Advantages and disadvantages

Attention

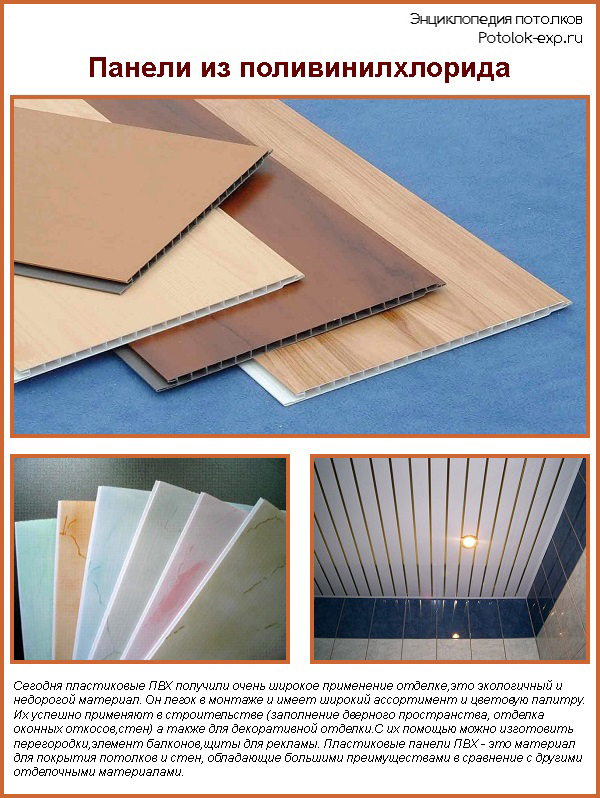

Most often, consumers pay their attention to plastic lining for the ceiling due to the low price and simple installation.

Coating Benefits

- High quality plastic, environmentally friendly, which makes the coating safe for humans.

- If a visual defect or damage appears on a panel, the entire structure does not need to be disassembled, but only the panel with a flaw is removed.

- The service life of the cladding is at least 15 years with proper care.

- Ease of installation, which is available even to people without skills.

- Dismantling does not require destruction of the surface or coating elements. The panels can be reused.

- The plastic is highly resistant to fluctuations in humidity and temperature, does not deform, does not change the color of the decorative layer.

- Differs in resistance to microorganisms - mold, fungus, insects.

- Any contamination can be removed simply, wet cleaning with non-abrasive cleaning agents is allowed.

- Due to the decorativeness of the coating, after the installation of the panels, finishing is not required.

- The details are light, which does not require strong metal profiles, and allows you to install the frame from the guides of the "economy" category.

- Possible organization of spot lighting or installation of pendant lights.

- A space is created between the surface of the ceiling slab and the panels, into which additional insulation and communications, including electrical wiring, can be placed.

- Complex and expensive preparation of the ceiling surface is not required: leveling, priming and other measures.

PVC panel coating has several disadvantages

- small gaps will be visible between the plates;

- if only plastic plates are used, then there are few design options; for an original look, it will be necessary to attract other types of finishes;

- if the power of the luminaires is too high, then the edges of the panels adjacent to them may melt;

- low resistance to UV radiation, the appearance of areas of burnout on the surface;

- after installation for several days, a characteristic smell of plastic is felt in the room;

- if a fire occurs, then PVC products, as a result of melting, will emit toxic smoke with harmful effects on humans;

- the surface of the slabs is fragile, therefore, mechanical influences and physical loads are poorly tolerated by them, they easily crack, break as a result of an impact.

Important

Due to the many advantages and resistance to moisture, such panels are often installed in the bathroom, kitchen, bathroom and other rooms with similar microclimate indicators.

Selection of PVC panels

So, you know what kind of material it is, now you need to select PVC panels and purchase them. First you need to decide on the size. At the moment, in hardware stores, you can see plastic panels either in the form of lining or in the form of rectangular plates with the dimensions shown in the table below.

Table. Standard sizes of PVC panels.

| Type of | Length, mm | Width, mm |

|---|---|---|

| Lining | 3000 | 100 |

| Reinforced lining | 3000 | 125 |

| Rectangular Panels | 2600 to 3000 | 150 to 500 |

| Sheets | 1500 to 4000 | 800 to 2000 |

How do you know if you have good material in front of you? How not to unknowingly purchase low-quality PVC panels that will crack during installation or lose their color after a couple of years of service?

Ceiling panel prices

ceiling panels

Possible shapes and textures of PVC panels

When going to a hardware store, you should pay attention to the following points.For small rooms, the most suitable will be PVC panels of the "lining" type

They should also be preferred if you want to have a ceiling made of plastic, stylized as wooden boards. And for larger premises, it is better to take panels or sheets of polyvinyl chloride. As for the thickness, it is predominantly the same for all types of PVC sheets and is 10 millimeters.

Stiffening ribs of PVC panels should not show through from the front side. Also count their number - the more ribs, the stronger and more durable the panel structure.

The surface of the material must be perfectly flat, without any defects, chips or damage.

The mounting and mounting shelves must be flexible enough so that they do not break when you try to bend them.

Try to press lightly on the PVC panel. If a crack or dent appears on the surface, then this is a low-quality specimen, which you should refuse to purchase.

Take a few panels and try to stack them together

Good material fits smoothly and without gaps.

Pay attention to the appearance of purchased PVC panels - copies from all packages must be monochromatic and have the same texture. In some situations, PVC sheets from different batches have slight color differences.

What to look for when buying PVC panels: 1. The number of stiffeners: the fewer there are, the more unstable the product.

The edges of the plastic tile must be intact and straight. 3. The surface of the PVC panel should be evenly painted, smooth and free from unevenness. 4. The two panels must be properly connected in the place of the joint groove.

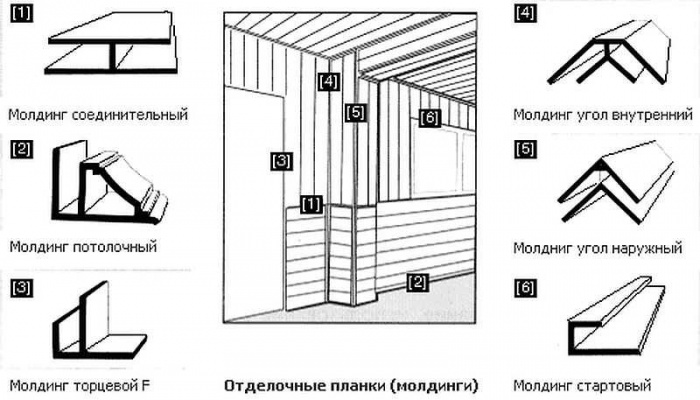

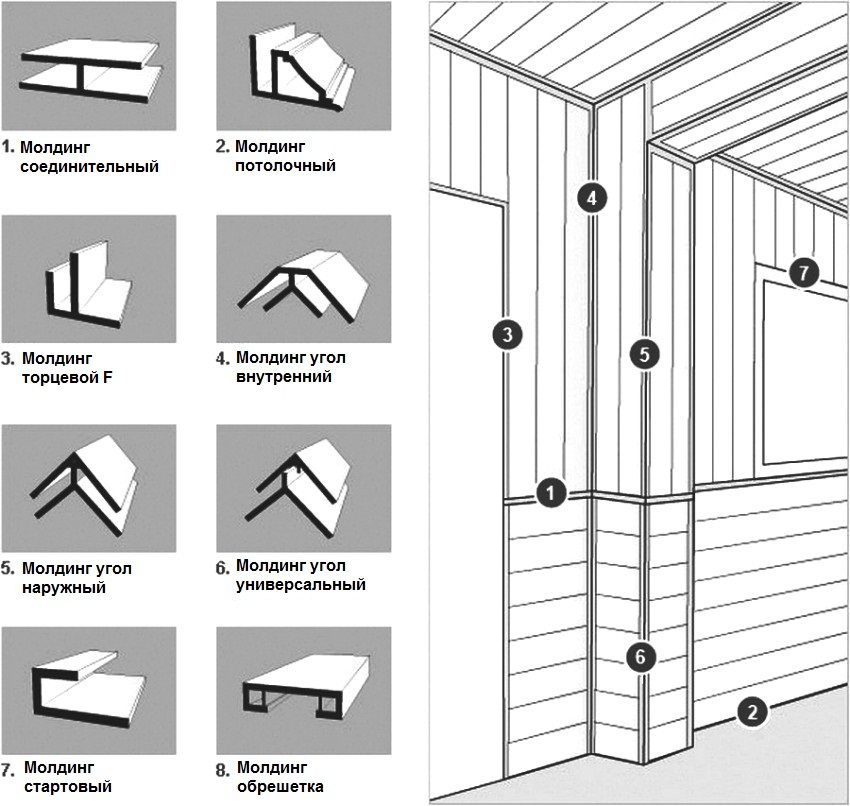

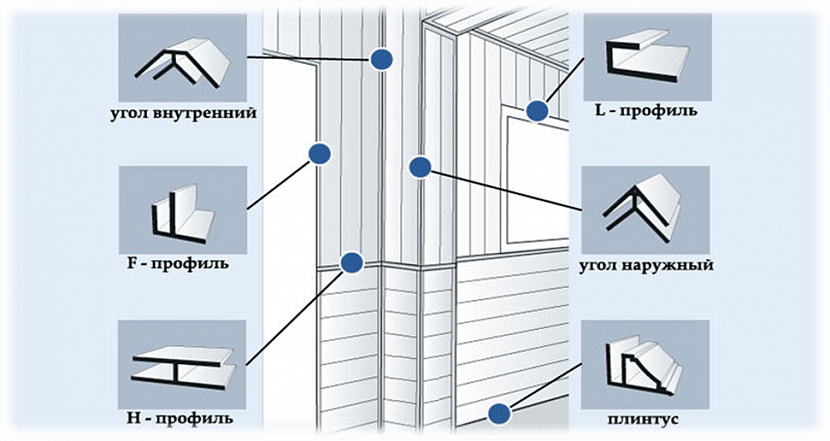

In addition to the PVC sheets themselves, you will need to purchase an installation profile. It consists of two "shelves", one of which is attached to the frame, and the other is connected to the plastic panels. Both starting and finishing PVC sheets are attached to the installation profile

When choosing it, you should pay attention to the thickness of the plastic and whether the profile does not have any bends or defects.

PVC panel ceilings

Do not forget to also buy a ceiling plinth - it not only serves as a decorative element of the future ceiling, but also closes the gap between the wall and the ceiling made of PVC panels. Usually such skirting boards are called fillets, made of plastic and attached with glue.

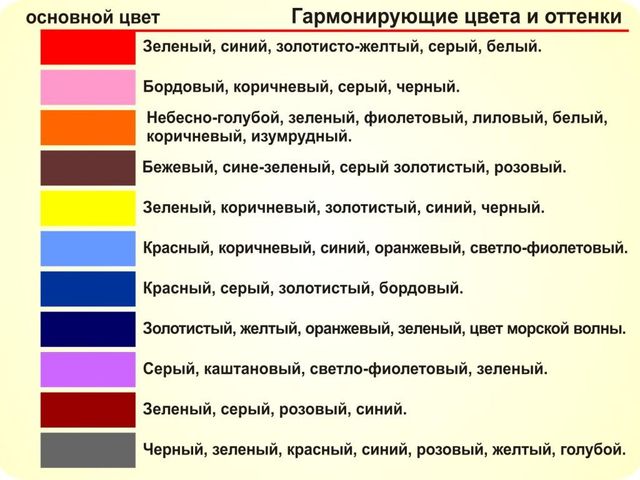

As for the appearance of the purchased PVC panels, you must determine it yourself, based on the design project of finishing the room and your own taste. Your attention will be presented with many options for panels of various colors and textures. Here you can advise to use a color matching chart so that the appearance of the ceiling matches well with the color of the walls and furniture.

Color matching table in the interior

Advantages and disadvantages

Plastic panels are a popular and common wall covering. They can be found in many shops that specialize in decoration materials.

Wide sheets and lining made of plastic are in great demand, because they have many positive qualities.

- First of all, it should be noted the durability of such finishing materials. In our climate, their service life can be more than 20 years.

- Such materials are durable. They are not afraid of dampness and moisture. In addition, they are not subject to rotting, as, for example, natural wood.

- Plastic panels do not require complex and regular maintenance. Dust and dirt do not accumulate on their surface. If the finish is dirty, then it will turn out to be cleaned with a regular damp cloth.

- PVC panels have sound insulating properties, so they are perfect for wall cladding.

- Using plastic panels, you can divide the space into functional zones.

- Plastic panels are lightweight materials that make them easy to work with. All processes can be handled without the involvement of assistants.

- Plastic is a very malleable material - it lends itself to various types of processing without problems. Therefore, in stores you can find PVC panels that have a variety of colors, textures, prints and ornaments.

- These finishing materials can be used in a wide variety of interior styles. The only exception can be only pretentious and pompous ensembles, in which extremely expensive and natural elements should be present.

- You can install plastic canvases both in a city apartment and in a private house.

- Various communications, such as electrical wiring, can be hidden behind the panels.

- It is quite possible to install PVC panels on walls with your own hands, since this process is not difficult and inaccessible. To do this, you do not need to stock up on expensive tools.

Of course, PVC wall panels are not ideal finishing materials. They also have their own weaknesses.

Let's consider them in more detail.

PVC panels are flammable. In case of fire, these materials burn quite strongly, spreading suffocating smoke in the room.

Many consumers note that after the installation of plastic panels, an unpleasant chemical odor remains in the room for a long time, which cannot be eliminated by ordinary ventilation. Of course, in this case, a lot depends on the quality of the purchased plastic.

PVC panels cannot be called "breathable" finishing materials

They do not allow air to move through the ceilings, and this is very important for sufficient ventilation in the room.

Plastic panels have voids in which various insects and parasites are often found.

PVC sheets are fragile material. They break when hit hard

It will hardly be possible to get rid of such deformations later - the material will have to be changed.

Knowing all the advantages and disadvantages of PVC panels, it will be easier to work with them. You will be able to avoid many mistakes during the installation process.

Preparation

When carrying out preparatory work prior to finishing the ceiling, it is not enough to calculate the amount of required materials

It is worth focusing on the presence of cracks, chips and other surface defects.

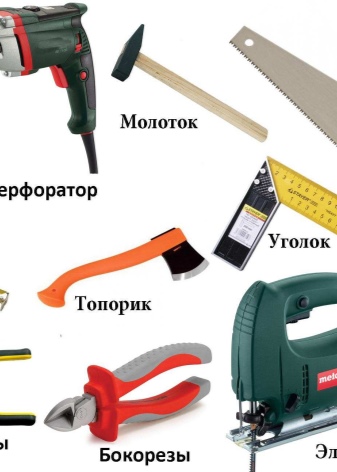

The following is a complete list of tools that you may need to work with.

- A puncher will be needed when installing the frame.

- The screwdriver is used when attaching panels to beams or metal profiles. In principle, a puncher can be used for this purpose, but it is quite heavy, so it will be difficult for a beginner without work experience to cope with it.

- A construction stapler is needed if the ceiling panels are fastened with brackets.

- The level is used to improve the accuracy of marking.

- Marker - for various markings.

- Roulette.

- Circular saw or jigsaw - will be required at the stage of installation of the frame for cutting off the profile elements.

- Ladder. Since it is supposed to work at height, therefore, a fulcrum is needed. In the absence of a ladder, you can use a regular table, but a professional tool is still safer and more reliable.

- Rubber mallet - used when adjusting PVC panels.

- Corners.

If you plan to design decorative elements, then you should purchase a molding.

After all the necessary calculations have been made and the tools have been purchased, you can proceed to surface preparation and finishing directly.

To do this, do the following:

- the old coating is removed;

- all lighting and electrical equipment is disassembled;

- the ceiling is cleared of dust and dirt.

After that, you should tap the surface of the ceiling with a hammer - this will allow you to detect defects that must be corrected before starting work.

The preparation is finished by applying a primer.After the surface dries out, start installing the ceiling directly.

General requirements for surfaces

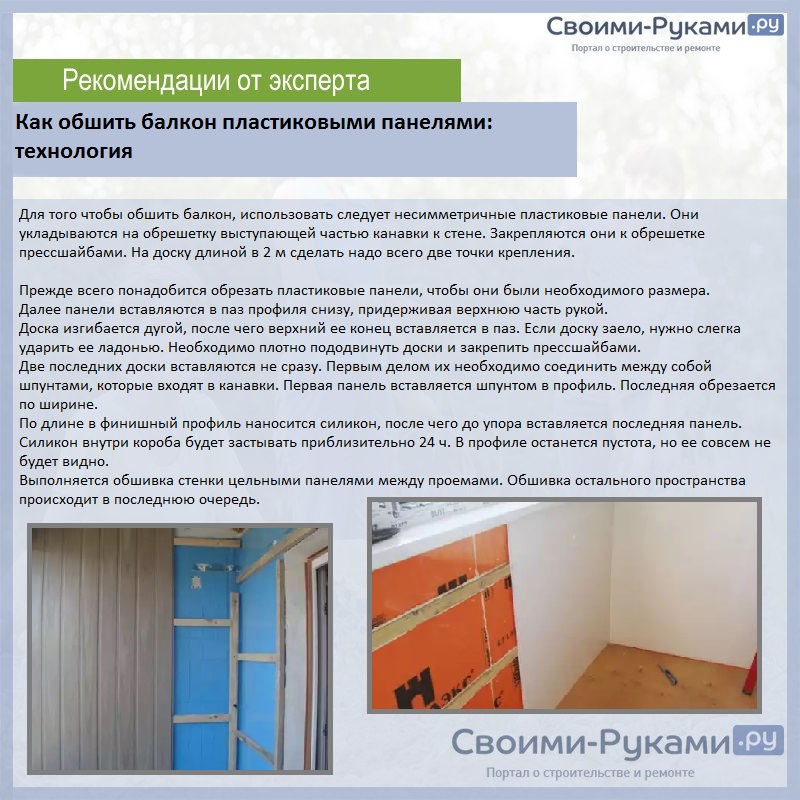

One of the benefits technology of wall decoration with plastic clapboard - low requirements for surfaces. There is no need to specially plaster and level the walls with putty, only large cracks are repaired. The height of the irregularities can be up to one 1–1.5 centimeters; anything larger must be cut down.

Large potholes can be repaired with cement mortar or putty.

Repair of major defects

Check the evenness of the walls with the rule

Mold Prevention Products

Rubbing walls with an anti-fungal agent

The climatic parameters between the wall and the cladding are the most favorable for the reproduction of fungi and other microorganisms, it is impossible to destroy them later. We'll have to remove the casing, do disinfection and vapor protection. Only after such events can you begin to install plastic panels. No matter how carefully you remove the cladding, you cannot do without damaging the materials. If you can buy the missing ones with the same characteristics - great. If not, you will have to buy new materials for the entire scope of work.

Mounting options

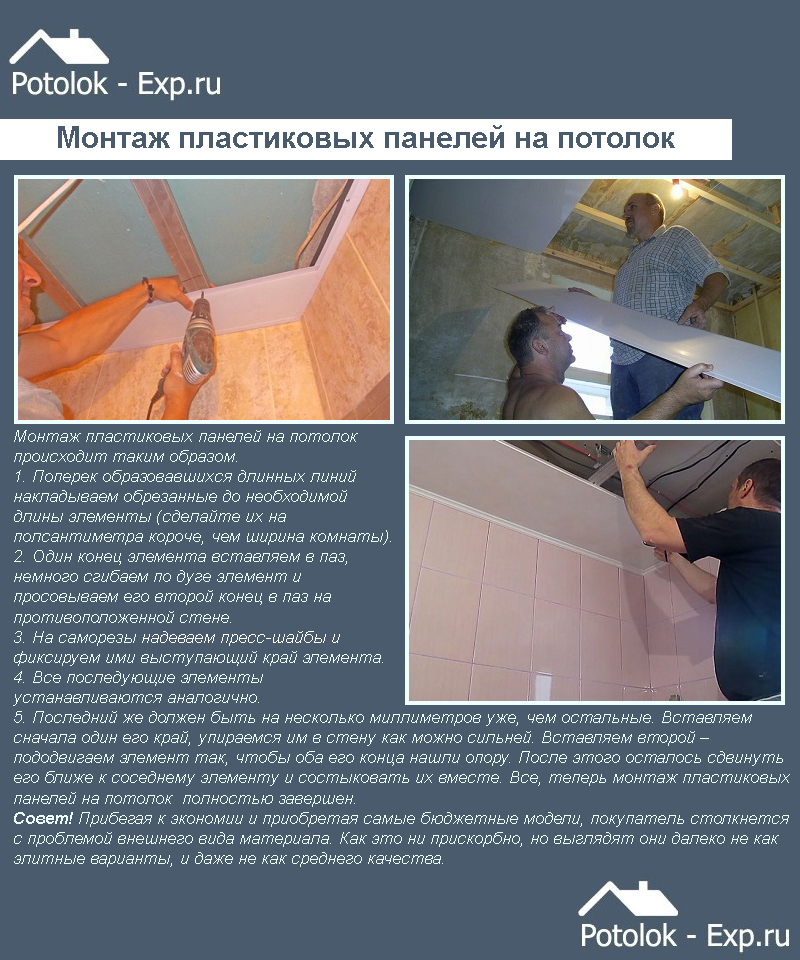

All work on finishing the ceiling with PVC panels can be easily and simply carried out even by a non-professional. Nevertheless, you should know the basic nuances of various installation methods.

As a rule, the panels are fastened either framelessly or using a hinged frame.

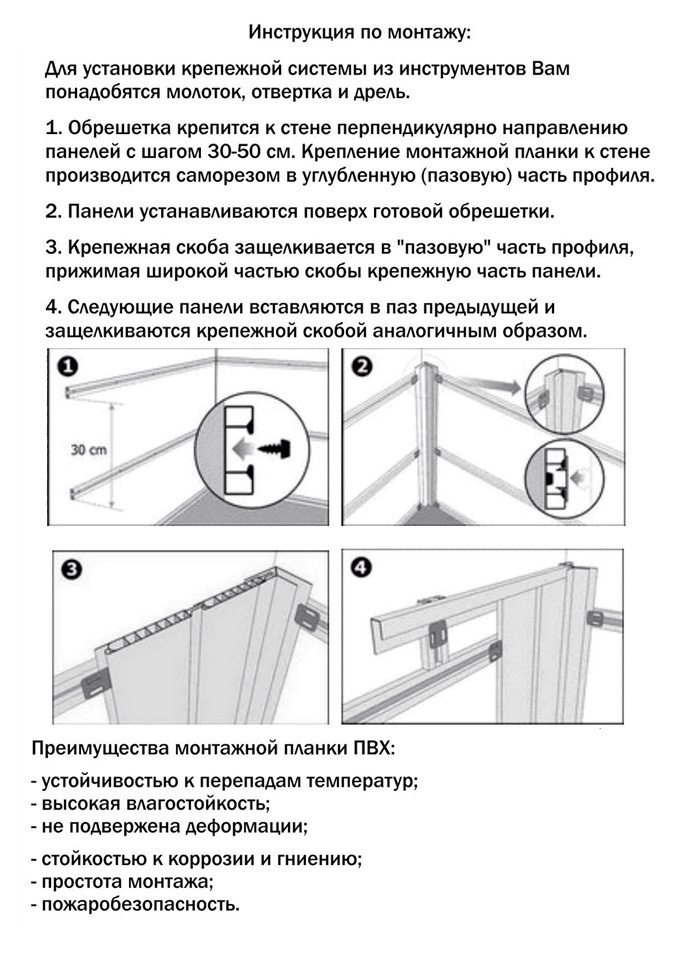

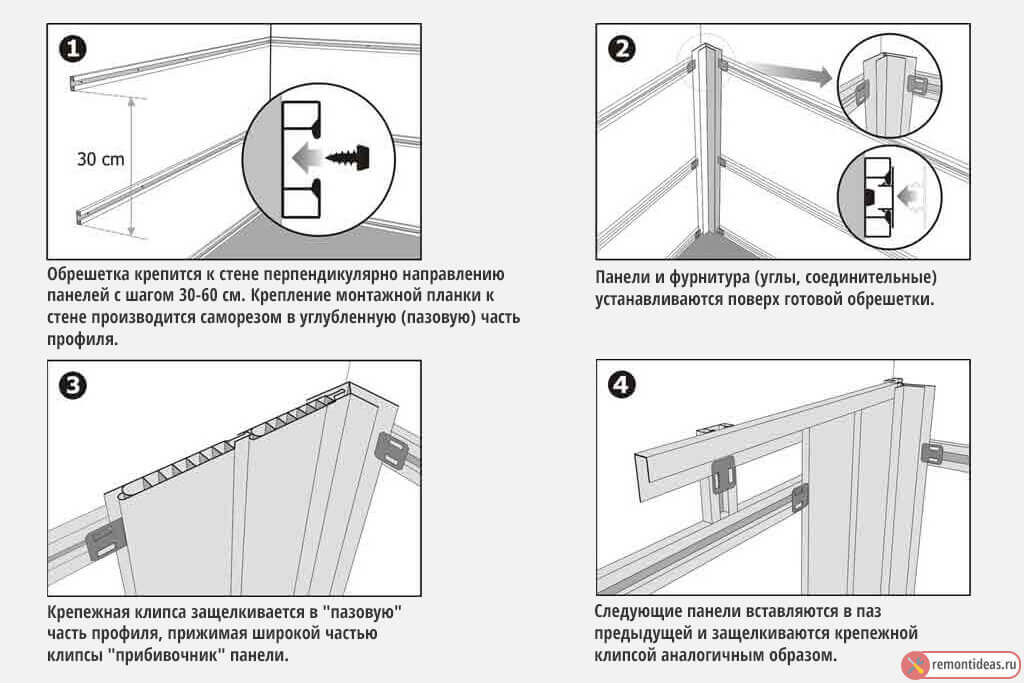

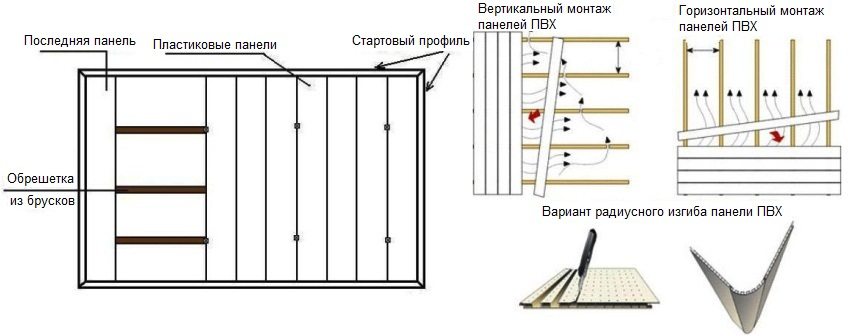

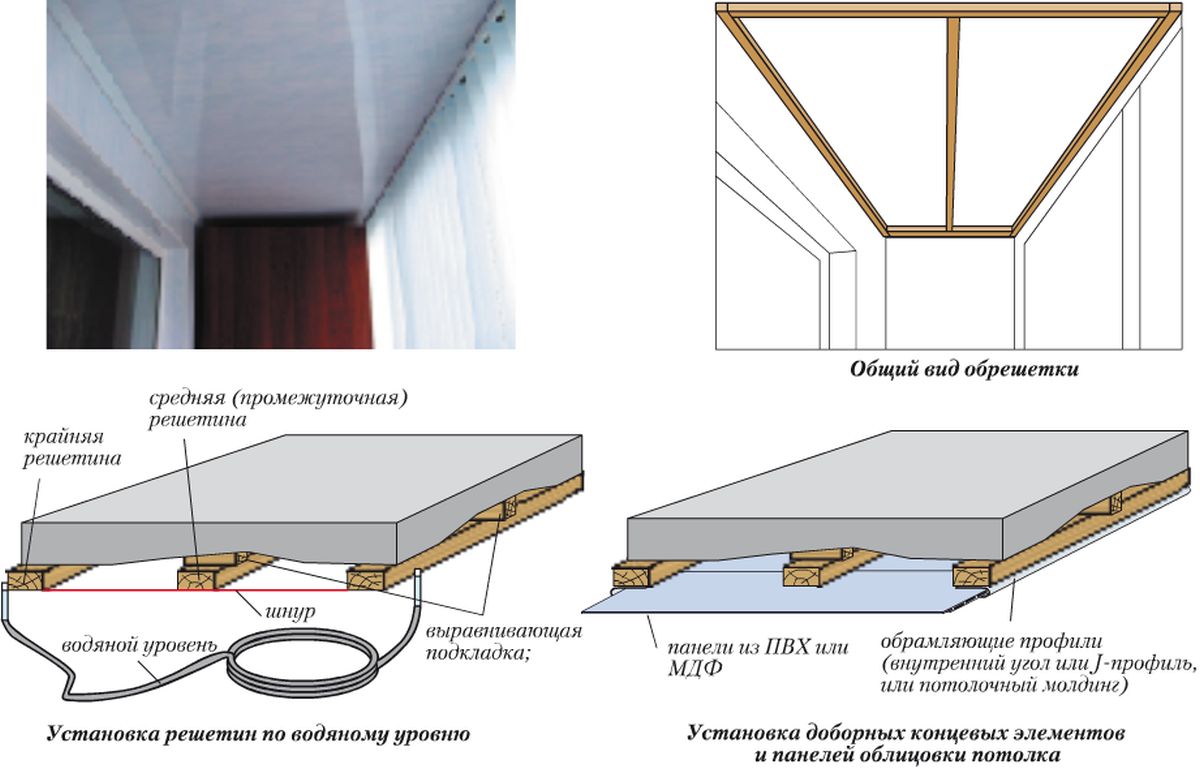

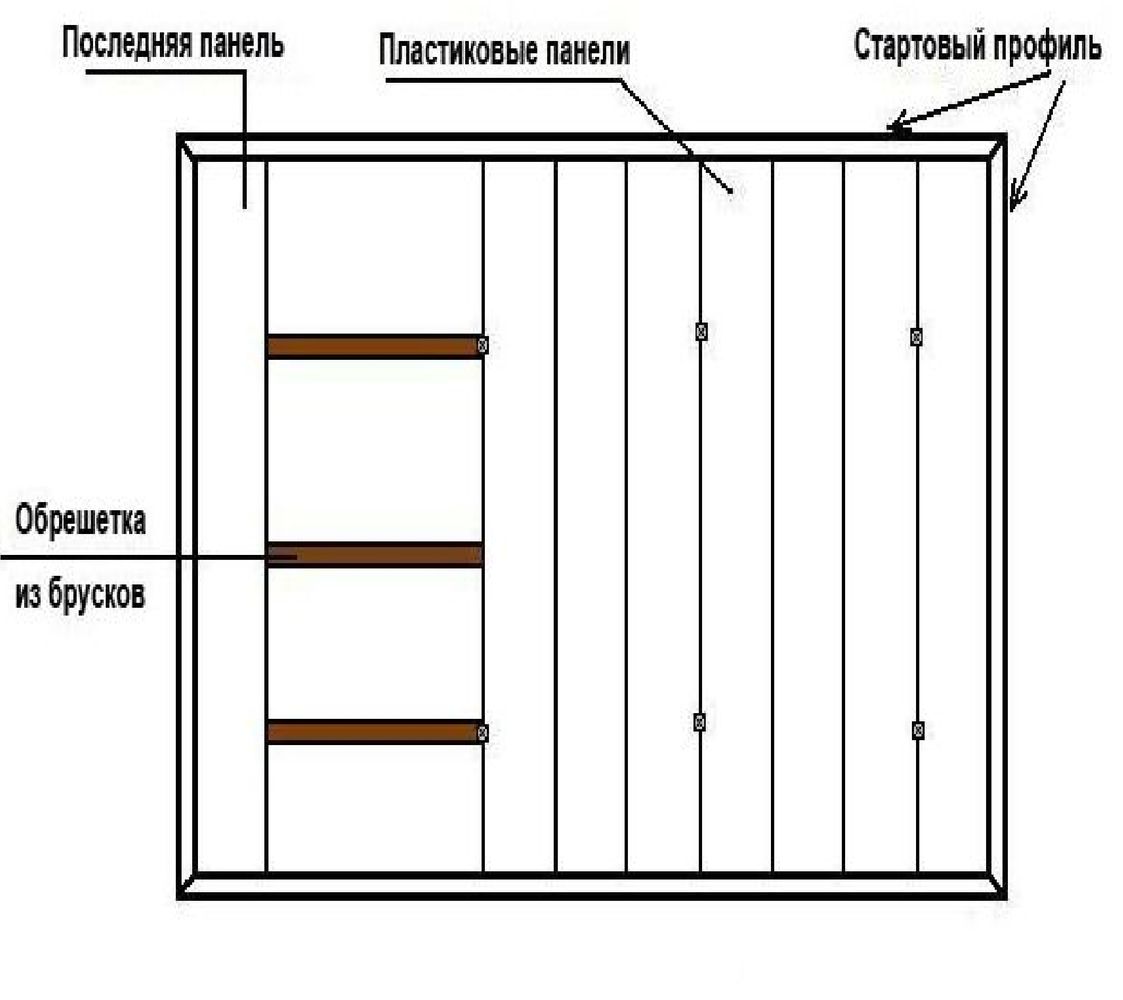

Lathing

One of the ways to mount the panels is to attach them to the frame. This is especially true when it comes to uneven surfaces. The basis of the frame is the lathing. This is a device that allows high-quality installation in rooms of any type (with a high level of humidity, unheated, etc.). To install the frame, the involvement of specialists is not required, all work can be done by hand.

To fix the lathing, you should use a wooden beam, plastic or metal profile strips.

The choice of material depends on:

- the height of irregularities on the surface of the ceiling;

- indoor moisture level;

- experience of the master with materials of different types.

However, on the shelves, plastic profiles for the lathing are rare guests. Finding them on the free market is quite problematic. The disadvantages of overlapping include the possibility of using it only on flat surfaces. If the defects in the base exceed 5 mm, then it will not be possible to achieve a perfect coverage.

Metal and wooden battens are more popular due to their affordability, durability and resistance to adverse weather conditions. These materials have long and firmly established themselves as the most optimal for the production of cladding for the ceiling and further fastening of ceiling tiles.

Hanging frame

High-quality finishing of the ceiling with panels is a simple matter, but it requires great care and meticulousness.

Frame structures are used in rooms with a high humidity index, as well as in poorly heated rooms. Otherwise, the coating will quickly deform, and over time it will become unusable and simply disappear.

It is not necessary to cut the panels in advance, this can lead to unpleasant surprises and unnecessary damage to the material. It is more expedient to cut the slabs in fact, applying them to the crate and fixing the boundaries of the required element.

Last but not least, it is necessary to dock the panels and decorate the joints; for this purpose, skirting boards and styrofoam borders are used, which are installed with liquid nails.

As you can see, there is nothing difficult in fixing the panels to the ceiling; even an amateur in decoration can handle the work.

Choice and difference from wall

Ceiling PVC panels consist of two sheets of plastic, which are attached with special stiffeners.A large fastening strip runs along the length of the sheet on one side, and a small fastening strip on the opposite side. The large one is used to fix the PVC sheet to the frame, and the small one is used to adhere the sheets to each other.

All parts have a spike on the side, which contributes to greater structural strength. Ceiling panel manufacturers guarantee that the product will last 10 years.

Ceiling panels are conventionally divided into several types.

By the type of connection, there are:

- suture - after installation, there is a visible joint between the individual parts;

- seamless - the joints remain invisible to the outside view.

Several types are distinguished depending on the color scheme.

- Solid panels are simple yet practical and are UV resistant. They do not change their shade throughout the entire period of operation.

- Lacquered - the surface of such panels is treated with a glossy layer of varnish, which strengthens the panel and also gives it a stylish decorative look. The disadvantages of such models include the appearance of scratches with minimal physical impact.

- With a pattern - a pattern is applied on the outside of the product. Such panels are made from softer plastic, so their price is lower, but the service life is also shorter.

- Laminated - panels imitate natural wood and stone, they are extremely sensitive to sunlight, under the influence of UV rays they begin to crack and lose their consumer properties.

Plastic panels have a number of advantages over other finishing materials.

- they last longer than materials of natural origin;

- reliably protect the ceiling from the adverse effects of external factors;

- the material is easy to use, divided into sheet, plate and rack. they are easy to care for and can be wired underneath (for example, plaster does not allow wiring).

According to their shape, the panels are subdivided into sheet, slab and rack.

- Sheet panels, as a rule, are large, they are fixed to the ceiling using small nails, and the gaps are rubbed with special sealants.

- Tiled panels in their design resemble ordinary tile-tiles, are small in size, differ in aesthetics and ease of use.

- Rack materials look like lining, and they are mounted in the same way using special construction brackets.

Ceiling panels differ from wall counterparts. Wall ones are much heavier and more durable, since they must withstand additional stress (shelves / furniture / other decorative elements). Ceiling slabs, on the other hand, are thin and fragile. They are lightweight, which greatly facilitates their installation and fixation to the ceiling. At the same time, it is easier to damage them, but this cannot be considered a disadvantage - the ceiling has a minimum of physical impact, so there is simply no need for the panels to have a dense structure.