Consumption of combined drying oil

This most common grade for the protective coating of wooden elements varies in consumption depending on the application. As a rule, manufacturers set an average value of 150-300 grams per square meter. This value changes significantly if an ordinary brush with natural bristles is used, in which case the consumption can increase to 350-400 grams. Spraying is more often used, or the use of a roller, due to which a minimum indicator can be achieved.

Additionally, this parameter is influenced by the technology of applying the solution to the surface. The varnish does not need to be applied in several layers, however, experts recommend using two separate layers and spraying them evenly after the first coat has completely dried.

Tips and tricks for use

- Before buying, you should carefully read what is written on the product packaging label, namely for which types of work it can be used (external or internal), which manufacturer and its coordinates

- The inside of the container must not contain any foreign matter.

- When using Oksol, no open sources of fire should be allowed. All electrical lighting and electrical equipment are explosion-proof.

- The room in which it is supposed to work with drying oil must be well ventilated or equipped with supply and exhaust ventilation.

- Before opening, the container with the liquid must be shaken thoroughly.

- For a thinner layer, a wide brush or roller is recommended.

- Use rubber gloves (household or medical) to protect your hands.

Compliance with the elementary rules for handling drying oil allows you to get a high-quality coating quickly and easily.

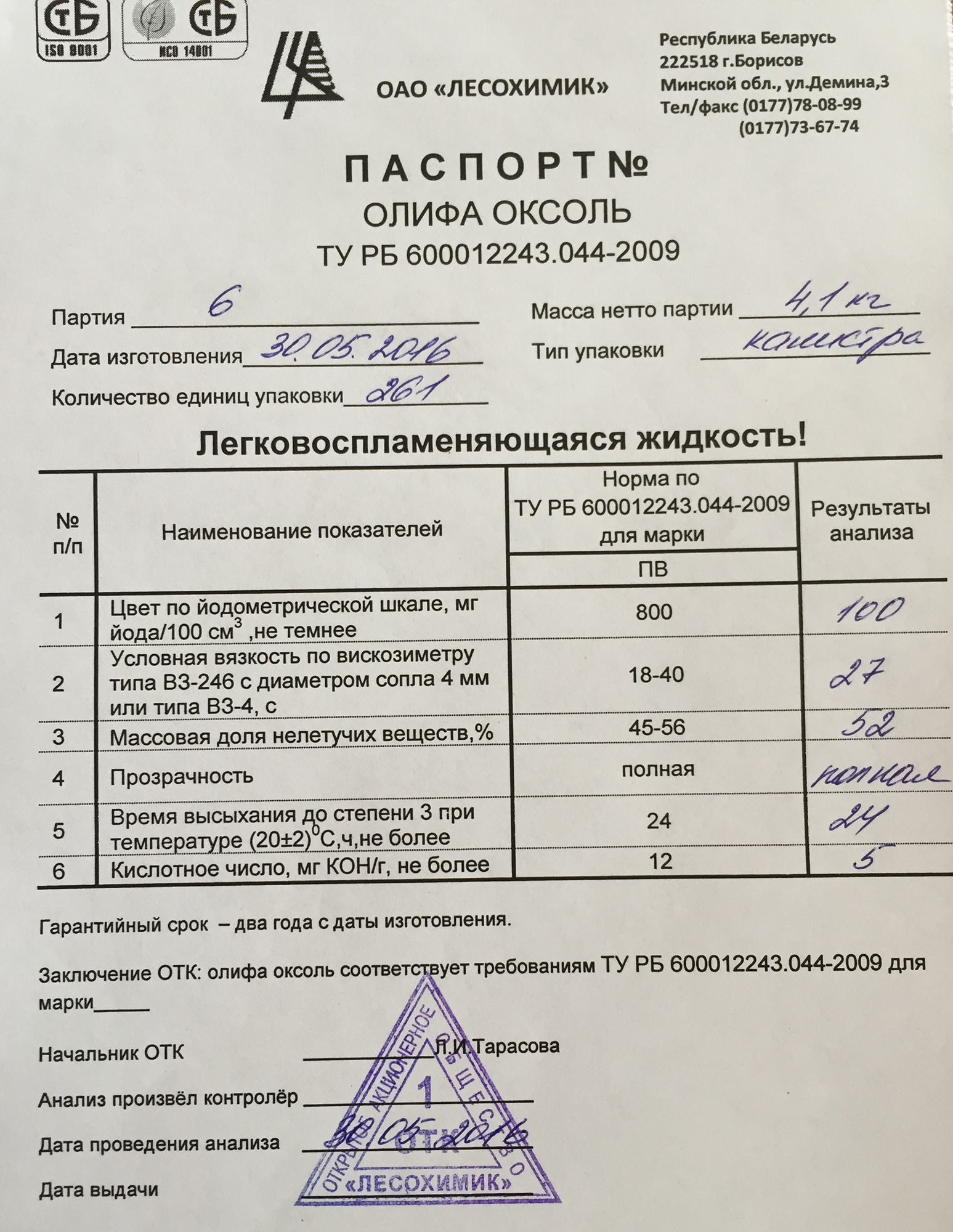

Specifications and Certificate of Conformity

Currently, any paint and varnish coating has a corresponding certificate of conformity, which allows the product to be sold openly, and also used for industrial purposes. In this case, the standard TU 6-10-1208-76 is provided. Let's consider in more detail the main characteristics of this substance:

- complete drying of the coating occurs in a day;

- there is a hardness of the formed film in the amount of 0.1 unit;

- this version of the substance has complete transparency;

- a moderate consumption of the substance is provided, depending on the method of applying drying oil to the prepared surface;

- the material belongs to flammable and explosive compositions;

- assigned conventional viscosity 20-60 units;

- this substance is available in two different grades, depending on the intended use.

All the characteristics presented in relation to the combined drying oil correspond to GOST. This type of coating has proven itself perfectly as a proper protection of wood from moisture, as well as counteracting fungus, insects and rodents. Basically, this type is used in the production of furniture and other attributes.

Selection, recommendations for the use of drying oil.

When choosing a type, brand of drying oil, in addition to the recommendations given in the relevant standards and technical conditions, one should additionally take into account the efficiency of drying oils associated with the consumption of vegetable oil for their manufacture, the durability of coatings based on them.

The consumption of vegetable oil per 1 ton of finished drying oil is for: natural drying oil - 960 kg, combined drying oil - 700 kg, oxol drying oil - 510 kg, pentaphthalic drying oil - 330 kg, glyphthalic drying oil - 295 kg.

At the same time, the durability of coatings (determined at atmospheric stations for coatings pigmented with red lead) is for: pentaphthalic drying oil - 5 years, glyphtal drying oil - 4-5 years, for natural polymerized, oxidized drying oils, respectively - 3-4 and 2.5-3 years, for drying oil "oxol" brand PB — 1.5-2 years.

Proceeding from this, glyphthalic, pentaphthalic, alkyd varnishes (as the most profitable) should be used for the manufacture of paints intended for outdoor work, and oxol varnishes should be used only for diluting thick-grated paints based on combined varnishes to working viscosity in the production of internal works.

Natural oil varnishes are advisable to use for the manufacture of thick-grated and ready-to-use oil paints for external and internal work. However, in terms of the weather resistance of the coatings formed, they are inferior to alkyd drying oils.

Purpose and use of drying oil Oksol

The product is a viscous liquid product, which contains several components at once. The task of the product is the surface treatment of wood material, the preparation of the plastered surface, and is also used as a solvent for thinning oil paint.

Oksol oil varnish is a very toxic and flammable agent, therefore it requires compliance with certain safety measures.

Dyeing should be carried out only in special clothing that reliably protects the skin of the hands from contact with the product.

When working, it is necessary to use a respirator to protect the respiratory organs of a person.

In addition to protecting the human body, you need to think about the presence of ventilation in the room in which it is planned to carry out paintwork.

It is important to take into account the microclimate in the room: the air in the room should not be lower than 15 degrees, and the humidity should not be higher than 80%.

Before applying, the place for the intended painting should be cleaned of all kinds of dirt and greasy stains, then sanded and wiped off the surface. If the product has not yet been used, then it must be thoroughly mixed. In the case of repeated use, drying oil can thicken, then it needs to be slightly diluted with a solvent. The product is evenly applied to the treated area with a roller or brush in a thin layer. The next one can be applied only after the previous layer has completely dried.

Oksol is not used for painting floors and surfaces that are exposed to multiple influences during the day. This product has gained wide popularity in the building materials market due to its excellent properties and high efficiency. Well-known domestic enterprises are engaged in the production of Oksol linseed oil: PO Khimtek (Yaroslavl), Vesta Color LLC (Kazan), Tex company (St. Petersburg). The products meet the requirements of GOST 190-78 “Oksol oil varnish. Specifications ", has an affordable price and high quality indicators.

Oksol varnish brands

On sale there are two brands of funds that differ in the name of the main component and its percentage:

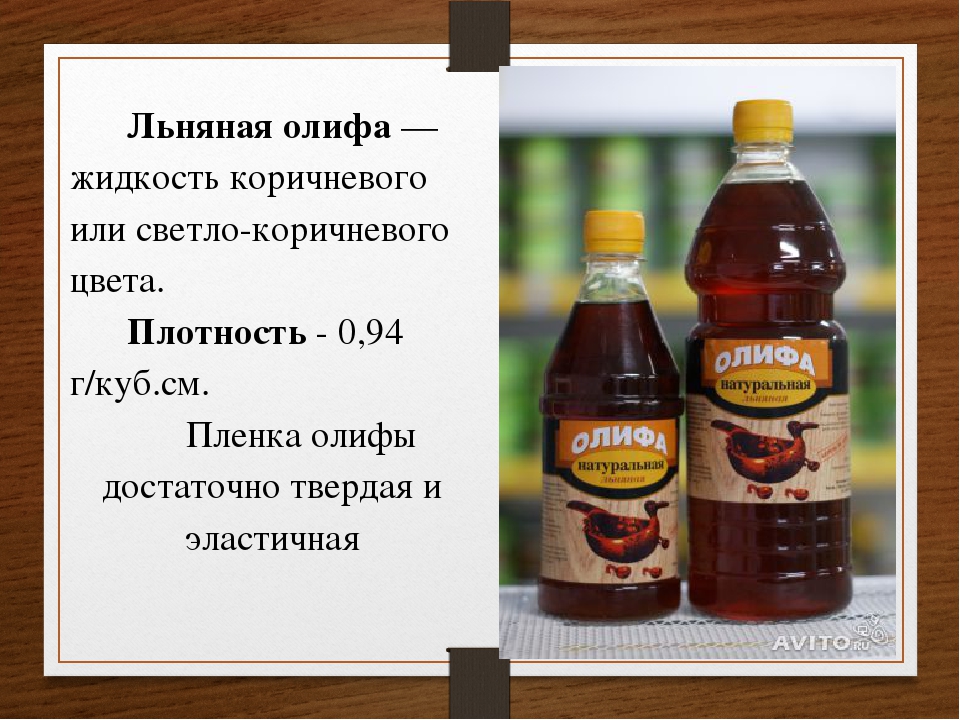

- "B" - the basis of the product is natural linseed or hemp oil. Linseed varnish is considered the most acceptable for outdoor use, since it creates a denser protection and provides a wicking coating;

- "PV" - the product uses the rest of the natural oils (soybean, sunflower, corn, grape). Such drying oil is less resistant to external influences.

Both brands of the product are not inferior in technical characteristics to other types of drying oil (natural, combined, alkyd). The surface is obtained with a spectacular gloss, water-resistant. It freezes, of course, only after a day, but it has good durability.

Review of popular manufacturers

To date, there are various brands on sale that produce combined drying oil.Often there are low-quality products, which is why it is recommended to choose the following manufacturer options:

- Production brand VGT.

- Foreign trade mark TIKURILLA.

- High-quality and popular Ceresit mixtures.

- Also worth noting are the domestic brands PRESTIGE and Yarko.

- The Kudo trademark stands out separately.

There are also other options for high-quality combined drying oil, however, the most popular and proven substances that are popular with buyers were listed here.

Selection criteria and varietal differences

In practice, there is a variant of a substance of two separate varieties. The main differences are in the color shade according to the iodized scale, namely 220 and 700. The difference also occurs in drying. As a rule, the first grade completely freezes within a day, as for the second grade, then the full drying of the coating occurs within 12 hours

In order to choose the right type, you have to take into account the following points:

First of all, it is required to take into account the purpose of the substance that will be used for work.

The main type of work to be done using the solution is also taken into account.

The manufacturer who released this type of substance for wood covering is separately taken into account.

It is important to consider the available budget that you can afford to purchase the appropriate coverage option.

Also, the choice of a suitable option is influenced by the type of coating that will be processed.

Finally, the choice is influenced by such an indicator as the tool used for the work and the coverage area.

If all these parameters are taken into account, it is possible to choose the correct type of coating that will be used for processing a wooden surface. In practice, a lot depends on the manufacturer, since not all brands present on the modern market produce really high-quality products and use certified materials in production

We breed silver

We dilute silver oil with linseed oil

In order for you to understand how to breed silver and why it is so in demand, I decided to start with its benefits:

- In addition to the fact that silver has the ability to lie down in an even layer, it emphasizes the relief and texture of the painted surface

- It is very strong and durable. After drying, the coating does not peel off, and it can be very difficult to remove the paint on purpose.

- Manufacturers assure that silverfish lasts about 7 years in air, and about three years in water

- The diluted material fits perfectly on various surfaces, therefore, it is covered with both wood, metal or concrete

- The paint is non-toxic and dries very quickly

- The originality of painted products and surfaces is incomparable with conventional dyes

It is very simple to dilute silver oil with linseed oil, for this it is enough to use proportions of 1: 3 or 1: 4, where 1 is part of the powder, and 3 and 4 are drying oil or varnish. If during the mixing process you get a mixture that is too thick, then it can be diluted with white spirit. By the way, the use of a solvent is important for the method of applying paint:

- If you paint with a brush, you may not need to use a solvent.

- But for a spray gun, a dilution in proportions of 1: 1 is simply necessary, since a too thick mixture will not pass through the nozzle

After diluting the silver with combined linseed oil, the process of dyeing the products begins. As usual, it all starts with the preparation and cleaning of the surfaces, if you completely removed the old coating, then the primer can not be used. In other cases, the application of an adhesive solution is simply necessary. Apply at least two or three coats of silver paint, only in this case you will get a truly beautiful surface.The quality of do-it-yourself work will also affect the heat resistance, as well as the frost resistance of the material. Therefore, take all the processes very seriously.

The use of the combined composition

Drying oil combined brand k3 technical characteristics

If we talk about GOST, it becomes clear that a mixture of natural oils is used for the production of combined drying oil, as well as the previous lining of raw materials with the help of which the material acquires one or another property. Let's find out what paints and varnishes according to GOST are produced on the basis of this drying oil:

Ready-made oil paints

- Ocher MA15

- Surik MA15

- Mummy MA15

Combined drying oil of the K-3 brand is the most popular and popular due to the fact that it can be used for mixtures, the work of which is possible both in internal and external processes. A little later, we will get acquainted with the technical characteristics, which indicate the indicators for grades 1 and 2 of the K-3 brand. Two grades are used for paints and varnishes with different colors. And if the former is applicable for lighter shades due to its maximum transparency, the latter emphasizes darker shades.

Before working with drying oils, it is necessary to familiarize yourself with safety precautions in accordance with GOST, since if natural drying oil is a combustible mixture. That combined is also explosive.

Important! The storage of the material should take place away from an open source of fire, and the process of working with the mixture itself should be extremely careful.

Differences and required information

Before you start discussing the material, you should have some idea of the material. If you are a beginner and have not yet used this material, then remember: drying oil is called unpigmented paintwork materials, which is a film-forming material. There are oil, synthetic and composite solutions, and if we talk about the combined mixture of the K-3 brand, then it belongs to the group of oil.

But the synthetic ones include alkyd drying oil and pentoli. Last but not least, I would like to say about the compositional group - it includes refined products of oil, shale and various resins. The vocation of the combined drying oil K-3 is to make oil paints that are ready for use, as well as to dilute thickly grated mixtures. In addition, with the help of the combined mixture, wood surfaces are impregnated, which are intended for painting with oil paints.

Important! The use of drying oil brand K-3 is permissible both indoors and outdoors. Thanks to this, even wooden canopy posts are processed with its help, which must be protected from the negative effects of moisture.

Combined drying oil of the K-3 brand is a transparent material with a characteristic yellow tint, which is less obvious for the 1st grade and more intense for the second. By the way, when processing wood with this material, a natural noble shade with shine appears. It is very easy to find out how much drying oil dries: at an optimal temperature of 18-22 degrees, the process of forming a hard coating will last about 1 day. If you work with linseed oil yourself, then use small portions of the material, while tightly close the total mass with a lid.

If we compare the Combined drying oil brands 3 and 2, then the second is used for paints intended only for interior work. Its presence allows the material to dry evenly, while the layer will be uniform. Drying oil K 2 is also transparent, but with a characteristic shade that is slightly darker than grade 1 of the combined K-3 brand. The material is applied with a brush to the previously prepared and completely dried wood, while drying time of drying oil K-2 lasts absolutely, as with the combined mixture K-3 - 24 hours at the optimum temperature.

Storage of drying oil

Proceeding from the fact that the drying oil contains oil and solvents, it belongs to explosive and fire hazardous materials, therefore, in the room where the work is performed, it is required to provide natural ventilation or forced ventilation equipment in an explosion-proof design. In case of contact of the material on the skin surface of a person, it is required to wipe and rinse well with soapy water. When storing drying oil, it is required to ensure that the container is tightly closed and protected from moisture and sunlight, and is far from fires and electrical appliances. When thickening, it is allowed to dilute the drying oil with any solvent available to you, suitable for oil paints in a ratio of 1:10.