Plexiglass properties

- Ease. The density of plexiglass is 1.19 g / cm3. Compared to other materials, plexiglass is almost 2.5 times lighter than ordinary glass, 17% lighter than compact PVC and 7% lighter than polyester glass, therefore, when building self-supporting structures, the use of additional supports is not required. Plexiglas has the same weight as polycarbonate and is 15% heavier than polystyrene.

- Moisture resistance. Used for yacht glazing, aquarium production.

- Impact resistance. The impact resistance of acrylic sheet is 5 times higher than that of ordinary silicate glass.

- Resistant to weathering. Plexiglas is not afraid of 40-degree frosts - it is able to work in a wide temperature range, without softening or deforming at high temperatures, and without cracking or warping at low temperatures, it is resistant to adverse weather events. Acrylic glass is highly resistant to aging. Its mechanical and optical properties do not change appreciably under long-term atmospheric exposure.

- Organic glass transmits 90% of ultraviolet rays, while it has good lightfastness and an excellent level of resistance to UV rays, without requiring special protection. This is due to the fact that, by its chemical nature, plexiglass is transparent to ultraviolet radiation. Therefore, ultraviolet light is not retained in the mass of the polymer and does not destructively affect its internal structure (ultraviolet rays do not cause yellowing and degradation, and the material does not lose its mechanical properties for 10 or more years).

- Light transmission. The absence of its own color and transparency make it possible to ensure high light transmission. The light transmission of acrylic sheets is the same as that of glass. Light transmission is up to 93% of visible light (only 8% of incident light is reflected) - more than any other polymer material. The color of plexiglass does not change over time, retains its original color. Light transmission of "matte" plexiglass can range from 20% (ie, be practically "dull") to 75% (translucent). Sheets with 50-75% light transmission are used, for example, for the production of lamps. The optimal light transmission for advertising products with internal illumination is 25-30%.

- Acrylic glass is resistant to various gasespresent in the city air and the air of the sea coasts. It is also resistant to moisture, bacteria and microorganisms, has a high chemical resistance to inorganic substances, salts and their solutions. On the other hand, organic substances such as chlorine derivatives of hydrocarbons, ketones and ethers are solvents for acrylic glass.

- Plexiglass is a flammable material, but when burning, it is not as dangerous as other flammable plastics, since it does not emit any poisonous gases. Ignition temperature - 460-635 ° С.

- Acrylic - environmentally friendly material, does not produce any toxic substances and is absolutely safe. It can be used outdoors and indoors, including in children's and medical institutions. Plexiglas can be fully reused after recycling.

- Acrylic glass is easy to process. It can be cut, drilled, glued, bent and shaped, polished and milled, painted and engraved (including laser engraving) and has excellent adhesion to all kinds of self-adhesive vinyls.

- Acrylic glass bends easily "cold" (without heating).

- Plexiglass - thermoplastic material, that is, it has the ability to soften when heated and retain, when cooled, the shape that was given to it.Cast acrylic glass is perfectly shaped, which makes it possible to make three-dimensional products for various purposes from it, including exclusive bas-relief and full-volume illuminated advertising products.

- The softening point of acrylic glass (depending on the manufacturer and brand) is in the range of 90-110 ° C, the maximum temperature for its application is 80-100 ° C.

- 10-year guarantee for the preservation of all properties of plexiglass, without changing its optical, physical, mechanical and operational characteristics.

- Good dielectric properties. The molecular structure of organic glass is such that it prevents the penetration of electrically charged particles into its fibers. Hence the low electrical conductivity of acrylic, which allows it to be used in the production of the widest range of products.

Composition and properties

Plexiglas contains thermoplastic acrylic resin with various additives, therefore this material is also called acrylic glass. Due to additives, it is possible to achieve a particular color of the final product, as well as other features such as increased strength, sound absorption and heat resistance.

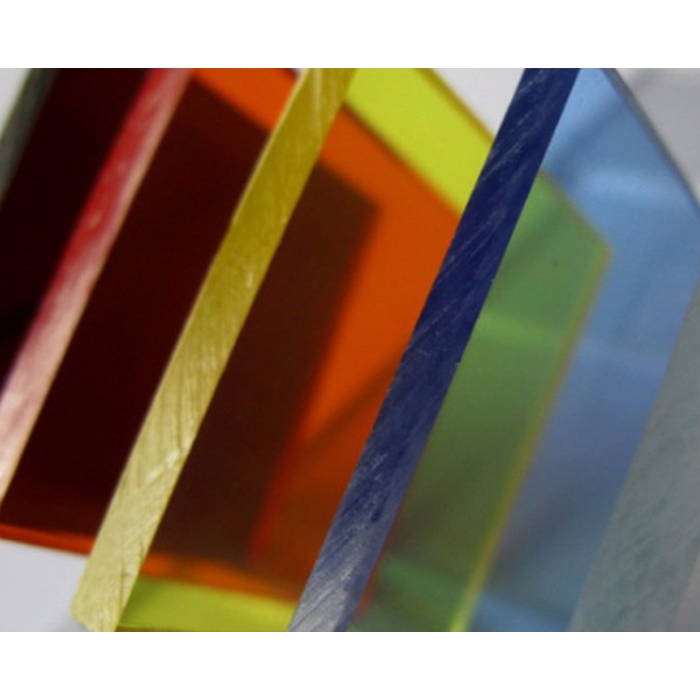

The color spectrum of organic glass is quite wide, starting from light beige shades and ending with maroon and black colors. Smoky and bronze shades are considered popular. Plexiglass of bright colors, such as blue, red, yellow, is a very popular material among designers and builders. They prefer organic glass over ordinary glass because it is much more convenient to work with.

Unlike ordinary glass, plexiglass is easy to process. It can be drilled, cut, milled and sanded. The material is suitable for tapping and threading with other elements. When heated, the plastic properties of plexiglass increase, and in this state it lends itself to bending and molding.

Various products are obtained from organic glass by processing. For this, the processes of vacuum action, stamping, hot and cold forming are used. For example, the famous Scottish sculptor Rob Mulholland makes absolutely amazing works of art from acrylic glass.

In comparison with ordinary glass, the following features of organic glass can be distinguished:

- resistance to environmental influences (moisture, temperature) is higher for organic glass;

- organic glass resists the effects of aggressive environments better;

- plexiglass has much less weight;

- plexiglass is softer than ordinary glass, minor influences can leave scratches;

- easily cut and processed with a mechanical tool or laser;

- indicators of light transmittance of plexiglass are comparable to those of ordinary glass or exceed them;

- does not form fragments when damaged;

- has good thermal plasticity, can take complex shapes;

- does not fade or fade over time;

- retains its optical properties for a long time.

The disadvantages of plexiglass include its flammability.

However, in comparison with other types of polymers, organic glass does not emit toxic substances during combustion, and the use of special additives and coatings can significantly increase the fireproof properties of the material.

In the price range, organic glass sits between ordinary glass and other types of synthetic polymers. The price for colored plexiglass is lower than for polycarbonate and polyethylene.

Types of plexiglass

Extrusion (squeezing) and casting are methods of making organic glass. According to the manufacturing method, the final product is called cast or extrusion. The production method affects the characteristics of plastic, introduces a number of restrictions on its use.

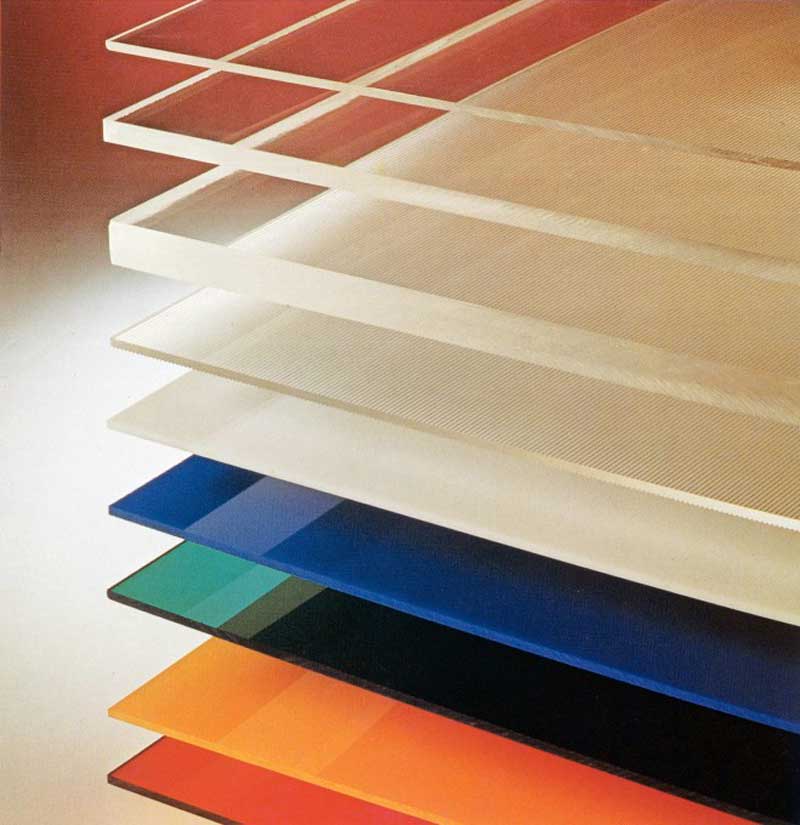

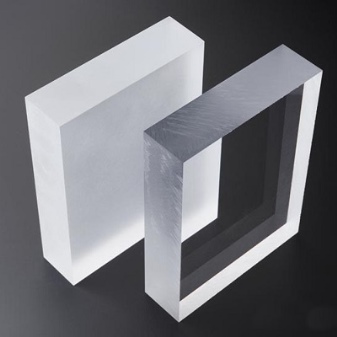

In appearance, plexiglass is classified into:

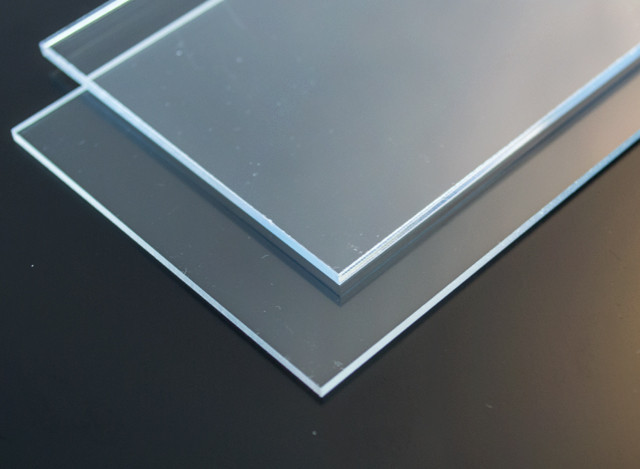

- transparent;

- matte;

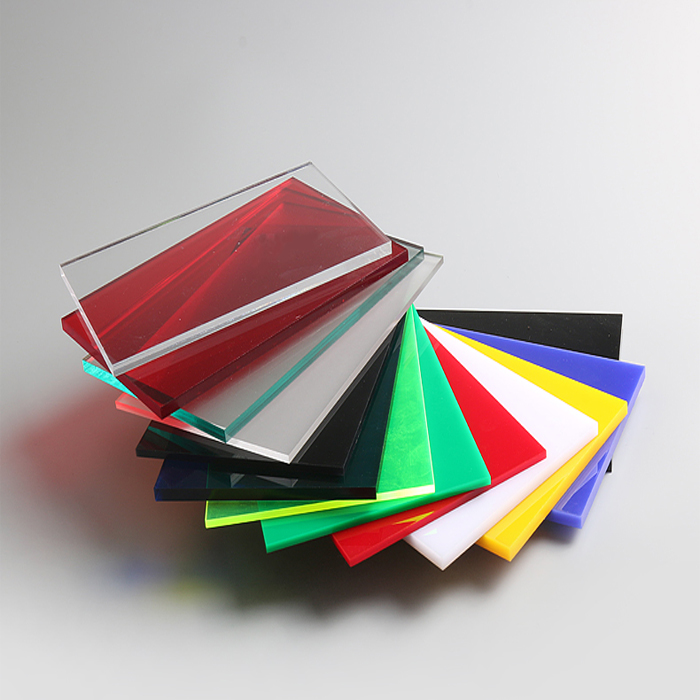

- colored.

You can buy plexiglass in the form of a finished product or a semi-finished product. On the market there are:

- sheets;

- rods;

- pipes;

- blocks;

- other products.

To determine the manufacturing method, you should familiarize yourself with the marking of the finished material:

- HT - extrusion;

- GS - injection molded.

Extrusion

Extruded polymethyl methacrylate (PMMA) plexiglass is characterized by weak intermolecular bonds (low molecular weight). Because of this, it is used for products with simple shapes. Extruded plexiglass is made by continuous extrusion of molten mass, consisting of PMMA granules, through a slotted forming "head" of the extruder. Then they are cooled, cut into pieces according to the given dimensions. The production of extruded plexiglass is carried out on extruder lines. The manufacturing process is continuous.

Extruded plexiglass of domestic production is marked: SEP, ACRYMA.

Casting

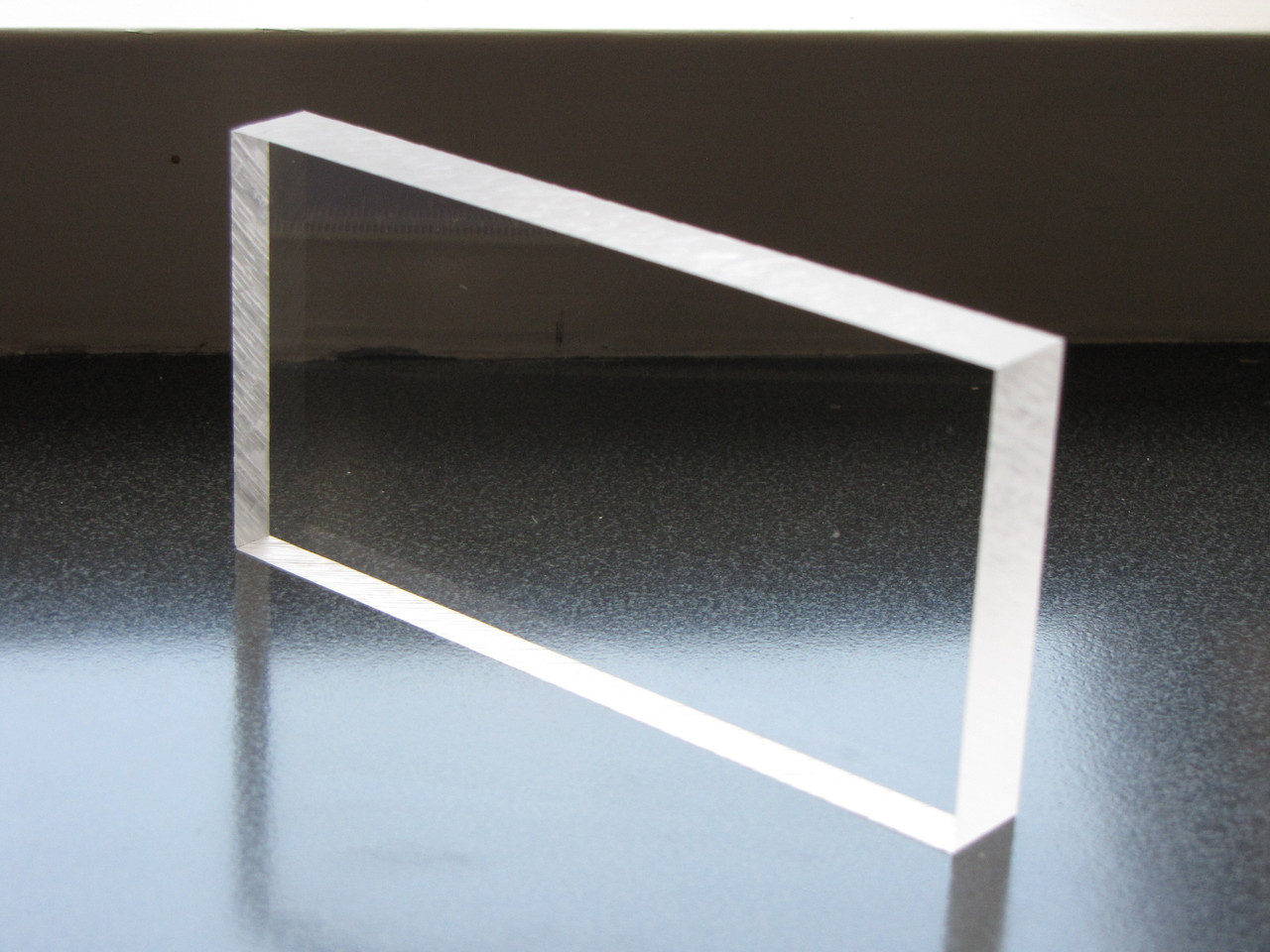

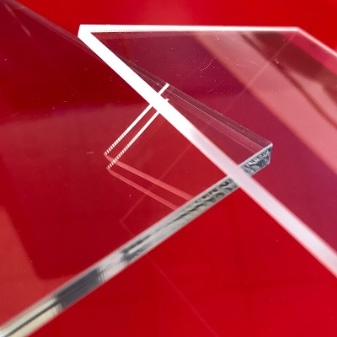

Block or cast transparent thermoplastic is characterized by stronger intermolecular bonds (high molecular weight). This allows us to obtain products with improved performance in comparison with extrusion. Cast plexiglass has a smooth surface, high transparency, impact resistance, crack resistance. It can be polished, molded. Cast organic glass is heat resistant. The possibility of secondary re-forming of products is allowed. Also, cast plexiglass is characterized by higher chemical resistance, high thickness stability.

The method of manufacturing cast plexiglass is pouring liquid MMA monomer between 2 glass planes, followed by polymerization and hardening. In the production of block plexiglass, the thickness difference reaches 30%, and shrinkage during heating - 2%.

Domestic molded plexiglass is marked: TOSP, TOSP-N, TOSP-U, TOSN.

Sheet

Sheet plexiglass is produced in accordance with the requirements of GOST 10667-90.

Sheet lighting glass is produced in accordance with GOST 9784-75. To give the required technical characteristics during production, polyvinyl chloride or polystyrene is introduced into the composition (to impart light scattering to varying degrees).

Sheet sizes: thickness 0.8-30 mm, length - 100-1600 mm, width 100-1400 mm. Other sizes are available.

Frosted plexiglass, or double satin, is found on the polymer market. Through additional machining, the material acquires a rough, matte surface. Also, this effect can be obtained due to the introduction of special additives into the composition. The light transmittance of a matte sheet is from 20 to 70%, while that of an ordinary sheet sheet is up to 92%.

The area of application of sheet organic glass is very extensive: advertising signs, partitions, decorative elements and much more.

Plexiglass rods (rods)

Polymer round or square bar made in accordance with GOST 17622-72 and other tech. conditions. Supplied plastic: matt, transparent, painted.

The technical characteristics of these products correspond to the brand of plexiglass from which the product is made.

For square rods, the diameter of the circumscribed circle is from 10 to 40 mm. Round rods are available in diameters from 2 to 100 mm. The standard bar length is 2 meters. By agreement with the customer, the dimensions may vary.

Plexiglass rods are used in different areas: the implementation of design solutions, decor items, the furniture industry, the manufacture of some equipment, etc.

Stamps

Sheet lighting plexiglass is produced by grades:

- SE - extrusion;

- SB - block;

- BOT - transparent, made by extrusion;

- SBS - flame retardant block;

- SBPT - block with increased heat resistance.

BOT is transparent, other brands are cloudy.

Technical domestic plexiglass is produced plasticized (TOSP) and unplasticized (TOSN).

TOSP, in turn, can be designed for:

- TOSP-N - production of acrylic bathtubs, shower trays, sanitary ware, etc. (plumbing);

- TOSP-U - thermo and light stabilized.

According to GOST 10667-90, plexiglass sheet is also marked: CO (organic), then indicate the temperature at which the polymer softens (for example, 95, 120, 133) and a letter designation indicating the field of application (K - structural, A - aviation) ...

Plexiglas TOSP

Technical plexiglass of domestic production, manufactured in accordance with the requirements of GOST 17622-72, TU 2216-271-05757593-2001. According to this standard, this material can be produced:

- opaque colored (primary colors are blue, red, yellow, green, orange and white);

- transparent colorless;

- transparent colored.

It lends itself well to machining. The plasticizers included in the composition increase the plasticity, slightly reduce the softening point of the polymer.

According to GOST, technical characteristics of TOSP:

- impact strength of organic glass TOSP from 8.8 to 13 kJ / m2 (determined by the sheet thickness);

- tensile strength - not less than 61.7 MPa;

- softening temperature - not less than 92 ºС;

- density at 23 ° C - 1180 kg / m3;

- elongation at break - not less than 2%;

- linear shrinkage - about 3.5%.

TOSP plexiglass is the most popular, it is used in a variety of areas: from decor and everyday life to parts for various purposes in industry.

Organic glass TOSN

According to GOST 17622-72, TOSN organic glass (unplasticized) has the following technical characteristics:

- density at 23 ° C - 1180 kg / m3;

- elongation at break - not less than 3.5%;

- tensile strength - 70 MPa;

- linear shrinkage - about 3.5%;

- softening temperature - not lower than 110 ºС;

- impact strength of thermoplastic - from 8.8 to 15 kJ / m2 (depending on thickness).

The plastic is characterized by high resistance to stress and cannot be molded. Withstands higher operating temperatures than TOSP (90 versus 80 degrees Celsius).

Species overview

Today manufacturers offer the consumer a wide range of organic glass. There is a thin sheet, block, thick tinted anti-vandal glass on the market. The area of its use directly depends on the type of material. For example, patterned corrugated decorative glass is used for interior design. In the engineering, medical, and construction industries, transparent polymers are considered relevant.

Different types of plexiglass look different, they can be matte and colored. Often, consumers prefer light-scattering, tempered, cast, flexible, heat-resistant, heat-resistant, fluorescent, textured glass made by extrusion and other methods.

By transparency

Plexiglas can be transparent, opaque or frosted. The first type of product has a high light transmittance. It is characterized by double-sided smoothness and shine. The thickness of this material is 5 mm. Frosted milk glass transmits light by 20-70%.

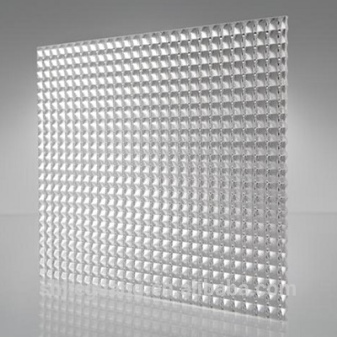

By surface type

By type, the surface of plexiglass is smooth and corrugated. A material with a grooved surface is inherent in waviness and the presence of geometric protrusions. Often this material is produced with a matte surface. The relief of glass can distort the optical properties of the product, as well as reduce its transparency.

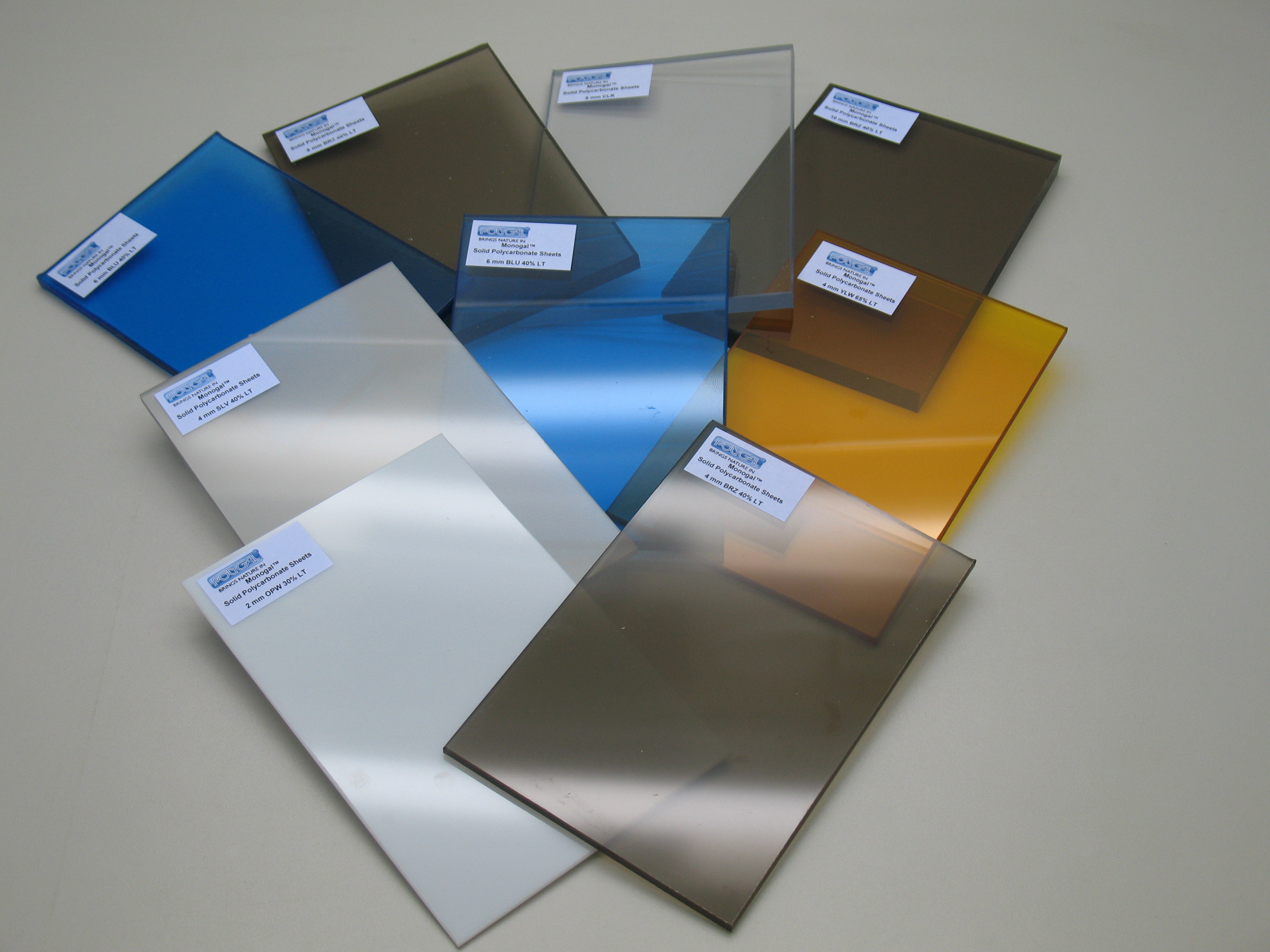

By color

Colored organic glass is available in a variety of colors and shades. The material is blue, red, yellow, silver, golden, black. This polymer is both transparent and uniformly colored on both sides. Currently, light blue, brown, smoky glass is considered especially popular. The corrugated colored product can be decorated with such patterns as drops, crushed ice, waves, honeycombs.

Home bending techniques

Necessary materials

In order to give the orsglass the desired configuration, you can use one of several popular methods:

- Heating the material with a building hair dryer;

- By boiling;

- With the help of nichrome wire.

Depending on how the plexiglass is folded, you will need a heating element (a hair dryer, nichrome wire, or a saucepan of boiling water). In addition, prepare:

- A hacksaw for metal;

- Vise for secure fixation of the plexiglass plate;

- Thomas for bending (pipe, bar, countertop, etc.);

- Abrasive material for grinding the edges of the product;

- A little water (to cool the material while cutting).

Preparatory work

If your future product requires the use of a small piece of plexiglass, then first you need to cut it off from the common canvas. To do this, securely fix the plexiglass in a vice and cut off the desired piece with a metal hacksaw. Do not forget to lay soft material in the places of fixation, which will prevent damage to the plexiglass.

For cutting plexiglass, you can use both a hand hacksaw and a jigsaw

Important: use only a sharp hacksaw. Otherwise, the material may be damaged and deformed.

When cutting plexiglass, cool the cutting line with water. This will avoid overheating of the plexiglass and its possible melting.

Otherwise, the material can be damaged and deformed. When cutting plexiglass, cool the cutting line with water. This will avoid overheating of the plexiglass and its possible melting.

Boil flexion

This is the easiest way to bend plexiglass, requiring virtually no additional tools.

5. Leave the part formed from plexiglass until it cools completely.

Using a construction hair dryer

If you have to bend a large enough piece of plexiglass, then use a building hair dryer for this purpose. Its power will allow you to process a large area of organic polymer material in an extremely short time.

Using nichrome wire

With the help of a nichrome wire carefully stretched under the plexiglass, it is possible to achieve bending of the material in a straight line without effort. To do this, follow these steps:

Video: bending plexiglass with nichrome wire

We bring to your attention a short video that will clearly demonstrate how to bend plexiglass using nichrome wire.

V home cutting plexiglass very rarely required. Typically, this work is carried out by specialists in the workshops. However, this skill can be useful in everyday life. After all, sometimes there is a desire to make a vase, an aquarium or a small decorative table with your own hands. So, the subject of our review is plexiglass. How to cut such material?

How to work with the material?

Plexiglass is quite easy to process, it can be easily cleaned, cut and tinted. This polymer can be cut with a metal hacksaw. However, in this case, you can spend a lot of effort and result in poor quality stitches. The best option for cutting plexiglass is considered to be the use of a cutter, which looks like a saw with one tooth. In addition, this thermoplastic can be cut using a circular saw or by scraping with a glass shard.

The use of plexiglass is impossible without polishing it. Before proceeding with the procedure, it is necessary to prepare the surface, for this, with the help of fine sandpaper, you need to sand all the irregularities. Experts advise using water when working. Manual polishing is carried out using a piece of flannel or a piece of woolen cloth, which are pre-lubricated with a polishing paste. The end of the work is carried out with the same cloth, but in an oiled form. To finish polishing faster, you can use a buffing wheel.

Forming organic glass is possible at temperatures from 110 to 135 degrees above zero. Under such conditions, the polymer becomes plastic and bends well. When the temperature is lower, the thermoplastic becomes brittle and loses its quality characteristics.

To carry out the molding of plexiglass, you must use a plywood matrix or a wooden punch. The procedure should be carried out on the floor, in the company of a partner. When the material warms up, it should be removed from the oven and placed on the matrix. After 10 minutes, the finished product can be removed from the mold.

For gluing plexiglass, dichloroethane is used in pure form or dissolved with shavings. For the procedure, two surfaces are lubricated with a substance and pressed tightly, removing air bubbles. The bonding site should grasp in a couple of minutes.

For uniform coloring of thermoplastic, it is recommended to polish the surface in advance, removing chips and scratches. The next step is to prepare a dye solution, which should contain alcohol and a dye. The organic glass product should be held in a heated dye solution, and then transferred to a container with cold water. After cooling, organic glass must be wiped dry with soft paper or cloth. At the end of the staining procedure, it is recommended to polish the polymer product.

For information on how to quickly and accurately cut plexiglass, see the next video.

Advantages and disadvantages

The main advantage of organic glass over ordinary silicate glass is its low density and ease of processing. Plexiglas is much (more than 2 times) lighter than its silicate counterpart. In addition, this polymer does not oxidize in air, is highly resistant to moisture, does not cloud over time, is an excellent sound-reflecting material, and has low thermal conductivity.

Plexiglas easily bends when heated and retains its shape after cooling, which makes it possible to make building and decorative structures of almost any configuration from it. It is especially easy to form molded organic glass, which makes it possible to use it for the manufacture of volumetric structures of a rather complex shape.

Due to its good frost resistance, this polymer is successfully used in structures with operating temperatures up to minus 60 ° C. When heated, it can withstand temperatures up to 100 ° C without reducing its mechanical characteristics. At normal temperatures, organic glass does not emit toxic substances, is completely safe for humans, resistant to microorganisms, and does not attract rodents and insects.

The disadvantages of plexiglass include:

- is a flammable material;

- interacts with alcohols (ethanol, methanol);

- prone to chipping;

- sensitive to scratches;

- prone to cracks at bending points.

Application of acrylic sheet

High indicators of technical characteristics of organic glass make it possible to use it in various fields of activity. Initially, the material was used for the needs of military aviation, but gradually the area of application of acrylic has expanded. This was facilitated by a gradual change in the composition of the synthetic polymer, which made it possible to significantly improve its physicochemical properties.

Polymethyl methacrylate produced today for the defense industry can withstand high temperatures and not react with reactive substances.

Transparent sheet acrylic, like ordinary silicate glass, is used for glazing the facades of buildings for various purposes. The relatively low weight of the synthetic material makes it possible to reduce the load on the structure of the supporting frame and increase the glazing area.At the same time, the supporting structures themselves can be made of thinner elements, which has a positive effect on the aesthetic qualities of the entire structure. Although the price of transparent sheet acrylic is higher than that of silicate glass, the convenience and safety of its use is often the determining factor when choosing a material for facade glazing.

Acrylic sheets are also used for glazing some types of auto and motor vehicles, sheds, gazebos, greenhouses and greenhouses. Transparent protective structures of various control and measuring devices, such as speedometers, counters, gauges, level indicators, and so on, are made of plexiglass.

Colored acrylic sheets are used for the construction of advertising, informational and commercial structures: scoreboards, light boxes, decorative structures, stained-glass windows. A huge number of lighting equipment has glazing made of sheet acrylic: lamps, lampshades for lamps and floor lamps, light boxes, volumetric letters with electric lighting.

A lot of interior details are made from sheet polymethyl methacrylate. Among them are colored inserts on furniture facades, filling of interior doors and partitions, decorative decorations. A separate area of use for colored acrylic is interior lighting hanging canvases.

Cutting methods for organic glass

Sheet material can of course be cut with a hacksaw

on metal, but it's too troublesome. And the seam is of poor quality.

To improve matters, they use special homemade large-toothed

hacksaw blades. But it is best to use cutters. The cutter is, by

essentially, a saw with only one tooth. Sharpen it on emery from a piece

hacksaws (steel P9, P18) and take it into the handle by hand. Put on a sheet of plexiglass

a steel ruler and cut with a cutter several times until the material is

cut in half. Then they just break it, and the edge of the fracture is cleaned with the usual

joiner jointer. A homemade jointer is very convenient for this purpose, consisting

from a rasp with two handles, or you can simply - a cycle made from a piece

an old cutter with a straight rectangular edge. There is one more method of scraping - with

using a shard of ordinary glass. Its plane touches the processed edge -

in this case, the surface is completely transparent. Plexiglass can be cut

and on a circular saw with conventional cutters for metal with a thickness of 0.5-1 mm. True, in

during operation, they quickly heat up, the material begins to smoke, and the processed

the surface is rough, foamed. For this reason, receive

straight cut is very difficult. But if the cutter is cooled, this will not happen.

Adapt a regular bottle for this by placing it on one side of the cutter and

filling with water. Supply water through a plastic hose with a diameter of 2-3 mm. 0,5 l

enough for an hour of work. During breaks, the hose can be clamped with a clothespin. Water

cooling increases productivity 2-3 times. But most importantly, it turns out

very smooth translucent surface. If the cutter is polished, and the teeth

sharpened with a touchstone, then you can get completely transparent. Cut

organic glass sheets conveniently with a special cutter knife,

made from an old hacksaw blade

The cutting edge is ground on a regular emery

stone. The handle of the cutter is wrapped with a wire of the MGShV type with a section of 0.50-75 Rmm2, and

then with insulating tape. A sheet of organic glass is placed on a table or board with

smooth surface, and then, applying a ruler to the glass, several times

hold the edge of a knife along the cutting line. The edges of the sheet on the cut are obtained

smooth and often do not require additional processing. With preliminary

when marking the sheet, it must be borne in mind that the width of the furrow should be equal to the thickness

hacksaw blades.Figured details from sheet organic glass can

cut with a regular jigsaw. Relatively low melting point

organic glass allows you to cut it in the following way. Into a jigsaw instead of

files insert a nichrome wire with a diameter of about 0.5 mm, to the ends of which

supply a voltage of 3-4 V from a step-down transformer (the jigsaw must be with

wooden frame or with insulated clamps). At the point of contact with

the heated wire will melt organic glass. This way you can

cut plates of any shape. It is not recommended to apply a higher voltage,

since organic glass ignites when overheated. Cut out

organic glass, various figured parts can be used with a heated

wire with a diameter of not more than 0.5 mm made of high resistance alloy (nickel,

nichrome, etc.), to which it is attached.

To heat the wire, you can use

direct or alternating current with a voltage of 6-12 V.