Installation technology

If you decide to clad the walls with MDF panels, you should choose an algorithm for the work. Installation can be carried out with glue or on a metal or wood frame. Such finishing can be made semi-antique, everything will depend on the texture of the products.

At the first stage, the markup is performed. Choosing a wooden lathing, you get the advantages in the form of its easy installation and environmental friendliness of the material. Installation is started with angled vertical slats. They are placed in pairs to form an angle. The parts are fixed horizontally according to the same algorithm. Window and doorways deserve special attention. Along the perimeter, the rails are installed without taking into account whether they have a step mark.

Wood trim is installed from the corner. At the panel it is necessary to saw off the ridge, attaching the next one to this element with the help of a lock. The cladding is fixed with small nails. Under the headset, when it comes to the walls of the kitchen, MDF panels are not installed. The gaps formed between the floor and the wall are closed with corners or decorative skirting boards that can be installed with glue.

During installation MDF panels for wood in addition, you can insulate the walls with sheet materials or foam. If pipes are located behind the cladding, the height of the profile is calculated taking into account the thickness and stock.

Decorative plaster

This general term is called a layer of building-decorative mixture applied to the surface of the walls. It evens out the walls, insulates them, insulates them, and, of course, is one of the most ancient methods of ennobling a home inside and out.

Plaster mixes can be divided according to two criteria - the composition of the mix and the artistic qualities.

Mineral plaster

Mineral plaster is the most economical type of plaster. This is due to the basis of the mixture - cement, which is "seasoned" with chemical additives that give increased moisture resistance. To this can be added environmental safety, vapor permeability, resistance to fungi and mold, temperature extremes, as well as fire safety.

Mineral plaster is the most economical type of plaster. This is due to the basis of the mixture - cement, which is "seasoned" with chemical additives that give increased moisture resistance. To this can be added environmental safety, vapor permeability, resistance to fungi and mold, temperature extremes, as well as fire safety.

Among the disadvantages is not a very diverse color palette and the complexity of application. But the average period of operation of the mineral coating does not exceed 15 years.

In addition to the mineral, there is also: silicate, based on liquid glass; silicone based on silicone resins; polymer - with acrylic resin in the composition. The longest service life of silicone and mineral plasters.

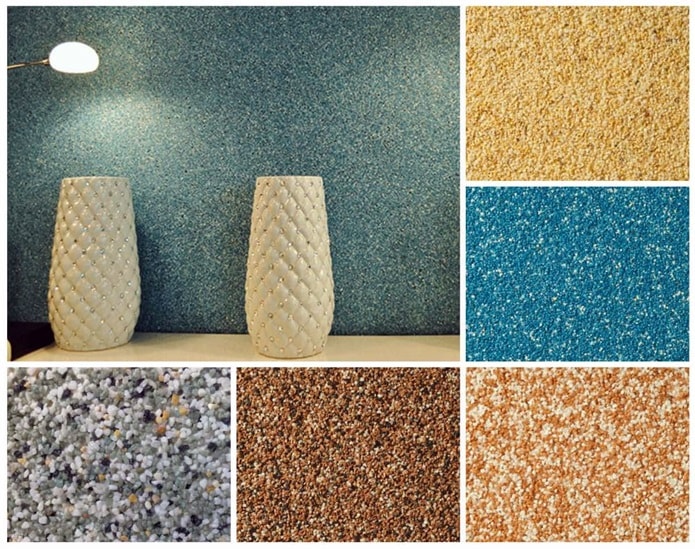

Textured plaster

Textured (structural) decorative plaster is a way of decorating walls that can be called an unfading classic. Due to the fact that the plaster mixture contains various additives (pebbles, fibers, marble chips or crushed brick), such a finish can look like rock, valuable wood, cork bark, patterns in the sand, cracked clay, buried velvet. The well-known "fur coat" and bark beetle plaster - a popular way of decorating halls and hallways for many decades, also belong to the textured types of plaster.

The well-known "fur coat" and bark beetle plaster - a popular way of decorating halls and hallways for many decades, also belong to the textured types of plaster.

Textured plaster is an excellent solution for those who want to get a unique interior. She will definitely provide picturesqueness, sophistication. And at the same time also strength, durability, fire resistance. Plaster will help hide small defects on the walls, and its price does not bite at all. Textured plaster will not disgrace any of the palace, classic interior styles, it will be a good find for the hall, living room, dining room.

Judging by the reviews, this design has one drawback - it is difficult to remove it when there is a need for a new repair. The time during which the textured plaster will not lose its attractiveness is 15-20 years.

Venetian plaster

It is hard to believe that this type of coating is more than 500 years old. "Venetian" creates the impression of a noble stone - marble, granite, onyx, jasper, opal, malachite, amber. Such a sophisticated type of decoration literally asks for the walls of spacious living rooms, where there are fireplaces, canvases hang in magnificent frames and the spirit of the Renaissance soars. Venetian plaster is unique: there are no two identical pieces of it in the world! It is she who can be seen inside the palaces of the Venetian Doges, the villas of the Italian aristocrats. "Venetian" is not only charmingly beautiful, but also safe, moisture-resistant, durable and capable of pleasing the eye not for years, but for centuries! But the price is right for her.

It is hard to believe that this type of coating is more than 500 years old. "Venetian" creates the impression of a noble stone - marble, granite, onyx, jasper, opal, malachite, amber. Such a sophisticated type of decoration literally asks for the walls of spacious living rooms, where there are fireplaces, canvases hang in magnificent frames and the spirit of the Renaissance soars. Venetian plaster is unique: there are no two identical pieces of it in the world! It is she who can be seen inside the palaces of the Venetian Doges, the villas of the Italian aristocrats. "Venetian" is not only charmingly beautiful, but also safe, moisture-resistant, durable and capable of pleasing the eye not for years, but for centuries! But the price is right for her.

Wall decoration options in a wooden house

There are many options for finishing a wooden house. It all depends on the operating conditions, finances, your desire and the style of the room.

Clean log house finished with paints and varnishes

If you strive for naturalness and environmental friendliness, you live in a region with a stably dry and stable climate, then a log house made of natural wood will suit you.

In such a house, you will always be haunted by the aroma of natural wood.

This type of decoration is becoming more and more popular with our stars. This primordially Russian style makes the room lively and the microclimate healthy. This type of finish attracts with its beauty, durability, environmental friendliness, uncomplicated design and simplicity. Such projects can be recreated with historical accuracy the way houses were built many centuries ago.

Lining as a wall decoration with wood when it is impossible to polish the timber

Lining is a traditional material for home decoration. Its advantages are obvious - it is easy to install, looks quite aesthetically pleasing. The lamellas, with the help of special fasteners, are connected tightly.

Clapboard paneling creates a perfectly flat and beautiful surface

Other advantages of this material include:

- quick installation;

- environmental friendliness;

- many shades of coverage;

- made from different types of wood.

Among the disadvantages are:

- high price;

- the need to erect a crate;

- the need for careful care.

Preparatory moments include not only the installation of the lathing, but also the processing and inspection of the lamellas themselves

It is important to pre-sand and dry them.

The final stage is lining the lining with varnish, sanding and another varnishing.

Block house - is a more modern type of lining. Usually, such blocks are made of high quality wood that does not shrink, is not inferior in strength and strength, and in many respects even surpasses classical materials.

The block house allows you to preserve the unique microclimate of the room

In addition, this finishing material does not lose its original quality due to the processing of wood. The texture of the material is no different from natural wood.

The main advantages of a block house:

- mechanical strength;

- environmental friendliness;

- aesthetic appearance;

- light weight;

- ease of assembly.

For interior decoration, lamellas with a thickness of no more than 25 mm are better suited. With an increase in thickness, difficulties may arise with high-quality fastening of the battens. In addition, this can lead to a decrease in the internal space of the room, which is highly undesirable. The disadvantages of the material include too low vapor permeability and increased flammability.

If you buy material in winter, then it is important to put it in a warm room to dry

Decorating a wooden house inside with plasterboard

Drywall is the ideal solution for when you need to hide or hide something.It can be some kind of communications, or defects in planning. Usually drywall is used when leveling walls. Most often, in a wooden house, drywall is used for finishing ceilings or erecting interior partitions. In addition, such coatings will be a good solution for bathrooms.

Drywall with a moisture-resistant coating can protect your bathtub walls from excess moisture

In addition, the drywall is fire-resistant. This is just the case when they can sheathe fireplaces or a stove, additionally protecting the wooden walls from overheating and fire.

For wooden houses, lathing from a bar is used as a basis for drywall

Wall panels of different types

Wall panels for finishing a wooden house are quite a popular option. The choice of materials is quite large. The finish under natural veneer looks very interesting, as well as made of laminated MDF, which is not afraid of moisture and can repeat almost any texture.

MDF boards are able to imitate the patterns of not only wood, but also leather, bamboo, gypsum

Why wall panels are good:

- simple and easy installation;

- good heat and sound insulation;

- stylish appearance.

The panels are also convenient because you can choose them for any size. They are also attached to the lathing and have a tongue-and-groove fastening system. Externally, the seams are almost invisible. The coating looks like a single monolith.

Decoration with MDF plates can be selected for any interior

Related article:

MDF panels

MDF panels are a modern modification of particle boards known as chipboards. In the production of MDF, however, harmful phenol is not used, which makes this product environmentally friendly. The advantages of MDF include a wide range of products: manufacturers offer multi-colored, ornamented panels, smooth and with a relief surface. It is enough to simply attach them to the walls, they are durable, with a high coefficient of thermal conductivity, insensitive to mold and mildew, and since they are covered with a laminated film, they are also resistant to moisture. The service life of MDF panels is 15 years.

MDF panels are a modern modification of particle boards known as chipboards. In the production of MDF, however, harmful phenol is not used, which makes this product environmentally friendly. The advantages of MDF include a wide range of products: manufacturers offer multi-colored, ornamented panels, smooth and with a relief surface. It is enough to simply attach them to the walls, they are durable, with a high coefficient of thermal conductivity, insensitive to mold and mildew, and since they are covered with a laminated film, they are also resistant to moisture. The service life of MDF panels is 15 years.

Wall decoration with plasterboard

Drywall will align the walls perfectly

Drywall will align the walls perfectly

Plasterboard coating on brick walls is a widely used finishing option. This technology has many positive aspects, thanks to which gypsum plasterboard is very popular when creating a wide variety of interior interiors for premises for various purposes:

- from plasterboard, you can make a perfectly flat surface, which greatly simplifies the implementation of subsequent work on wallpapering, laying tiles or simply painting;

- walls made of gypsum plasterboard are capable of carrying the load from the weight of household appliances, furniture and decorative elements;

- gypsum plasterboard can not only sheathe brick walls, but also make niches, pilasters, columns and other architectural details that can decorate the room being finished;

- when finishing a brick wall from the inside with gypsum plasterboard, in parallel, it is possible, if necessary, to make additional insulation of the walls by laying insulation between the main wall and the sheets of plasterboard.

Mount drywall with self-tapping screws

Mount drywall with self-tapping screws

In addition, the popularity of gypsum plasterboard is associated with the technology of its installation available to everyone, which consists in performing simple operations:

- On the brick walls, a special metal gypsum profile is exposed along the plumb line and level.

- Durable sheets are attached to the frame with self-tapping screws.

- The seams are putty and glued with a reinforcing tape, excluding the formation of cracks.

- The holes in the places of passage of the self-tapping screws are also putty.

- The filled areas are sanded and primed.

Wall panels for interior decoration

Decorating a wooden house inside with wall panels gives a completely different stylistic result. This finishing material is made from different materials with different textures:

- wood;

- bamboo;

- MDF (laminated and veneered);

- glass (smooth with applied photo printing, embossed, colored, transparent, matte);

- plastics and plastics;

- skin.

They are type-setting or panel board. Typesetting - long thin elements, connected to each other according to the principle of "thorn-groove". Lining is, in fact, also wall panels. It's just that it has long been used as an independent category of finishing materials. Panel wall panels differ in geometry - they have a comparable length and width.

Everything is usually collected on a crate (like a lining), the bars of which are stuffed taking into account the size of the chosen finish. This material is loved by designers: materials, textures and colors allow you to realize a variety of ideas. Such interior decoration of a wooden house can be very expensive - leather - or cheap - MDF panels. But the appearance is quite decent.

If the wall panels according to the technology should be laid on glue (gypsum, for example), then the backing plates - plywood, gypsum fiber board, etc. Plates are placed on this substrate with glue. An example is shown in the video.

Clapboard decoration inside the house

Lining is the leader among finishing materials. It is used both inside and outside the house, only with different treatments (impregnations and paints are taken for external or internal work). There are different types of it. It's not just about different types of wood or different board widths. There are also different profiles: smooth, wavy, imitating a timber or log house. There are several options in the photo below.

The most popular types of lining for interior decoration of a wooden house inside

Finishing of a wooden house inside can also be made from lining with a non-standard profile

For finishing inside the house, the lining is taken not thick: 1.5-2 cm is enough. It costs less, and will fulfill its functions. The slats can be placed horizontally, vertically, at an angle. From the combinations of all these directions, you can get the amazing beauty of the panel, but this is a laborious task.

When nailing the crate or planks, you need to be aware of the shrinkage of the log house and the ability of the wood to swell and shrink. Do not nail the trim and battens close to the floor and ceiling, leave 2-4 cm each to compensate for these extensions.

Clapboards are used to decorate both the walls and the ceiling. And here and there it looks more than decent, and such a finish is relatively inexpensive. It is cheaper (and easier to perform) only to cover it with plywood and paste the wallpaper. This, by the way, is a popular option for decorating a country house inside an economy class. With a sufficient level of performance, this method can also be used to decorate premises not only in the suburban version. The only objection is the glue that is used in the manufacture of plywood. But if you take it to the I class of emission (allowed for use in childcare facilities), then, probably, nothing terrible will happen.

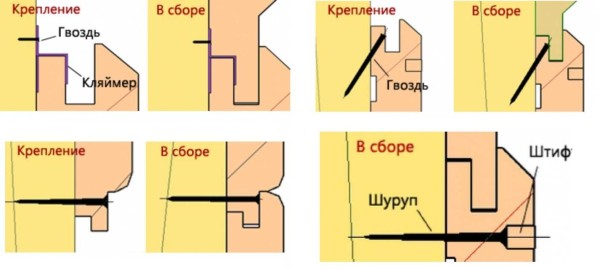

Mounting methods

Previously, they did not particularly worry and nailed the lining into the face (into the front surface) through and through. In the best case, they used nails without caps or finishing nails (they have very small caps). Sometimes the hats were smeared putty on wood and sanded, sometimes closed the holes from the screws with pins. This is for the most fastidious and demanding finishes.

Methods for fixing the lining

Today, even this method is considered not the most aesthetic: the traces can still be seen. To not see anything, they use secret methods:

- nails or screws are driven into a thorn or groove at an angle;

- using cleats (cleats).

Both of these methods require patience and accuracy: thin, small nails are used, they need to be nailed so as not to damage the front surface. To make it easier, you can hit not with nails, but with staples from a construction stapler. Staples are taken with a narrow back and long legs, made of stainless steel with sharpening.Although there are models of staplers that "shoot" nails with a very small head. For fixing the lining - the very thing. They also use self-tapping screws. A comparison of the two methods is made in the video.

There is one caveat. If you bought non-chamber drying lining (its moisture content is 7-8%), it will gradually dry out. There will be gaps between the planks and you will either have to put up with them, or nail all the planks again. Sometimes two or three times. There is no way to avoid this. You can only choose a profile in which the gaps will be invisible (profiles "Softline" and "Standard" in the figure in the previous section). In this regard, you need to think carefully about the better to fix the lining for the first time: it will have to be removed. Therefore, it is advisable to make it easy and not to collapse. Here everyone decides for himself: it is more convenient for someone to work with self-tapping screws, someone with nails. Both methods are not ideal (it is difficult to pull out the nails, and you need to drill a hole under the screw head), but both are acceptable.

Sometimes it becomes necessary to dock the lining with a wall of logs. Difficulty can arise due to the fact that the wall has a non-linear shape. You can outline it using a small piece of lining, to which a simple pencil is attached. Putting the plank and leading along the wall with a piece of lining with a pencil, transfer the shape of the log to the plank. By carefully sawing along the marked line, an almost perfect match can be achieved.

You may be interested in reading about how to install laminate flooring.

Material characteristic

The house can be sheathed using the available variety of materials

The house can be sheathed using the available variety of materials

A log house can be sheathed using the following products:

- lining;

- drywall;

- block house;

- PVC panel;

- MDF panel;

- wood material: OSB, chipboard or plywood.

Now let's look at each cladding material in more detail.

Using lining

The lining is a simple board, with built-in special grooves, due to which the tree fits snugly together

The lining is a simple board, with built-in special grooves, due to which the tree fits snugly together

The lining is a simple board with built-in special grooves, due to which the tree fits snugly together. The photo shows the floor and walls finished with clapboard

The disadvantage of using the lining is its stereotyped nature, such an internal design looks good, but it is unlikely that it will work to give some individuality to the rooms. Of the advantages of the lining, it can be noted:

- a huge selection of wood species;

- various types of product processing;

- environmental friendliness of the material;

- pleasant aroma inside the house.

Using a block house

If you like rounded logs, a block house would be ideal.

If you like rounded logs, a block house would be ideal.

If you like a rounded log, but you do not know how to sheathe a house inside from a bar, a block house will be the ideal option. This material is widely used in the decoration of cottages, the tree is able not only to decorate the room, but also to give maximum comfort and coziness. Of the advantages of this material, it is worth noting:

- high environmental friendliness, products are made from natural varieties of wood, which undergo special drying;

- mechanical strength allows the product not to lose its appearance and positive characteristics;

- has an aesthetic appearance, is able to decorate any home;

- simple way of fastening.

The disadvantages include:

- low vapor permeability;

- high flammability of the material.

Block house looks great inside a wooden house

Using drywall

Recently, drywall is often used to decorate wooden buildings.

Recently, drywall is often used to decorate wooden buildings.

Recently, drywall is often used to decorate wooden buildings. However, experts do not recommend using gypsum, because it has several disadvantages. If you perform internal work immediately after building a house, drywall may crack or deform during shrinkage.It is also worth noting that after fixing the gypsum sheets, they must be plastered and painted. The joints are sealed, which makes the space in the house clogged.

PVC panel

If you want to save money, but do not know how to sheathe a house from a bar inside, a plastic panel is the most economical option.

If you want to save money, but do not know how to sheathe a house from a bar inside, a plastic panel is the most economical option.

If you want to save money, but do not know how to sheathe a house from a bar inside, a plastic panel is the most economical option. Of the advantages, it can be noted:

- ease of mounting;

- high resistance to moisture;

- a large selection of color palette panels.

The disadvantages of the material include:

- low environmental friendliness;

- panels are not able to pass steam and air;

- when ignited, they quickly melt and release hazardous and harmful substances for human health.

According to home owners, the main area of application of plastic panels is non-residential or utility rooms.

Using MDF panels

MDF panels are produced from a more environmentally friendly material than plastic

MDF panels are produced from a more environmentally friendly material than plastic

MDF panels are produced from a more environmentally friendly material than plastic. The surface of the product is quite flat, which does not require complex finishing. Fastening of panels can be performed either by directly fixing to the wall, or using a frame device. Manufacturers produce MDF panels of various designs, colors and textures, with their help you can decorate any room in the house.

It should be noted that the MDF panel is able to additionally insulate and soundproof the walls.

Interesting colors can make rooms unique and stylish. The photo shows a room sheathed with MDF

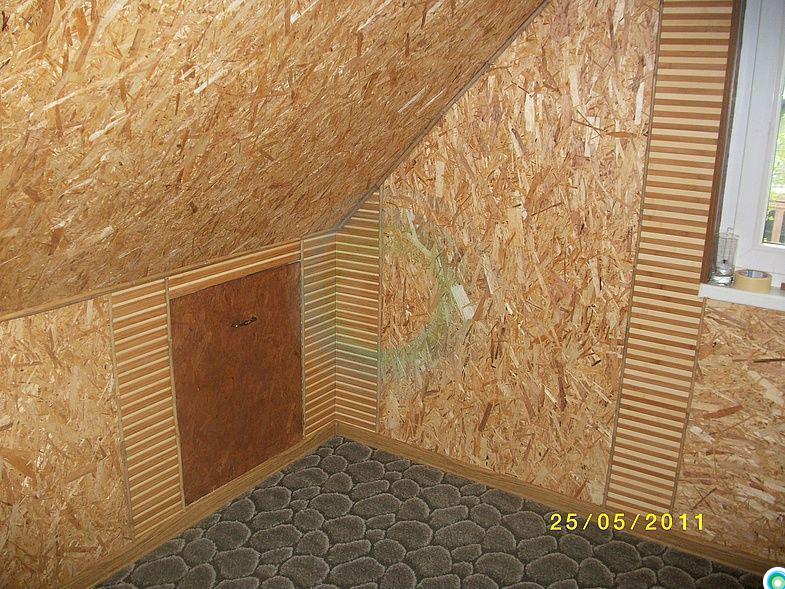

Use of wood material

All products made of wood material (OSB, plywood and chipboard) are used to perform rough work, but they are practically not used for final finishing work.

All products made of wood material (OSB, plywood and chipboard) are used to perform rough work, but they are practically not used for final finishing work.

All products made of wood material (OSB, plywood and chipboard) are used to perform rough work, but they are practically not used for final finishing work. In addition, in the production process, wood products are treated with special adhesives and impregnations, which evaporate and negatively affect human health.

Work order

Before sheathing the walls with plywood, you should take care of high-quality surface preparation and the construction of a reliable frame for the future structure. It is necessary to take care of the preparation of all the necessary components:

- Bars for the construction of the frame. Their thickness should be 1 cm more than the thickness of the insulation boards. All components of the structure (bars and slats) are treated with special compounds that provide full protection against moisture and other negative influences, significantly increasing the service life of the products.

- Material for heat and sound insulation. It is better to choose foil plates that guarantee high-quality waterproofing. Mineral wool, which is lightweight, durable and resistant to harmful insects and rodents, is ideal.

- Fasteners. Self-tapping screws with a length of at least 60 mm.

- Directly plywood for cladding the interior walls of the house.

First of all, wooden walls should be prepared by treating them with special impregnating compounds, with which you can protect against the appearance of mold, harmful insects and premature destruction. It can be an antiseptic primer with deep penetration. All cracks found on the surface of the walls must be repaired with polyurethane foam, the excess of which, after hardening, is cut off with an ordinary wallpaper (clerical) knife.

Butt-laying allows you to create a solid surface.

Now they provide reliable waterproofing, on top of which you can attach slats and lay mineral wool. The assembly of the frame begins with the creation of the lathing.To do this, a horizontal starting profile (bar) is attached along the entire perimeter of the room under the ceiling and on the floor, to which vertical racks will later be attached with self-tapping screws under the control of the building level. The distance between the posts is 60 cm.

Horizontal lintels are fixed at a distance of 40-50 cm, making the frame more rigid. After laying the thermal insulation material, proceed directly to the sheathing of the frame with plywood sheets. The photo shows that they are all butt-attached. Seams and joints are processed depending on what the finish will be.

Many ordinary people strive to preserve the natural structure of wood, emphasizing its special pattern with the help of special impregnating compounds. Such substances help not only to make the coating more attractive in appearance, but also provide effective protection against moisture, mildew and mold.

The video instruction will help you understand how to use plywood not only to decorate, but also to protect the walls of your house.