wall remain the same - a perfectly flat surface. Self-tapping screws are a guarantee that over time the finish will not fall off under its own weight.

The technology is simple: the panel is installed in its place and fixed on the fasteners. However, there are some nuances:

When the walls are made of wood, or similar materials such as SIP panels or chipboard, the finishing sheets can be fixed with nails or self-tapping screws.

If the wall is brick or concrete, it is important to markup for future panels, drill holes, insert dowels. This is a guarantee that the fasteners will not be pulled out.

The disadvantage of this installation method is the presence of hats in the surface, which are difficult to hide. In this case, you need to drown the screws a little and close them with decorative overlays.

Installation on the lathing

This is the way in which the curvature of the walls is not important. The advantages are that wires and other communications can be hidden under the frame. And if the house is cold, then there is an opportunity to insulate the room. Minus - the usable space in the room decreases. Nevertheless, it is best to fix fiberboard panels on the frame. No messy work, wall leveling and priming required.

Installation process:

- Wooden or metal bars are attached to the wall at a distance of 30–40 cm from each other.

- After creating the lathing, you can lay the insulation material (if any).

- It remains to nail the fiberboard panels to the finished crate with nails or self-tapping screws. For reliability, you can use glue.

In the end, to make the finish perfect, you can resort to using platbands, skirting boards, corners and other elements. Thanks to this, the room will receive a complete look and will be pleasing to the eye.

As you can see, the fiberboard wall panel is an excellent solution for interior decoration. The material has many advantages and is appreciated for its versatility. It is safe and durable. And if the owner does not have the opportunity to finish with brick, stone, tile or natural wood, then the products will help make dreams come true.

Interesting solutions in interior design

To equip the kitchen space, you need to choose materials that will protect the surface of the working rest area from splashes of grease, water and soot. A kitchen apron must be durable and durable

Therefore, when choosing wall panels, pay attention to the quality of the material.

An interesting design solution is the play of contrasts. For example, if the kitchen set is white, then the skinals can be black or red. It looks very original and adds bright colors to the space.

If you do not like brightness and prefer calmer colors, then the kitchen can be decorated in neutral colors.For example, for a classic kitchen, a light kitchen set with a white countertop and a light lilac glass apron is suitable.

Wall panels in the form of a mosaic look very original. You can lay out such panels as you like, the drawing does not have to be combined. If the apron is decorated with a mirror effect, then the kitchen will look even more interesting.

Anyone can decorate the kitchen in an original way, you just need to be able to combine the shades of the walls, the kitchen unit and the kitchen apron. The wall area should be part of the interior. It is possible to install wall panels yourself if you follow the instructions. You can complete the design of the kitchen apron with the help of LED backlighting, which will illuminate the workspace in Night time.

7photos

What are wall panels

A variety of ready-made modules in the form of plates, sheets, blocks and strips of rectangular or complex shapes. They are made of various materials suitable for various premises, there are large-format sheets that can quickly cover huge areas, and there are exclusive piece slabs for creating luxurious elite interiors.

Advantages and disadvantages of using

Why are panels for wall decoration so good and why they are popular:

- a huge range of textures and color combinations to create any complex design solutions;

- increased strength indicators due to the multi-layer and combination of natural bases and polymer binders;

- environmental Safety;

- durability, repairs will get bored, but will look great;

- ease of installation and replacement of individual elements without disassembling the entire wall panel;

- resistance to ultraviolet radiation and exposure to water and detergents, which makes cleaning and maintenance easier;

- do not require special preparation of the base surface, renew and level the walls with defects;

- give the walls additional useful properties: visually expand the space, insulate, soundproof;

- the ability to both buy ready-made panels and make them yourself.

There are also relative disadvantages to using such a finish:

- panels based on natural valuable species of wood or stone cost a lot;

- some models are afraid of moisture.

To avoid damage to the walls due to moisture, you should not choose, for example, wood panels for the kitchen and bathroom.

What are decorative panels for interior wall decoration: nuances of application in the interior and advantages

With the help of decorative panels, you can solve many problems of decorating your interior. They will help disguise unsightly wires, hide uneven walls, as well as help insulate the room and deal with high-quality sound insulation for your home.

You can use wall panels for interior decoration as an interesting decor. The material will help to change the structure of the walls and make the interior more original.

To create a luxurious interior in a classic style, it is not necessary to purchase expensive materials - you can choose panels of an unusual shape

There are ways to use this material:

- sheathing the bottom or top of the wall will create the desired accent;

- the use of finishing panels for interior decoration as an exquisite decor for walls;

- combination of panels and lighting;

Backlighting will help to create an original design

- panels can be applied to the entire wall. Products made from natural materials are suitable for cladding a home library, billiard room or study;

- panels of different materials are used to give the interior an unusual effect.

Panels with photo printing can become a real interior decoration

Do you know that the fashion for such panels came to us in the 18th century from Europe. This material was used to decorate interiors back in the days of Catherine II.In Soviet times, decoration was used to decorate office buildings.

Currently, the use of panels for interior wall decoration is a rational and economical solution.

How the decorative panels look can be seen in the video:

Let's look at the main advantages of using such a material:

- Ease of use. Ease of maintenance and installation work;

- Security. Environmentally friendly materials are used for manufacturing;

- Durability. With proper installation and care, it can last for many years;

- A large assortment. You can purchase products from different materials, different textures and colors;

- Versatility. They allow not only to decorate the interior, but are also responsible for the heat-insulating and noise-insulating qualities.

The panels can be used to decorate some part of the wall. The original panel will harmoniously fit into the interior

Consider the cons:

Adaptation to conditions. Before using the panels, they must be left in the room where the repair will be carried out. This will allow you to understand how the material will behave in the future;

Fragility

Some materials require careful handling during installation and transportation;

Reduce space. They can "eat up" a significant area of the room;

Harm of artificial materials

Some materials can be hazardous when heated.

3 How to install panels with your own hands

It has already been noted that this material does not require any special skills or tools. But it is necessary to familiarize yourself with the installation technology itself in order to do all the work with high quality.

Installation of moisture-resistant panels on walls

There are two main ways of attaching moisture-resistant panels to walls - on a frame and on glue. Let's take a closer look at each of them:

- Frame. Here you should be prepared for the fact that the useful area of the room will slightly decrease, since 2-3 cm will go on each side.This point should be taken into account, since a bathroom, a sink and even a toilet bowl are usually placed in the bathroom. If we compare the frame and glue method, then the first is somewhat more complicated. The main catch here is the correct assembly of the frame. How long the lamellas will last on the walls will depend on how correctly the structure is mounted and its rigidity is observed. Accordingly, this moment will affect the term and quality of operation. After all, you can buy the best material, but mount it not according to the rules, then complaints may arise that low-quality panels were sold.

- Glue. With this method, no special tricks are foreseen. Unlike the frame, here the bathroom space will remain untouched. Due to the absence of voids, the risk of mechanical damage to the panels is much lower. In this version, the walls are pre-prepared - cleaned, leveled, puttyed, etc. After that, the surface is covered with special glue, on which the sheets are already attached. If the base surface does not have significant defects, then the panels will help to hide them perfectly even without preliminary preparation. If there are irregularities and defects, you should think about plastering or leveling with drywall. The only thing is that the glue method does not allow laying engineering communications under the cladding or making additional insulation.

Moisture-resistant panels for the bathroom are an excellent budget option for renovating a bathroom. But they do not allow you to create an exclusive design for such a room.

This is due to the fact that such cladding is not entirely intended for decorating walls, so manufacturers do not seek to expand their range.

Methods for installing moisture-resistant MDF for the bathroom

The choice of this or that method of installing MDF panels on the walls is fully determined by the evenness of the walls.Let's not beat around the bush, but let's say right away that these panels are mounted on flat walls with glue, and on strongly curved and heaped levels they are installed using frame technology. Let's consider these technologies in more detail.

Installation of panels with glue. A very simple installation option, but, as mentioned above, smooth walls are needed for it. Moisture-resistant MDF board can be glued using two types of adhesives - standard in such situations, "liquid nails" and polyurethane foam with low pressure during the polymerization process. For example, Makroflex 65 is mainly used for the installation of door blocks. This foam does not squeeze out or change the position of the material to be glued during the curing process.

You need to wait until it dries completely and then gently clean it off.

Frame installation method. The process is quite complicated - you need to assemble the frame so that all its elements are located in a single plane along the vertical level of the horizon. It is made either from a wooden beam or from plasterboard profiles, which is preferable. To begin with, the perimeter of the plane is formed from the ud profile, then, according to the dimensions of the MDF panels, this plane is reinforced by the bearing profiles cd, which take the main load from the panels. Simply put, they are attached to them by means of the same glue and special cleats, for the installation of which the panels must be equipped with grooves. It is this version of the installation of moisture-resistant laminated MDF that makes it possible to produce associated insulation and additional sound insulation of the walls. In addition, behind such panels it is quite convenient to hide electrical, pipeline and other communications. The only drawback of this technology is the fact that the frame takes up some useful area of the room - in other words, it steals space that can be used more practically.

There are no other ways to install moisture-resistant MDF wall panels on walls without damaging their front layer. Alternatively, they can be fixed with self-tapping screws through pre-drilled holes, but, you yourself understand that there is nothing good in such a mount, even if you subsequently install plugs on the caps of the screws.

And in conclusion, the topic about moisture-resistant sheet panels MDF for walls I will add only one thing - in particular, I will say about the variety of front decorative coating. In this regard, all MDF panels produced today can be divided into four types. These are veneered panels (maximum imitation of natural wood), glossy panels (a great way to visually expand the space of a room), painted panels (their feature can be called deep color) and so-called 3D panels, the ridge of which is volume. Which one you choose, your business is the only one, oh what should be constantly remembered, this is about the fact that such a decor will affect the perception of the room as a whole. Harmony is needed here.

Installation methods

Installation of wall panels

There are 3 main ways to install decorative panels:

1 per frame (crate)

2on glue

3 on self-tapping screws directly to the wall

The advantages of the first method are that in the resulting free space between the panel and the wall, you can lay the necessary communications: wires, cables, pipes, add insulation. However, this would mean a loss of 10-15 cm of usable area on each side.

Only lightweight finishing elements can be glued directly to the wall and exclusively on a flat surface. It will also not work to mask the unevenness of the walls with different thicknesses of glue.

If the room is small, then it is best to mount the finishing panels vertically - this will visually "stretch" the space. Large apartments can be tiled with horizontal or vertical tiles.

On the crate

Installation of panels on the crate

In this manner fasten plastic and wood panels... It happens like this:

1 Long wooden bars or metal profiles are nailed to the wall, perpendicular to the direction of the future installation of the panels. The distance between them should be on average 40 cm

2 On the seamy side of the casing, mark the attachment points

3 Clamps are attached to decorative elements

4The clamps are inserted using grooves into the profile holes

5Each element is attached to the lathing with self-tapping screws

6 The outer and inner corners are concealed with decorative fittings.

If you need to fasten two panels with different types of fasteners, then use an H-shaped profile, the slopes are trimmed with slats fixed to the U-shaped structure.

Installation on lathing

The main thing in this finishing method is to clearly align the first panel. If this is not done, then the whole structure will "go", creating a sloppy look.

In damp and unheated rooms, the crate is made of aluminum profiles, in dry rooms - of wood. Panels in the form of slats and made of plastic are connected to each other with fasteners called "thorn-groove", and other types - with fasteners called "groove-groove".

On glue

Lightweight panels are attached to "liquid nails"

For installation of panels in dry rooms, specialized glue-based solutions ("liquid nails", gypsum-cement) are used. They are applied to the entire surface of the panel. It is not necessary to coat the wall with glue - it is better to prime it first.

In this way, only light sheet materials are attached. When dismantling and re-repairing, the glue will have to be peeled off.

DIY decorative plaster of walls. Overview of simple solutions: how to make, how to apply putty | 115+ Photos & Videos

The positive qualities of the panels

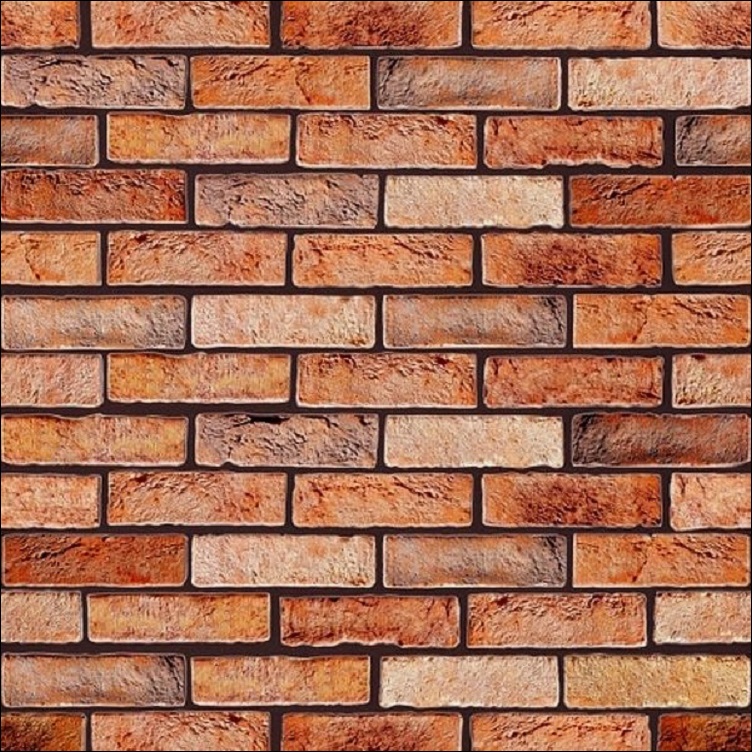

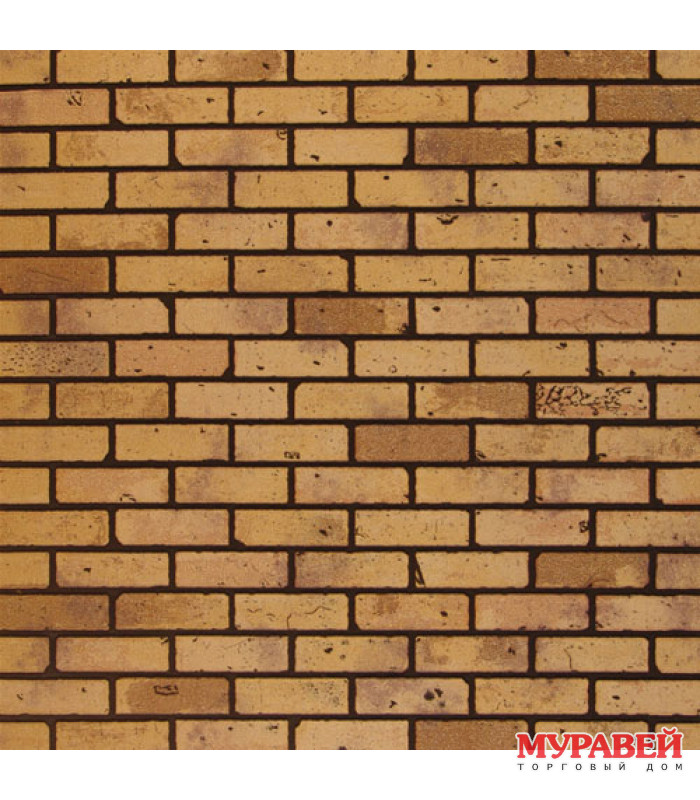

Well, in order to make sure that stone panels not only deserve to exist, but also are in high demand, consider some of the advantages. So, let's start reviewing and studying the advantages:

- The versatility of the material in relation to surfaces and places of use. The decorative panel is a versatile finishing material. This material can be used both in residential premises and in public;

- Possesses excellent qualities of thermal insulation and sound insulation due to the fact that during installation it is possible to use an additional layer of insulation, which is mounted between the wall surface and the material;

- Mounting. Simplicity and simplicity allows everyone to carry out installation work. To do this, it is not necessary to purchase an expensive, professional, special construction tool, as well as to possess the professional skills of an installer. All that is needed for work is the material for the lathing (in the case when the frame mounting method is used), a stapler and staples. Convenience also represents the absence of the need to prepare the bases before applying this finishing material to them. This is one of those types of material, which requires a minimum of time to install. Spending a little time is accompanied by the system of fastening the panels to each other (groove-comb). Installation is carried out in a different direction. Considering that the panel is made with a special technology, it can create an imitation of almost any material on its surface, in our case it is a stone;

-

Reliability and durability. Considering the fact that decorative panels have high indicators of strength, reliability, and, consequently, durability, they can be on your walls for a long time, while you will not have any desire or need to change them to another material;

- Price. The price of this material will seem a little high, but the material fulfills it completely. Given its reliability and durability, this will allow you to save on repairs in the future;

- Care.The use of special materials in the creation allows you to confidently carry out wet cleaning of this material (for wet cleaning, you can use any cleaning agent that does not contain chemicals), moreover, it is enough to clean it once a month. The particular advantage is that the panel does not attract dust. Yes, some small elements of models with a relief surface still attract dust, and therefore, as a rule, they are usually used for bathrooms and kitchens.